The global motorcycle aftermarket parts market, driven by rising customization trends and an expanding base of enthusiasts, is projected to grow at a CAGR of 5.8% from 2023 to 2028, according to Mordor Intelligence. Within this dynamic landscape, custom motorcycle handlebars have emerged as a key segment—both a functional upgrade and a style statement. With North America and Europe leading in customization demand, OEMs and aftermarket suppliers alike are scaling innovation in materials, ergonomics, and design. As riders increasingly seek personalized aesthetics and improved riding comfort, the demand for high-quality, custom handlebars has surged. This growth has fueled the rise of specialized manufacturers who blend precision engineering with artisanal craftsmanship. Based on production volume, export reach, customer reviews, and material innovation, here are the top 10 custom motorcycle handlebar manufacturers shaping the industry today.

Top 10 Custom Motorcycle Handlebars Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 HeliBars

Domain Est. 1997

Website: helibars.com

Key Highlights: Each HeliBars motorcycle handlebar extender and motorcycle handlebar riser is American-made in our Maine factory by skilled engineers obsessed with performance ……

#2 Burly Brand

Domain Est. 2003

Website: burlybrand.com

Key Highlights: Find Motorcycle Handlebars and Harley Handlebars from Burly Brand, America’s premier manufacturer of motorcycle lowering kits, handlebars, and cable kits….

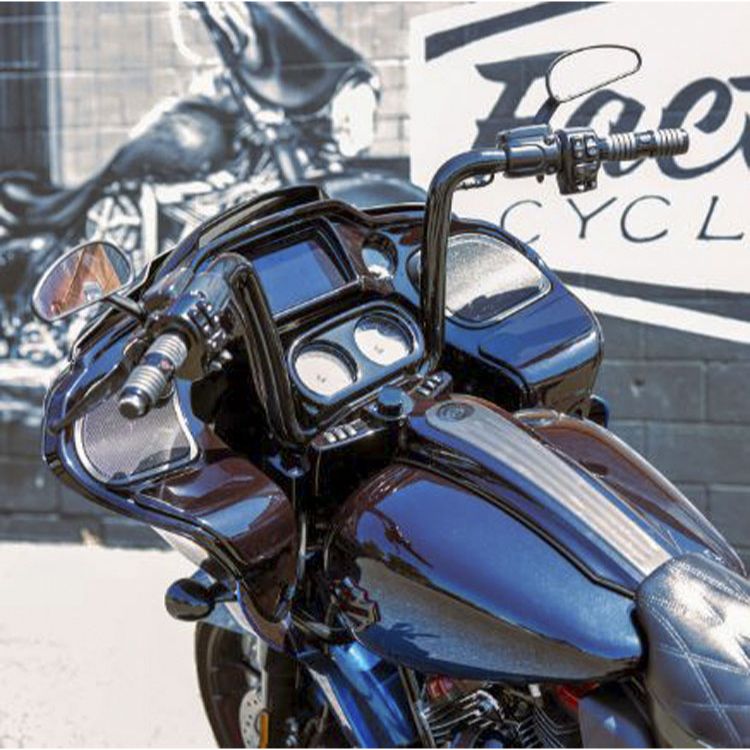

#3 Fat Baggers Inc.

Domain Est. 2004

Website: fatbaggers.com

Key Highlights: Fat Baggers Inc. creates innovative custom parts for Harley Davidsons. Our handlebars are the easiest in the industry to ship and install….

#4 Handlebars

Domain Est. 1996

#5 Kuryakyn Motorcycle Parts

Domain Est. 1996

Website: kuryakyn.com

Key Highlights: We know you want to customize your bike and kick it up a notch, and with our Kuryakyn motorcycle parts, you can do just that! Explore our collection today….

#6 Paul Yaffe Originals

Domain Est. 1998

Website: paulyaffeoriginals.com

Key Highlights: 5-day delivery 7-day returnsPaul Yaffe is an elite, highly-honored custom motorcycle designer with over 30 years in the industry. He’s a two-time “Builder of the Year” and record t…

#7 ProTaper Handlebars, Grips, & Controls

Domain Est. 1999

Website: protaper.com

Key Highlights: Easily locate high-quality handlebars, grips, drive components, and accessories tailored to your bike’s specifications for optimal performance and reliability….

#8 Motorcycle Handlebars

Domain Est. 2004

Website: lowbrowcustoms.com

Key Highlights: Free delivery over $99Shop a huge selection of custom motorcycle handlebars for Harley, choppers, Sportsters, and bobbers. Discover unique, high-quality bars that bring style and ….

#9 Kraus Moto

Domain Est. 2007

Website: krausmotorco.com

Key Highlights: Free delivery over $300 30-day returnsKraus Moto is an American brand dedicated to designing, engineering, and manufacturing Harley and Indian high-performance motorcycle parts and…

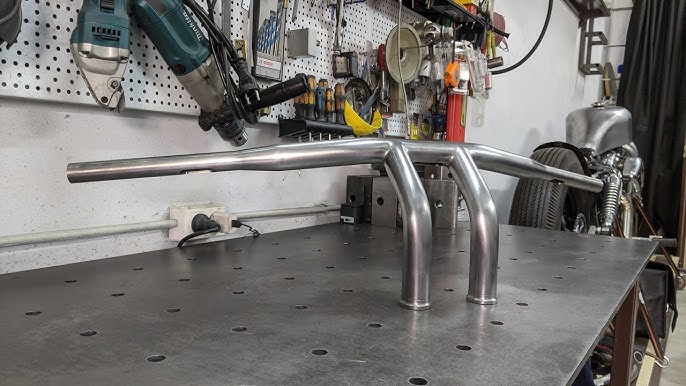

#10 Custom Handlebars by Kinetic Motorcycles

Domain Est. 2013

Expert Sourcing Insights for Custom Motorcycle Handlebars

2026 Market Trends for Custom Motorcycle Handlebars

The custom motorcycle handlebar market is poised for dynamic evolution by 2026, driven by shifting consumer preferences, technological advancements, and a growing global passion for personalized riding experiences. As the motorcycle aftermarket sector matures, handlebars—central to both aesthetics and ergonomics—will reflect broader industry transformations.

Rising Demand for Personalization and Aesthetic Diversity

By 2026, riders will increasingly seek handlebars that express individual identity and complement unique bike builds. This trend will drive demand for diverse styles beyond classic ape hangers and drag bars, including hybrid designs, minimalist flat bars, and asymmetrical configurations. Custom finishes—such as brushed titanium, ceramic coatings, and integrated LED lighting—will gain popularity, enabling riders to match handlebars with their bike’s overall theme. Online configurators and 3D modeling tools will empower consumers to co-design handlebars, accelerating the shift from mass production to made-to-order solutions.

Growth of the Premium and Luxury Custom Segment

The luxury motorcycle aftermarket will expand, with high-end custom handlebars becoming status symbols. Brands will focus on premium materials like aerospace-grade aluminum, carbon fiber, and hand-forged steel, emphasizing craftsmanship and exclusivity. Limited-edition collaborations between handlebar manufacturers and renowned custom bike builders or designers will emerge as key market differentiators, commanding premium pricing and driving brand loyalty.

Integration of Smart Technology

Handlebars will evolve into functional control hubs by 2026. OEMs and aftermarket suppliers will incorporate handlebar-integrated technologies such as heated grips with app-controlled temperature settings, built-in Bluetooth controls, and modular mounts for digital displays and action cameras. Ergonomic designs with embedded wiring channels will simplify the integration of electronics, appealing to tech-savvy riders who value seamless connectivity and enhanced riding comfort.

Sustainability and Eco-Conscious Manufacturing

Environmental considerations will influence material sourcing and production. Recycled aluminum and low-impact manufacturing processes will become selling points as eco-conscious consumers demand sustainable products. Brands that emphasize carbon footprint reduction, ethical sourcing, and recyclable packaging will gain competitive advantage, especially among younger demographics.

Regional Market Expansion and E-Commerce Dominance

While North America and Western Europe remain strong markets, Asia-Pacific—particularly India, Japan, and Southeast Asia—will see accelerated growth due to rising disposable income and a burgeoning custom bike culture. E-commerce platforms will dominate distribution, offering global access to niche and independent handlebar brands. Social media and digital content will play a pivotal role in trend dissemination, with influencers shaping consumer preferences through build showcases and product reviews.

Conclusion

By 2026, the custom motorcycle handlebar market will be defined by personalization, technological integration, and sustainability. Manufacturers who innovate in design, embrace digital customization tools, and align with evolving consumer values will lead the industry. As motorcycles become extensions of personal identity, handlebars will remain a focal point of both function and artistry in the custom riding experience.

Common Pitfalls Sourcing Custom Motorcycle Handlebars (Quality, IP)

Sourcing custom motorcycle handlebars—especially from overseas manufacturers—can offer cost savings and design flexibility, but it also presents significant risks if not managed carefully. Two of the most critical areas where businesses stumble are quality control and intellectual property (IP) protection. Being aware of these pitfalls is essential for a successful sourcing strategy.

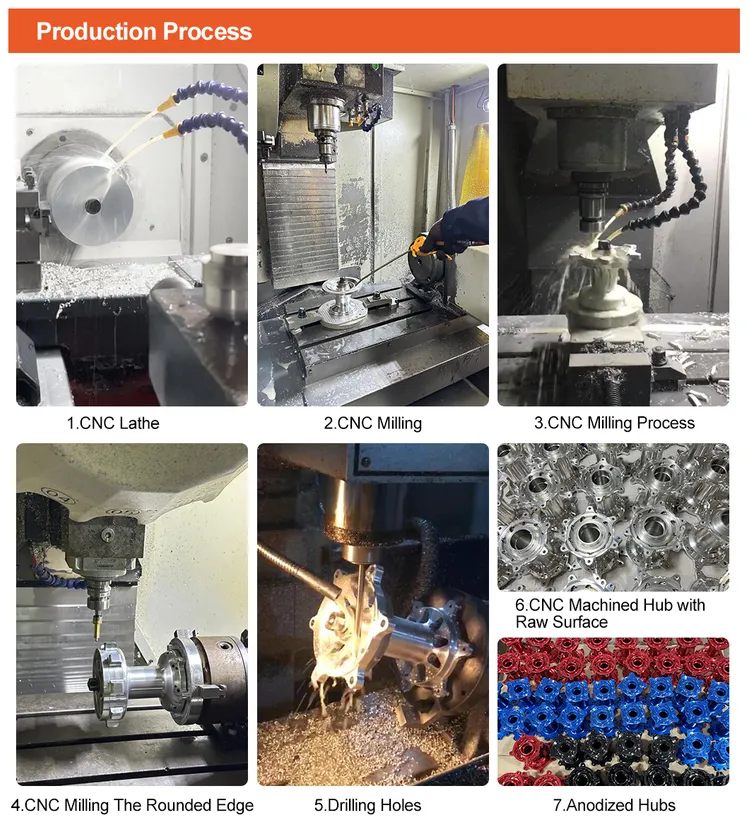

Quality Inconsistencies and Substandard Materials

One of the most frequent issues when sourcing custom handlebars is inconsistent product quality. Many suppliers may provide excellent samples but fail to maintain those standards during mass production. Key concerns include:

- Use of Inferior Materials: Some manufacturers substitute high-grade aluminum or steel with cheaper, weaker alloys to cut costs. This compromises strength, durability, and rider safety.

- Poor Welding and Finishing: Inadequate welding techniques or inconsistent powder coating/anodizing can lead to structural weaknesses and premature corrosion.

- Tolerance and Dimensional Inaccuracy: Handlebars must meet precise ergonomic and mounting specifications. Poor tooling or lax quality control can result in parts that don’t fit or affect ride handling.

- Lack of Certification or Testing: Reputable handlebars often undergo stress testing, vibration testing, or compliance with standards like DOT or TÜV. Many low-cost suppliers skip these validations.

Mitigation Strategy:

Require material certifications (e.g., mill test reports), conduct factory audits, and implement third-party inspections during and post-production. Clearly define tolerances and quality benchmarks in your purchase agreement.

Intellectual Property (IP) Infringement and Design Theft

Custom handlebar designs are valuable IP assets, and sourcing internationally increases the risk of design theft or unauthorized reproduction:

- Design Replication by Suppliers: A manufacturer you commission to produce your custom design may copy it and sell identical or similar handlebars to your competitors.

- Infringement of Existing Patents: Your custom design might unintentionally mimic a patented handlebar shape, mounting system, or ergonomic feature, exposing you to legal action.

- Lack of Legal Recourse: Enforcing IP rights in certain countries is difficult or prohibitively expensive, especially without registered patents or design rights in the manufacturing jurisdiction.

Mitigation Strategy:

File design patents or utility models before sharing detailed blueprints. Use strong, jurisdiction-specific NDAs and manufacturing agreements that explicitly prohibit duplication or third-party sales. Consider working with suppliers in countries with stronger IP enforcement records.

By proactively addressing quality and IP risks, businesses can protect their brand reputation, ensure rider safety, and safeguard their competitive advantage in the custom motorcycle market.

Logistics & Compliance Guide for Custom Motorcycle Handlebars

Custom motorcycle handlebars are specialized aftermarket components that require careful attention to logistics and regulatory compliance throughout their manufacturing, shipping, and sale. This guide outlines key considerations for businesses involved in the production, import, export, or distribution of custom handlebars.

Product Classification & Tariff Codes

Accurate product classification is essential for international trade. Custom motorcycle handlebars typically fall under the following Harmonized System (HS) codes:

- HS 8714.19: Parts and accessories for motorcycles, not electrically propelled, specifically for steering.

- Confirm with local customs authorities, as classifications may vary by country and material (e.g., aluminum vs. steel).

Ensure correct classification to avoid delays, fines, or incorrect duty assessments during import/export.

Material & Manufacturing Compliance

Custom handlebars must meet applicable safety and material standards depending on the target market:

- United States: While there is no federal mandate specifically for aftermarket handlebars, manufacturers must comply with general safety standards under the Consumer Product Safety Act (CPSA). Voluntary compliance with standards such as SAE J1063 (for strength and fatigue testing) is recommended.

- European Union: Must comply with ECE Regulation 78 (Motorcycle Steering Mechanisms) if sold as part of a complete vehicle or replacement part. CE marking may be required depending on national regulations.

- Canada: Subject to the Motor Vehicle Safety Act (MVSA); while handlebars themselves are not specifically regulated, they must not compromise vehicle safety.

- Australia: Comply with the Australian Design Rules (ADR), particularly ADR 15/XX for steering systems, if installed on a registered vehicle.

Use certified materials (e.g., ASTM or ISO-grade steel/aluminum) and maintain documentation of material sourcing and testing.

Packaging & Shipping Logistics

Proper packaging ensures product integrity and compliance with carrier requirements:

- Use durable packaging to prevent bending or scratching during transit.

- Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up”).

- For international shipments, include commercial invoices, packing lists, and certificates of origin.

- Consider freight options: air for speed (small batches), sea for cost efficiency (bulk orders).

- Insure high-value shipments and use trackable delivery methods.

Import/Export Documentation

Ensure all required documentation is prepared for customs clearance:

- Commercial Invoice: Includes product description, value, currency, and terms of sale (e.g., FOB, DDP).

- Packing List: Details weight, dimensions, and quantity per package.

- Bill of Lading (BOL) or Air Waybill (AWB): Required by carriers for shipment tracking and delivery.

- Certificate of Origin: May be required to determine tariff eligibility under trade agreements (e.g., USMCA, EU trade pacts).

- Import Licenses/Permits: Verify if required—usually not for handlebars, but depends on destination country.

Regulatory Compliance & Liability

Selling custom handlebars carries potential liability if the product contributes to an accident:

- Provide clear installation instructions and warning labels (e.g., “Professional installation recommended,” “Improper fit may affect handling”).

- Include compatibility information (e.g., suitable for Harley-Davidson Sportster 2018–2023).

- Disclaimers should state that modifications may affect motorcycle handling and safety.

- Consider product liability insurance, especially for international markets.

Aftermarket Certification & Market Access

While certification is not always mandatory, voluntary certification enhances credibility:

- DOT (U.S.): Not required for handlebars alone, but some states may inspect aftermarket parts during vehicle inspections.

- TÜV (Germany): Third-party testing organization; TÜV certification can facilitate market access in Europe.

- ADR Compliance (Australia): Aftermarket parts must not render a vehicle non-compliant; provide ADR compliance statements if possible.

Environmental & Safety Standards

- Comply with REACH (EU) and RoHS regulations if using coatings or finishes with restricted substances.

- Adhere to local waste and recycling regulations for metal fabrication byproducts.

- Follow OSHA (U.S.) or equivalent workplace safety standards in manufacturing facilities.

Final Recommendations

- Consult with a customs broker or trade compliance expert when entering new markets.

- Maintain detailed records of testing, materials, and compliance documentation.

- Regularly review regulations, as standards for motorcycle parts may evolve.

By proactively addressing logistics and compliance, manufacturers and distributors of custom motorcycle handlebars can reduce risks, ensure smooth operations, and build trust with customers worldwide.

In conclusion, sourcing custom motorcycle handlebars requires careful consideration of design, material, compatibility, and craftsmanship to ensure both performance and aesthetic satisfaction. Whether opting for local fabricators, established manufacturers, or overseas suppliers, it is essential to verify quality standards, lead times, and customization capabilities. Clear communication of specifications, material preferences (such as steel, aluminum, or carbon fiber), and finish requirements will help achieve the desired outcome. Additionally, evaluating cost, minimum order quantities, and shipping logistics plays a crucial role, especially when sourcing in bulk or from international vendors. Ultimately, partnering with reliable and experienced suppliers who understand motorcycle ergonomics and safety standards ensures a successful custom build that enhances both comfort and style on the road.