The global mesh tarpaulin market is experiencing robust growth, driven by rising demand across construction, agriculture, logistics, and outdoor sectors. According to a report by Mordor Intelligence, the global tarpaulin market was valued at USD 8.92 billion in 2023 and is projected to reach USD 11.45 billion by 2029, registering a CAGR of 4.1% during the forecast period. A significant portion of this growth is attributed to the increasing adoption of custom mesh tarps, which offer superior breathability, UV resistance, and durability for specialized applications. Factors such as urban infrastructure development, expanding agricultural activities, and the need for efficient freight containment are further accelerating demand. With customization becoming a key differentiator, manufacturers are investing in advanced weaving technologies and high-density polyethylene (HDPE) materials to meet evolving customer requirements. In this competitive landscape, seven manufacturers have emerged as leaders in innovation, scalability, and product customization—setting the standard for quality and performance in the custom mesh tarp market.

Top 7 Custom Mesh Tarps Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pulltarps®

Domain Est. 1996

Website: pulltarps.com

Key Highlights: We offer custom-made tarps so you can build your ideal truck tarp system for your dump truck or utility trailer. From heavy duty mesh tarps and waterproof vinyl ……

#2 Tarps, Canopies, Kits & Metal Fittings

Domain Est. 1997

Website: tarps.com

Key Highlights: Custom orders. Need a specific size or setup? We make custom tarps to match your exact needs. High-Quality Tarps, Kits, & Metal Fittings for Every Project….

#3 Mesh Tarps

Domain Est. 2006

Website: tarpsamerica.com

Key Highlights: Free delivery over $300 30-day returns…

#4 Mesh Tarps

Domain Est. 2010

Website: tarpsnow.com

Key Highlights: 3–9 day deliveryBrowse our collection of Mesh Shade Tarps. Many of our Mesh Products can very easily be created as Custom Tarps to fit unique sizes through our Custom Size ……

#5 Custom Mesh Tarps

Domain Est. 2015

Website: coversandall.com

Key Highlights: In stock Rating 4.5 (335) Shop for Custom Mesh Tarps in Square & Rectangle Shapes made with 1000 Denier PVC coated polyester with Up to 2 years warranty….

#6 Shade Mesh Poly Tarp 14ft

Domain Est. 2016

Website: nationalpatiocovers.com

Key Highlights: Free delivery 30-day returnsShade Mesh tarps provide up to 73% shade protection and 27% light allowance and allow air and water to pass through. Click to see sizing options….

#7 Custom Heavy Duty Mesh Tarp

Domain Est. 2019

Expert Sourcing Insights for Custom Mesh Tarps

2026 Market Trends for Custom Mesh Tarps

The custom mesh tarp market is poised for significant evolution by 2026, driven by technological advancements, shifting industry demands, and growing sustainability imperatives. Here’s a breakdown of key trends shaping the landscape:

Rising Demand Across Diversified Sectors

Custom mesh tarps are increasingly sought after beyond traditional construction and agriculture. By 2026, industries such as renewable energy (solar farm shading), urban landscaping, sports facilities, and disaster relief operations will drive demand. Customization capabilities—tailored sizes, UV resistance levels, tensile strength, and mesh density—will allow manufacturers to serve niche applications, boosting market penetration.

Technological Integration and Smart Materials

Advancements in material science will lead to the adoption of smart mesh fabrics embedded with sensors for real-time monitoring of environmental conditions (e.g., wind load, temperature, humidity). These intelligent tarps will appeal to logistics, construction, and agriculture sectors seeking data-driven protection solutions. Additionally, 3D modeling and AI-driven design tools will streamline the customization process, reducing lead times and improving accuracy.

Sustainability as a Competitive Advantage

Environmental regulations and corporate ESG goals will push manufacturers toward eco-friendly production. By 2026, biodegradable polymers, recycled HDPE/Polyethylene, and low-impact dyes will become standard in premium custom mesh tarp offerings. Brands emphasizing circular economy practices—such as take-back programs and recyclability certifications—will gain a distinct edge in both B2B and government procurement markets.

Regional Growth and Supply Chain Resilience

North America and Europe will maintain strong demand due to infrastructure renewal projects and strict safety standards. Meanwhile, Asia-Pacific will emerge as a high-growth region, fueled by urbanization and industrial expansion. To mitigate global supply chain risks, manufacturers will increasingly localize production and adopt just-in-time manufacturing models, enhancing responsiveness to custom orders.

E-Commerce and Digital Customization Platforms

Online platforms enabling users to design, visualize, and order custom mesh tarps will dominate. Augmented reality (AR) tools will allow customers to preview tarp fit and function in real-world settings. This digital shift will reduce reliance on traditional sales channels and empower SMEs and individual consumers to access tailored solutions affordably.

In summary, the 2026 custom mesh tarp market will be defined by innovation, sustainability, and digital transformation, creating opportunities for agile, customer-centric suppliers who can deliver high-performance, eco-conscious, and precisely engineered solutions.

Common Pitfalls When Sourcing Custom Mesh Tarps (Quality, IP)

Sourcing custom mesh tarps involves more than just finding a supplier—it requires careful attention to both product quality and intellectual property (IP) protection. Overlooking these aspects can lead to performance issues, safety risks, legal disputes, and reputational damage. Below are key pitfalls to avoid:

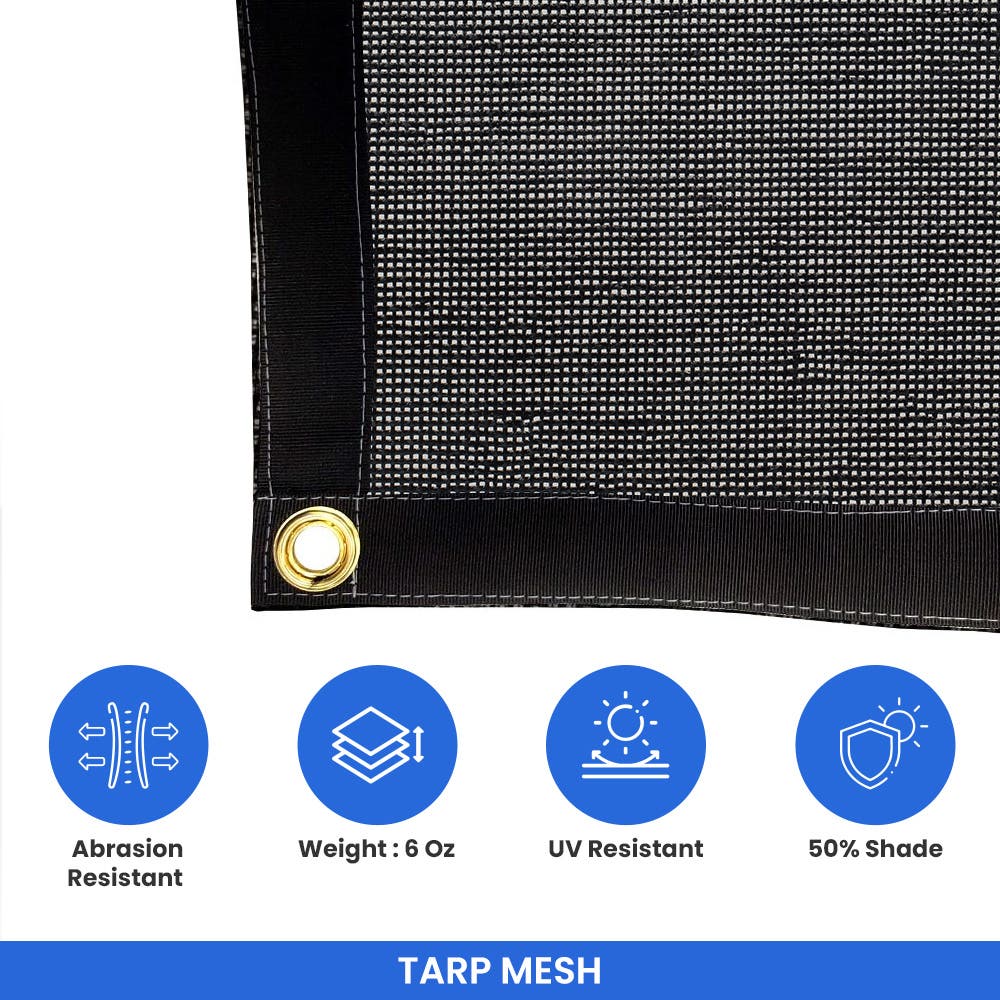

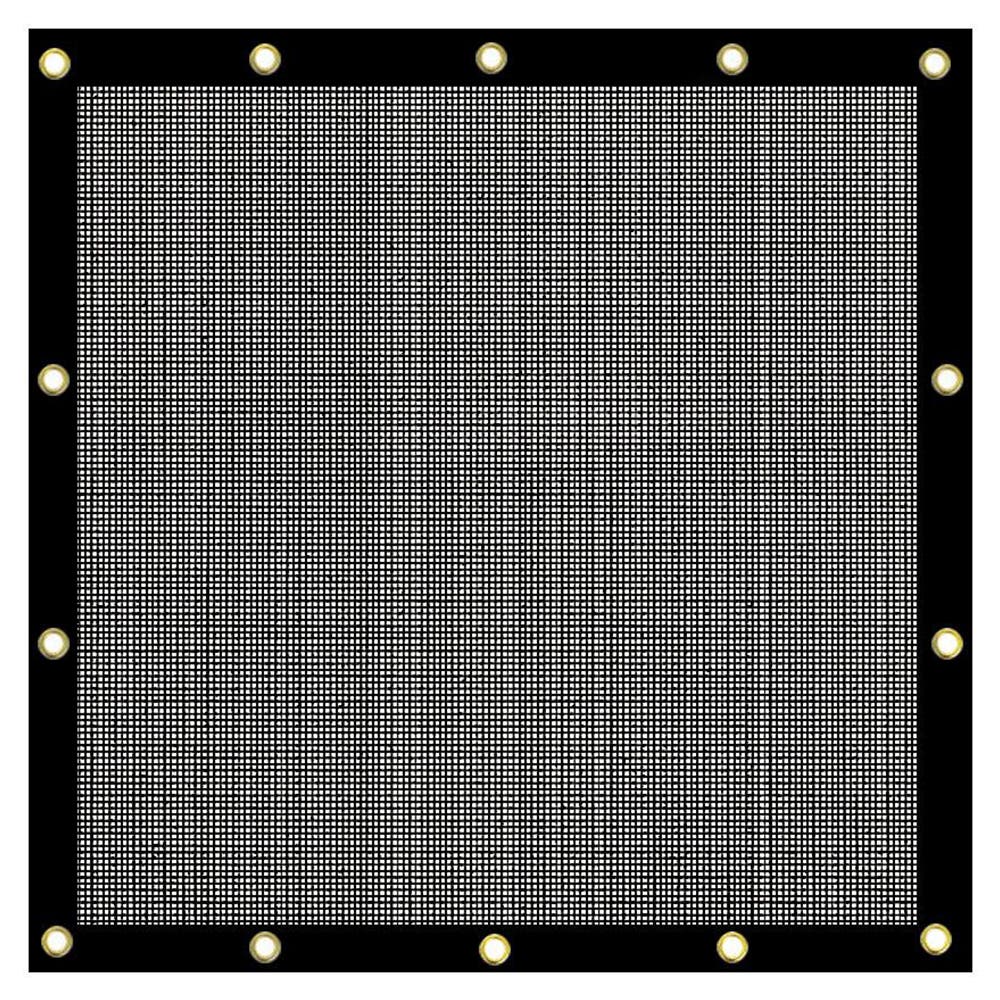

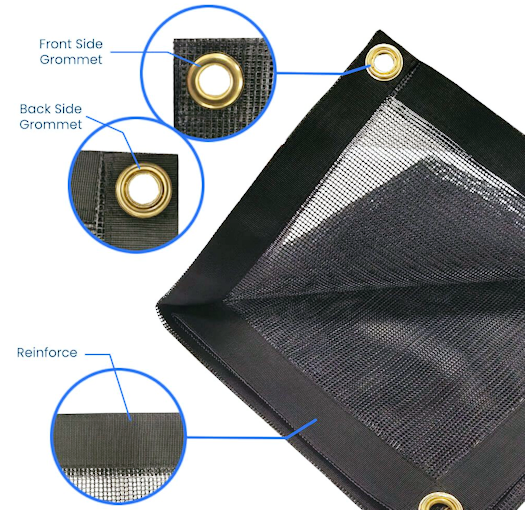

Poor Material and Construction Quality

One of the most frequent issues is receiving mesh tarps made from substandard materials or with inconsistent manufacturing. Low-quality polyethylene or polyester mesh may degrade quickly under UV exposure, lack proper tensile strength, or tear easily under load. Inadequate stitching, weak reinforced edges, or poorly attached grommets can compromise structural integrity. Always verify material specifications (e.g., denier count, UV inhibitors, tear strength) and request physical samples before placing bulk orders.

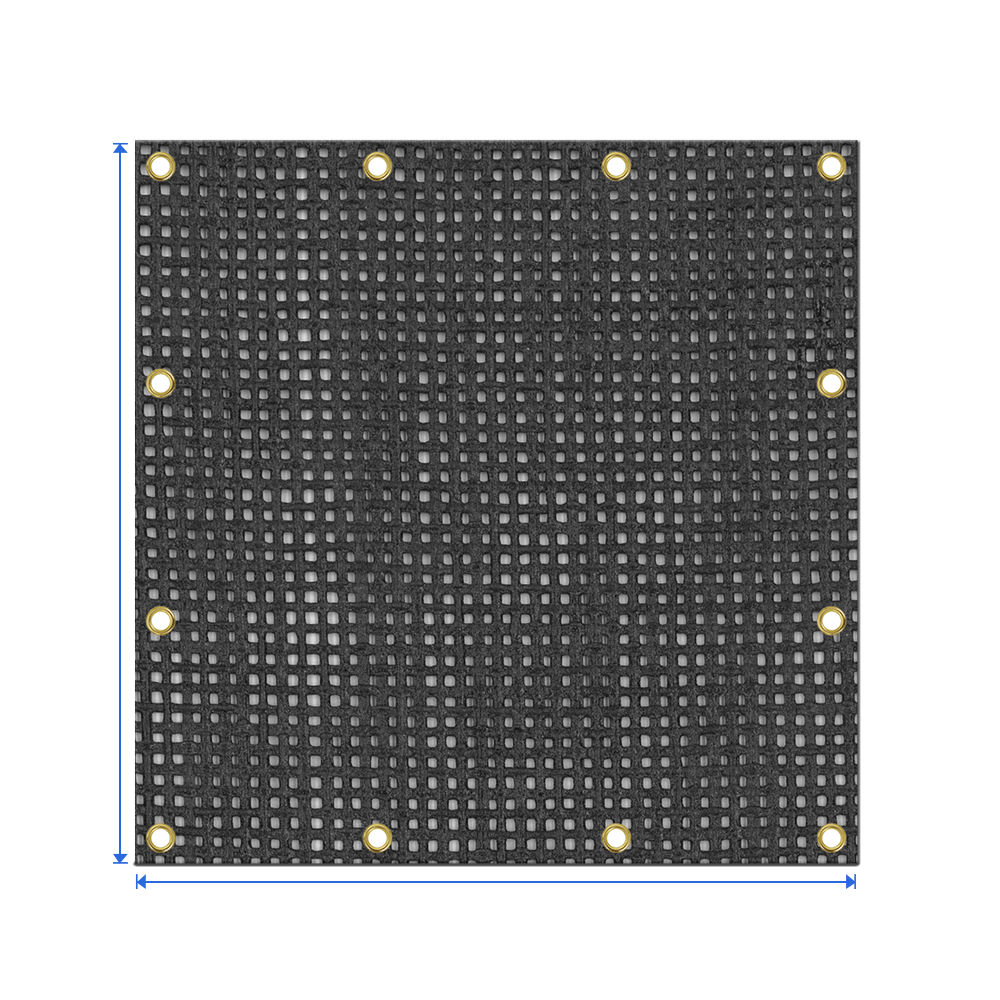

Inaccurate Customization and Sizing

Custom mesh tarps must meet precise dimensions and design requirements. Suppliers may misinterpret technical drawings or overlook critical details like grommet spacing, hem types, or mesh density. This can result in tarps that don’t fit properly or fail to perform as intended. To mitigate this risk, provide detailed CAD files or exact specifications and confirm production prototypes before full-scale manufacturing.

Lack of Quality Control Processes

Suppliers without rigorous quality assurance (QA) systems may deliver inconsistent batches. Without in-line inspections or third-party testing, defects such as uneven weave, color variation, or weak welds can go unnoticed. Ask about the supplier’s QC protocols, certifications (e.g., ISO), and whether they conduct batch testing for durability and compliance.

Intellectual Property (IP) Theft or Misuse

When providing custom designs, logos, or proprietary patterns, there’s a risk that suppliers—especially overseas manufacturers—may reproduce and sell your designs without authorization. This is particularly common in regions with weak IP enforcement. Always establish a clear legal framework before sharing sensitive designs.

Inadequate Legal Protection and Agreements

Failing to use a comprehensive contract exposes your business to IP risks and quality disputes. Ensure agreements include clauses covering confidentiality, IP ownership, usage rights, and non-compete terms. A well-drafted contract should explicitly state that all custom designs remain your sole property and prohibit the supplier from replicating or reselling them.

Overreliance on Supplier Claims Without Verification

Many suppliers make bold claims about durability, UV resistance, or compliance with industry standards (e.g., ASTM, CPAI-84). However, these claims may not be backed by verifiable test reports. Request independent lab certifications and, when possible, conduct your own performance testing to validate specifications.

Choosing Based Solely on Price

Opting for the cheapest supplier often leads to compromised quality or hidden costs from rework, returns, or safety failures. A low upfront price may reflect inferior materials or corners cut in production. Evaluate total cost of ownership, including durability, maintenance, and risk exposure, rather than focusing on initial cost alone.

Supply Chain and Communication Gaps

Poor communication, language barriers, or lack of transparency in the supply chain can delay production and lead to misunderstandings. Ensure your supplier provides regular updates, clear points of contact, and traceability throughout manufacturing. Consider working with suppliers who offer digital collaboration tools or project management support.

By proactively addressing these pitfalls—through due diligence, strong contracts, and quality verification—you can source custom mesh tarps that meet performance standards while safeguarding your intellectual property.

Logistics & Compliance Guide for Custom Mesh Tarps

Overview

Custom mesh tarps are specialized protective covers used across industries such as construction, agriculture, transportation, and events. Their breathable, lightweight design makes them ideal for applications requiring ventilation and UV resistance. However, producing, shipping, and using these tarps involves specific logistical and compliance considerations to ensure quality, safety, and regulatory adherence.

Manufacturing & Material Compliance

Ensure all raw materials (e.g., polyethylene, UV inhibitors, reinforcing threads) meet industry standards such as ASTM D2563 (for polyethylene films) or ISO 1889 (for fabric tensile strength). Verify that inks and coatings used in customization comply with REACH (EU), RoHS (electronics), or Prop 65 (California) where applicable. Manufacturers should provide certification of compliance (CoC) for all materials.

Customization & Design Specifications

All custom designs, logos, and dimensions must be approved in writing before production. Confirm that mesh density (measured in percentage openness) meets customer requirements and industry needs—for example, 30%-50% openness for wind load reduction on scaffolds. Design files should be provided in vector format (AI, EPS, or PDF) with bleed and safe zone margins.

Packaging & Labeling

Package tarps individually or in bundles using recyclable polywrap or kraft paper. Clearly label each package with:

– Product name and SKU

– Dimensions and mesh percentage

– UV protection rating (e.g., 3000 hours tested)

– Care and usage instructions

– Compliance marks (e.g., CE, ANSI, OSHA if applicable)

– Country of origin (mandatory for U.S. imports under FTC rules)

Domestic & International Shipping

Use freight carriers experienced in handling bulk textile or tarp shipments. For domestic U.S. shipments, comply with Department of Transportation (DOT) guidelines for load securement if tarps are used in transport. For international shipping:

– Provide commercial invoices with HS Code 6307.90 (Other Made-up Articles, Textile)

– Include packing lists and certificates of origin

– Adhere to customs regulations in destination countries (e.g., UKCA marking for UK, CCC for China if applicable)

Import & Export Regulations

Verify tariff classifications and import duties using the Harmonized System (HS). Be aware of anti-dumping measures or quotas on plastic products in certain regions. For exports, comply with the U.S. Export Administration Regulations (EAR) if using dual-use materials or technology (rare for basic tarps, but relevant for high-tech variants).

Safety & Performance Standards

Custom mesh tarps used in construction or transportation must meet relevant safety codes:

– OSHA 1926.501 for fall protection and debris netting

– ASTM D4876 for plastic mesh fence/tarp strength

– NFPA 701 for flame resistance if used in public events (especially tents or stages)

Third-party testing reports should be maintained and available upon request.

Environmental & Sustainability Compliance

Comply with local waste and recycling laws. Offer take-back programs or recycling guidance for end-of-life tarps. If marketing as recyclable or eco-friendly, ensure claims are substantiated under FTC Green Guides to avoid misleading advertising.

Documentation & Recordkeeping

Maintain records of:

– Material safety data sheets (MSDS/SDS)

– Test reports for strength, UV, and flame resistance

– Customer design approvals

– Shipping and customs documentation

Retention period: minimum 5 years for compliance audits.

Customer Compliance Guidance

Provide end-users with a compliance checklist including:

– Proper installation methods to meet safety standards

– Maximum wind load recommendations

– Inspection and maintenance schedules

– Disposal and recycling options

By following this guide, suppliers and users of custom mesh tarps can ensure efficient logistics operations and full compliance with regulatory requirements across global markets.

In conclusion, sourcing custom mesh tarps requires careful consideration of material quality, durability, UV resistance, mesh density, and proper customization options to meet specific application needs—whether for construction, agriculture, outdoor events, or debris control. Working with a reputable supplier who offers precise sizing, reinforced edges, grommet placement, and color options ensures optimal performance and longevity. Additionally, comparing pricing, lead times, and customer service responsiveness helps achieve a balance between cost-efficiency and product reliability. By thoroughly evaluating these factors, businesses and individuals can secure high-quality, custom mesh tarps that effectively serve their functional and environmental requirements.