The global measuring tools market, driven by steady expansion in construction, manufacturing, and DIY sectors, is projected to grow at a CAGR of 5.2% from 2023 to 2028, according to Mordor Intelligence. Within this landscape, custom measuring tapes—tailored for branding, specialized applications, or ergonomic design—have emerged as high-value offerings for industries ranging from architecture to industrial maintenance. As demand for precision and personalized tooling increases, manufacturers with strong customization capabilities, quality control, and global supply chains are gaining competitive advantage. This growing niche reflects broader trends in tool personalization and brand integration, fueling innovation among leading producers. Based on production scalability, OEM/ODM experience, and market reach, the following six manufacturers stand out as top providers of custom measuring tapes worldwide.

Top 6 Custom Measuring Tape Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

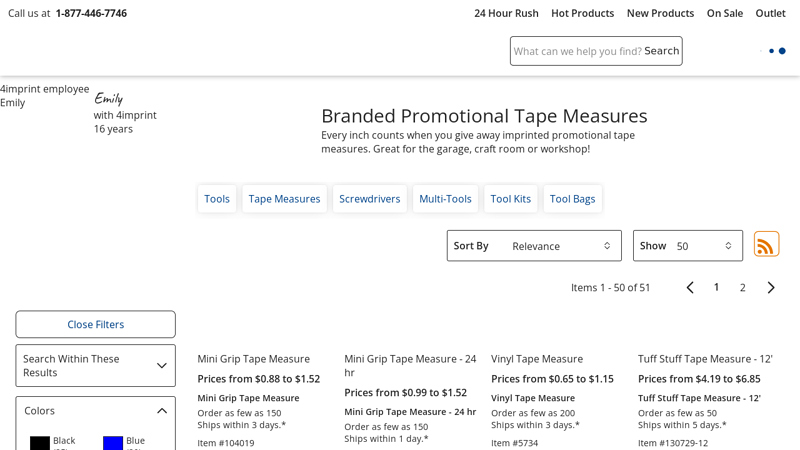

#1 Custom Tape Measures – Bulk

Domain Est. 1994

Website: deluxe.com

Key Highlights: 90-day returnsCustomize mini tape measures, keychains, and more with your logo and design to create promotional tape measures for brand awareness….

#2 US Tape

Domain Est. 1997

Website: ustape.com

Key Highlights: Since 1876, US Tape has been providing unique, dependable, top-quality tools to hardworking professionals in an array of industries….

#3 Shop Custom Tape Measures

Domain Est. 1998

#4 Custom Products

Domain Est. 1999

Website: perfectmeasuringtape.com

Key Highlights: Most tape measures in our online store are customizable in quantities as small as 50 and can be ordered online in 3 simple steps….

#5 Custom Tape Measures

Domain Est. 2002

Website: lazerdesigns.com

Key Highlights: $10 deliveryThese custom tape measures are available in a variety of sizes and styles. Take a look at these personalized tape measures online at Lazer Designs!…

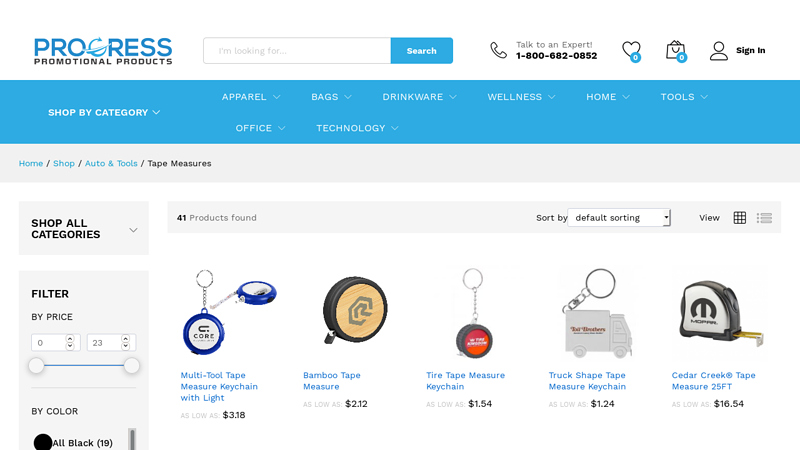

#6 Custom Printed Tape Measures

Website: progresspromo.com

Key Highlights: Promote your business with a custom logo tape measure. Variety of professional and keychain measuring tape – 5FT, 6FT, 8FT, 10FT, ……

Expert Sourcing Insights for Custom Measuring Tape

H2: 2026 Market Trends for Custom Measuring Tape

The global custom measuring tape market is poised for notable transformation by 2026, driven by technological advancements, evolving consumer preferences, and increasing demand across diverse industries. A deeper analysis reveals several key trends shaping the trajectory of this niche yet essential product segment.

H2: Rising Demand in Construction and DIY Sectors

The construction industry continues to be a primary driver for custom measuring tapes, especially with the global surge in infrastructure development and residential projects. Customization features—such as branded logos, specific measurement units (metric/imperial), and durable materials—are increasingly sought after by contractors and engineering firms for branding and utility. Concurrently, the do-it-yourself (DIY) movement, accelerated by home renovation trends and online tutorial platforms, has expanded the consumer base. Custom tapes with user-friendly designs, ergonomic cases, and personalized aesthetics are gaining popularity among hobbyists and independent craftsmen.

H2: Technological Integration and Smart Features

By 2026, smart measuring tapes are expected to capture a growing share of the market. Integration with digital technologies—such as Bluetooth connectivity, mobile app synchronization, and laser-assisted distance measurement—is enhancing accuracy and functionality. Custom smart tapes allow for data logging, project tracking, and cloud storage, appealing to professionals in architecture, interior design, and surveying. While still a premium segment, decreasing costs of embedded electronics are making these advanced tools more accessible, signaling a shift from purely mechanical devices to hybrid solutions.

H2: Growth in Promotional and Branded Applications

Custom measuring tapes are increasingly used as promotional merchandise by corporations, trade associations, and real estate agencies. Their practicality, longevity, and visibility make them effective branding tools. In 2026, manufacturers are expected to offer greater personalization options, including full-color printing, QR code integration, and eco-friendly materials, to meet the demand for sustainable promotional products. This trend is supported by rising marketing budgets allocated to branded merchandise in competitive industries.

H2: Sustainability and Eco-Conscious Manufacturing

Environmental concerns are influencing material choices and production processes. By 2026, there is a projected increase in demand for measuring tapes made from recycled plastics, biodegradable components, and sustainably sourced metals. Brands emphasizing eco-certifications and low-carbon manufacturing are likely to gain favor among environmentally conscious B2B and B2C customers. This shift aligns with broader industry trends toward circular economy practices and corporate sustainability goals.

H2: Regional Market Dynamics and E-Commerce Expansion

The Asia-Pacific region is anticipated to lead market growth due to rapid urbanization, expanding manufacturing sectors, and rising disposable incomes. China, India, and Southeast Asian countries are emerging as both production hubs and key consumer markets. Meanwhile, North America and Europe maintain strong demand, fueled by technological adoption and high construction activity. E-commerce platforms are playing a pivotal role in market expansion, offering customized tapes with quick turnaround times and global reach. Online configurators that allow users to design their own tapes in real time are enhancing customer engagement and driving sales.

In conclusion, the 2026 custom measuring tape market will be defined by innovation, personalization, and sustainability. Companies that leverage digital tools, respond to eco-demands, and cater to both professional and consumer needs will be best positioned for growth in this evolving landscape.

Common Pitfalls When Sourcing Custom Measuring Tapes (Quality and Intellectual Property)

Sourcing custom measuring tapes may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to significant risks, including product failure, legal disputes, and reputational damage. Here are the most common pitfalls to avoid:

1. Underestimating Material Quality and Durability

Many buyers focus on aesthetics or price while neglecting the mechanical performance of materials. Low-grade steel tapes, weak outer casings, or subpar spring mechanisms can lead to inaccurate measurements, premature breakage, or safety hazards. Always verify material specifications (e.g., tempered steel for blades, UV-resistant casing plastics) and request physical samples for stress testing.

2. Inconsistent Print Quality and Legibility

Custom printing—logos, scales, or instructional text—can suffer from smudging, fading, or misalignment if not properly managed. Poor screen printing or ink adhesion may compromise readability, especially in harsh environments. Ensure your supplier uses weather-resistant inks and high-resolution printing processes, and approve print samples before mass production.

3. Inaccurate Calibration and Measurement Precision

Even small deviations in tape calibration can result in significant measurement errors. Some suppliers may not adhere to international standards (e.g., ISO 9001 or ANSI/NIST). Require documented calibration certificates and conduct third-party verification, especially for applications requiring high precision (e.g., engineering, construction, or safety equipment).

4. Overlooking Environmental Resistance

Custom tapes used outdoors or in industrial settings must resist moisture, temperature extremes, UV exposure, and corrosion. Failing to specify IP (Ingress Protection) ratings or environmental testing (e.g., salt spray tests for corrosion resistance) can result in rapid deterioration. Clearly define operating conditions and request compliance with relevant environmental standards.

5. Ignoring Intellectual Property Risks in Design and Branding

Using copyrighted symbols, patented tape mechanisms, or proprietary scale designs without permission can expose your business to IP infringement claims. Ensure your custom design does not replicate patented tape reel mechanisms, unique measurement markings, or protected branding elements. Conduct an IP audit and obtain necessary licenses when incorporating third-party designs.

6. Lack of Design Ownership and Usage Rights

When working with suppliers or third-party designers, it’s critical to establish who owns the final design files, molds, and branding elements. Without a clear agreement, the supplier may retain rights to your custom design, limiting your ability to switch manufacturers or scale production. Use contracts that explicitly assign IP ownership to your company.

7. Supplier Non-Compliance with Regulatory Standards

Depending on your market, measuring tapes may need to comply with metrology regulations (e.g., NIST-traceable calibration in the U.S., CE marking in Europe). Some suppliers may claim compliance without proper certification. Request proof of regulatory conformity and verify testing procedures to avoid customs delays or product recalls.

8. Failure to Secure Long-Term Supply Agreements

Custom tooling and design setup can be costly. If the supplier decides to discontinue your product or raise prices unilaterally, you may face supply chain disruptions. Negotiate long-term supply agreements that include tooling ownership, minimum order guarantees, and price stability clauses.

By proactively addressing these quality and IP pitfalls, businesses can ensure reliable, compliant, and legally secure custom measuring tape sourcing—protecting both product performance and brand integrity.

Logistics & Compliance Guide for Custom Measuring Tapes

Custom measuring tapes—often branded promotional items or specialized tools—require careful attention to logistics and compliance to ensure smooth international shipping and regulatory adherence. This guide outlines key considerations for businesses importing, exporting, or distributing custom measuring tapes.

Product Classification & Tariff Codes

Custom measuring tapes are typically classified under the Harmonized System (HS) code 9017.80, which covers “Drawing, measuring or mathematical instruments, not elsewhere specified or included.” Specific sub-codes may vary by country and material (e.g., plastic, metal, fabric tape). Accurate classification is critical for determining import duties, taxes, and customs clearance procedures.

- US HTS Code Example: 9017.80.8000 – Other measuring instruments

- EU Combined Nomenclature (CN): 9017 80 00 – Other drawing, measuring or mathematical instruments

Verify with local customs authorities or a licensed customs broker to ensure correct classification.

Labeling & Marking Requirements

Custom measuring tapes must comply with country-specific labeling regulations, especially when branded or used for commercial purposes.

- Country of Origin Marking: Required in most markets (e.g., “Made in China”) and must be permanently affixed and legible.

- Measurement Standards: Must display units (metric, imperial, or dual) clearly. In the EU and Canada, metric units are mandatory.

- Branding & Logos: Ensure trademark compliance and avoid misleading claims.

- Safety & Compliance Labels: No major safety warnings are typically required unless marketed as a children’s product.

Packaging & Shipping Considerations

Proper packaging ensures product protection and compliance with shipping regulations.

- Material Compatibility: Use recyclable or environmentally friendly packaging where possible to meet regional sustainability laws (e.g., EU Packaging Waste Directive).

- Dimensional Stability: Measuring tapes should be packed to avoid spring deformation during transit.

- Barcoding & UCC Labels: Include GTIN (UPC/EAN) and shipping labels for retail distribution and warehouse logistics.

- Hazardous Materials: Standard measuring tapes are non-hazardous; however, avoid adhesives or coatings with restricted substances.

Regulatory Compliance

Custom measuring tapes must meet relevant technical and safety standards depending on the destination market.

- United States (FCC/CPSC):

- No FCC certification required (non-electronic).

- If marketed to children under 12, compliance with CPSIA (Consumer Product Safety Improvement Act) is mandatory—includes lead, phthalates, and mandatory third-party testing.

- European Union (CE Marking):

- No CE marking required for basic manual measuring tapes.

- Must comply with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regarding restricted substances (e.g., cadmium, certain phthalates).

- Follow General Product Safety Directive (GPSD) for overall safety.

- Canada:

- Consumer Product Safety Act (CCPSA) applies if intended for children.

- Labeling must be in English and French.

- UK (Post-Brexit):

- UKCA marking may be required for certain products; currently, CE is still accepted in most cases.

- Follow UK REACH regulations.

Import/Export Documentation

Ensure proper documentation to avoid customs delays.

- Commercial Invoice: Includes product description, value, HTS code, country of origin, and terms of sale (e.g., FOB, DDP).

- Packing List: Details quantity, weight, dimensions, and packaging type.

- Bill of Lading / Air Waybill: Required for freight tracking and delivery.

- Certificate of Origin: May be required for preferential tariff treatment under trade agreements.

- Import Licenses: Generally not required for measuring tapes, but verify with local authorities.

Intellectual Property & Brand Protection

- Trademark Clearance: Confirm that logos, slogans, or designs on the tape do not infringe existing trademarks.

- Design Patents: Avoid replicating patented tape designs or mechanisms.

- Customs Recordation: Register trademarks with customs agencies (e.g., US CBP IP Recordation) to prevent counterfeit imports.

Sustainability & Environmental Compliance

- WEEE, RoHS, or Battery Directives: Not applicable to non-electronic measuring tapes.

- Plastic Restrictions: Some regions restrict single-use plastics—ensure packaging complies (e.g., EU Single-Use Plastics Directive).

- Recyclability: Design tapes and packaging for recyclability; disclose materials used.

Conclusion

Successfully managing the logistics and compliance of custom measuring tapes involves accurate classification, proper labeling, adherence to regional safety standards, and thorough documentation. By proactively addressing these factors, businesses can avoid customs delays, ensure product safety, and maintain brand integrity in global markets. Always consult with legal or customs experts for market-specific guidance.

In conclusion, sourcing custom measuring tapes requires careful consideration of several key factors, including material quality, accuracy, customization options, supplier reliability, and cost-effectiveness. Whether for branding, specialized applications, or unique functional requirements, selecting a reputable manufacturer ensures that the final product meets both performance standards and aesthetic expectations. It is essential to clearly define specifications such as length, units of measurement, tape material (e.g., fiberglass, steel, or cloth), case design, and any branding elements like logos or colors. Conducting thorough supplier evaluations, requesting samples, and reviewing minimum order quantities and lead times will help streamline the procurement process. Ultimately, a well-sourced custom measuring tape not only serves a practical purpose but also enhances brand visibility and customer satisfaction, making it a valuable investment for businesses across various industries.