The global custom mat market has experienced steady growth, driven by rising demand across commercial, industrial, and residential sectors for branded, safety, and promotional flooring solutions. According to Grand View Research, the global entrance matting market was valued at USD 2.1 billion in 2022 and is projected to expand at a CAGR of 5.8% from 2023 to 2030, fueled by increasing construction activities and a growing emphasis on interior aesthetics and hygiene. Additionally, Mordor Intelligence forecasts continued expansion in the custom and promotional mats segment, supported by heightened branding initiatives in retail, hospitality, and corporate environments. As businesses prioritize both functionality and brand visibility, the need for high-quality, customizable matting solutions has intensified—making it essential to partner with manufacturers who combine innovation, durability, and design flexibility. Amid this growing landscape, nine custom mat manufacturers have emerged as industry leaders, leveraging advanced printing technologies, sustainable materials, and scalable production to meet diverse client needs.

Top 9 Custom Mat Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Quality Mat Company

Domain Est. 2001

Website: qmat.com

Key Highlights: Quality Mat Co. manufactures premium hardwood crane mats, laminated mats, rig mats and more. 1000’s of new and used mats in stock….

#2 The Custom Mat Co.

Domain Est. 2017

Website: thecustommatco.com

Key Highlights: We make personalized logo mats for any application using a mix of hand-craftsmanship and modern technology right here in the USA….

#3

Domain Est. 2018

Website: mamatting.com

Key Highlights: An industry-leading manufacturer with more than 50 years of experience developing mats designed to make facilities safer, cleaner, and more comfortable….

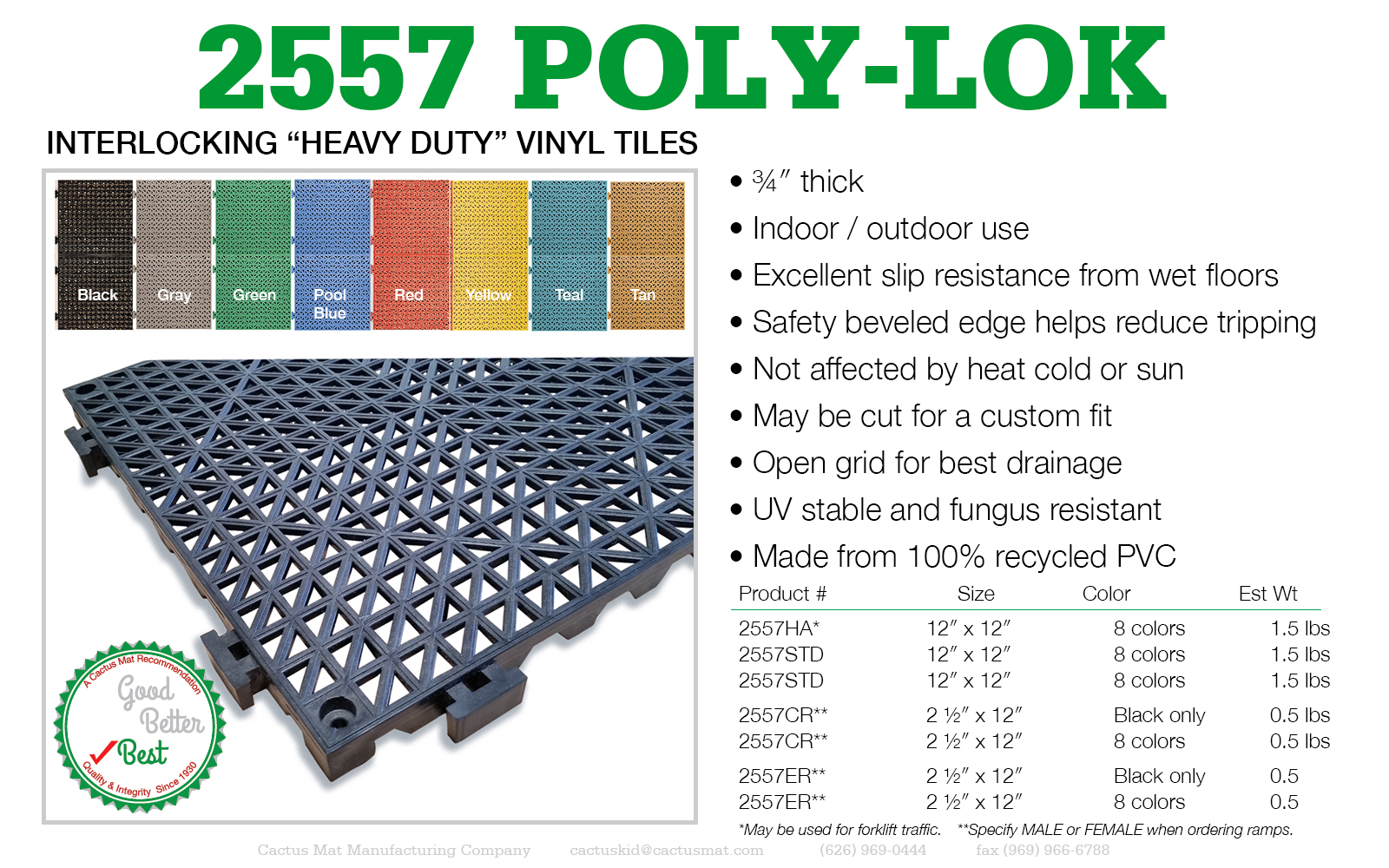

#4 Cactus Mat

Domain Est. 1998

Website: cactusmat.com

Key Highlights: We offer the widest selection of mats and matting with over 2000 styles, colors, and sizes. From logo entrance mats to anti-fatigue and anti-slip solutions….

#5 Personalized Doormats & Mats

Domain Est. 1998

#6 Custom Mat Company

Domain Est. 1999 | Founded: 1994

Website: chairmats.net

Key Highlights: We manufacture and distribute custom chair mats. Selling the highest quality chair mats, since 1994. What We Offer Great Service Our customer service reps will ……

#7 Custom-Mats.com: Custom Logo Mats

Domain Est. 2000

Website: custom-mats.com

Key Highlights: Custom-Mats.com is your source for quality logo mats perfect for your business and branding needs. We offer a large selection of logo mats for many ……

#8 Logo Mats, LLC

Domain Est. 2005 | Founded: 2004

Website: logomatsllc.com

Key Highlights: Since 2004, Logo Mats, LLC has been a leader in producing high performance matting for the promotional products, sign and print industries….

#9 Matboard and More

Domain Est. 2012

Website: matboardandmore.com

Key Highlights: We sell pre cut mats and custom picture frames in any size, color and quantity. Our products also include custom matting, backing boards, clear bags, show kits, ……

Expert Sourcing Insights for Custom Mat

H2: Market Trends Shaping the Custom Mat Industry in 2026

The custom mat industry is poised for significant transformation by 2026, driven by evolving consumer preferences, technological advancements, and sustainability imperatives. Key market trends indicate a shift toward personalization, eco-conscious materials, smart integration, and expanded commercial applications.

-

Personalization and On-Demand Manufacturing

By 2026, demand for highly personalized mats—featuring custom logos, artwork, colors, and dimensions—will continue to grow, especially in residential and promotional markets. Advances in digital printing and automated cutting technologies enable cost-effective, made-to-order production with faster turnaround times. E-commerce platforms with intuitive design tools empower consumers to create bespoke mats easily, driving direct-to-consumer (DTC) sales. -

Sustainability and Eco-Friendly Materials

Environmental concerns are reshaping material choices. Recycled rubber, natural fibers (such as coir and jute), and biodegradable backing systems are gaining traction. Brands that emphasize circular economy principles—offering take-back programs or compostable mats—will appeal to eco-conscious buyers, particularly in North America and Europe. Regulatory pressures and green certifications will further push manufacturers toward sustainable sourcing and low-impact production methods. -

Smart and Functional Mats

In commercial and industrial sectors, integration of smart technology into custom mats is emerging. By 2026, expect growth in sensor-embedded entrance mats that monitor foot traffic, detect moisture, or alert maintenance staff. Anti-fatigue mats with posture support or temperature regulation will become standard in workplaces, driven by ergonomics and occupational health standards. -

Expansion in Commercial and Healthcare Applications

The healthcare, hospitality, and retail sectors will increasingly adopt custom mats for branding, safety, and infection control. Antimicrobial and fluid-resistant mats tailored to facility layouts will see heightened demand. Healthcare facilities, in particular, will prioritize custom-designed mats that comply with hygiene standards and reduce slip-and-fall risks. -

Global Supply Chain Optimization and Localized Production

Post-pandemic supply chain resilience remains a priority. By 2026, many custom mat manufacturers will adopt nearshoring or onshoring strategies to reduce lead times and respond quickly to regional trends. Regional manufacturing hubs will support faster delivery and lower carbon footprints, especially in high-demand markets like the U.S., Germany, and Japan. -

Growth in Niche and B2B Markets

Beyond home and office use, custom mats will gain ground in niche areas such as automotive interiors, event branding, and photography backdrops. B2B demand—especially from corporations seeking branded floor solutions for trade shows, lobbies, and retail spaces—will fuel innovation in durable, portable, and reusable mat designs.

In summary, the 2026 custom mat market will be defined by personalization at scale, sustainability, technological integration, and diversification into high-value commercial applications. Companies that leverage digital platforms, adopt green practices, and anticipate sector-specific needs will lead the market.

Common Pitfalls in Sourcing Custom Mats: Quality and Intellectual Property Risks

Sourcing custom mats—whether for branding, safety, or functionality—can be a strategic advantage, but it comes with significant risks if not managed carefully. Two critical areas where companies often encounter problems are quality inconsistencies and intellectual property (IP) vulnerabilities. Understanding these pitfalls is essential to ensure a successful procurement process.

Quality-Related Pitfalls

Inconsistent Material Standards

One of the most frequent issues in custom mat sourcing is variability in material quality. Suppliers, especially overseas manufacturers, may use substandard materials—such as inferior rubber, recycled fibers, or low-grade dyes—to cut costs. This leads to mats that wear out quickly, fade, or fail to perform in wet or high-traffic environments.

Lack of Clear Specifications

Without detailed technical specifications (e.g., thickness, weight per square foot, anti-slip ratings, colorfastness), suppliers may interpret requirements loosely. This ambiguity often results in final products that don’t meet functional or aesthetic expectations.

Inadequate Prototyping and Testing

Skipping or rushing the sampling phase increases the risk of receiving large production batches with design or material flaws. Without proper testing for durability, moisture absorption, or chemical resistance, companies may face safety issues or customer complaints post-delivery.

Poor Manufacturing Oversight

When working with third-party manufacturers, especially in low-cost regions, limited on-site quality control can result in inconsistent stitching, misaligned logos, or uneven backing. Relying solely on pre-shipment inspections may not catch all defects.

Intellectual Property-Related Pitfalls

Unprotected Designs and Logos

Custom mats often feature proprietary designs, trademarks, or copyrighted artwork. If proper IP agreements are not in place, suppliers may reuse or resell these designs to competitors, leading to brand dilution or legal disputes.

Lack of IP Clauses in Contracts

Many sourcing agreements fail to explicitly state who owns the rights to the design, tooling, or digital files. This omission can result in disputes over ownership or prevent the buyer from sourcing the same mat from another supplier in the future.

Supplier Misuse of Brand Assets

Unauthorized use of a company’s logo or branding on other products or marketing materials by the supplier is a common IP risk. Without confidentiality and non-disclosure agreements (NDAs), companies have little recourse.

Reverse Engineering and Design Copying

Once a mat design is shared with a manufacturer, especially in regions with weak IP enforcement, there is a risk that the supplier or affiliated factories will replicate the product and sell it independently. This is particularly prevalent with innovative or high-margin custom mat designs.

Mitigation Strategies

- Define detailed quality standards and include them in purchase agreements.

- Require and approve physical prototypes before mass production.

- Conduct regular factory audits or use third-party inspection services.

- Secure IP rights legally through contracts specifying ownership and usage rights.

- Use NDAs and confidentiality clauses when sharing design files.

- Register trademarks and design patents when applicable, especially in key manufacturing countries.

By proactively addressing these quality and IP challenges, businesses can protect their brand integrity, ensure product performance, and avoid costly legal or operational setbacks.

Logistics & Compliance Guide for Custom Materials

This guide outlines the essential logistics and compliance considerations when sourcing, handling, and managing custom materials. Adhering to these standards ensures regulatory compliance, supply chain efficiency, and product quality.

Material Specifications and Documentation

Ensure all custom materials meet defined technical specifications, including dimensions, tolerances, material composition, and performance requirements. Maintain comprehensive documentation, including Material Data Sheets (MDS), Certificates of Conformance (CoC), and any engineering drawings. These documents must be readily accessible for audits and traceability.

Regulatory Compliance

Custom materials must comply with relevant regional and international regulations. This includes REACH, RoHS, and conflict minerals reporting (e.g., Dodd-Frank Section 1502) for electronics and industrial components. Verify that suppliers adhere to environmental, health, and safety (EHS) standards and provide necessary compliance certifications.

Import/Export Controls

Determine the correct Harmonized System (HS) codes for custom materials to ensure accurate customs declarations. Assess export control requirements, especially for dual-use items regulated under EAR or ITAR. Secure required licenses or authorizations before shipment to avoid delays or penalties.

Packaging and Labeling

Package custom materials to prevent damage during transit, considering fragility, moisture sensitivity, and hazardous properties if applicable. Label all shipments with required information: part numbers, batch/lot numbers, handling instructions, and safety warnings. For international shipments, include multilingual labels as needed.

Transportation and Handling

Select appropriate transportation methods based on material sensitivity, delivery timelines, and cost. Use carriers experienced in handling specialized or high-value goods. Implement handling procedures to avoid contamination, degradation, or safety risks—especially for temperature-sensitive or hazardous materials.

Inventory and Traceability

Implement a system to track custom materials from receipt through production. Use barcodes or RFID tags for real-time inventory visibility. Maintain lot-level traceability to support recalls, quality investigations, and compliance audits.

Supplier Qualification and Audits

Only source custom materials from pre-qualified suppliers who meet your organization’s quality and compliance standards. Conduct periodic supplier audits to verify ongoing adherence to contractual and regulatory requirements.

Risk Management and Contingency Planning

Identify risks such as supply chain disruptions, regulatory changes, or material shortages. Develop contingency plans, including alternative sourcing options and safety stock levels, to maintain business continuity.

Adhering to this guide ensures that custom materials are managed efficiently and in full compliance with applicable laws and industry best practices.

Conclusion for Sourcing Custom Mats

Sourcing custom mats requires a strategic approach that balances quality, cost, customization options, and reliable supply chain management. After evaluating various suppliers, material options, production capabilities, and lead times, it is clear that selecting the right partner is crucial to ensuring the final product meets both functional and aesthetic requirements. Prioritizing suppliers with proven experience in customization, strong quality control processes, and responsive customer service helps mitigate risks and supports long-term success.

Additionally, considering sustainability—through eco-friendly materials and ethical manufacturing practices—not only aligns with growing environmental concerns but can also enhance brand reputation. Clear communication of design specifications, timely sampling, and rigorous quality checks throughout the production process are essential steps to achieving a high-quality end product.

In conclusion, effective sourcing of custom mats hinges on thorough due diligence, strong supplier relationships, and a focus on value beyond just cost. By making informed decisions at every stage, businesses can secure custom mats that deliver performance, durability, and brand consistency.