Imagine turning your wildest designs, inside jokes, or bold statements into wearable art—without the hassle of inventory, printing presses, or upfront costs. Welcome to the world of custom-made t-shirts, where creativity meets convenience in a single, soft cotton canvas. Thanks to the booming print-on-demand (POD) trend, anyone with a vision can launch their own apparel line from the comfort of their home. From indie artists to savvy entrepreneurs, POD platforms are revolutionizing how we think about fashion—making it personal, sustainable, and instantly accessible. In this post, we’ll dive into how custom t-shirts are reshaping self-expression and why the fusion of design freedom and on-demand production is more than just a trend—it’s the future of fashion.

Top 8 Best Custom Make T Shirt Services (2026 Review)

Reviewed for Print Quality, Pricing & Turnaround Time

#1 T

Online Since 1999

Website: customink.com

Create your own t-shirt design from scratch, upload your own artwork or ask an expert for design help. It’s all possible in our state-of-the-art design lab.

#2 Custom Print Shop

Online Since 2003

Website: rushordertees.com

Free delivery · Free 45-day returnsDesign and print high-quality custom t-shirts at affordable prices. No Minimums. Free Shipping. Fast turnaround. Rush delivery options. Expert service.

#3 Threadbird: Custom T Shirt Printing, High

Online Since 2010

Website: threadbird.com

At Threadbird, we are all about customization and we are committed to making your custom t shirt printing & apparel dreams come true.

#4 : Design & Print Shirts Online

Online Since 1999

Website: vistaprint.com

Starting from $10.00 4.8 5.9K · 3–8 day deliveryDesign and print your own high quality custom t-shirts at an affordable price. Browse shirts across various styles, price points and brands.

#5 Works in Progress NYC

Online Since 2006

Website: worksinprogressnyc.org

We print silk screen, digital full color images, or many types of cool vinyl on t-shirts; long sleeve, short sleeve, ringers, production samples, onesies, …

#6 at Real Thread

Online Since 2009

Website: realthread.com

14-day returnsOur custom printed and embroidery t-shirt services deliver a best-in-class custom tee that everyone will want to wear. 100% customizable & retail-quality …

#7 Custom Printed T-Shirts in 24 Hrs

Online Since 2013

Website: 24hrtees.net

Upload your art and buy rush custom printed t-shirts & more in minutes! Fast custom t-shirt printing ships in as few as 24 hours. No minimums!

#8 Custom Print Shop

Online Since 2001

Website: undergroundshirts.com

Free delivery over $50 30-day returnsCreate custom t-shirts with your designs. High-quality printing, fast delivery, and endless customization options. Start designing your personalized tees …

Expert Guide: Ordering custom make t shirt

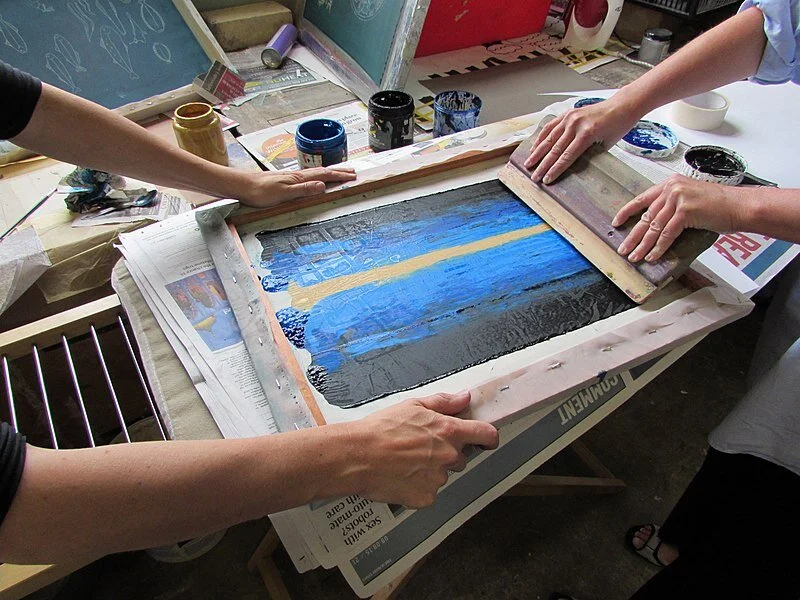

Comparison of Screen Printing, DTG, and Heat Transfer for Custom T-Shirts

| Method | Best For | Durability | Cost |

|---|---|---|---|

| Screen Printing | Large orders, simple designs, bold colors | High – lasts many washes | Low per unit (high setup cost) |

| DTG (Direct-to-Garment) | Small orders, detailed/full-color designs, quick turnaround | Moderate – may fade over time | High per unit (low setup cost) |

| Heat Transfer | Small batches, one-offs, text/logos, light fabrics | Low to Moderate – may crack or peel | Low setup, moderate per unit |

Guide to Choosing Fabrics for Custom Made T-Shirts: 100% Cotton vs. 50/50 Blend vs. Tri-Blends

When creating custom t-shirts, selecting the right fabric is essential for comfort, durability, appearance, and how your design turns out. The most common fabric choices are 100% cotton, 50/50 cotton-polyester blends, and tri-blends. Each has its own advantages and ideal use cases.

100% Cotton

Pros:

– Soft and breathable: Offers a natural feel and excellent comfort, especially in warm weather.

– Eco-friendly: Biodegradable and made from a renewable resource.

– Great for printing: Holds vibrant ink well, especially with screen printing or direct-to-garment (DTG) methods.

– Classic look and feel: Preferred for a traditional, vintage-inspired aesthetic.

Cons:

– Prone to shrinking: May shrink after washing if not pre-shrunk.

– Less durable over time: Can wear out faster, especially with frequent washing.

– Wrinkles easily: Requires ironing for a crisp appearance.

– Absorbs moisture: Can feel heavy when wet and takes longer to dry.

Best For: Casual wear, eco-conscious brands, classic designs, and customers who value natural fibers.

50/50 Cotton-Polyester Blend

Pros:

– Durable and long-lasting: Resists wear, pilling, and fading better than 100% cotton.

– Minimal shrinkage: Holds its shape well after washing.

– Moisture-wicking: Dries faster and resists sweat better than cotton alone.

– Budget-friendly: Often more affordable than premium fabrics.

Cons:

– Less breathable: Can feel warmer and less comfortable in hot climates.

– Less soft initially: May not feel as soft as 100% cotton or tri-blends (though it softens over time).

– Not eco-friendly: Polyester is derived from petroleum and is less biodegradable.

Best For: Workwear, promotional shirts, active environments, and cost-effective bulk orders.

Tri-Blends (Typically 50% Polyester, 25% Cotton, 25% Rayon)

Pros:

– Ultra-soft and silky feel: Offers a luxurious, vintage-inspired drape.

– Lightweight and breathable: Comfortable for all-day wear.

– Excellent shape retention: Resists shrinking and wrinkling.

– Faded, vintage look: Ideal for trendy, fashion-forward designs.

Cons:

– Higher cost: More expensive due to the blend complexity.

– Less durable under stress: Can be more prone to snagging or stretching.

– Special care needed: May require gentle washing to maintain quality.

Best For: Fashion apparel, boutique brands, lifestyle brands, and premium custom tees with a soft, lived-in look.

Choosing the Right Fabric for Your Needs

- Choose 100% cotton for a classic, natural feel and eco-friendly appeal.

- Opt for 50/50 blend for durability, affordability, and performance in active or work settings.

- Go with tri-blend for a soft, stylish, and modern look—perfect for fashion-forward custom t-shirts.

Consider your audience, intended use, budget, and desired look when making your fabric choice. The right fabric can elevate your custom t-shirt from ordinary to outstanding.

How to Get the Best Price for Custom Made T-Shirts (Including Bulk Quantity Breaks and Artwork Tips)

When ordering custom-made t-shirts in bulk, getting the best price involves smart planning, understanding pricing structures, and preparing your artwork correctly. Follow these key strategies to maximize value without sacrificing quality.

Take Advantage of Bulk Quantity Breaks

Screen printers and apparel suppliers offer lower per-unit prices as your order quantity increases. These are known as “quantity breaks.” Here’s how to use them:

- Know the Break Points: Typical breaks occur at 50, 100, 250, and 500 units. For example, pricing might drop significantly when moving from 49 to 50 shirts. Always ask for a pricing tier chart.

- Order Slightly Above Break Points: If you need 45 shirts, consider ordering 50 to benefit from the lower rate.

- Consolidate Orders: Combine needs across teams, events, or departments to reach higher volume tiers.

- Split Sizes, Not Quantities: Most suppliers allow size splits (S, M, L, XL) within a single design order—this doesn’t affect pricing as long as the total quantity meets the break.

Choose the Right T-Shirt Style and Brand

Not all blanks are created equal. To save money:

- Opt for Value-Focused Brands: Gildan, Hanes, and Bella+Canvas offer quality at lower price points.

- Stick to Basic Colors: White and black are typically cheapest; specialty or fashion colors may increase cost.

- Select Lighter Fabric Weights: 4.5 oz or 5.3 oz cotton is often less expensive than premium 6+ oz fabric.

Minimize Print Complexity

Printing cost is heavily influenced by design complexity. Simplify to save:

- Limit Print Colors: Each additional color increases setup and printing time. Stick to 1–3 colors when possible.

- Choose Simpler Designs: Avoid gradients, fine lines, and photorealistic details that require advanced (and costly) printing methods.

- Use One-Location Printing: Printing on just the front (or just the back) reduces labor and setup costs vs. multi-location prints.

Prepare Print-Ready Artwork

A well-prepared design speeds up production and avoids extra fees:

- Use Vector Files (AI, EPS, SVG): These scale without quality loss and are preferred by printers.

- High-Resolution Raster Files (300 DPI): If using Photoshop, ensure your design is 300 dots per inch at actual print size.

- Specify Pantone (PMS) Colors: This ensures color accuracy and reduces guesswork for the printer.

- Provide a Mockup: Help the printer visualize your vision and reduce revision rounds.

Get Multiple Quotes

Don’t settle on the first supplier. Request quotes from at least 3–5 reputable screen printers or online platforms (like Custom Ink, Printful, or local shops). Compare:

- Base shirt cost

- Setup fees

- Printing cost per unit

- Artwork assistance (free or fee-based)

- Turnaround time and shipping

Consider Alternative Printing Methods

Depending on your design and quantity, other methods might offer savings:

- DTG (Direct-to-Garment): Cost-effective for small batches or full-color designs—but higher per-unit cost than screen printing for large runs.

- Dye Sublimation: Great for all-over prints on polyester blends, but limited to light-colored shirts.

- Screen Printing: Best for large orders with simple designs and few colors.

Final Tips for the Best Deal

- Order Off-Season: Avoid peak times (e.g., back-to-school, holidays) when demand—and prices—rise.

- Ask About Discounts: Some suppliers offer first-time, nonprofit, or educational discounts.

- Factor in All Costs: Include shipping, taxes, and any setup fees when comparing quotes.

- Request a Physical Sample: Confirm print and fabric quality before committing to a large order.

By leveraging bulk pricing, simplifying your design, and preparing professional artwork, you can significantly reduce the cost of custom t-shirts—without sacrificing quality.

Choosing the right custom t-shirt provider requires careful consideration of several key factors to ensure quality, reliability, and value for your needs. Start by evaluating the provider’s product quality—review fabric types, stitching, and overall durability. Look for a variety of shirt styles, sizes, and color options to match your preferences and audience.

Next, assess the customization capabilities: the print methods offered (such as screen printing, direct-to-garment, or heat transfer), design flexibility, color accuracy, and minimum order requirements. A user-friendly design tool and responsive customer support can greatly enhance your experience.

Don’t overlook pricing and turnaround time—compare costs across providers, but remember that the cheapest option may compromise on quality. Consider customer reviews and testimonials to gauge reputation and reliability.

Lastly, choose a provider that aligns with your values, whether that’s sustainability, ethical manufacturing, or local sourcing.

In conclusion, the right custom t-shirt provider balances quality, customization, affordability, and service. Take time to research and sample products when possible—this investment upfront ensures your final product makes a lasting impression.