The global aftermarket automotive parts market, including custom truck accessories like mud flaps, is experiencing robust growth driven by increasing commercial vehicle production, rising demand for vehicle customization, and enhanced regulatory focus on road safety and debris control. According to Grand View Research, the global automotive aftermarket parts market was valued at USD 817.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. Custom-made truck mud flaps, in particular, have gained traction among fleet operators and individual truck owners seeking improved functionality, brand personalization, and compliance with regional road safety standards. As demand grows for durable, tailored solutions resistant to heavy-duty conditions, a select group of manufacturers has emerged as leaders in precision engineering, material innovation, and customization capabilities. Based on production scale, customer reviews, lead times, and technological investment, the following nine manufacturers represent the top providers of custom-made truck mud flaps worldwide.

Top 9 Custom Made Truck Mud Flaps Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Mud Flap Manufacturer

Domain Est. 1996

Website: corporate.lippert.com

Key Highlights: We are a mud flap manufacturer supplying a complete line of custom-fit, vehicle-specific mud flaps for most truck makes and models, including hitch-mounted ……

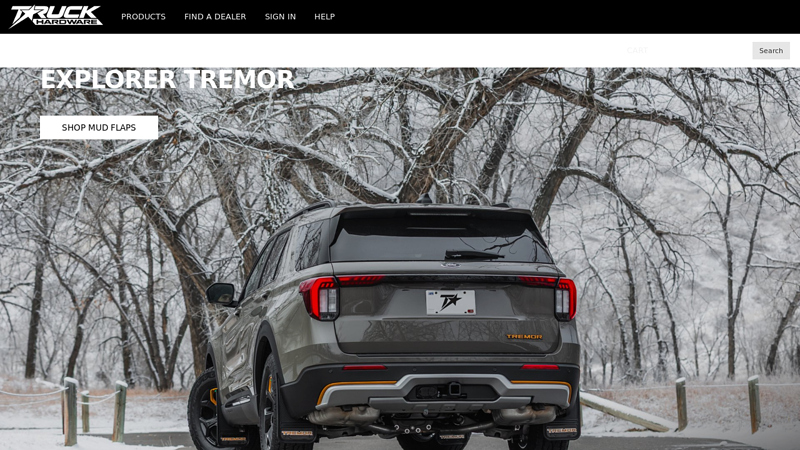

#2 Truck Hardware

Domain Est. 2006

Website: truckhardware.ca

Key Highlights: Truck Hardware designs and produces aftermarket pickup truck accessories, including the Gatorback Mud Flap….

#3 Mudflaps

Domain Est. 1995

Website: american-biltrite.com

Key Highlights: Customized Flap. Personalized mudflaps are the most economical form of highly visible advertising with THOUSANDS of appearances per mile for JUST PENNIES A DAY!…

#4 Mud Flaps

Domain Est. 1997

Website: minimizer.com

Key Highlights: Minimizer offers both poly and rubber mud flaps in a variety of sizes. Our hot-stamping process creates the most durable mud flaps on the market….

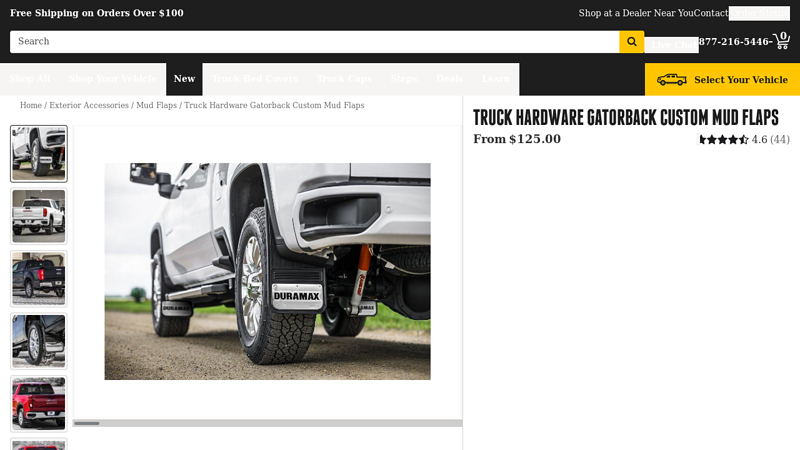

#5 Truck Hardware Gatorback Custom Mud Flaps

Domain Est. 1998

Website: realtruck.com

Key Highlights: In stock Rating 4.6 (44) Constructed from ½” thick heavy-duty rubber · Custom fit for your year, make, & model · Perfectly contoured to your wheel well creating maximum clearance…

#6 #1 Source For Custom Mud Flaps

Domain Est. 1999

Website: usaflap.com

Key Highlights: We make mudflaps for Semi Trucks & Commercial Vehicles that can be ordered plain (as “Blanks”) or customized with graphics and/or text. Our in-house graphic ……

#7 Viking Mud Flaps

Domain Est. 2000

Website: vikingmudflaps.com

Key Highlights: Discover Viking Mud Flaps, a leading supplier of custom imprinted poly, rubber, and quarter fender truck and trailer mud flaps. Get a personalized quote today!…

#8 Mud Flaps For Pick Up Trucks SUVs and Motorhomes by DuraFlap

Domain Est. 2002

Website: duraflap.com

Key Highlights: We custom design our drill-less mud flaps to any size and then shift them to fit with your aftermarket wheels. We custom design our drill-less mud flaps to ……

#9 Mud Flaps

Domain Est. 2020

Website: tso.co

Key Highlights: In stock Rating 4.7 (44) TSO Mud Flaps are designed for lifted trucks with oversized tires. Constructed for 304 stainless steel and powder coated for durability….

Expert Sourcing Insights for Custom Made Truck Mud Flaps

H2: 2026 Market Trends for Custom Made Truck Mud Flaps

The market for custom made truck mud flaps is poised for notable evolution by 2026, driven by shifting consumer demands, advancements in materials and manufacturing, and a growing emphasis on vehicle personalization and regulatory compliance. Several key trends are expected to shape the industry over the next few years.

1. Rising Demand for Personalization and Branding

By 2026, personalization will continue to be a dominant trend in the commercial trucking and enthusiast vehicle sectors. Custom made mud flaps offer fleet operators and individual truck owners a cost-effective way to display branding, logos, slogans, or unique designs. As businesses increasingly focus on brand visibility and drivers seek to express individuality, the demand for customizable options—such as full-color graphics, embossed logos, and LED-lit flaps—will rise significantly.

2. Expansion of E-Commerce and Direct-to-Consumer Platforms

Online customization platforms are expected to play a crucial role in market growth by 2026. Advancements in user-friendly design tools allow customers to create, visualize, and order custom mud flaps from their smartphones or computers. This shift enables faster turnaround times, broader geographic reach, and reduced overhead costs for manufacturers. Integration with 3D modeling and augmented reality (AR) previews may further enhance the online buying experience.

3. Adoption of Advanced and Sustainable Materials

Material innovation will drive performance and sustainability in custom mud flaps. By 2026, there will be an increasing shift toward eco-friendly, durable materials such as recycled rubber, biodegradable polymers, and thermoplastic elastomers (TPE). These materials offer improved resistance to weather, abrasion, and UV degradation, while aligning with environmental regulations and consumer preferences for sustainable products.

4. Regulatory and Safety Compliance Influences

Government regulations related to road safety, splash and spray reduction, and vehicle standards will continue to influence design and material requirements. Custom mud flap manufacturers will need to ensure their products meet or exceed regional compliance standards (e.g., FMVSS in the U.S. or ECE regulations in Europe). This compliance focus will encourage innovation in functional design without compromising aesthetic customization.

5. Growth in Fleet and Commercial Vehicle Markets

The logistics, transportation, and construction industries are expected to maintain robust demand for durable, branded truck accessories. Custom mud flaps serve both functional and marketing purposes for fleet operators, contributing to a projected rise in B2B sales. Integration with fleet management systems and bulk customization services will cater to large-scale commercial clients.

6. Technological Integration and Smart Features

By 2026, the emergence of “smart” truck accessories may extend to mud flaps. Innovations such as embedded sensors to monitor wear and tear, RFID tags for fleet tracking, or integrated lighting for improved visibility could differentiate premium custom products. While still in early stages, these features represent a potential growth frontier.

Conclusion

The 2026 market for custom made truck mud flaps will be characterized by increased personalization, digital ordering platforms, sustainable materials, and functional innovation. Manufacturers who leverage technology, prioritize compliance, and cater to both aesthetic and practical needs will be well-positioned to capture growing demand across commercial and consumer segments.

Common Pitfalls Sourcing Custom Made Truck Mud Flaps (Quality, IP)

Sourcing custom-made truck mud flaps involves navigating several potential challenges, particularly concerning product quality and intellectual property (IP) protection. Failing to address these can lead to substandard products, legal disputes, and reputational damage.

Quality Consistency and Material Integrity

One of the most frequent pitfalls is inconsistent product quality, especially when sourcing from overseas manufacturers. Custom mud flaps must withstand harsh environmental conditions, including extreme temperatures, UV exposure, and road debris. Suppliers may use inferior rubber or composite materials that degrade quickly, crack, or lose flexibility. Without clear specifications and rigorous quality control (QC) processes—such as on-site inspections or third-party testing—buyers risk receiving batches that fail durability standards or do not meet safety regulations.

Lack of Prototyping and Testing Validation

Skipping or inadequately managing the prototyping phase can result in functional flaws in the final product. Custom designs often require multiple iterations to ensure proper fit, flexibility, and performance. Without physical samples and real-world testing, issues like improper mounting alignment, inadequate splash coverage, or premature wear may go undetected until after mass production, leading to costly rework or recalls.

Inadequate Intellectual Property Protection

Custom mud flap designs—especially those with unique shapes, logos, or proprietary materials—represent valuable IP. A major risk arises when contracts fail to clearly assign ownership of the design and tooling. Suppliers in some regions may replicate or resell the design to competitors if not legally bound by non-disclosure agreements (NDAs) and IP assignment clauses. Without proper legal safeguards, buyers may lose exclusive rights to their innovation.

Poor Communication and Specification Ambiguity

Miscommunication about design specifications, tolerances, or performance requirements often leads to deviations from the intended product. Dimensions, color matching, branding elements, or material grades that aren’t meticulously documented can result in deliverables that don’t meet expectations. Using vague or incomplete technical drawings increases the likelihood of errors, especially when working across language and cultural barriers.

Hidden Tooling and Setup Costs

Custom tooling (e.g., molds for rubber flaps) is often required for production. Some suppliers may underquote initial costs and later add unforeseen charges for mold modifications, storage, or usage rights. Buyers may also discover they do not own the tooling, limiting future sourcing options and creating dependency on a single manufacturer.

Supply Chain and Compliance Risks

Custom components must comply with regional safety and environmental standards (e.g., DOT regulations in the U.S. or ECE rules in Europe). Sourcing without verifying compliance can result in shipment rejections or legal penalties. Additionally, relying on a single supplier without contingency planning exposes buyers to disruptions due to production delays, geopolitical issues, or quality lapses.

Avoiding these pitfalls requires thorough due diligence, detailed contracts, proactive quality management, and strong IP safeguards throughout the sourcing process.

Logistics & Compliance Guide for Custom Made Truck Mud Flaps

Product Classification & HS Code

Identify the correct Harmonized System (HS) code for custom truck mud flaps, typically falling under rubber or plastic automotive parts (e.g., 4016.93 or 3926.20). Accurate classification ensures proper customs valuation, duty rates, and compliance with import regulations in the destination country.

Material Compliance & Environmental Regulations

Ensure all materials used (rubber, thermoplastic, reinforced composites) meet regional environmental and safety standards. Verify compliance with REACH (EU), RoHS (electronics components if applicable), and Proposition 65 (California) to restrict hazardous substances. Use certified, sustainable materials where required.

DOT & FMVSS Standards (U.S. Market)

For sale in the United States, confirm that custom mud flaps comply with Department of Transportation (DOT) regulations and relevant sections of the Federal Motor Vehicle Safety Standards (FMVSS), particularly FMVSS No. 125 (engine compartment integrity) and general vehicle equipment rules. While mud flaps are not directly regulated, they must not interfere with vehicle safety systems.

Dimensional & Installation Specifications

Custom mud flaps must adhere to dimensional guidelines that prevent overhang beyond the tire width, typically no more than 12 inches (30 cm) as per U.S. and Canadian standards. Ensure designs allow for proper ground clearance and do not obstruct lights, reflectors, or license plates.

Country-Specific Certification Requirements

Research and comply with certification needs in target markets:

– European Union: CE marking may be required if mud flaps are part of a safety system; otherwise, adherence to ECE regulations for vehicle components is recommended.

– Canada: Comply with the Motor Vehicle Safety Act (MVSA) and ensure conformity with CMVSS standards.

– Australia/New Zealand: Meet ADR standards under the Road Vehicle Standards Act.

Labeling & Traceability

Each custom mud flap must include permanent labeling with:

– Manufacturer name or trademark

– Country of origin

– Material type

– Size or model number

– Compliance markings (e.g., DOT, CE if applicable)

Maintain production records for traceability in case of recalls or audits.

Packaging & Shipping Logistics

Use durable, weather-resistant packaging to prevent damage during transit. Clearly label packages with:

– Product description and SKU

– Handling instructions (e.g., “Fragile,” “Do Not Stack”)

– Importer of record and end-user details

Optimize packaging dimensions to reduce shipping costs and carbon footprint.

Import Documentation

Prepare accurate documentation for international shipments, including:

– Commercial invoice (with full product description, value, and HS code)

– Packing list

– Certificate of Origin

– Material Safety Data Sheet (MSDS), if required

– Any third-party test reports or compliance certificates

Customs Clearance & Duties

Partner with a licensed customs broker to facilitate smooth clearance. Declare the correct transaction value and ensure all preferential trade agreements (e.g., USMCA, CETA) are leveraged to reduce or eliminate import duties where applicable.

After-Sales Compliance & Warranty

Provide customers with compliance documentation and installation guidelines. Maintain a warranty policy that aligns with regional consumer protection laws (e.g., EU Consumer Rights Directive, Magnuson-Moss Warranty Act in the U.S.).

Continuous Regulatory Monitoring

Subscribe to regulatory updates from transportation and customs authorities in target markets. Regularly review changes in environmental, safety, and labeling requirements to maintain ongoing compliance.

In conclusion, sourcing custom-made truck mud flaps requires a careful balance of material quality, customization capabilities, durability, and cost-efficiency. By partnering with a reliable manufacturer or supplier that offers design flexibility, high-performance materials (such as heavy-duty rubber or polyurethane), and compliance with industry regulations, fleet operators and businesses can ensure optimal protection, longevity, and brand visibility. Conducting thorough supplier evaluations, requesting samples, and considering long-term value over upfront cost will ultimately lead to a successful sourcing decision that enhances vehicle performance, safety, and aesthetics.