Imagine turning your wildest designs—whether it’s a nostalgic doodle, your brand’s bold new logo, or a funny quote that never fails to get laughs—into a wearable masterpiece, all without holding a single piece of inventory. That’s the magic of custom-made t-shirts in today’s digital age. Fueled by the soaring popularity of Print on Demand (POD) technology, creating personalized apparel has never been easier, more affordable, or more accessible. From independent artists launching side hustles to entrepreneurs scaling global brands from their laptops, POD is reshaping how we think about fashion, creativity, and business. In this post, we’ll dive into why custom t-shirts are having a major moment and how you can ride the wave—no sewing machine required.

Top 8 Best Custom Made T Shirts Services (2026 Review)

Reviewed for Print Quality, Pricing & Turnaround Time

#1 Custom Print Shop

Online Since 2003

Website: rushordertees.com

Free delivery · Free 45-day returnsDesign and print high-quality custom t-shirts at affordable prices. No Minimums. Free Shipping. Fast turnaround. Rush delivery options. Expert service.

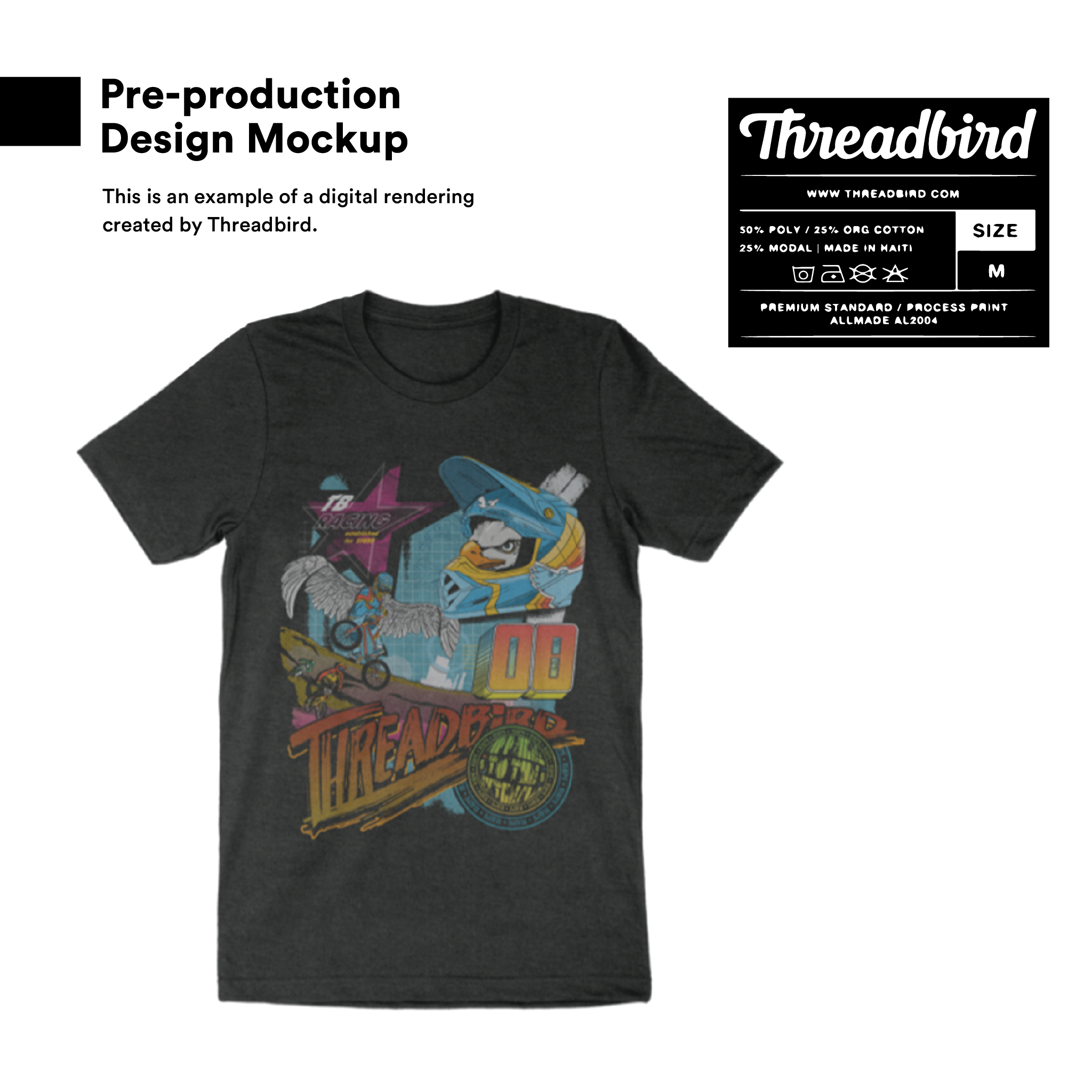

#2 Threadbird: Custom T Shirt Printing, High

Online Since 2010

Website: threadbird.com

At Threadbird, we are all about customization and we are committed to making your custom t shirt printing & apparel dreams come true.

#3 Custom T-Shirt Printing

Online Since 1997

Website: instantimprints.com

Personalized shirts with your logo or design. We create t-shirts with custom designs using the latest technologies in direct to garment, heat transfers, …

#4 : Design & Print Shirts Online

Online Since 1999

Website: vistaprint.com

Starting from $10.00 4.8 5.9K · 3–8 day deliveryDesign and print your own high quality custom t-shirts at an affordable price. Browse shirts across various styles, price points and brands.

#5 at Real Thread

Online Since 2009

Website: realthread.com

14-day returnsOur custom printed and embroidery t-shirt services deliver a best-in-class custom tee that everyone will want to wear. 100% customizable & retail-quality …

#6 DTLA Print

Online Since 2010

Website: dtlaprint.com

High Quality Custom T-Shirts, Hoodies, Hats, & Tote Bags. Full Package Eco-Friendly Screen Printing, Embroidery & Private Label Services | DTLA Print.

#7 Custom Print Shop

Online Since 1995

Website: bonfire.com

Order custom shirts and apparel with ease on Bonfire. ✓Premium products. ✓No minimums. ✓Bulk discounts. ✓No upcharge for plus sizes. Start your order today!

#8 Custom Print Shop

Online Since 2001

Website: undergroundshirts.com

Free delivery over $50 30-day returnsCreate custom t-shirts with your designs. High-quality printing, fast delivery, and endless customization options. Start designing your personalized tees …

Expert Guide: Ordering custom made t shirts

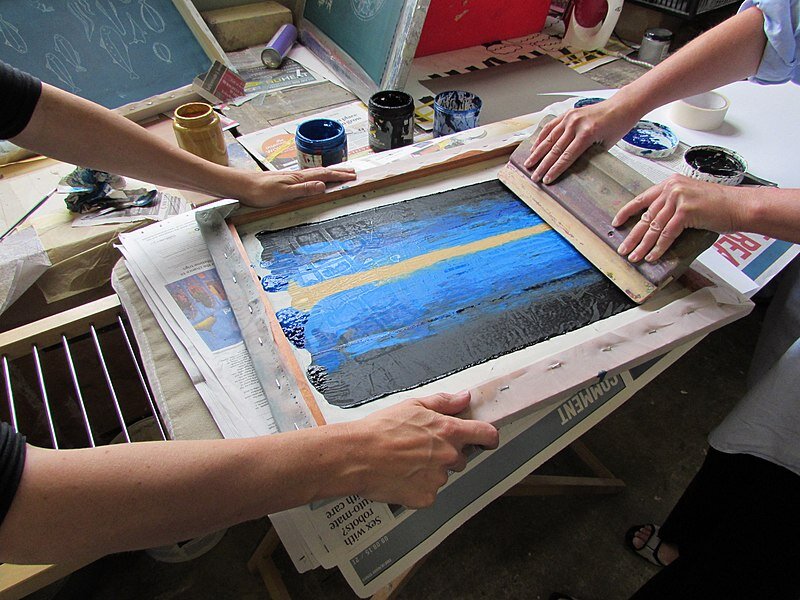

Comparison of Custom T-Shirt Printing Methods

| Method | Best For | Durability | Cost |

|---|---|---|---|

| Screen Printing | Large orders, simple designs with few colors, bold graphics | High – lasts many washes without fading | Low per unit for bulk; higher setup cost |

| DTG (Direct-to-Garment) | Detailed, full-color designs, photos, small batches or single items | Moderate to High – may fade after many washes | Moderate – higher per unit, no setup fees |

| Heat Transfer | Small runs, quick turnaround, complex designs or text-heavy graphics | Low to Moderate – can crack or peel over time | Low for small quantities; cost adds up for large orders |

100% Cotton vs. 50/50 Blend vs. Tri-Blends: Your Guide to Choosing Fabrics for Custom T-Shirts

When designing custom t-shirts, one of the most important decisions you’ll make is the fabric. The material affects not only how the shirt feels and wears but also how your design prints and how customers perceive the quality. Let’s break down the three most popular fabric options: 100% cotton, 50/50 blends, and tri-blends.

100% Cotton: Classic Comfort and Softness

Pros:

– Soft and breathable: Pure cotton is naturally soft against the skin and allows for excellent airflow, making it ideal for warm weather or active wear.

– Eco-friendly appeal: Cotton is biodegradable and renewable, appealing to environmentally conscious consumers.

– Great for printing: Cotton absorbs ink well, producing vibrant, crisp results—especially with screen printing and direct-to-garment (DTG) methods.

– Timeless feel: Offers that classic, familiar t-shirt experience many people love.

Cons:

– Prone to shrinking: Especially if not pre-shrunk, 100% cotton can shrink in the dryer.

– Less durable over time: May wear out faster, pill, or lose shape with repeated washing.

– Wrinkles easily: Requires ironing or steaming for a neat appearance.

Best For: Casual tees, promotional giveaways, eco-friendly products, and fans of traditional comfort.

50/50 Blend: The Balanced Performer

What It Is: A mix of 50% cotton and 50% polyester, combining the best of both fibers.

Pros:

– Durable and long-lasting: Polyester adds strength and resistance to shrinking and stretching.

– Affordable: Often more cost-effective than tri-blends or premium cottons.

– Retains shape: Holds its form better over time and resists wrinkles.

– Good printability: Works well with most printing techniques, though colors may not be as vibrant as on 100% cotton.

Cons:

– Less breathable: Polyester doesn’t breathe as well as cotton, which can make the shirt feel warmer.

– Slight synthetic feel: May not have the same soft, natural hand-feel as 100% cotton.

– Pilling over time: Can develop small fabric balls with frequent wear and washing.

Best For: Budget-conscious brands, event shirts, sports teams, and workwear—where durability and value are key.

Tri-Blends: The Premium, Soft Touch

What It Is: Typically a blend of 50% polyester, 25% combed cotton, and 25% rayon (often from viscose). This combination creates a smooth, lightweight fabric.

Pros:

– Luxuriously soft: Feels silky and smooth—often compared to a vintage or worn-in tee.

– Excellent drape: Flatters the body with a slightly fitted, elegant silhouette.

– Resists shrinking and fading: Polyester and rayon contribute to long-term shape and color retention.

– Great for detailed prints: Smooth surface enhances print clarity and soft-hand inks.

Cons:

– Higher price point: More expensive than 100% cotton or 50/50 blends.

– Less breathable: Due to high synthetic content, may not be ideal for high-activity use.

– Delicate care needed: Can be less durable under heavy use and may require gentle washing.

Best For: Fashion-forward apparel, boutique brands, gift items, and customers seeking a premium feel.

Choosing the Right Fabric for Your Needs

- Prioritize comfort and breathability? Go with 100% cotton.

- Need durability and affordability? Choose a 50/50 blend.

- Want a soft, stylish, premium look and feel? Opt for a tri-blend.

Ultimately, your choice depends on your brand, target audience, intended use, and budget. Many successful custom apparel lines offer multiple fabric options to suit different preferences—giving customers the flexibility to choose their ideal fit and feel.

How to Get the Best Price for Custom Made T-Shirts (Bulk Quantity Breaks & Artwork Tips)

Ordering custom t-shirts in bulk can be a cost-effective way to promote your brand, team, or event—but only if you know how to optimize your order. By leveraging quantity breaks and preparing your artwork correctly, you can significantly reduce your per-unit cost. Here’s how to get the best price on custom t-shirts.

Understand Bulk Quantity Breaks

Most screen printing and embroidery companies offer tiered pricing based on order volume. The more shirts you order, the lower your cost per unit. Knowing how these breaks work is key to maximizing savings.

- Typical Quantity Tiers: Common bulk breaks include 25, 50, 100, 250, and 500+ units. For example, ordering 99 shirts might cost $12 each, while jumping to 100 could drop the price to $8 each.

- Plan Ahead: If you’re close to a tier threshold, consider increasing your order size to reach the next break—even if you don’t need all the shirts immediately. Extra shirts can serve as backups or future inventory.

- Mix-and-Match Options: Some suppliers allow different colors or sizes within the same design to count toward the bulk quantity. Confirm with your printer if this applies.

Choose the Right Shirt Style

The type of t-shirt directly impacts your price. Basic, value-priced garments (e.g., Gildan 5000 or Bella+Canvas 3001) offer the lowest cost and are ideal for large orders on a budget.

- Opt for Standard Colors: Neutral colors like black, white, navy, and gray are usually cheaper and more readily available than specialty colors.

- Avoid Premium Fabrics Unless Necessary: Organic cotton, tri-blends, or performance wear cost more. Stick with 100% cotton or standard blends for maximum savings.

Simplify Your Design to Reduce Printing Costs

Every design decision affects pricing—especially with screen printing, where setup fees and ink layers add up.

- Limit the Number of Print Colors: Each additional color requires a separate screen and setup cost. A one- or two-color design is significantly cheaper than a four-color design.

- Use Simpler Artwork: Avoid gradients, fine details, and halftones, which increase printing complexity and cost. Bold, solid designs print faster and more affordably.

- Stick to One Print Location: Chest prints are usually the cheapest. Adding sleeves, backs, or multiple locations increases labor and setup time.

Prepare Print-Ready Artwork

Submitting correctly formatted artwork prevents delays and extra fees.

- Use Vector Files (AI, EPS, SVG): Vector graphics scale infinitely without losing quality and are preferred by printers. Avoid low-resolution JPEGs or PNGs.

- Specify Pantone (PMS) Colors: If color accuracy is important, provide Pantone color codes to ensure consistency across batches.

- Outline Text and Convert Fonts: In programs like Adobe Illustrator, convert all text to outlines to prevent font issues on the printer’s end.

- Submit High-Resolution Raster Files (if needed): If using a raster image (like for photo printing), ensure it’s at least 300 DPI at the final print size.

Request Quotes from Multiple Suppliers

Don’t settle for the first quote—compare at least 3–5 reputable screen printers or online custom apparel platforms.

- Ask About Setup Fees: Some companies charge a one-time screen setup fee per design per color. Others waive it for large orders.

- Check for Hidden Costs: Inquire about fees for additional services like shipping, color matching, or rush orders.

- Look for Promotions: Many suppliers offer seasonal discounts, first-time customer deals, or free shipping on bulk orders.

Time Your Order Strategically

- Avoid Rush Fees: Plan ahead and allow 2–3 weeks for production. Rush orders can double printing costs.

- Order Off-Peak: Late fall or winter (outside back-to-school and summer event seasons) may yield better pricing or availability.

Final Tips for Maximum Savings

- Consolidate Orders: If your organization needs shirts periodically, batch orders together to hit higher quantity breaks.

- Use DTG for Small Runs, Screen Print for Large: For under 50 shirts with complex designs, Direct-to-Garment (DTG) printing may be cost-effective. For 50+ units, screen printing usually wins on price.

- Ask About Reorders: Some printers offer discounted rates for reorders of the same design since setup is already complete.

By combining smart ordering strategies with well-prepared artwork, you can dramatically reduce the cost of custom t-shirts—without sacrificing quality. Plan ahead, leverage bulk breaks, and choose simplicity to get the best value.

Choosing the right custom t-shirt provider requires careful consideration of several key factors to ensure quality, value, and satisfaction. Start by evaluating the provider’s print quality and fabric options—opt for companies that use durable materials and offer a range of printing methods like screen printing, DTG, or embroidery to suit your design needs. Consider customization flexibility, including sizing, color choices, and design support. Pay close attention to pricing and minimum order requirements, balancing affordability with quality. Reliable customer service, clear turnaround times, and transparent shipping policies are also crucial. Finally, read customer reviews and request samples when possible to verify consistency and professionalism. By prioritizing these aspects, you can select a custom t-shirt provider that meets your specific needs, whether for personal use, events, or business branding.