Gone are the days when a standard graphic tee or plain white shirt cut it as self-expression. Today, fashion is personal—deeply personal. From quirky inside jokes to bold artistic statements, people aren’t just wearing clothes; they’re telling stories. Enter the era of custom-made t-shirts, where your imagination is the only limit. Fueled by the rise of personalized fashion and powered by Print on Demand (POD) technology, creating a one-of-a-kind tee has never been easier—or more accessible. Whether you’re launching a side hustle, promoting a cause, or just want to stand out from the crowd, custom t-shirts are transforming the way we think about style. Welcome to the revolution, one unique design at a time.

Top 10 Best Custom Made T Shirts Companies (2026 Review)

Reviewed for Print Quality, Pricing & Turnaround Time

#1 T-Shirt & Apparel Printing

Online Since 2001

Website: undergroundshirts.com

Design custom t-shirts and apparel with Underground Printing. Offering screen printing, embroidery, and fast delivery on all orders.

#2 Custom Print Shop

Online Since 2003

Website: rushordertees.com

Free delivery · Free 45-day returnsDesign and print high-quality custom t-shirts at affordable prices. No Minimums. Free Shipping. Fast turnaround. Rush delivery options. Expert service.

#3 Real Thread

Online Since 2009

Website: realthread.com

Trust Real Thread for your custom apparel needs. From screen printing to embroidery, we offer sustainable solutions with guaranteed quality and delivery.

#4 Threadbird: Custom T Shirt Printing, High

Online Since 2010

Website: threadbird.com

At Threadbird, we are all about customization and we are committed to making your custom t shirt printing & apparel dreams come true.

#5 : Design & Print Shirts Online

Online Since 1999

Website: vistaprint.com

Starting from $10.00 4.8 5.9K · 3–8 day deliveryDesign and print your own high quality custom t-shirts at an affordable price. Browse shirts across various styles, price points and brands.

#6 Custom T Shirts, Hats & Hoodie Printing & Embroidery

Online Since 1999

Website: teamshirts.com

High quality custom T-shirt printing ✓ Free shipping ✓ Save up to 65% ✓ Easy T-Shirt Creator ✓ 10000+ free graphics ▷ Create your own designs.

#7 DTLA Print

Online Since 2010

Website: dtlaprint.com

High Quality Custom T-Shirts, Hoodies, Hats, & Tote Bags. Full Package Eco-Friendly Screen Printing, Embroidery & Private Label Services | DTLA Print.

#8 Bonfire

Online Since 1995

Website: bonfire.com

Design premium custom merch to sell online or place a direct order. Upload your design in our free online tool & choose products to print on.

#9 Custom-made T-shirts.

Online Since 2005

Website: tailorstore.com

Free delivery · Free 14-day returnsOur custom-made T-shirts will have you looking your best with minimum effort and maximum comfort. Customize and create to your liking using our design tool.

#10 Personalized Work Shirts, Custom Printed T

Online Since 2009

Website: tshirtbydesign.com

Free delivery over $50 30-day returnsWe offer a variety of unique and personalized work shirt templates that are designed to help your business get started with custom printed company shirts.

Expert Guide: Ordering custom made t shirts

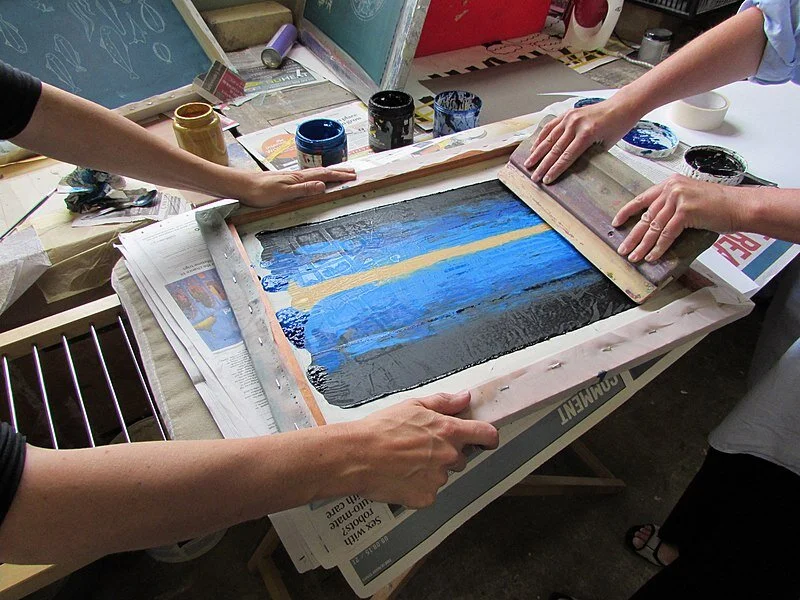

Screen Printing vs. DTG vs. Heat Transfer: Custom T-Shirt Printing Comparison

| Feature | Screen Printing | Direct-to-Garment (DTG) | Heat Transfer |

|——–|——————|————————–|—————|

| Best For | Large orders, simple designs, long-term durability | Small orders, full-color/photographic designs, detailed artwork | Very small orders, quick turnaround, DIY/home use |

| Print Quality | High for solid colors; limited detail and color gradients | Excellent for photos/complex graphics; handles gradients well | Good to very good; may feel stiff or show edges over time |

| Color Capability | Limited by number of screens (typically 1–6 colors) | Full-color printing (unlimited colors) | Full-color printing (unlimited colors) |

| Fabric Compatibility | Best on 100% cotton; works on cotton blends (not ideal for 100% polyester) | Best on 100% cotton; poor adhesion on polyester/dark fabrics without pretreatment | Works on cotton, polyester, blends, and performance fabrics |

| Durability | Excellent—inks bond deeply with fabric; withstands many washes | Good on cotton; may fade after 30–50 washes, especially on dark garments | Varies; vinyl transfers may crack; inkjet transfers less durable; typically lasts 20–40 washes |

| Setup Time & Cost | High setup (screen creation); cost-effective for bulk orders | Minimal setup; higher per-unit cost for large quantities | Minimal setup; low upfront cost; ideal for one-offs |

| Minimum Order Quantity | High (usually 20+ pieces to be cost-effective) | Low (1+ pieces) | Very low (1 piece) |

| Turnaround Time | Slower for small runs due to setup; faster for large batches | Fast for small orders; slower than screen printing for bulk | Very fast; can print on-demand in minutes |

| Feel on Shirt | Soft to medium hand feel; heavier with more colors | Soft, like a natural fabric print | Can be stiff or plasticky, especially with vinyl |

| Cost Efficiency | Most cost-effective for large orders | More expensive per unit; less efficient for bulk | Low startup cost; higher per-unit cost for volume |

| Design Flexibility | Changes require new screens; not ideal for frequent design swaps | High flexibility—easy to change designs between prints | High flexibility—easy to switch designs instantly |

| Eco-Friendliness | Uses plastisol or water-based inks; screen cleaning uses water/chemicals | Uses water-based inks; more eco-friendly; less waste | Varies; sublimation is eco-friendly; vinyl creates more waste |

Summary:

– Screen Printing is best for large-volume, simple designs with vibrant solid colors.

– DTG excels at detailed, full-color artwork on cotton, ideal for small batches or one-off custom shirts.

– Heat Transfer offers speed and flexibility for small runs or mixed designs but may compromise on feel and longevity.

Choose based on your order size, design complexity, fabric type, and durability needs.

Guide to Choosing Fabrics for Custom Made T-Shirts: 100% Cotton vs. Tri-Blends vs. Polyester

When creating custom t-shirts, selecting the right fabric is crucial for comfort, durability, appearance, and how well your design prints. The most common options—100% cotton, tri-blends, and polyester—each offer unique benefits and trade-offs. Here’s a breakdown to help you make the best choice for your needs.

100% Cotton

Pros:

– Soft & Breathable: Cotton is naturally soft and allows air circulation, making it ideal for everyday wear and warm climates.

– Comfortable Feel: Offers a classic, familiar feel that many people prefer.

– Great for Printing: Absorbs ink well, making it excellent for screen printing and direct-to-garment (DTG) printing.

– Eco-Friendly Option: Biodegradable and renewable, especially when organically grown.

Cons:

– Prone to Shrinking: Can shrink if not pre-shrunk or washed improperly.

– Less Durable Over Time: May wear out faster, especially with frequent washing.

– Wrinkles Easily: Requires ironing or special care to maintain a crisp look.

– Absorbs Moisture: Holds sweat, which can make it feel damp during physical activity.

Best For: Casual wear, promotional events, eco-conscious brands, and classic t-shirt designs.

Tri-Blends (Typically Cotton/Polyester/Rayon)

Pros:

– Ultra-Soft & Lightweight: Blending fibers creates a smooth, silky texture often compared to vintage tees.

– Excellent Drape: Flatters the body with a slightly relaxed, flowing fit.

– Reduced Shrinkage: More stable than 100% cotton due to synthetic content.

– Color Retention: Vibrant prints with good fade resistance over time.

Cons:

– Less Breathable: Not as airy as pure cotton, so may feel warmer.

– Pilling Over Time: Can develop small fabric balls with repeated wear and washing.

– Higher Price Point: Typically more expensive than 100% cotton or polyester.

– Sensitivity to Heat: Requires gentle washing to avoid damage.

Best For: Fashion-forward apparel, premium gift wear, women’s cuts, and soft-style designs.

Polyester

Pros:

– Durable & Long-Lasting: Resists shrinking, stretching, and wrinkling.

– Moisture-Wicking: Pulls sweat away from the body, ideal for activewear.

– Quick-Drying: Great for sports, events, or humid environments.

– Colorfast: Holds vibrant dyes well and resists fading.

– Low Maintenance: Easy to care for and retains shape after washing.

Cons:

– Less Breathable: Can trap heat and feel clammy in hot weather.

– Static & Odor Retention: Prone to static electricity and may hold odors without antimicrobial treatment.

– Less Soft Feel: Can feel synthetic or plasticky compared to cotton or tri-blend.

– Environmental Impact: Not biodegradable; derived from petroleum.

Best For: Performance wear, sportswear, outdoor events, and sublimation printing (all-over designs).

How to Choose the Right Fabric

Consider these factors when deciding:

– Intended Use: Everyday wear? Workouts? Gifts?

– Climate: Hot and humid? Go breathable (cotton or tri-blend). Active use? Choose moisture-wicking (polyester).

– Print Method: DTG and screen printing work well on cotton and tri-blends. Sublimation requires polyester.

– Budget: Cotton is usually most affordable; tri-blends and performance polyester cost more.

– Sustainability Goals: Opt for organic cotton or recycled polyester if eco-friendliness is a priority.

By matching your fabric choice to your audience and purpose, you’ll ensure your custom t-shirts look great, feel comfortable, and stand the test of time.

How to Get the Best Price for Custom Made T-Shirts (Bulk Discounts & Artwork Tips)

Getting custom t-shirts for your team, event, or business doesn’t have to break the bank. By understanding bulk pricing and preparing your artwork efficiently, you can significantly reduce your costs without sacrificing quality. Here’s how:

Leverage Bulk Discounts Effectively

The most significant savings on custom t-shirts come from ordering in bulk. Here’s how to maximize those discounts:

- Order Larger Quantities: Pricing per shirt drops dramatically as your order size increases. Moving from 12 to 24 shirts often cuts the per-unit cost nearly in half. Consider sizes like 50, 100, or 250+ for the best rates.

- Consolidate Designs: Instead of ordering multiple small batches with different designs, combine orders. A single order of 100 shirts with one design is much cheaper per shirt than two orders of 50 with different designs.

- Standardize Colors and Sizes: Ordering the same shirt color across all sizes and minimizing the number of different shirt styles (e.g., sticking to one brand and cut) reduces setup and production complexity, lowering costs.

- Choose Basic, High-Volume Shirt Styles: Popular, plain-color cotton tees (like Gildan or Bella+Canvas 3001) are produced in massive quantities, making them significantly cheaper than specialty fabrics (polyester, tri-blend) or premium brands.

- Limit Print Locations and Colors: Each additional print location (front, back, sleeve) and ink color adds setup and printing time. A single-color print on the front is the most economical option.

- Compare Multiple Printers: Get quotes from several screen printers and online custom apparel companies. Be sure to compare apples-to-apples (same shirt type, quantity, print size, colors, locations).

- Consider Off-Peak Timing: Some printers offer slight discounts during slower seasons. Avoid holiday rushes when demand (and prices) are highest.

Optimize Artwork Preparation to Save Money

Proper artwork setup prevents delays, reprints, and extra fees:

- Provide High-Resolution, Print-Ready Files: Supply vector files (AI, EPS, SVG) whenever possible. They scale infinitely without quality loss. If using raster images (PNG, JPG, TIFF), ensure they are at least 300 DPI at the actual print size. Low-res artwork may require costly recreation.

- Simplify Your Design: Complex, multi-color designs require more screens and labor. Opt for bold, clean graphics with fewer colors. Designs with gradients or photorealistic elements are often better suited (and cheaper) for DTG (Direct-to-Garment) printing, but screen printing excels with solid colors.

- Use Spot Colors Wisely: For screen printing, define your colors using standard spot color systems like Pantone (PMS). This ensures color accuracy and simplifies the ink mixing process. Avoid designs requiring many unique or custom-mixed colors.

- Outline Fonts and Convert Text to Paths: In vector files, convert all text to outlines (or paths) before sending. This prevents font substitution issues if the printer doesn’t have your specific font installed.

- Specify Print Size and Placement Clearly: Provide exact dimensions (e.g., 10″ wide) and the precise location on the shirt (e.g., centered on the chest, 3″ down from the collar). Include a mockup if possible. Ambiguity leads to errors and costly corrections.

- Separate Color Layers (if required): Some printers may ask for individual color layers (especially for multi-color screen printing). Follow their specific file preparation guidelines to avoid setup fees.

- Get a Physical Proof: Always request a physical print proof (or at least a high-quality digital proof) before the full production run. This catches color, sizing, or placement errors early, preventing expensive reprints on the entire batch.

By strategically planning your order size, simplifying your design, and preparing flawless artwork, you can achieve professional-looking custom t-shirts at the most competitive price possible.

Choosing the right custom t-shirt provider requires careful consideration of several key factors to ensure quality, value, and customer satisfaction. Start by evaluating the provider’s print quality and fabric options—opt for companies that use durable materials and offer a variety of printing techniques (such as screen printing, DTG, or sublimation) to suit your design needs. Pay attention to customization flexibility, including sizing, color choices, and design placement.

Consider the provider’s pricing structure and minimum order requirements; look for transparent pricing without hidden fees and flexible order sizes for both personal and business use. Fast turnaround times and reliable shipping options are essential, especially for time-sensitive projects.

Customer service and ease of use matter too—choose a provider with a user-friendly design tool, responsive support, and clear communication. Finally, review customer feedback and request samples if possible to assess product and service quality firsthand.

Ultimately, the best custom t-shirt provider balances quality, affordability, and service to meet your specific needs—whether for events, branding, or personal expression. Take the time to research and compare options to make an informed choice that delivers great results.