Picture this: You’re scrolling through your favorite online store and a t-shirt stops you mid-scroll—not just because of the color or cut, but because of that bold, unmistakable logo emblazoned across the chest. That logo? It’s more than just design—it’s identity, attitude, and storytelling all stitched into one powerful visual. In today’s world of Print on Demand (POD), where anyone with a vision can launch a clothing brand from their living room, a custom logo isn’t just a nice-to-have—it’s your brand’s secret weapon.

Thanks to booming POD platforms like Printful, Teespring, and Redbubble, creating and selling t-shirts with custom logos has never been easier—or more competitive. With low upfront costs and zero inventory risk, creators, entrepreneurs, and artists are flooding the market with fresh, personalized designs. But here’s the catch: in a sea of sameness, your logo is what makes your brand stand out. It’s the first impression, the memory stick, the reason someone hits “add to cart.”

So, whether you’re building a brand, promoting a cause, or launching a side hustle, nailing your custom t-shirt logo isn’t just about looking good—it’s about showing up with purpose in an industry where design drives demand.

Top 10 Best Custom Logo For T Shirts Services (2026 Review)

Reviewed for Print Quality, Pricing & Turnaround Time

#1 T-Shirt & Apparel Printing

Online Since 2001

Website: undergroundshirts.com

Design custom t-shirts and apparel with Underground Printing. Offering screen printing, embroidery, and fast delivery on all orders.

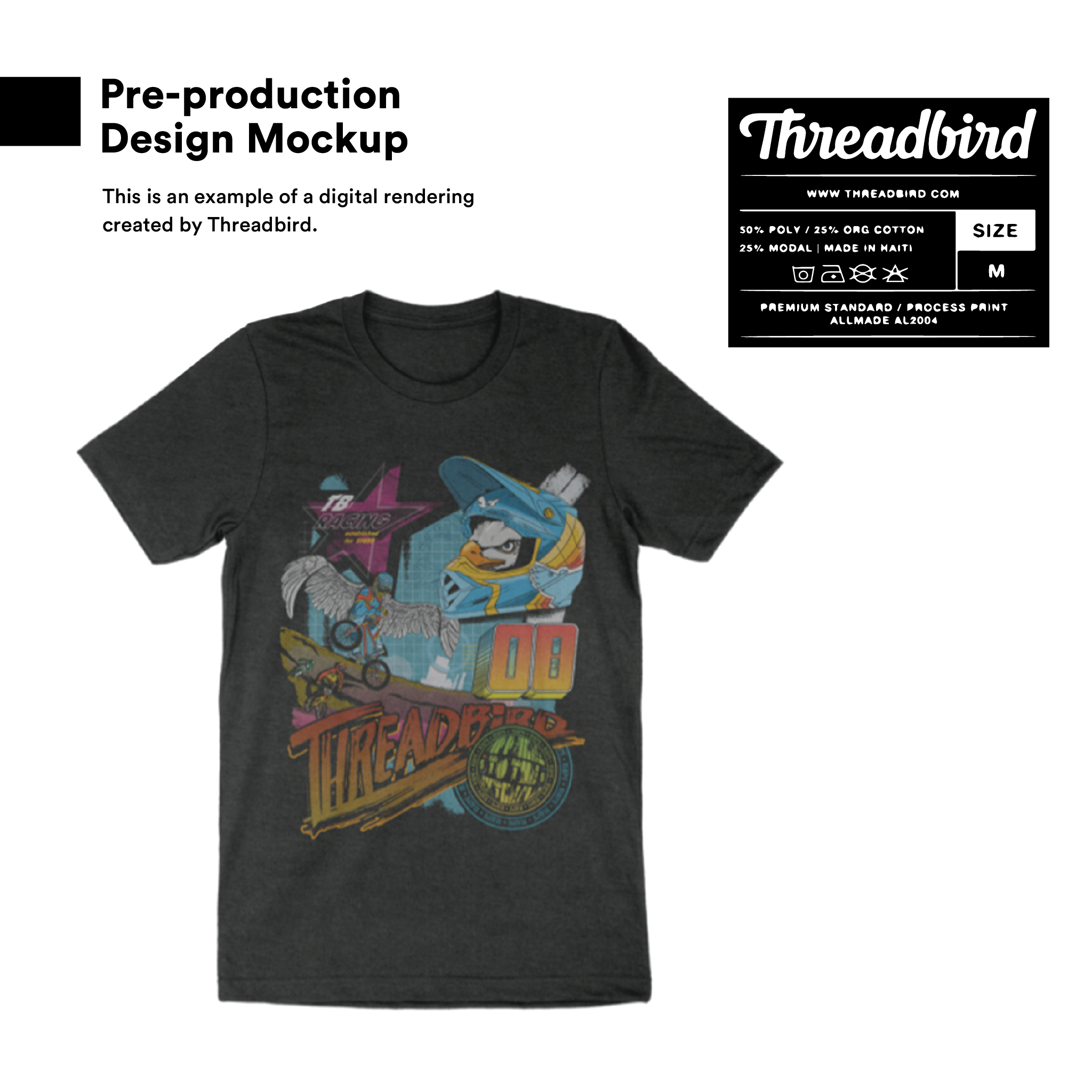

#2 Threadbird: Custom T Shirt Printing, High

Online Since 2010

Website: threadbird.com

At Threadbird, we are all about customization and we are committed to making your custom t shirt printing & apparel dreams come true.

#3 Custom Print Shop

Online Since 2003

Website: rushordertees.com

Free delivery · Free 45-day returnsCreate custom t-shirt designs and logos instantly with Rush Order Tees’ free AI Design Wizard. No design skills needed—just describe your idea! How Much Do …

#4 Shop Custom Apparel

Online Since 1998

Website: 4imprint.com

Build your brand from head to toe with custom logo apparel. Shop T-shirts, jackets, pants, uniforms and more promotional clothing ready for your logo.

#5 Queensboro

Online Since 1996

#6 Real Thread

Online Since 2009

Website: realthread.com

Custom Printed T-Shirts, Hats & Apparel. Browse top-notch garments, upload designs, and get quality custom printed or embroidered apparel in as little as 3 days …

#7 Custom Screen Printed Uniform T-Shirts

Online Since 1994

Website: business.landsend.com

Free delivery over $99Shop for custom screen printed T Shirts for work uniforms on Lands End Business Outfitters. Add your company logo using our customization tool!

#8 T

Online Since 1999

Website: customink.com

Create your own t-shirt design from scratch, upload your own artwork or ask an expert for design help. It’s all possible in our state-of-the-art design lab.

#9 Premium

Online Since 2002

Website: gotprint.com

4.5 4.8K It’s easy to print your own photo, illustration, or company logo on any of our shirts. For best results, please start with our downloadable T-shirt template, …

#10 Personalized Work Shirts, Custom Printed T

Online Since 2009

Website: tshirtbydesign.com

Free delivery over $50 30-day returnsWe offer a variety of unique and personalized work shirt templates that are designed to help your business get started with custom printed company shirts.

Expert Guide: Ordering custom logo for t shirts

Comparison Table: Screen Printing, DTG, and Heat Transfer for Custom T-Shirt Logos

| Method | Best For | Durability | Cost |

|---|---|---|---|

| Screen Printing | Large orders, bold designs, bright colors on dark fabrics | High – withstands many washes; may crack over time if low-quality ink | Low per unit for bulk; high setup cost for small runs |

| DTG (Direct-to-Garment) | Small orders, detailed/full-color designs, light fabrics | Moderate to high – softer feel but may fade slightly after many washes | Higher per unit; no setup fees – cost-effective for small quantities |

| Heat Transfer | One-offs, fast turnaround, complex/photographic designs | Low to moderate – can peel, crack, or fade with repeated washing | Low upfront cost; higher per unit for bulk; equipment investment optional |

100% Cotton vs. 50/50 Blend vs. Tri-Blends: Choosing the Best Fabric for Custom Logo T-Shirts

When creating custom logo t-shirts, selecting the right fabric is crucial—it impacts comfort, durability, print quality, and overall brand perception. The three most popular fabric choices are 100% cotton, 50/50 cotton-polyester blends, and tri-blend fabrics. Here’s how they compare to help you make the best decision for your logo apparel.

100% Cotton: Classic Comfort and Softness

Pros:

– Soft and breathable: Offers a natural, comfortable feel ideal for everyday wear.

– Excellent ink absorption: Provides vibrant, crisp results for screen printing—perfect for bold logos and detailed designs.

– Eco-friendly appeal: Biodegradable and often preferred by environmentally conscious customers.

Cons:

– Prone to shrinking: May shrink up to 5–7% if not pre-shrunk.

– Less durable: More likely to wear, pill, or fade over time, especially after repeated washes.

– Wrinkles easily: Requires more care during washing and ironing.

Best for:

Brands focused on authenticity, comfort, and high-quality prints—especially for promotional events, retail merchandise, or casual workwear where a classic look is desired.

50/50 Cotton-Polyester Blend: Balanced Performance

Pros:

– Durable and long-lasting: Resists shrinking, fading, and pilling better than 100% cotton.

– Low maintenance: Wrinkle-resistant and quick-drying, making it ideal for active lifestyles.

– Cost-effective: Typically more affordable than high-end cotton or tri-blend options.

Cons:

– Less breathable: Polyester can trap heat, making it less comfortable in hot weather.

– Print quality trade-off: Ink sits more on the surface, which may reduce vibrancy compared to 100% cotton.

Best for:

Corporate giveaways, employee uniforms, or events where durability and value are top priorities. Great when shirts will see frequent use and washing.

Tri-Blend (Usually Cotton/Polyester/Rayon): Ultra-Soft and Stylish

Pros:

– Buttery soft feel: Combines the best qualities of each fiber for a luxurious, vintage-like texture.

– Excellent drape: Flatters the body with a lightweight, slightly fitted look—ideal for fashion-forward branding.

– Minimal shrinkage: More stable than 100% cotton after washing.

Cons:

– Higher cost: Generally more expensive than cotton or 50/50 options.

– Delicate print surface: Requires specialized printing techniques (like soft-hand inks) to avoid cracking.

– Less durable for heavy use: Not ideal for rugged environments or industrial settings.

Best for:

Premium merchandise, boutique branding, or lifestyle brands aiming for a modern, trendy aesthetic. Perfect for retail sales or influencer collaborations.

Final Tips for Choosing the Right Fabric

- Consider your audience: Employees may prefer durability (50/50), while customers might appreciate softness (tri-blend).

- Match fabric to print method: Screen printing works best on cotton; DTG (direct-to-garment) adapts well to blends.

- Think long-term: Blends offer better longevity, while cotton offers classic appeal.

- Request samples: Test fabrics in person to evaluate texture, weight, and how your logo appears.

Choosing the right fabric ensures your custom logo t-shirts look great, feel comfortable, and reflect your brand’s identity—whether you’re going classic, practical, or premium.

How to Get the Best Price for Custom Logo T-Shirts (Bulk Quantity Breaks & Artwork Tips)

Ordering custom logo t-shirts in bulk can be a cost-effective way to promote your brand, team, or event—but only if you know how to maximize savings. By leveraging quantity breaks and preparing your artwork correctly, you can significantly reduce your per-unit cost while maintaining high quality.

Understand Bulk Quantity Breaks

Most screen printing and embroidery companies offer tiered pricing based on order volume. The more shirts you order, the lower the cost per shirt.

- Know the Break Points: Typical quantity tiers are 12, 24, 36, 48, 72, 100, 200+, etc. Ordering just above a break (e.g., 75 instead of 72) can still qualify for the lower rate.

- Plan for Future Needs: If you anticipate needing more shirts later, ordering a larger batch now can save money long-term.

- Split Sizes, Not Quantities: You can mix sizes and colors within a single design order without losing the bulk discount—just keep the design consistent.

- Compare Vendors: Different suppliers have different break thresholds. Use online quote tools to compare prices across multiple printers.

Choose the Right Printing Method

The printing technique impacts both cost and quality:

- Screen Printing: Most cost-effective for large quantities (50+ units) and simple designs with few colors. Setup costs are higher, but the per-unit price drops significantly with volume.

- DTG (Direct-to-Garment): Better for complex, full-color designs and smaller runs. Less cost-efficient in bulk due to slower production.

- Embroidery: Ideal for logos on polos or hats. Cost is based on stitch count—simpler logos are cheaper.

Optimize Your Logo Artwork

Proper artwork preparation prevents delays, extra fees, and reprints—saving you time and money.

- Use Vector Files (AI, EPS, SVG): These scale infinitely without losing quality and are preferred by printers. Avoid blurry logos from social media or websites.

- Simplify Your Design: Fewer colors = lower screen printing costs. Convert complex designs to 1–3 spot colors where possible.

- Specify Pantone (PMS) Colors: Ensures color consistency across large batches. Avoid exact matches to RGB-only colors from screens.

- Provide High-Resolution Raster Files (300 DPI): If you must use PNG or JPG, ensure they are high resolution and properly sized for the print area.

- Avoid Tiny Details and Fine Lines: These may not print clearly, especially on textured fabric. Test small text and thin lines at actual print size.

Tips for Maximum Savings

- Bundle Orders: Combine orders with other departments or groups to reach higher quantity tiers.

- Choose Standard Colors: Basic t-shirt colors (black, white, navy, gray) are cheaper than specialty or fashion shades.

- Stick to One Design: Multiple designs increase setup fees. Use one logo with varied placement (e.g., chest vs. back) to save.

- Negotiate: For very large orders (200+), ask for a custom quote—many suppliers offer additional discounts for volume.

- Order Off-Season: Some screen printers offer promotions during slower months (e.g., winter for summer apparel).

By understanding quantity breaks, selecting the right printing method, and submitting print-ready artwork, you can secure high-quality custom t-shirts at the lowest possible price. Always request a physical or digital proof before full production to avoid costly mistakes.

Choosing the right custom t-shirt provider requires careful consideration of several key factors to ensure quality, reliability, and value. Start by evaluating the quality of materials and printing techniques—opt for providers that use durable fabrics and offer a range of printing options like screen printing, DTG, or heat transfer, depending on your design and volume needs. Assess customization capabilities, including design support, color options, and garment variety, to ensure they align with your vision.

Delivery speed and shipping policies are crucial, especially for time-sensitive projects, so look for transparent timelines and reliable fulfillment. Customer service and user experience—such as easy online ordering, design tools, and responsive support—can greatly enhance the process. Additionally, reading customer reviews and requesting samples can provide real-world insights into the provider’s performance.

Finally, compare pricing not just on a per-shirt basis but with consideration for bulk discounts, setup fees, and overall value. By balancing quality, service, customization, and cost, you can select a custom t-shirt provider that meets your specific needs and delivers professional, satisfying results.