There’s something undeniably cool about wearing a t-shirt that feels like you—maybe it’s your inside joke turned graphic, your favorite quote splashed in bold type, or a design that pays tribute to your niche obsession. That personal touch is exactly what’s fueling the skyrocketing popularity of custom jersey t-shirts. Once reserved for sports teams or concert merch, jersey tees have evolved into a stylish, comfortable canvas for self-expression—and thanks to Print on Demand (POD) technology, creating your own has never been easier.

Gone are the days of bulk orders and upfront inventory. Today’s creators, entrepreneurs, and fashion enthusiasts are leveraging POD platforms to design, market, and sell unique custom jersey t-shirts with zero risk. From TikTok influencers launching their own apparel lines to small businesses promoting their brand in a laid-back, athletic-inspired aesthetic, the POD revolution is making customization accessible to everyone. Welcome to the era where your imagination is the only limit—and your next statement piece starts with a single click.

Top 10 Best Custom Jersey T Shirt Services (2026 Review)

Reviewed for Print Quality, Pricing & Turnaround Time

#1 T-Shirt & Apparel Printing

Online Since 2001

Website: undergroundshirts.com

Design custom t-shirts and apparel with Underground Printing. Offering screen printing, embroidery, and fast delivery on all orders.

#2 : Design & Print Shirts Online

Online Since 1999

Website: vistaprint.com

Starting from $10.00 4.8 5.9K · 3–8 day deliveryDesign and print your own high quality custom t-shirts at an affordable price. Browse shirts across various styles, price points and brands.

#3 – New York, NY Screen Printing

Online Since 1999

Website: locations.customink.com

Design custom t-shirts at Custom Ink’s New York, NY location. Visit us in store for live help, free shipping, and a guaranteed delivery date!

#4 Custom T Shirts, Hats & Hoodie Printing & Embroidery

Online Since 1999

Website: teamshirts.com

High quality custom T-shirt printing ✓ Free shipping ✓ Save up to 65% ✓ Easy T-Shirt Creator ✓ 10000+ free graphics ▷ Create your own designs.

#5 Custom Print Shop

Online Since 2003

#6 at Real Thread

Online Since 2009

Website: realthread.com

14-day returnsOur custom printed and embroidery t-shirt services deliver a best-in-class custom tee that everyone will want to wear. 100% customizable & retail-quality …

#7 Customnia / / Design Your T

Online Since 2022

Website: customnia.com

8-day deliveryCustomnia is a printing service that helps people to express themselves by making high-quality merchandise. We provide customized printed merchandise, …

#8 Gifted NYC: Custom Printed Graphic T

Online Since 2005

Website: giftednyc.com

Gifted NYC is a premier custom graphic t-shirt printing company that offers top quality shirt printing services for an affordable price.

#9 ooShirts: Cheap Custom T

Online Since 2007

Website: ooshirts.com

Custom t-shirts for less! ooShirts is the leader in affordable t-shirt printing. Free shipping & setup. Design your own t-shirts at awesomely low prices!

#10 Custom Jersey in New York City, NY

Online Since 2010

Expert Guide: Ordering custom jersey t shirt

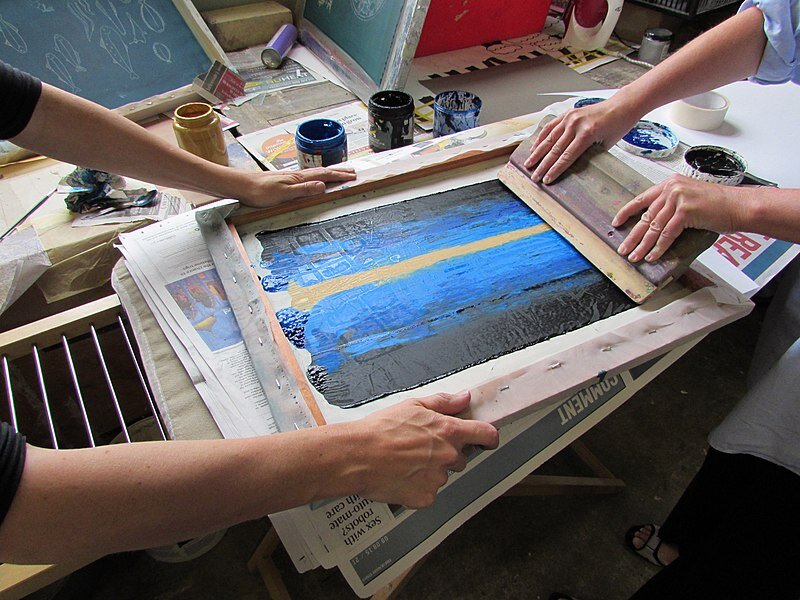

Comparison Table: Screen Printing, DTG, and Heat Transfer for Custom Jersey T-Shirts

| Method | Best For | Durability | Cost |

|---|---|---|---|

| Screen Printing | Large orders, simple designs, bold colors | High – lasts many washes with proper care | Low per unit for bulk; high setup cost for small runs |

| DTG (Direct-to-Garment) | Small orders, detailed/full-color designs, photos | Moderate – can fade or crack over time with frequent washing | Higher per unit; no setup fees, cost-effective for small batches |

| Heat Transfer | Very small orders, rush jobs, complex designs | Low to Moderate – prone to cracking and peeling after repeated washes | Low initial cost; higher per unit than screen printing for large quantities |

Guide to Choosing Fabrics for Custom Jersey T-Shirts: 100% Cotton vs. 50/50 Blend vs. Tri-Blends

Selecting the right fabric is crucial when designing custom jersey t-shirts, as it directly affects comfort, durability, appearance, and how your design prints. Here’s a breakdown of the three most popular fabric options to help you make an informed decision.

100% Cotton

Pros:

– Soft and Comfortable: Offers a natural, breathable feel, ideal for sensitive skin and warm climates.

– Eco-Friendly: Biodegradable and made from a renewable resource.

– Excellent Print Quality: Absorbs ink well, resulting in vibrant, crisp prints—especially with screen printing.

– Classic Look and Feel: Delivers a traditional, heavyweight cotton t-shirt experience.

Cons:

– Prone to Shrinkage: Can shrink significantly after washing, especially if not pre-shrunk.

– Less Durable: More susceptible to wear, pilling, and fading over time.

– Wrinkles Easily: Requires ironing or steaming to maintain a neat appearance.

– Absorbs Moisture: Holds sweat and takes longer to dry, which may feel damp during physical activity.

Best For: Casual wear, promotional shirts, screen-printed designs, and customers who prioritize natural fibers and softness.

50/50 Cotton-Polyester Blend

Pros:

– Balanced Performance: Combines the softness of cotton with the durability and moisture-wicking properties of polyester.

– Reduced Shrinkage: More stable than 100% cotton and holds its shape better over time.

– Affordable: Typically less expensive than tri-blends and offers good value.

– Good Print Surface: Works well with both screen printing and direct-to-garment (DTG) printing.

Cons:

– Slightly Less Soft: Can feel a bit stiffer than 100% cotton, especially in lower thread counts.

– Less Breathable: Polyester content reduces breathability compared to pure cotton.

– Pilling Risk: May develop surface pilling with frequent washing and wear.

Best For: Active wear, work uniforms, events, and situations where durability and cost-effectiveness are priorities.

Tri-Blend (Typically 50% Polyester, 25% Cotton, 25% Rayon)

Pros:

– Luxurious Softness: Known for an ultra-soft, lightweight, and slightly heathered texture—often compared to vintage or premium tees.

– Excellent Drape: Flatters the body with a smooth, flowing fit.

– Moisture-Wicking: Polyester helps move sweat away from the skin, while rayon adds softness.

– Color Retention: Vibrant prints with excellent fade resistance over time.

– Minimal Shrinkage: Very stable wash after wash.

Cons:

– Higher Cost: More expensive than 100% cotton or 50/50 blends.

– Delicate Fabric: Can be more prone to snagging or abrasion due to rayon content.

– Not Ideal for Heavy Designs: Lightweight nature may not support very thick or plastisol ink prints as well.

Best For: Fashion-forward tees, boutique apparel, DTG printing, and customers seeking a premium, soft hand-feel with a modern aesthetic.

Final Tips for Choosing the Right Fabric

- Consider the Use Case: Will the shirt be worn casually, during events, or for athletic purposes?

- Think About Print Method: Screen printing works best on cotton and 50/50 blends, while DTG shines on tri-blends.

- Prioritize Comfort and Care: Evaluate how the fabric feels and how easy it is to maintain.

- Budget Matters: Factor in cost per unit, especially for bulk orders.

By understanding the strengths and trade-offs of 100% cotton, 50/50 blends, and tri-blends, you can confidently select the ideal fabric for your custom jersey t-shirt project—ensuring both satisfaction and style.

How to Get the Best Price for Custom Jersey T-Shirts (Bulk Quantity Breaks & Artwork Tips)

Ordering custom jersey T-shirts in bulk can be a cost-effective way to outfit a team, promote your brand, or create merchandise. To maximize value and minimize costs, focus on smart ordering strategies and efficient artwork preparation. Here’s how to get the best possible price:

Leverage Bulk Quantity Breaks

One of the most effective ways to reduce your per-unit cost is by taking full advantage of quantity breaks offered by suppliers:

-

Order at Tier Thresholds: Most screen printers and apparel suppliers offer tiered pricing (e.g., 12–47 units, 48–71 units, 72–143 units, 144+ units). The price per shirt drops significantly at each threshold. For example, ordering 144 shirts typically costs much less per unit than ordering 100. Plan your order to hit the next pricing tier.

-

Consolidate Orders: If you need shirts over time, combine future needs into one large order. Storing extra shirts is often cheaper than paying higher per-unit prices on multiple small runs.

-

Group Orders: Collaborate with colleagues, teams, or community groups to pool orders. More units = better pricing for everyone.

-

Compare Suppliers: Not all suppliers have the same break points or pricing structures. Get quotes from multiple vendors and ask specifically about their bulk discounts and minimums.

Optimize Artwork for Lower Printing Costs

Your design choices directly impact printing expenses. Simplify your artwork to reduce production complexity and cost:

-

Limit Print Colors: Each ink color requires a separate screen and setup. A one- or two-color design is significantly cheaper than a five-color design. Stick to flat, solid colors where possible.

-

Use Simpler Designs: Avoid gradients, fine details, or photorealistic images, which can require specialty techniques like simulated process printing—this increases time and cost.

-

Vector Art Preferred: Provide vector artwork (AI, EPS, or PDF with outlined text) instead of raster files (JPG, PNG). Vector files scale without quality loss and are easier for printers to work with, reducing prep time and potential errors.

-

Single-Location Printing: Printing on just the front or back is cheaper than multi-panel printing (e.g., front and sleeves). If possible, limit the number of print locations.

-

Avoid Flash Curing for Dark Shirts: If printing on dark jersey fabric, underbase printing (white ink layer) and flash curing increase costs. Consider using lighter-colored shirts or water-based inks for a softer feel and lower expense.

Additional Cost-Saving Tips

-

Choose Standard Sizes and Colors: Stick to common sizes (S–XXL) and base colors (black, navy, white). Specialty sizes (3XL+) or custom fabric dyes can hike up costs.

-

Order Off-Peak: Some printers offer discounts during slower seasons. Avoid holiday rushes and major sports events when demand (and prices) spike.

-

Skip Embellishments: Avoid add-ons like embroidery, puff ink, or rhinestones unless essential—they significantly increase labor and material costs.

-

Get a Physical Proof: While a small upfront cost, a physical print proof can prevent costly reprints due to color or alignment issues.

By strategically planning your order size, simplifying your design, and working with reputable suppliers, you can achieve high-quality custom jersey T-shirts at the best possible price.

Choosing the right custom t-shirt provider requires careful consideration of several key factors to ensure quality, reliability, and value. Start by evaluating the provider’s product quality—look for durable fabrics, accurate color representation, and consistent printing techniques. Assess customization options, including design tools, printing methods (such as screen printing, DTG, or sublimation), and the ability to accommodate specific design needs.

Pricing and minimum order requirements are also critical; compare costs across providers while watching for hidden fees. Reliability is reflected in turnaround time, shipping options, and customer service—read reviews and check responsiveness. Additionally, eco-conscious buyers should consider sustainable practices like organic materials or eco-friendly inks.

Ultimately, the best custom t-shirt provider aligns with your specific needs—whether that’s bulk affordability, premium quality, design flexibility, or fast delivery. By balancing these factors and possibly ordering samples first, you can confidently select a provider that delivers excellent results for your project.