Imagine turning your wildest ideas into wearable art—no inventory, no upfront costs, just creativity on demand. That’s the magic of custom ink T-shirt design in today’s digital age. From quirky slogans to eye-catching graphics, personalized tees have evolved from backyard screen-printing projects to a global phenomenon, supercharged by the rise of Print on Demand (POD) technology. As more entrepreneurs, artists, and brands tap into platforms that print and ship designs only when orders come in, the barriers to launching a clothing line have all but vanished. In this post, we’ll dive into how custom ink design is reshaping self-expression—and how POD trends are putting the power of fashion into the hands of anyone with a vision and a laptop.

Top 5 Best Custom Ink T Shirt Design Services (2026 Review)

Reviewed for Print Quality, Pricing & Turnaround Time

#1 T

Online Since 1999

Website: customink.com

Create your own t-shirt design from scratch, upload your own artwork or ask an expert for design help. It’s all possible in our state-of-the-art design lab.

#2 Custom Print Shop

Online Since 2003

Website: rushordertees.com

Design and print high-quality custom t-shirts at affordable prices. No Minimums. Free Shipping. Fast turnaround. Rush delivery options. Expert service.

#3 Ink: Custom Apparel & Design

Online Since 2004

Website: inkteam.com

Ink is a custom screen printing company based in the Little Rock, Arkansas area. We provide expert guidance, custom artwork, and quality screen printing.

#4 Ink

Online Since 2011

Website: customtshirtsink.com

We provide quality custom decorated apparel. We are industry professionals with more than 20 years of experience in the screen printing industry.

#5 For anyone thinking of using Custom Ink…

Online Since 2004

Website: t-shirtforums.com

It DOES say that you can save $.50 per shirt if you let them print their logo on the OUTSIDE of the shirt. I did not choose that for obvious …

Expert Guide: Ordering custom ink t shirt design

Comparison of Custom T-Shirt Printing Methods

| Method | Best For | Durability | Cost |

|---|---|---|---|

| Screen Printing | Large orders, simple designs with limited colors, bold graphics | High – lasts many washes if cured properly | Low to medium per unit (cost-effective for bulk) |

| DTG (Direct-to-Garment) | Small orders, detailed or full-color designs, photo-realistic artwork | Medium – may fade after repeated washing | Medium to high per unit (less economical for large runs) |

| Heat Transfer | One-off designs, quick turnaround, complex designs on various surfaces | Low to medium – can crack or peel over time | Low setup cost, higher per-unit cost for bulk |

100% Cotton vs. 50/50 Blend vs. Tri-blends: Choosing the Best Fabric for Your Custom Ink T-Shirt Design

When designing custom t-shirts, the fabric you choose significantly impacts comfort, durability, print quality, and overall wearability. Understanding the differences between 100% cotton, 50/50 blends, and tri-blends helps you select the perfect material for your project. Here’s a breakdown to guide your decision:

100% Cotton

Pros:

– Soft and Breathable: Offers a natural, comfortable feel—ideal for warm weather and everyday wear.

– Excellent Print Absorption: Absorbs ink well, resulting in vibrant, opaque prints—especially for dark garments.

– Eco-Friendly: Biodegradable and often available in organic options.

– Classic Feel: Preferred by customers who love the traditional cotton t-shirt experience.

Cons:

– Prone to Shrinking: Can shrink significantly after washing, especially if not pre-shrunk.

– Less Durable: May wear out or develop holes faster with frequent use and washing.

– Wrinkles Easily: Requires ironing or steaming for a crisp look.

– Less Stretch: Offers minimal stretch, which may affect fit during movement.

Best For: Casual wear, promotional events, eco-conscious brands, and designs with bold, solid colors.

50/50 Blend (50% Cotton / 50% Polyester)

Pros:

– Balanced Performance: Combines cotton’s softness with polyester’s durability and wrinkle resistance.

– Reduced Shrinkage: More stable than 100% cotton during washing and drying.

– Affordable: Often more budget-friendly than high-end tri-blends.

– Good Print Surface: Works well with screen printing and direct-to-garment (DTG) methods.

Cons:

– Less Breathable: Higher polyester content can trap heat, making it less ideal for hot climates.

– Slight Sheen: May have a slight synthetic sheen, which can affect print appearance.

– Pilling: Can develop small fabric balls (pills) over time with friction.

Best For: Workwear, high-use environments, affordable bulk orders, and designs requiring durability.

Tri-blends (Usually 50% Polyester / 25% Cotton / 25% Rayon)

Pros:

– Ultra-Soft & Drapey: Feels luxurious with a silky, vintage-inspired drape—popular for fashion-forward tees.

– Lightweight & Comfortable: Excellent for layering or warm-weather wear.

– Minimal Shrinkage: Typically pre-shrunk and highly stable.

– Unique Aesthetic: Offers a heathered, slightly muted look that complements artistic designs.

Cons:

– Higher Cost: More expensive than cotton or 50/50 blends.

– Delicate Fabric: Less durable—can snag or tear more easily.

– Ink Absorption Varies: Rayon absorbs ink quickly, which may cause bleeding with detailed prints; DTG often works better than screen printing.

– Not Ideal for Heavy Prints: Thick ink layers may crack or feel stiff on soft tri-blends.

Best For: Premium apparel, boutique brands, lifestyle designs, and soft-hand prints like water-based inks.

Final Tips for Choosing

- Consider Your Audience: Active users may prefer 50/50 blends; fashion-conscious buyers love tri-blends.

- Think About Print Method: DTG printing excels on tri-blends and cotton; screen printing works well on all, but adjust ink types accordingly.

- Test First: Order samples to feel the fabric and test print quality before bulk production.

- Balance Budget & Quality: Match your fabric choice to your brand positioning and pricing strategy.

By aligning your fabric choice with your design style, target market, and intended use, you’ll create custom t-shirts that look great, feel comfortable, and stand the test of time.

How to Get the Best Price for Custom Ink T-Shirt Design (Bulk Quantity Breaks, Artwork Tips)

Ordering custom t-shirts in bulk can be a cost-effective way to promote your brand, team, or event. To maximize savings and ensure a high-quality result, it’s important to understand how pricing works and how to prepare your design properly. Here’s how to get the best price on your custom ink t-shirt order.

Understand Bulk Quantity Breaks

One of the most effective ways to reduce your per-unit cost is by leveraging bulk quantity breaks. Most screen printing companies offer tiered pricing based on the number of shirts ordered.

- Know the thresholds: Common quantity breaks occur at 24, 48, 72, 100, 250, and 500 units. Ordering just above a break (e.g., 101 instead of 100) can significantly lower the unit price.

- Estimate accurately: Order enough to take advantage of the next pricing tier, but avoid over-ordering to prevent excess inventory.

- Combine orders: If you’re part of a group or organization, consider pooling orders to reach higher quantity tiers and share the savings.

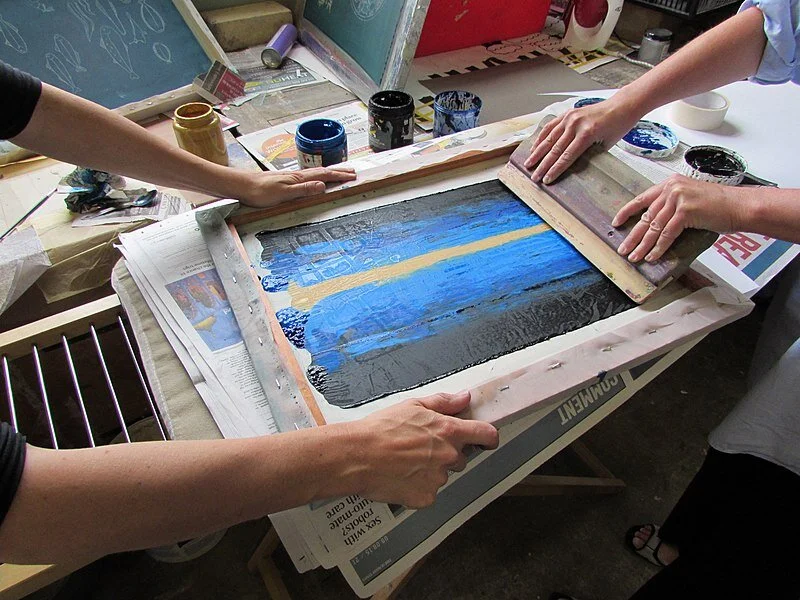

Choose the Right Print Method

The printing technique affects both cost and quality. For bulk orders, screen printing is typically the most economical.

- Screen printing: Best for large quantities and simple designs with limited colors. Cost per shirt decreases with volume.

- Direct-to-Garment (DTG): More cost-effective for small runs or complex, full-color designs. Less ideal for bulk due to slower production and higher per-unit costs.

- Heat transfer or vinyl: Suitable for very small orders or specialty fabrics, but not cost-efficient for bulk.

Simplify Your Design

The complexity of your artwork directly impacts the price. Reducing design elements can lead to substantial savings.

- Limit print colors: Each additional ink color requires a separate screen and setup fee. Stick to 1–3 colors for the best pricing.

- Use larger print areas wisely: Oversized prints use more ink and may increase cost. Optimize design size to balance visibility and economy.

- Avoid gradients and fine details: These can be difficult to reproduce with screen printing and may require more expensive techniques.

Prepare Print-Ready Artwork

Submitting professional-quality artwork reduces production delays and potential extra charges.

- Use vector files: Supply logos or graphics in vector format (e.g., .AI, .EPS, .SVG) for crisp, scalable printing.

- High-resolution raster files: If using .PNG or .JPEG, ensure a resolution of at least 300 DPI at the intended print size.

- Outline fonts: Convert text to outlines in vector software to prevent font issues during printing.

- Provide color codes: Specify PMS (Pantone) or CMYK values to ensure accurate color matching.

Choose Affordable Shirt Styles and Colors

Garment cost varies widely based on brand, material, and color.

- Opt for basic styles: 100% cotton or cotton/poly blends from value brands (e.g., Gildan, Hanes) are typically the most budget-friendly.

- Select standard colors: White and light-colored shirts are usually cheaper than dark or specialty colors, which may require underbase printing.

- Stick to one style: Ordering multiple shirt styles increases setup and inventory costs.

Compare Quotes and Negotiate

Don’t settle for the first quote you receive.

- Request multiple quotes: Get estimates from at least 3–5 reputable printers, providing identical specs for accurate comparison.

- Ask about discounts: Inquire about first-time customer discounts, referral programs, or seasonal promotions.

- Negotiate on large orders: If ordering 250+ units, you may be able to negotiate a lower price per unit or waived setup fees.

Plan Ahead to Avoid Rush Fees

Rush orders can increase costs by 25–50%.

- Allow 7–14 days production time: Standard turnaround is typically 7–10 business days.

- Place orders early: Especially for events, holidays, or back-to-school seasons when demand peaks.

By understanding quantity breaks, simplifying your design, preparing quality artwork, and shopping strategically, you can achieve professional-looking custom t-shirts at the best possible price.

Choosing the right custom t-shirt provider ultimately depends on your specific needs, budget, and expectations for quality and service. To make the best decision, start by clearly defining your goals—whether it’s for a personal project, business branding, or a special event. Prioritize providers that offer high-quality materials and printing techniques (such as screen printing, direct-to-garment, or heat transfer) that match your design complexity and desired durability.

Evaluate customization options, including fabric types, color choices, sizing inclusivity, and design tools. Excellent customer service, turnaround time, and shipping options are equally important—especially if you’re working under tight deadlines. Always request samples when possible to assess fabric feel and print quality firsthand.

Finally, compare pricing transparently, keeping an eye out for hidden fees, and read customer reviews to gauge reliability and satisfaction. By balancing quality, service, affordability, and reputation, you can confidently select a custom t-shirt provider that meets your needs and delivers outstanding results.