The custom highway signs market has experienced steady growth driven by increasing infrastructure investments, rising road safety regulations, and the expansion of smart transportation systems worldwide. According to Grand View Research, the global traffic management system market—of which custom highway signage is a critical component—was valued at USD 4.8 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 11.3% from 2024 to 2030. Similarly, Mordor Intelligence reports that growing urbanization and government initiatives to modernize aging transportation networks are accelerating demand for durable, compliant, and intelligent traffic signage solutions. This surge has led to a competitive landscape of manufacturers specializing in customized, reflective, and weather-resistant highway signs tailored to regional specifications and safety standards. As regulatory requirements become more stringent and cities adopt smart mobility infrastructure, the role of high-quality, precision-engineered signage has never been more vital. Below, we highlight the top 10 custom highway signs manufacturers leading innovation, compliance, and scalability in this expanding sector.

Top 10 Custom Highway Signs Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 National Highway Products

Domain Est. 2000

Website: nationalhighway.com

Key Highlights: National Highway Products, Inc. is proud of its full selection of MUTCD Traffic Signs for all of your construction, guide, handicap, neighborhood watch….

#2 National Supplier of Traffic Signs, Roll

Domain Est. 2002

Website: ricesigns.com

Key Highlights: Rice Signs is a leading manufacturer of traffic signs and highway safety products. We sell to individuals, businesses, contractors, and to government ……

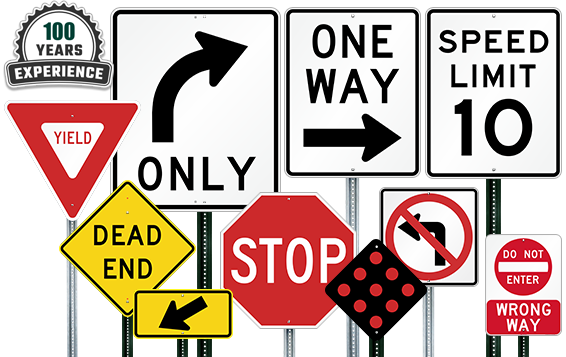

#3 Traffic Signs

Domain Est. 1996

Website: trafficsigns.com

Key Highlights: Shop high-quality regulatory traffic signs for roads, parking, and safety needs. Find stop, ADA, custom signs, and more to improve traffic flow and safety….

#4 National Sign and Signal

Domain Est. 1997

Website: nationalssc.com

Key Highlights: We have become the premier source of state-of-the-art custom traffic signs and signals in any size and shape, for virtually any application you can dream up….

#5 The Traffic Sign Store

Domain Est. 2002

Website: trafficsignstore.com

Key Highlights: The Traffic Sign Store offers the lowest prices and fastest service nationwide for reflective traffic or custom signs – for highway, home, work or play….

#6 Traffic Signs

Domain Est. 2003

Website: trafficsign.com

Key Highlights: Our custom design tool is easy to use and there are thousands of customizable traffic sign templates to choose from, allowing you to build a custom sign in just ……

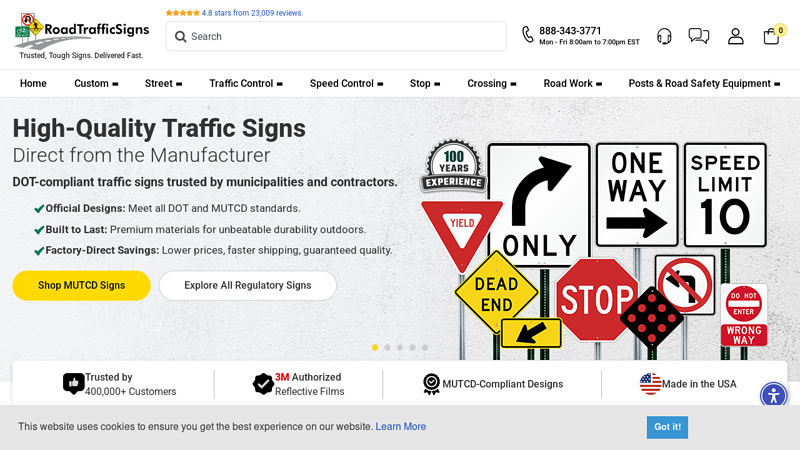

#7 Traffic Signs

Domain Est. 2004

Website: roadtrafficsigns.com

Key Highlights: Shop official road traffic signs online. MUTCD-compliant, rustproof with 3M reflectivity. Fast shipping, bulk discounts, custom options, unmatched quality….

#8 Custom Street & Traffic Signs

Domain Est. 2004

Website: dornbossign.com

Key Highlights: 8–15 day delivery · 14-day returnsCreate your own custom street and traffic signs at Dornbos Sign and Safety! Our signs are made of Highway Department of Transportation grade mate…

#9 USA Traffic Signs

Domain Est. 2005

Website: usa-traffic-signs.com

Key Highlights: USA Traffic Signs is a national supplier of road and traffic signs, street signs, sign posts, hardware, custom signs, parking signs, and more…

#10 Sign Manufacturing & Installation

Domain Est. 2006

Website: roadsafetraffic.com

Key Highlights: RoadSafe specializes in the manufacture of signs for the road construction industry and can serve all your needs with standard and custom signage….

Expert Sourcing Insights for Custom Highway Signs

2026 Market Trends for Custom Highway Signs

Growing Demand for Smart and Connected Infrastructure

By 2026, the custom highway signs market is expected to experience significant growth driven by the global shift toward intelligent transportation systems (ITS). Governments and transportation departments are increasingly investing in smart infrastructure that integrates real-time data, IoT sensors, and adaptive signage. Custom highway signs are evolving beyond static messages to include dynamic elements such as variable message signs (VMS), solar-powered displays, and integration with traffic management centers. This trend is particularly strong in North America and Europe, where urban congestion and safety concerns are accelerating the adoption of responsive signage solutions.

Increased Emphasis on Sustainability and Eco-Friendly Materials

Environmental regulations and corporate sustainability goals are shaping material choices in the custom highway signs sector. By 2026, manufacturers are expected to prioritize recyclable aluminum substrates, low-VOC reflective coatings, and energy-efficient LED lighting. Solar-powered signs are gaining traction, especially in remote or rural areas where grid access is limited. This trend aligns with broader infrastructure sustainability initiatives and is supported by government incentives promoting green public projects.

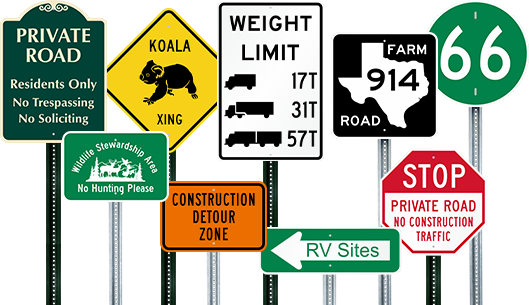

Customization and Regional Branding

Municipalities and state departments of transportation are increasingly using custom highway signs not just for navigation, but also for regional branding, tourism promotion, and cultural expression. In 2026, expect to see more localized designs that reflect regional identity—through typography, color schemes, and bilingual or multilingual messaging—particularly in diverse or tourist-heavy areas. This trend supports public engagement and enhances wayfinding while maintaining compliance with federal standards like the MUTCD (Manual on Uniform Traffic Control Devices).

Advancements in Reflective and Visibility Technologies

Safety remains a top priority, and technological improvements in sign visibility are a key trend. By 2026, high-performance prismatic sheeting (e.g., ASTM Type XI) will become more standard in custom sign manufacturing, improving nighttime readability and reducing accident rates. Additionally, anti-glare and anti-fog coatings are being integrated into sign faces, especially in regions prone to adverse weather conditions. These innovations support Vision Zero initiatives and contribute to lower maintenance costs over time.

Regulatory Harmonization and Compliance Automation

As regulations around traffic control devices become more complex, there is a growing demand for custom sign providers to ensure compliance with local, national, and international standards. By 2026, many manufacturers are expected to adopt digital design platforms that automatically validate signs against MUTCD, TCDs (Transportation Control Devices), or European EN standards. This shift reduces errors, accelerates production, and supports public agencies in meeting audit and safety requirements efficiently.

Expansion of Public-Private Partnerships (PPPs)

The funding landscape for highway infrastructure is evolving, with more public-private partnerships emerging to support large-scale transportation upgrades. These collaborations are driving demand for custom signage in toll roads, managed lanes, and smart corridors. By 2026, private entities involved in infrastructure development will increasingly commission specialized signage for branding, user guidance, and dynamic pricing displays, further expanding the custom highway sign market.

In summary, the 2026 custom highway signs market will be shaped by technological innovation, sustainability mandates, and the need for smarter, safer, and more personalized transportation infrastructure. Companies that adapt to these trends through advanced manufacturing, compliance expertise, and design flexibility are poised for growth in this evolving sector.

Common Pitfalls When Sourcing Custom Highway Signs: Quality and Intellectual Property Risks

Sourcing custom highway signs involves more than just finding a low-cost manufacturer—overlooking key quality and intellectual property (IP) concerns can lead to project delays, legal issues, and compromised safety. Here are the most common pitfalls to avoid:

Poor Material and Construction Quality

Many suppliers cut corners by using substandard materials such as low-grade aluminum, non-compliant reflective sheeting, or inadequate rust protection. Signs made with inferior materials degrade quickly when exposed to weather, reducing visibility and lifespan. Always verify material specifications (e.g., ASTM standards) and request samples before placing bulk orders.

Non-Compliance with Regulatory Standards

Custom signs must meet strict transportation regulations like the MUTCD (Manual on Uniform Traffic Control Devices) in the U.S. or equivalent national standards. Suppliers unfamiliar with these requirements may produce signs with incorrect dimensions, fonts, colors, or reflectivity, rendering them illegal for public road use. Confirm that your vendor has experience with DOT-compliant signage.

Inconsistent Print and Color Accuracy

Highway signs rely on precise color matching for visibility and regulatory compliance. Poor-quality printing processes can result in inconsistent hues, fading, or misaligned graphics. Ensure the supplier uses calibrated digital printing and color-matching systems (e.g., Pantone or Munsell) and provides color certification.

Lack of Durability Testing

Outdoor signs face extreme conditions, including UV exposure, moisture, and temperature swings. Reputable manufacturers conduct accelerated weathering tests (e.g., ASTM G154 or ISO 4892). Avoid vendors who cannot provide test reports or warranties proving long-term durability.

Intellectual Property Infringement

Using logos, symbols, or designs without proper licensing can lead to legal action. For example, incorporating a state’s official emblem or a trademarked graphic without authorization violates IP law. Always obtain written permission or use only public domain or properly licensed artwork.

Unprotected Design and Custom Artwork

When you provide original designs or proprietary information to a supplier, there’s a risk they could reuse or resell them without your consent. Establish clear contractual terms specifying ownership of custom designs and include confidentiality clauses to protect your IP.

Hidden Costs from Rework and Replacements

Low initial quotes may not account for rework due to defects or non-compliance. Poor quality often leads to rejected shipments, project delays, and added logistics costs. Opt for transparent pricing that includes quality assurance and compliance verification.

By addressing these pitfalls early—through due diligence, clear contracts, and supplier vetting—you can ensure your custom highway signs meet both performance standards and legal requirements.

Logistics & Compliance Guide for Custom Highway Signs

This guide outlines the essential logistics and compliance considerations for the production, transportation, installation, and maintenance of custom highway signs. Adhering to these standards ensures safety, regulatory compliance, and operational efficiency.

Regulatory Compliance

All custom highway signs must comply with federal, state, and local regulations. In the United States, the primary regulatory framework is the Manual on Uniform Traffic Control Devices (MUTCD), published by the Federal Highway Administration (FHWA). Key compliance areas include:

- Design Standards: Signs must meet MUTCD specifications for color, shape, size, font (e.g., Highway Gothic), symbols, and message content.

- Retroreflectivity: Signs must maintain minimum retroreflectivity levels as defined by the MUTCD to ensure visibility at night.

- FHWA Approval: Custom sign designs may require official FHWA approval or must conform to an approved Standard Highway Sign (SHS) or Standard Highway Sign Detail Sheet.

- State Variations: Some states have supplemental manuals that modify or expand upon MUTCD standards; compliance with these is mandatory for projects within those jurisdictions.

Material & Manufacturing Standards

- Substrate Materials: Use of aluminum (typically 0.080” thick), galvanized steel, or high-density polyethylene (HDPE) as permitted by project specifications.

- Sheeting: Retroreflective sheeting must be certified and meet ASTM D4956 standards (e.g., Engineer Grade, High-Intensity Prismatic, Diamond Grade).

- Fabrication: Signs must be fabricated to avoid warping, bubbling, or non-uniform adhesion. Corners should be sealed to prevent moisture ingress.

- Certification: Manufacturers should provide material certifications and test reports upon request.

Permitting and Approvals

- Right-of-Way Permits: Installation on public roadways requires permits from the relevant transportation authority (state DOT, county, or municipal agency).

- Engineering Review: Custom signs may require structural engineering certification, especially for large or wind-exposed installations.

- Environmental & Historical Review: Projects near protected areas or historic sites may require additional assessments under NEPA or Section 106.

Transportation & Logistics

- Packaging: Signs must be packaged to prevent scratching, denting, or moisture exposure during transit. Use of edge protectors and waterproof wrapping is recommended.

- Shipping: Coordinate with carriers experienced in handling oversized or sensitive cargo. Ensure secure loading and use of straps or cradles to prevent shifting.

- Delivery Scheduling: Align deliveries with installation timelines and site access permissions. Avoid rush-hour traffic for urban installations.

- Inventory Management: Maintain a tracking system for sign inventory, including location, condition, and installation status.

Installation Requirements

- Location & Placement: Signs must be installed at specified distances, heights (typically 5–8 feet for roadside signs), and lateral offsets per MUTCD and design plans.

- Structural Support: Use appropriate posts (steel, aluminum, or composite), foundations (concrete or direct burial), and hardware meeting AASHTO or state DOT standards.

- Worker Safety: Installers must follow OSHA regulations, including proper use of PPE, traffic control plans (per MUTCD Chapter 6), and flagger protocols.

- Documentation: Record installation details (GPS coordinates, sign ID, date, installer) for asset management and compliance audits.

Maintenance & Inspection

- Routine Inspections: Conduct periodic inspections for damage, fading, obstruction (vegetation), and retroreflectivity degradation—at least annually or as required by jurisdiction.

- Cleaning & Repair: Clean signs as needed to maintain visibility. Repair or replace damaged or non-compliant signs promptly.

- Recordkeeping: Maintain logs of inspections, repairs, replacements, and compliance certifications for audit purposes.

Environmental & Sustainability Considerations

- Recycling: Recycle old aluminum signs and posts through certified scrap metal recyclers.

- Hazardous Materials: Handle and dispose of any components containing lead-based paint or other regulated substances in accordance with EPA and state regulations.

- Sustainable Practices: Opt for recyclable materials and energy-efficient manufacturing processes where feasible.

Conclusion

Compliance and effective logistics are critical to the successful deployment of custom highway signs. By following this guide, stakeholders—including manufacturers, contractors, and transportation agencies—can ensure that signs meet legal requirements, enhance road safety, and provide long-term value. Always consult the latest MUTCD edition and relevant state specifications before initiating any project.

Conclusion for Sourcing Custom Highway Signs

Sourcing custom highway signs requires careful consideration of regulatory compliance, material quality, visibility standards, and vendor reliability. Adherence to national and regional guidelines—such as the MUTCD (Manual on Uniform Traffic Control Devices) in the United States—is essential to ensure safety, legal compliance, and consistency with existing signage. Selecting durable materials like reflective aluminum with UV-resistant coatings guarantees longevity and performance under various environmental conditions.

Partnering with qualified manufacturers experienced in transportation infrastructure ensures precision in design, accurate color matching, and conformance to size and reflectivity standards. Additionally, streamlining the procurement process through competitive bidding, clear specifications, and effective project management helps control costs and timelines.

In conclusion, a strategic and informed approach to sourcing custom highway signs enhances road safety, supports efficient traffic management, and delivers long-term value for transportation projects. Prioritizing quality, compliance, and supplier expertise ensures that custom signage meets both functional requirements and regulatory expectations.