The global demand for specialty adhesive tapes has surged in recent years, driven by expanding applications across entertainment, sports, automotive, and industrial sectors. Gaffers tape, in particular—valued for its durability, clean removal, and matte finish—has become a staple in professional environments where reliability and performance are critical. According to a report by Grand View Research, the global adhesive tapes market was valued at USD 71.2 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 4.8% from 2024 to 2030. This upward trajectory is fueled by rising demand in electronics manufacturing, construction, and creative industries, where custom labeling and high-performance materials are increasingly prioritized. As brands seek differentiated solutions, custom gaffers tape manufacturers are stepping in to offer tailored colors, widths, branding, and performance specifications. With market dynamics favoring innovation and customization, we examine the top eight manufacturers leading the charge in quality, scalability, and niche-driven product development.

Top 8 Custom Gaffers Tape Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Bron Tapes

Domain Est. 1997

Website: brontapes.com

Key Highlights: Bron Tapes is the premier producer, converter, and distributor of pressure sensitive tapes, adhesives, and innovative solutions in North America….

#2 Gaff Tapes: Custom & 3M Gaffers Tape

Domain Est. 2012

Website: gafftapes.com

Key Highlights: Free delivery 14-day returnsShop custom gaffers tape, 3M and waterproof gaffer tape direct from the manufacturer. Compare gaffer tape vs painter’s tape. Order online today….

#3 Gaffer Tape – Premium & Industrial Grade

Domain Est. 2014

Website: elitetape.com

Key Highlights: Professional gaffers tape for film, theater, & events. Matte black cloth tape with no residue, strong hold, clean removal….

#4 Custom Gaffer Tape Suppliers & Manufacturers

Domain Est. 2016

Website: tapemanufacture.com

Key Highlights: Browse Gaffer Tape page and get more details of HX TAPE and our custom gaffer tape products. Get Price from gaffer tape suppliers online!…

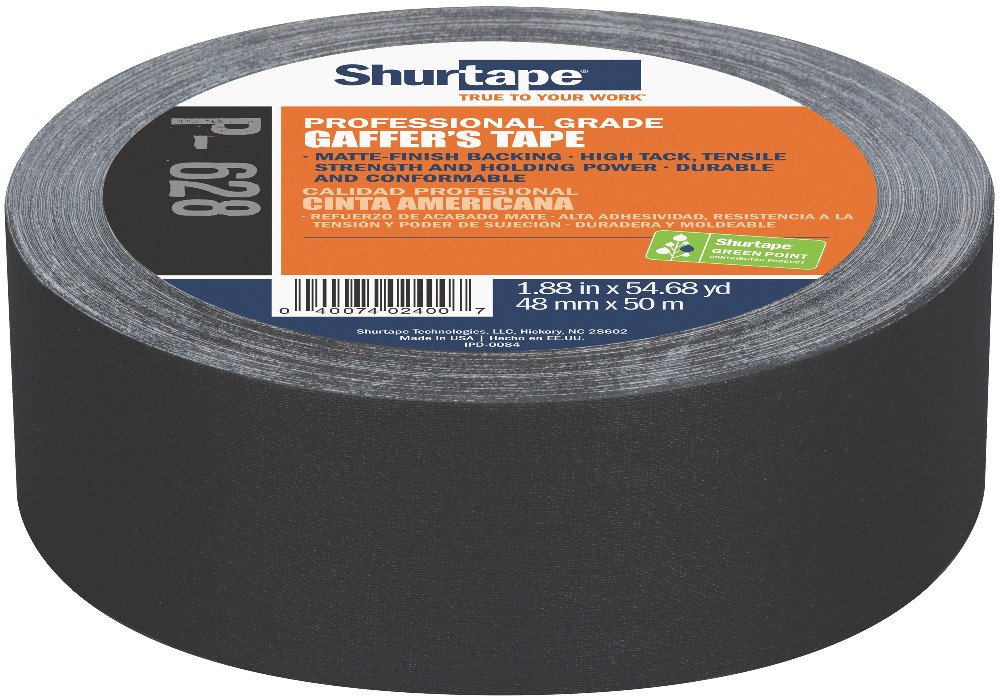

#5 Gaffer’s Tape

Domain Est. 1996

Website: shurtape.com

Key Highlights: Professional grade gaffer’s tape suited for general use in the convention, hospitality, exhibition and trade show industries….

#6 Gaffer / Duct Tapes

Domain Est. 1998

Website: gaffatape.com

Key Highlights: 14-day returnsGaffer, Duct and Cloth Tapes in over 30 colours and sizes. Wholesale Prices, Next Day Delivery Available….

#7 Custom Gaffers Tape

Domain Est. 2004

Website: nadco-inc.com

Key Highlights: In stock Rating 5.0 (47) To add a personalized touch, NADCO offers the option to customize your gaffer tape with logos, text, or graphics in a wide range of colors. This allows y…

#8 Commercial Gaffer Tape

Domain Est. 2013

Website: proxdirect.com

Key Highlights: 2 Inch 180FT 60YD Matte Black Commercial Grade Gaffer Tape Pros Choice Non-Residue · 3 Inch 180FT 60YD Matte Black Commercial Grade Gaffer Tape Pros Choice Non- ……

Expert Sourcing Insights for Custom Gaffers Tape

2026 Market Trends for Custom Gaffers Tape

Rising Demand in Niche Industries

By 2026, the custom gaffers tape market is expected to see significant growth driven by expanding applications in niche sectors such as film and television production, live events, sports branding, and industrial manufacturing. As brands increasingly seek personalized solutions for on-set identification, safety labeling, and promotional use, demand for customized tapes featuring logos, colors, and specific messaging will rise. The film industry, in particular, continues to rely on gaffers tape for cable management and equipment labeling, with custom versions enhancing organization and brand visibility.

Growth in Customization and Branding

Branding has become a key differentiator in competitive markets, and custom gaffers tape allows companies to extend their identity into operational environments. By 2026, manufacturers are expected to offer advanced printing technologies, enabling high-resolution logos, QR codes, and serialized batch labeling directly on tape. This trend is especially notable in corporate event management and facility maintenance, where branded tape serves both functional and marketing purposes.

Sustainable and Eco-Friendly Materials

Environmental concerns are shaping product development across industries, and the gaffers tape market is no exception. By 2026, there will be a stronger push toward eco-conscious solutions, including biodegradable backings, water-based adhesives, and recyclable packaging. Custom tape providers will increasingly offer sustainable options to meet corporate sustainability goals, particularly in Europe and North America, where environmental regulations are tightening.

Expansion of E-Commerce and On-Demand Manufacturing

The accessibility of custom gaffers tape is being transformed by digital platforms. Online configurators allow customers to design, preview, and order personalized rolls with minimal lead time. By 2026, on-demand manufacturing and just-in-time delivery models are expected to dominate, reducing inventory waste and enabling small businesses and creative professionals to access custom solutions affordably. This shift supports the growing gig economy and independent content creators who require branded, functional tools.

Technological Integration and Smart Labeling

Emerging innovations may integrate smart features into custom gaffers tape, such as UV-reactive inks, temperature-sensitive adhesives, or conductive materials for temporary circuitry in prototyping. While still in early stages, these developments could open new applications in tech, education, and research sectors by 2026. Additionally, augmented reality (AR) markers printed on tape may allow maintenance teams or film crews to access digital instructions via smartphone scans.

Regional Market Dynamics

North America will remain a leading market due to its robust entertainment and industrial sectors, while Asia-Pacific is expected to see the fastest growth, fueled by expanding film production in India, South Korea, and Southeast Asia. Localized manufacturing hubs and regional customization preferences—such as color symbolism or language-specific labeling—will become increasingly important for global suppliers.

Conclusion

The 2026 custom gaffers tape market will be characterized by personalization, sustainability, and technological advancement. As industries demand more from functional tapes, the ability to deliver tailored, eco-friendly, and innovative solutions will define market leaders. Companies that invest in digital platforms, sustainable materials, and niche applications will be best positioned to capitalize on these evolving trends.

Common Pitfalls Sourcing Custom Gaffers Tape (Quality, IP)

Sourcing custom gaffers tape—whether for branding, specific performance needs, or unique aesthetics—can be a cost-effective and impactful solution. However, overlooking critical factors related to quality and intellectual property (IP) can lead to subpar products, supply chain disruptions, or even legal issues. Below are common pitfalls to avoid:

Poor Adhesion and Residue Issues

One of the most frequent quality concerns is inconsistent adhesive performance. Low-quality tapes may either fail to stick properly under stress or leave behind sticky residue, especially when removed after extended use. This is often due to inferior adhesive formulations or improper coating processes by manufacturers. Always request samples and conduct real-world testing under the conditions the tape will face (e.g., heat, moisture, duration).

Inconsistent Tensile Strength and Durability

Custom gaffers tape must maintain strength and resist tearing during use. Some suppliers cut costs by using lower-grade cloth backings or skimping on reinforcing fibers. This results in tapes that fray easily or lose integrity during handling. Ensure specifications include tensile strength metrics and verify them through third-party testing if possible.

Color and Print Fidelity Problems

Custom printing on gaffers tape (e.g., logos, safety markings) often suffers from poor color matching or ink bleeding, especially on textured cloth surfaces. Some manufacturers lack the capability to handle fine details or consistent print registration. Provide Pantone color codes and high-resolution artwork, and confirm the printing method (e.g., flexo, screen print) used by the supplier.

Non-Compliance with Industry or Safety Standards

Depending on the application (e.g., film production, industrial use), gaffers tape may need to meet certain fire-resistance or low-outgassing standards. Not all manufacturers adhere to these requirements. Clarify regulatory or safety certifications needed (e.g., UL, RoHS) and confirm compliance documentation before placing bulk orders.

Intellectual Property Infringement Risks

Using branded designs, logos, or copyrighted patterns without proper authorization can expose your business to legal action. Even if a supplier agrees to print a custom design, they may not verify IP rights, leaving you liable. Always ensure you have full rights or proper licenses for any artwork, trademarks, or patterns used on the tape.

Lack of IP Protection in Supplier Agreements

When developing proprietary tape formulations or unique designs, failing to secure IP rights in supplier contracts is a major risk. Without clear agreements, the manufacturer could replicate or resell your design to competitors. Use NDAs and include clauses that assign IP ownership to your company for custom developments.

Overlooking Minimum Order Quantities and MOQ Traps

Many overseas or low-cost suppliers impose high minimum order quantities (MOQs) to justify setup costs. This can lead to excess inventory or financial strain, especially if the product doesn’t meet expectations. Negotiate trial runs or smaller batches before committing to large orders.

Supply Chain and Quality Control Gaps

Sourcing from distant manufacturers may result in communication delays, inconsistent quality between batches, or lack of oversight. Without on-site quality checks or third-party inspections, defects may go unnoticed until shipment. Establish clear QC checkpoints and consider using inspection services before shipment.

By proactively addressing these pitfalls—through rigorous vetting, sample testing, legal review, and clear contractual terms—you can ensure your custom gaffers tape meets both performance standards and legal requirements.

Logistics & Compliance Guide for Custom Gaffers Tape

Overview

Custom gaffers tape is a specialized adhesive tape widely used in entertainment, film, theater, and industrial applications for temporary surface protection, marking, bundling, and securing cables. When producing, distributing, or importing custom gaffers tape—especially with printed logos, colors, or branding—logistics and compliance considerations are critical to ensure smooth operations, regulatory adherence, and customer satisfaction.

Material Composition and Safety Compliance

Gaffers tape typically consists of a cloth backing (often cotton or polyester) coated with a rubber-based or acrylic adhesive. Custom versions may include dyes, inks, and surface treatments. Compliance with safety standards includes:

– REACH (EU): Ensure all chemical components (adhesives, dyes) are registered and do not contain substances of very high concern (SVHC).

– RoHS (EU/UK): Applicable if tape is used in electronic environments; verify absence of restricted heavy metals.

– OSHA & CPSIA (USA): Assess for hazardous materials, especially if used in consumer-facing or theatrical products.

– Flammability Standards: In entertainment applications, compliance with NFPA 701 (flame resistance for stage materials) may be required. Confirm tape meets flame-retardant specifications if marketed for such use.

Labeling and Packaging Requirements

Proper labeling ensures regulatory compliance and aids logistics:

– Include product name, substrate material, adhesive type, dimensions (length, width, thickness), batch number, and manufacturer details.

– For custom printed rolls, ensure ink is non-toxic and complies with local labeling laws (e.g., California Prop 65 warnings if applicable).

– Clearly mark packaging with handling instructions (e.g., “Keep Dry,” “Store in Cool Place”) to prevent adhesive degradation during transit.

Import/Export Regulations

Cross-border shipping requires attention to:

– HS Code Classification: Gaffers tape typically falls under HS code 5903.90 (textile fabrics impregnated/coated with adhesives). Confirm with local customs authority for accuracy.

– Tariffs and Duties: Research duty rates based on destination country. Free Trade Agreements (e.g., USMCA, CPTPP) may reduce or eliminate tariffs.

– Documentation: Prepare commercial invoices, packing lists, and certificates of origin. For custom-branded products, include artwork approval records for intellectual property verification.

Transportation and Storage

Gaffers tape is sensitive to environmental conditions:

– Temperature Control: Avoid exposure to extreme heat (>120°F/49°C) or freezing conditions, which can compromise adhesive performance.

– Humidity: Store in dry environments to prevent moisture absorption, especially in cloth-backed varieties.

– Stacking & Handling: Use pallets and secure loads to prevent crushing. Avoid direct sunlight during transit to prevent color fading on custom prints.

Intellectual Property and Branding Compliance

Custom gaffers tape often features logos or trademarks:

– Obtain proper licensing for any third-party logos or copyrighted designs.

– Ensure branding does not mislead consumers (e.g., implying certification or affiliation).

– Retain artwork proofs and client-signed approvals to protect against IP disputes.

Environmental and Disposal Regulations

- Waste Disposal: Gaffers tape is typically non-recyclable due to mixed materials. Comply with local waste disposal regulations (e.g., EPA guidelines in the U.S.).

- Sustainability Claims: If marketing tape as “eco-friendly” or “biodegradable,” ensure claims are substantiated and compliant with FTC Green Guides or EU environmental labeling rules.

Quality Control and Testing

Implement pre-shipment quality checks:

– Verify print alignment, color consistency, and adhesion strength.

– Test for edge lifting, unwind performance, and residue upon removal.

– Maintain batch testing records for traceability in case of compliance audits or customer claims.

Conclusion

Successfully managing the logistics and compliance of custom gaffers tape requires proactive coordination across sourcing, manufacturing, shipping, and regulatory domains. By adhering to international standards, maintaining accurate documentation, and prioritizing product safety and quality, businesses can ensure reliable delivery and legal compliance in global markets.

In conclusion, sourcing custom gaffers tape requires a strategic approach that balances quality, customization options, cost, and supplier reliability. By clearly defining your needs—such as size, color, adhesive strength, and printed branding—you can identify manufacturers or suppliers capable of meeting your specifications. Conducting thorough research, requesting samples, and evaluating minimum order requirements will help ensure the final product performs reliably in demanding environments while enhancing brand visibility. Partnering with a reputable supplier that offers consistent quality and excellent customer service is key to a successful long-term sourcing solution. With the right preparation and due diligence, custom gaffers tape can become a valuable, professional tool for your team or organization.