The global demand for custom-cut perspex, also known as acrylic or polymethyl methacrylate (PMMA), has surged in recent years, driven by its widespread use in signage, displays, architectural applications, and industrial design. According to a 2023 report by Mordor Intelligence, the global acrylic sheet market was valued at USD 6.8 billion in 2022 and is projected to grow at a CAGR of 5.4% through 2028. This expansion is fueled by increasing demand for lightweight, durable, and aesthetically versatile materials across sectors such as retail, healthcare, and construction. Additionally, Grand View Research highlights that innovations in precision cutting technologies—such as CNC machining and laser cutting—are enabling manufacturers to offer increasingly complex custom geometries with high clarity and dimensional accuracy. As downstream industries prioritize design flexibility and sustainability, the ability to source high-quality, custom-fabricated perspex efficiently has become a critical competitive advantage. In this landscape, leading manufacturers are distinguished not only by production scale but also by technical precision, material sourcing transparency, and speed-to-delivery—all factors we evaluated to compile the top 10 custom-cut perspex manufacturers in the industry.

Top 10 Custom Cut Perspex Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Regal Plastic

Domain Est. 1996

Website: regalplastic.com

Key Highlights: With 15 locations and on-site custom design, cutting, drilling and fabrication services, we are your one-stop shop and source for everything plastic….

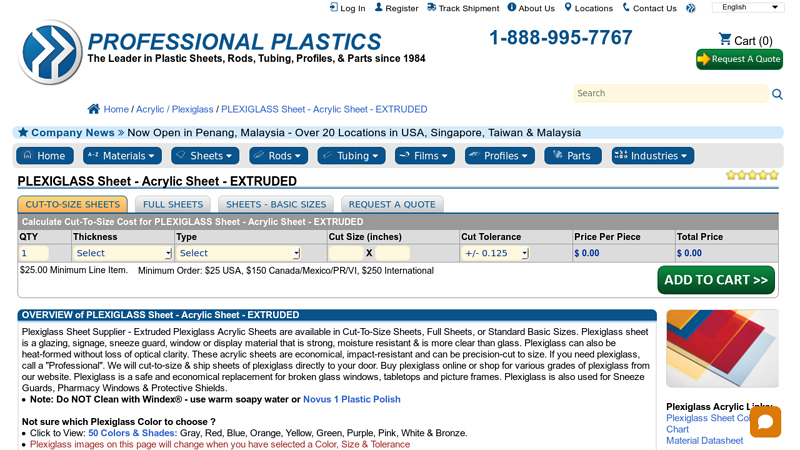

#2 Plexiglass Sheet

Domain Est. 1997

Website: professionalplastics.com

Key Highlights: 3-day returnsWe will cut-to-size & ship sheets of plexiglass directly to your door. Buy plexiglass online or shop for various grades of plexiglass from our website….

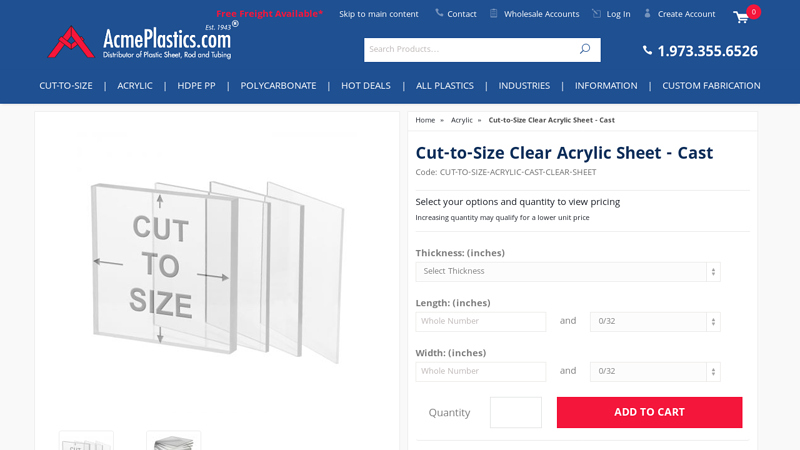

#3 Cut

Domain Est. 1997

Website: acmeplastics.com

Key Highlights: Free delivery 15-day returnsChoose from a range options for custom cut-to-size clear acrylic plexiglass sheets. We offer a variety of customization options and edge polishing metho…

#4 Plastic, Acrylic & Polycarbonate Sheet Supplier

Domain Est. 1997 | Founded: 1973

Website: acplasticsinc.com

Key Highlights: A&C Plastics has been a leading acrylic and polycarbonate sheet supplier since 1973. We have plastic, plastic sheets, acrylic sheets, PVC, ABS and more ……

#5 Min Plastics

Domain Est. 2000

Website: minplastics.com

Key Highlights: Official distributor of PLEXIGLAS®, Polycarbonate, Expanded/Foamed PVC, HDPE, Starboard, and Laser-Engraveable sheets. Supporting projects from cut-to-size ……

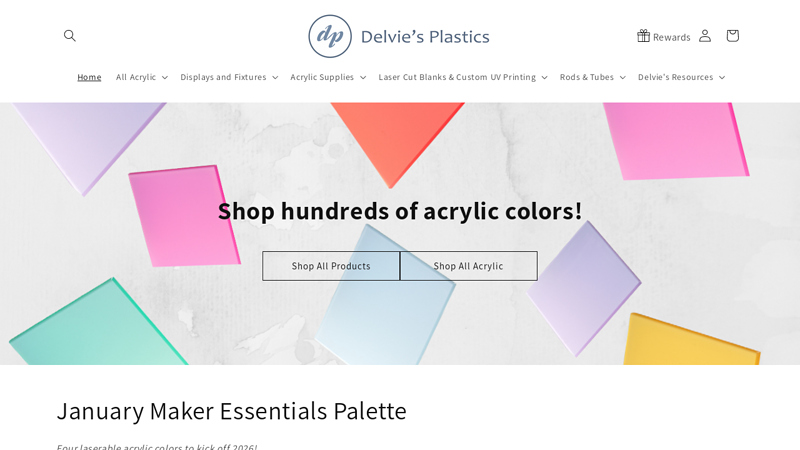

#6 Delvie’s Plastics

Domain Est. 2002

Website: delviesplastics.com

Key Highlights: 4-day delivery 30-day returnsAcrylic plexiglass sheet, cut to size, in hundreds of colors and thicknesses. With an emphasis on customer service, low prices, and the highest quality…

#7 PERSPEX®

Domain Est. 2010

Website: display.3acomposites.com

Key Highlights: PERSPEX® acrylic sheet is recognised as a premium product, one of the best quality acrylic materials in the world….

#8 Simply Plastics

Domain Est. 2011

Website: simplyplastics.com

Key Highlights: Simply Plastics are an online supplier of cut to size plastic sheet, tube and rod, all of which are available in various styles, colours, sizes and thicknesses….

#9 Custom Acrylics

Domain Est. 2015

Website: customacrylics.net

Key Highlights: We can cut, bend, or machine clear, smoked, or colored acrylic sheets to any size….

#10 RuudraScott Plastic

Domain Est. 2015

Website: ruudrascottplastics.com

Key Highlights: 14-day returnsCut to size plastics, just buy what you need. Stunning kitchen splashbacks, wetwalls, hygienic cladding & floor panels at wholesale price….

Expert Sourcing Insights for Custom Cut Perspex

2026 Market Trends for Custom Cut Perspex

The custom cut Perspex (acrylic) market is poised for dynamic evolution by 2026, driven by technological advancements, shifting consumer preferences, and expanding applications across diverse industries. Here’s an analysis of the key trends expected to shape the sector:

Rising Demand for Personalization and Aesthetic Innovation

By 2026, consumers and businesses will increasingly seek bespoke design solutions, propelling demand for custom Perspex products. Custom-cut acrylic is favored in retail displays, signage, interior décor, and consumer goods due to its clarity, lightweight nature, and design flexibility. The trend toward experiential retail and branded environments will drive demand for unique, eye-catching installations, such as laser-cut logos, 3D layered displays, and illuminated acrylic features.

Advancements in Digital Fabrication Technologies

Automation and precision manufacturing—especially CNC machining, laser cutting, and waterjet cutting—will continue to improve efficiency and reduce waste in custom Perspex production. By 2026, wider adoption of AI-driven design software and cloud-based customization platforms will enable faster prototyping and on-demand manufacturing. This will lower entry barriers for small businesses and designers, fueling market democratization.

Sustainability and Eco-Conscious Material Choices

Environmental concerns will significantly influence the Perspex market. While traditional acrylic is petroleum-based, demand for recycled and bio-based acrylic alternatives is expected to grow. Manufacturers investing in closed-loop recycling systems and offering post-consumer recycled Perspex will gain competitive advantage. Transparency in sourcing and lifecycle impact will become key differentiators for brands targeting eco-sensitive clients.

Expansion in Niche Applications

Beyond traditional uses in signage and displays, custom-cut Perspex will see growth in emerging sectors such as:

– Healthcare: Antimicrobial-coated acrylic partitions and protective screens.

– Architecture and Smart Homes: Integrated lighting panels, modular furniture, and acoustic panels.

– Retail and E-commerce: Custom packaging, display stands, and augmented reality-enabled acrylic interfaces.

– Art and Fashion: Designer collaborations featuring laser-etched or colored acrylic accessories and installations.

Regional Market Diversification and E-Commerce Growth

North America and Europe will remain strong markets due to high design sophistication and infrastructure, but Asia-Pacific—particularly China, India, and Southeast Asia—will experience accelerated growth. Urbanization, rising disposable incomes, and digital adoption will expand access to online custom fabrication services. E-commerce platforms offering instant quoting, 3D previews, and global shipping will dominate customer acquisition strategies.

Price Pressures and Material Innovation

Fluctuating petrochemical prices may impact raw material costs, prompting investment in alternative feedstocks and material efficiency. Innovations such as self-healing acrylics, UV-resistant coatings, and improved impact modifiers will enhance product performance and expand application potential, supporting premium pricing in high-value sectors.

In conclusion, the 2026 custom cut Perspex market will be characterized by heightened customization, technological integration, sustainability imperatives, and cross-industry application growth. Companies that embrace digital transformation and eco-innovation will be best positioned to capture value in this evolving landscape.

Common Pitfalls When Sourcing Custom Cut Perspex: Quality and Intellectual Property Risks

Sourcing custom cut Perspex (acrylic) offers design flexibility, but comes with potential pitfalls—particularly around material quality and intellectual property (IP) protection. Being aware of these risks helps ensure a successful procurement process.

Poor Material Quality and Inaccurate Fabrication

One of the most frequent issues is receiving Perspex that fails to meet specified standards. Low-tier suppliers may use recycled or substandard acrylic, leading to inconsistencies in clarity, color, thickness, or structural integrity. This can result in yellowing, warping, or brittleness over time. Additionally, inaccurate cutting—due to poorly maintained equipment or lack of precision—can render parts unusable, especially in tight-tolerance applications. Always verify supplier certifications (e.g., ISO standards), request material test reports, and, if possible, obtain physical samples before placing bulk orders.

Lack of Intellectual Property Protection

When providing custom designs for cutting, you risk exposing proprietary information. Some overseas or unvetted suppliers may not have robust IP policies and could reproduce or resell your designs without permission. This is particularly concerning for unique product components, branding elements, or patented designs. To mitigate this risk, use non-disclosure agreements (NDAs), work with reputable suppliers who respect IP rights, and consider watermarking or segmenting design files when sharing them. Choose partners located in jurisdictions with strong IP enforcement whenever feasible.

By proactively addressing these quality and IP concerns, businesses can safeguard their investments and ensure reliable, legally protected outcomes when sourcing custom cut Perspex.

Logistics & Compliance Guide for Custom Cut Perspex

Custom cut Perspex (acrylic) is widely used across industries for displays, signage, protective barriers, and architectural applications. Ensuring smooth logistics and compliance throughout the supply chain is essential for timely delivery, safety, and adherence to regulations. This guide outlines best practices for handling, shipping, and complying with relevant standards when managing custom cut Perspex products.

Material Handling & Packaging

Proper handling and packaging are critical to prevent scratches, cracks, or warping during transit.

- Surface Protection: Always retain the factory-applied protective film on both sides until final installation. Avoid removing it prematurely.

- Edge Protection: Use foam corner guards or edge protectors on all corners and edges to prevent chipping.

- Interleaving: When stacking sheets, place non-abrasive spacers (e.g., kraft paper or low-adhesion film) between layers to reduce friction.

- Packaging: Securely bundle sheets using stretch wrap or strapping on a wooden or plastic pallet. Avoid over-tightening straps, which can deform the material.

- Labeling: Clearly mark packages with “Fragile,” “This Side Up,” and “Protect from Moisture” labels.

Shipping & Transportation

Selecting the right shipping method and carrier significantly impacts product integrity.

- Mode of Transport: Use enclosed, climate-controlled vehicles when possible, especially in extreme temperatures. Perspex can expand or contract with temperature changes.

- Securement: Fully immobilize pallets within the vehicle to prevent shifting. Use straps or load bars to avoid lateral movement.

- Stacking: Never stack loads higher than recommended for the pallet strength. Limit stack height to prevent pressure damage.

- Transit Time: Minimize delivery time where feasible. Long transit durations increase handling risks.

Storage Guidelines

Proper storage ensures material quality is maintained before installation.

- Environment: Store indoors in a dry, well-ventilated area, away from direct sunlight and heat sources (e.g., radiators, furnaces).

- Positioning: Store sheets vertically in racks designed for flat materials. If horizontal storage is necessary, ensure flat, level support across the entire surface.

- Temperature: Maintain storage temperatures between 15°C and 25°C (59°F–77°F). Avoid freezing or excessive heat.

- Humidity: Keep relative humidity below 60% to prevent moisture absorption or static buildup.

Regulatory & Safety Compliance

Adherence to regional and international standards ensures legal and safe operations.

- Material Safety Data Sheet (MSDS/SDS): Provide SDS documentation detailing chemical composition, fire hazards, and first aid measures as required by OSHA (U.S.) or CLP/GHS regulations (EU).

- REACH & RoHS Compliance: Confirm that the Perspex material complies with EU REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives when exporting.

- Fire Safety Ratings: For applications in public buildings, ensure the Perspex meets local fire safety standards (e.g., ASTM E84 in the U.S., EN 13501-1 in Europe). Flame-retardant grades may be required.

- Customs Documentation (International Shipments): Include accurate HS codes (e.g., 3920.51 for polymethyl methacrylate sheets), commercial invoices, and certificates of origin to avoid delays.

Environmental & Sustainability Considerations

Growing emphasis on sustainability affects logistics and compliance decisions.

- Recyclability: Perspex is recyclable (Plastic #7). Provide end-of-life guidance to customers and consider take-back programs.

- Packaging Materials: Use recyclable or reusable packaging components (e.g., cardboard, recyclable plastic wrap) to minimize environmental impact.

- Carbon Footprint: Optimize shipping routes and consolidate shipments to reduce emissions. Consider carbon offset options for long-haul deliveries.

Quality Assurance & Documentation

Maintain transparency and traceability throughout the supply chain.

- Inspection: Conduct pre-shipment inspections to verify dimensions, cut accuracy, surface quality, and packaging integrity.

- Certificates: Provide material conformance certificates, cutting specifications, and compliance statements upon request.

- Batch Tracking: Implement lot or batch numbering for traceability, especially in regulated industries like healthcare or aerospace.

By following this logistics and compliance guide, businesses can ensure that custom cut Perspex is delivered safely, efficiently, and in accordance with all applicable regulations. Regular audits and staff training further support long-term operational excellence.

In conclusion, sourcing custom-cut Perspex requires careful consideration of material specifications, precision requirements, supplier reliability, and cost-efficiency. By identifying reputable suppliers with advanced cutting capabilities—such as CNC machining or laser cutting—you can ensure high-quality, accurate results tailored to your project’s needs. Additionally, evaluating factors like turnaround time, minimum order quantities, and post-production finishes will help streamline the procurement process. With the right supplier partnership, custom-cut Perspex offers a versatile, durable, and aesthetically pleasing solution for a wide range of applications in design, retail, signage, and manufacturing.