The global automotive accessories market is experiencing robust growth, driven by increasing demand for personalized vehicle interiors and enhanced comfort features. According to Grand View Research, the global automotive interior market size was valued at USD 118.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. A key segment within this space—custom cup holders—is gaining traction as consumers prioritize convenience, ergonomics, and vehicle-specific fitment. This rising demand has fueled the emergence of specialized manufacturers focusing on innovative, precision-engineered cup holder solutions for automotive, marine, RV, and specialty vehicle applications. As vehicle personalization becomes a differentiating factor for both OEMs and aftermarket buyers, the need for reliable, high-quality custom cup holder manufacturers has never been greater. Here, we highlight the top seven manufacturers leading the charge in design innovation, material quality, and customer-specific engineering.

Top 7 Custom Cup Holders Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Aircraft Cup Holders

Domain Est. 2002

Website: starrcompany.com

Key Highlights: We are the OEM of cup holders and ashtrays for various aircraft including Cessna, Beechcraft, Gulfstream, Bombardier, Dassault Falcon Jet, and many more….

#2 Custom Cupholders Company

Domain Est. 2003

Website: customcupholders.com

Key Highlights: Custom Cupholders Company. Available in two different depths. Elegant solutions for bulkhead mounting. Receptacles remove for easy cleaning….

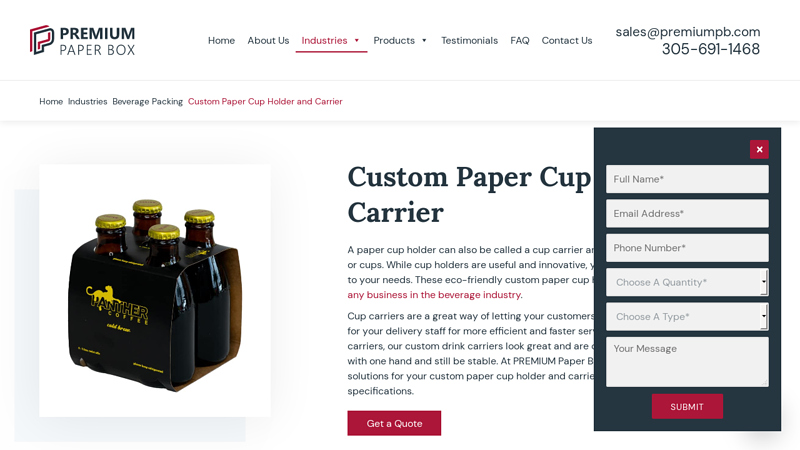

#3 Custom Paper Cup Holder and Carrier

Domain Est. 2009

Website: premiumpb.com

Key Highlights: We can create innovative and elegant paper cup holders and carriers that allow your clients and employees to carry multiple cups while ensuring that all ……

#4 boat and marine cup holders

Domain Est. 2012

Website: cudascustoms.com

Key Highlights: Custom Clamp-on Boat Beverage Drink Holder. Extremely durable high quality boat drink holders made of long lasting UV protected marine grade starboard….

#5 Custom Printed Drink Holders & Can Coolers

Domain Est. 2013

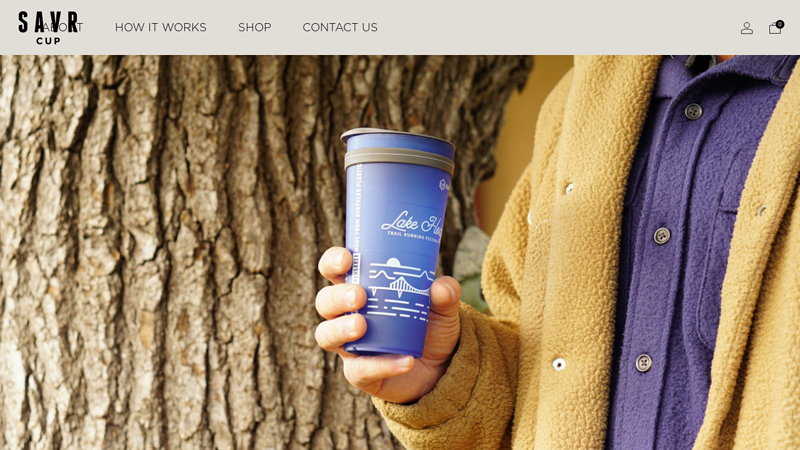

#6 SAVRcup

Domain Est. 2017

Website: savrcup.com

Key Highlights: Customized cups start at only $1.86, making sustainability affordable. Create unforgettable personalized cups for your next birthday, graduation, or wedding….

#7 Order Custom Carriers

Domain Est. 2018

Website: customboxline.com

Key Highlights: Drink holders with handles are easy to carry and safe to transport. Customize your beverage packaging with our high-quality offset printing, various surface ……

Expert Sourcing Insights for Custom Cup Holders

H2: 2026 Market Trends for Custom Cup Holders

The custom cup holder market in 2026 is poised for dynamic growth, driven by evolving consumer preferences, technological innovation, and broader societal shifts. This analysis identifies key trends shaping the industry landscape:

1. Personalization & Niche Targeting at Scale

By 2026, mass customization will become the norm. Advances in digital printing, AI-driven design tools, and automated manufacturing will enable affordable, rapid production of highly personalized cup holders. Expect hyper-targeted offerings: holders branded for micro-influencers, tailored to specific vehicle models (including EVs), or incorporating augmented reality (AR) elements via scannable codes. Consumers will demand unique designs reflecting individual identity, from pet photos to custom artwork, moving beyond basic logos.

2. Sustainability as a Non-Negotiable

Environmental responsibility will be paramount. Brands prioritizing 100% biodegradable, compostable, or recycled materials (e.g., bamboo, recycled ocean plastic, molded pulp) will gain significant market share. “Circular economy” models—offering take-back programs or discounts for returning used holders—will emerge. Transparency in sourcing and carbon footprint labeling will be critical differentiators, appealing to eco-conscious Gen Z and Millennial consumers.

3. Smart & Multifunctional Integration

Cup holders will evolve beyond passive accessories. Integration with smart technology is key: built-in wireless charging pads, Bluetooth trackers (e.g., Tile integration), or temperature-regulating materials for keeping beverages hot/cold. In automotive and RV sectors, holders with modular docks for phones, tablets, or dashcams will cater to the mobile workspace trend. Voice-activated controls via IoT connectivity could debut in premium segments.

4. Expansion into New Applications & Industries

Beyond beverage containers, custom holders will serve diverse needs:

– Healthcare: Ergonomic holders for IV bags or medical equipment in wheelchairs.

– Pet Care: Travel-friendly holders for pet water bottles in strollers or car seats.

– Home & Office: Stylish desk organizers combining cup holders with cable management.

– Events & Promotions: Biodegradable holders at festivals or as branded giveaways with embedded NFC chips for digital engagement.

5. E-Commerce & DTC Dominance

Direct-to-consumer (DTC) platforms will lead sales, leveraging social media (TikTok, Instagram) for viral marketing. AI-powered design configurators on e-commerce sites will enhance user experience. Subscription models (e.g., quarterly seasonal designs) and bundling with complementary products (e.g., tumblers, car accessories) will boost customer lifetime value. Global fulfillment networks will enable faster shipping, reducing barriers to international sales.

Conclusion

The 2026 custom cup holder market will be defined by hyper-personalization, uncompromising sustainability, smart functionality, and innovative applications. Success will favor agile brands that leverage technology for customization, prioritize eco-innovation, and expand beyond traditional use cases to meet the integrated, experience-driven demands of modern consumers.

Common Pitfalls When Sourcing Custom Cup Holders: Quality and Intellectual Property Issues

Sourcing custom cup holders—whether for automotive, marine, consumer electronics, or promotional use—can present hidden challenges. Two of the most critical areas where businesses encounter problems are quality inconsistencies and intellectual property (IP) risks. Understanding these pitfalls can help mitigate costly delays, legal disputes, and reputational damage.

Quality-Related Pitfalls

Inconsistent Material Standards

Suppliers may use subpar or non-durable materials to reduce costs, especially when specifications aren’t clearly defined. Plastics that degrade under UV exposure, metals prone to corrosion, or low-density foams can lead to premature failure. Always specify material grades (e.g., UV-stabilized ABS, food-grade silicone) and request material certifications.

Poor Tolerances and Fit Issues

Custom cup holders must accommodate specific cup sizes and shapes. If manufacturing tolerances are not tightly controlled, holders may be too tight (damaging cups) or too loose (failing to secure them). Require prototypes and dimensional drawings with acceptable tolerances before mass production.

Inadequate Durability Testing

Many suppliers skip real-world testing for temperature resistance, impact strength, or long-term wear. Without proper stress testing, cup holders may crack, warp, or lose elasticity. Insist on performance testing reports and conduct in-house drop, temperature, and cycle tests.

Inconsistent Finishing and Aesthetics

For branded or visible applications, surface finish matters. Issues like mold lines, uneven textures, color variations, or paint chipping can undermine brand perception. Establish detailed finish requirements and conduct pre-shipment inspections.

Intellectual Property-Related Pitfalls

Unprotected Designs and Reverse Engineering

Sharing design files without proper safeguards exposes your custom design to copying. Overseas manufacturers, in particular, may replicate and sell your cup holder design to competitors. Use Non-Disclosure Agreements (NDAs) and register design patents where possible.

Supplier Ownership of Tooling

If the supplier owns the mold or tooling used to produce your cup holder, they may claim rights to use it for other clients. Ensure contracts clearly state that tooling is customer-owned and include clauses preventing unauthorized use.

Infringement of Existing IP

Custom designs may unintentionally resemble patented cup holder mechanisms or aesthetic designs. Failure to conduct an IP clearance search could result in cease-and-desist letters or legal action. Work with legal counsel to assess freedom-to-operate before finalizing designs.

Lack of Trademark Protection on Branded Products

If your cup holder features logos or unique branding, failing to trademark these elements can leave your brand vulnerable. Ensure all visible branding is legally protected in your target markets before production begins.

Avoiding these pitfalls requires thorough due diligence, clear contractual agreements, and proactive quality and IP management throughout the sourcing process.

Logistics & Compliance Guide for Custom Cup Holders

This guide outlines the essential logistics and compliance considerations when manufacturing, shipping, and selling custom cup holders. Adherence to these guidelines ensures smooth operations, regulatory compliance, and customer satisfaction.

Product Design & Material Compliance

Custom cup holders must be designed with safety, durability, and environmental regulations in mind. Materials used should comply with relevant standards such as FDA regulations if the product comes into contact with food or beverages (e.g., silicone or plastic components). Ensure all materials are free from hazardous substances like phthalates, lead, and BPA, meeting REACH (EU) and CPSIA (U.S.) requirements. Flame resistance standards may also apply depending on the intended use (e.g., automotive applications).

Manufacturing & Quality Control

Partner with manufacturers that follow ISO 9001 or equivalent quality management systems. Implement clear product specifications and conduct regular quality audits. Each batch should undergo inspection for structural integrity, fit compatibility with common cup sizes, and resistance to heat or UV degradation. Maintain documentation of quality checks and corrective actions for traceability.

Labeling & Packaging Requirements

All custom cup holders must have accurate labeling, including product identification, country of origin, material composition, and any required safety warnings (e.g., “Not for children under 3” if small parts exist). Packaging should be durable to prevent damage during transit and comply with regional packaging waste directives (e.g., EU Packaging Waste Directive). Use recyclable materials where possible and include appropriate recycling symbols.

Import/Export Regulations

When shipping internationally, ensure compliance with customs regulations in both the origin and destination countries. Accurately classify the product using the correct HS (Harmonized System) code—typically under 3926.90 (plastic articles of apparel or accessories) or 8708.29 (accessories for vehicles). Prepare all necessary documentation, including commercial invoices, packing lists, and certificates of origin. Be aware of import duties, taxes, and any anti-dumping measures that may apply.

Transportation & Logistics

Choose appropriate shipping methods (air, sea, or ground) based on order volume, urgency, and cost. Use secure packaging to prevent shifting or damage during transit. For large orders, consider container freight or LTL (less-than-truckload) shipping with proper load stabilization. Partner with reliable freight forwarders and track shipments in real time. Maintain insurance coverage for loss or damage.

Environmental & Sustainability Standards

Assess the environmental impact of your supply chain. Opt for suppliers with sustainable practices and consider carbon footprint reduction strategies, such as consolidating shipments or using eco-friendly materials. Some regions require producers to participate in Extended Producer Responsibility (EPR) programs for packaging or plastic waste. Stay informed about upcoming green regulations that may affect distribution.

Regulatory Certifications

Obtain any required certifications based on the market and application. For automotive cup holders, compliance with FMVSS (Federal Motor Vehicle Safety Standards) or ECE regulations may be necessary. For retail consumer goods, ensure conformity with local consumer product safety laws. Keep certification records up to date and readily available for audits.

Returns & Reverse Logistics

Establish a clear returns policy that complies with local consumer protection laws (e.g., 14-day return window in the EU). Design a reverse logistics process to handle defective or unwanted items efficiently, including inspection, refurbishment, or recycling. Communicate return instructions clearly to customers to minimize logistical errors.

By following this guide, businesses can ensure their custom cup holders are delivered safely, legally, and sustainably across global markets.

In conclusion, sourcing custom cup holders requires careful consideration of several key factors including material quality, design flexibility, production capabilities, cost efficiency, and supplier reliability. Whether for automotive, marine, promotional, or industrial applications, custom cup holders should meet both functional needs and aesthetic preferences. By partnering with reputable manufacturers who offer prototyping, customization options, and scalability, businesses can ensure a product that enhances user experience and aligns with brand standards. Additionally, evaluating lead times, minimum order quantities, and sustainability practices contributes to a more strategic and responsible sourcing decision. Ultimately, investing time in thorough supplier vetting and design refinement leads to a durable, practical, and brand-enhancing solution.