The global automotive interior market is undergoing significant transformation, driven by rising consumer demand for personalized and premium vehicle experiences. According to Mordor Intelligence, the automotive interior market was valued at USD 97.4 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. A key segment within this expansion is custom car headliners, where consumers and OEMs alike are increasingly prioritizing acoustic insulation, aesthetic customization, and material innovation. As vehicles evolve into personalized lifestyle spaces, the demand for high-quality, tailor-fit headliner solutions has intensified. This growing trend has elevated the prominence of specialized manufacturers capable of blending advanced materials like non-woven fabrics, foam laminates, and eco-friendly composites with precise dimensional accuracy. Backed by industry growth and shifting consumer preferences, the following list highlights the top 9 custom car headliner manufacturers leading innovation, scalability, and design excellence in this niche yet critical segment of automotive interiors.

Top 9 Custom Car Headliner Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Roof Linings for Vintage Cars

Domain Est. 1999

Website: legendaryautointeriors.com

Key Highlights: 30-day returnsHeadliners for Classic Cars. Our authentic headliners are made to fit the original manufacturer specifications for your car’s specific make, model, and year….

#2 Products

Domain Est. 2015

Website: kasai-na.com

Key Highlights: Kasai is a full-service tier 1 automotive interior and exterior trim supplier providing Automotive Headliners, Vehicle Door Trims, Luggage & Trunk Trim….

#3 Headliner & Headlining Options for Cars, Trucks, and Wagons

Domain Est. 1999

Website: automotiveinteriors.com

Key Highlights: ABS Headliner Boards. Designed to replace your original automotive headliner board.Can be ordered with or without fabric. Vacuumed formed for a custom fit….

#4 Classic Car Headliner Replacements

Domain Est. 2001

Website: collectorsautosupply.com

Key Highlights: Free delivery 60-day returnsUpgrade the interior of your classic vehicle with a replacement headliner from Collectors Auto Supply! We have headliners for various classic cars and ….

#5 Classic Car Headliner Replacement & Restoration Kits

Domain Est. 2004

Website: newarkauto.com

Key Highlights: Free delivery 90-day returnsComplete headliner replacement kits for classic car restoration. Free fabric samples available. Pre-formed for perfect fit and authentic appearance….

#6 Auto Headliners

Domain Est. 2012

Website: ocautocarpets.com

Key Highlights: 4-day delivery · 180-day returnsWe are proud to offer the highest quality replacement headliners manufactured by ACME Headlining Co and made to fit like the original. In most case…

#7 AUTOMOTIVE

Domain Est. 2014

Website: texasfabricsandfoam.com

Key Highlights: 5–8 day delivery 14-day returnsSilver Lining foam backed headliner fabric comes in a variety of different colors and is perfect for use in just about any automobile….

#8 Starlight Headliner

Domain Est. 2021

Website: starlightcustom.com

Key Highlights: All Starlight products are made with authentic Fiber Optic lights, designed to be integrated directly into the headliner….

#9 Luxury Headliner Upholstery, Restoration & Customization

Domain Est. 2024

Website: supremeseamsautomotive.com

Key Highlights: Supreme Seams offers luxury and vintage car headliner restoration & custom headliner upholstery in New York & Connecticut….

Expert Sourcing Insights for Custom Car Headliner

2026 Market Trends for Custom Car Headliner

Rising Demand for Personalization and Luxury Upgrades

By 2026, the custom car headliner market is expected to be driven significantly by consumer demand for vehicle personalization. As automakers offer more standardized interiors, car owners are turning to aftermarket modifications to express individuality. Custom headliners—featuring unique fabrics like Alcantara, suede, color-matching, embroidery, or ambient lighting integration—are becoming key luxury upgrades. This trend is particularly strong among electric vehicle (EV) owners and luxury sedan/SUV drivers seeking a premium, tailored cabin experience.

Integration with Smart and Ambient Interior Technologies

The convergence of interior styling and smart technology will shape headliner innovation in 2026. Custom headliners are increasingly incorporating ambient lighting systems, integrated speakers, or even heads-up display projections. Some high-end models may include smart fabric sensors or micro-LED skies that simulate daylight or starry nights. These tech-enhanced headliners cater to consumers looking for immersive, multisensory driving environments, especially in EVs where quiet cabins emphasize interior quality.

Growth in DIY and Online Customization Platforms

The rise of e-commerce and digital design tools is empowering consumers to design and order custom headliners online. By 2026, platforms offering 3D visualization, material samples, and precise fitment calculators will lower entry barriers for DIY installations. This trend is supported by improved kits with peel-and-stick adhesives and modular designs, making professional-level results accessible to amateur enthusiasts and expanding market reach beyond traditional upholstery shops.

Sustainability and Eco-Friendly Material Innovation

Environmental consciousness will influence material choices in the custom headliner sector. By 2026, demand for sustainable fabrics such as recycled polyester, plant-based foams, and low-VOC adhesives is expected to grow. Brands emphasizing eco-certifications and transparent supply chains will gain competitive advantage, particularly among younger, environmentally aware consumers. This shift aligns with broader automotive trends toward green interiors and circular economy practices.

Expansion Driven by EV and Specialty Vehicle Markets

The booming electric vehicle market presents a major growth opportunity. EV owners often prioritize cabin comfort and aesthetics, making custom headliners a popular enhancement. Additionally, the rise of adventure vans, camper conversions, and specialty RVs will fuel demand for durable, sound-dampening, and thermally insulated custom headliners. Niche segments like car audio enthusiasts and show car builders will continue to drive innovation in acoustics and visual design.

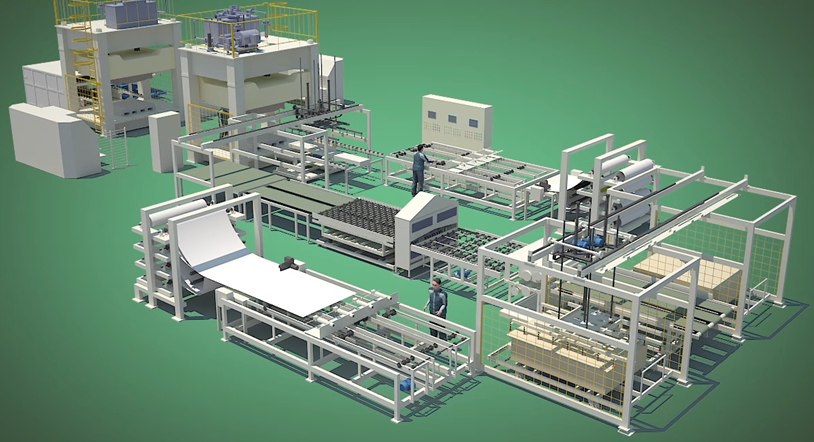

Supply Chain and Manufacturing Advancements

Advancements in digital manufacturing, such as automated cutting and CNC foam shaping, will improve precision and reduce lead times for custom headliners by 2026. Localized production hubs and on-demand manufacturing models will enhance scalability and reduce shipping costs. These efficiencies will make custom solutions more accessible and affordable, supporting broader market adoption across mid-tier vehicle segments.

Common Pitfalls When Sourcing Custom Car Headliners (Quality and Intellectual Property)

Sourcing custom car headliners involves balancing aesthetics, functionality, and legal compliance. However, businesses often encounter significant pitfalls related to quality control and intellectual property (IP) rights. Understanding these risks is crucial to avoid costly delays, product failures, or legal disputes.

Quality-Related Pitfalls

Inconsistent Material Quality

Suppliers may use substandard fabrics, foam, or adhesives to cut costs, leading to premature sagging, discoloration, or delamination. Without strict material specifications and third-party testing, the final product may not meet durability or aesthetic expectations.

Poor Fit and Dimensional Accuracy

Custom headliners must precisely match the vehicle’s roof contour. Inaccurate molds or CAD data from the supplier can result in ill-fitting headliners that require manual adjustments, increasing labor costs and reducing customer satisfaction.

Inadequate Craftsmanship and Finishing

Low-cost manufacturers may lack skilled labor, resulting in visible seams, uneven stitching, or improper padding. These defects compromise both appearance and acoustic performance, undermining the premium nature of custom interiors.

Lack of Environmental and Safety Compliance

Some suppliers fail to adhere to automotive-grade standards for flammability (e.g., FMVSS 302), VOC emissions, or recyclability. Using non-compliant materials can lead to regulatory issues or safety hazards in end-use vehicles.

Intellectual Property-Related Pitfalls

Unauthorized Use of OEM Designs

Copying headliner patterns, textures, or trims from original equipment manufacturers (OEMs) without permission infringes on design patents or copyrights. This exposes the buyer to legal action, product recalls, and reputational damage.

Supplier Ownership of Custom Tooling and Designs

Some suppliers retain ownership of molds, dies, or digital designs created during production. This limits your ability to switch manufacturers or scale production and may result in unexpected licensing fees.

Lack of IP Assignment Agreements

Without a formal contract stating that all IP developed during the sourcing process (e.g., custom patterns, embroidery designs) is assigned to the buyer, the supplier may claim rights to reuse or resell your proprietary designs.

Counterfeit or Gray Market Components

Suppliers may incorporate counterfeit trims, logos, or branded fabrics (e.g., Alcantara®) without proper licensing. This not only violates IP laws but also risks brand dilution and consumer mistrust.

Avoiding these pitfalls requires thorough due diligence, clear contractual agreements, and ongoing quality oversight throughout the sourcing process.

Logistics & Compliance Guide for Custom Car Headliners

Creating and distributing custom car headliners involves multiple logistical and regulatory considerations to ensure smooth operations, customer satisfaction, and legal compliance. This guide outlines key aspects to manage throughout the supply chain.

Product Design and Material Sourcing

Select materials that meet automotive safety and environmental standards, such as flame-retardant fabrics compliant with FMVSS 302 (Federal Motor Vehicle Safety Standard 302) in the U.S. or equivalent regulations in other regions (e.g., ECE R118 in Europe). Ensure all textiles, adhesives, and foams are sourced from reputable suppliers with documentation for material composition and compliance.

Manufacturing and Quality Control

Implement standardized production processes to maintain consistency in fit, finish, and durability. Conduct in-process and final inspections to verify product accuracy against vehicle-specific templates. Maintain traceability for materials and production batches to support recalls or compliance audits if necessary.

Packaging and Labeling

Use protective packaging to prevent creasing, dust, or moisture damage during transit. Clearly label packages with product details, vehicle compatibility (make, model, year), care instructions, and compliance markings (e.g., fire safety labels). Include bilingual labeling where required by local regulations.

Domestic and International Shipping

Choose reliable freight carriers experienced in automotive parts logistics. For international shipments, prepare accurate commercial invoices, packing lists, and certificates of origin. Classify products under the correct Harmonized System (HS) code—typically under heading 8708 (parts and accessories for motor vehicles). Be aware of import duties, taxes, and restrictions in target markets.

Regulatory Compliance

Ensure products comply with regional automotive regulations:

– United States: FMVSS 302 (flammability)

– European Union: ECE R118 (flammability), REACH (chemical safety), and RoHS (hazardous substances)

– Canada: Canada Motor Vehicle Safety Standard (CMVSS) 302

– Other Markets: Verify local requirements in countries such as Australia (ADR), Japan (MLIT), or South Korea (KOR)

Maintain technical files and test reports to demonstrate compliance upon request.

Customs Clearance and Documentation

Partner with customs brokers to streamline import/export procedures. Provide complete documentation, including:

– Bill of lading or airway bill

– Commercial invoice with declared value

– Packing list

– Compliance certificates (e.g., flammability test reports)

– Importer Security Filing (ISF) for U.S. shipments, if applicable

Ensure the declared value reflects fair market value to avoid delays or penalties.

Inventory and Order Fulfillment

Manage inventory using a warehouse management system (WMS) to track stock levels, vehicle-specific variants, and turnover rates. Optimize storage conditions to protect sensitive materials from humidity and temperature extremes. Fulfill orders promptly with accurate documentation and tracking.

Returns and Reverse Logistics

Establish a clear return policy for defective or incorrect headliners. Set up a process for inspecting returned items, restocking (if suitable), or disposal in compliance with environmental regulations. Minimize waste through recycling programs for foam and fabric scraps.

Environmental and Sustainability Practices

Adopt eco-friendly practices by using recyclable or biodegradable packaging and sourcing sustainable materials. Comply with waste disposal regulations for manufacturing byproducts. Consider certifications such as ISO 14001 to demonstrate environmental responsibility.

Recordkeeping and Audits

Maintain records of supplier certifications, quality inspections, shipping documents, and compliance test results for at least five years. Conduct regular internal audits to ensure adherence to logistics and compliance protocols.

By following this guide, businesses can ensure efficient, compliant, and customer-focused operations in the custom car headliner market.

In conclusion, sourcing a custom car headliner requires careful consideration of materials, craftsmanship, compatibility, and supplier reliability. Whether restoring a classic vehicle, upgrading for aesthetics, or improving insulation and sun protection, selecting the right headliner involves balancing quality, cost, and lead time. Partnering with a reputable supplier who offers customization options, uses durable and automotive-grade materials like cloth, suede, or vinyl, and provides precise fitment is essential. Additionally, verifying customer reviews, requesting samples, and confirming warranty or return policies can help ensure satisfaction. Ultimately, a well-sourced custom headliner enhances both the interior appearance and comfort of a vehicle, adding value and a personalized touch to the driving experience.