The global curved steel roof manufacturing industry is experiencing robust growth, driven by rising demand for aesthetically appealing, durable, and sustainable building solutions in both commercial and industrial sectors. According to Grand View Research, the global metal roofing market was valued at USD 31.6 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. This growth is fueled by increased construction activities, especially in emerging economies, and a shift toward energy-efficient building materials that curved steel roofs inherently support through improved thermal performance and design flexibility. As architects and developers increasingly embrace innovative structural forms, curved steel roofing systems have emerged as a preferred choice for iconic buildings, stadiums, airports, and modern industrial facilities. With rising investments in infrastructure and green building technologies, the demand for high-quality, precision-engineered curved steel roof solutions continues to climb—pushing leading manufacturers to enhance fabrication capabilities, material strength, and customization options. In this evolving landscape, eight manufacturers have distinguished themselves through technological innovation, global reach, and consistent quality—shaping the future of architectural steel roofing.

Top 8 Curved Steel Roof Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 ATAS International, Inc.

Domain Est. 1996

Website: atas.com

Key Highlights: ATAS International, an American, family-owned company with global reach, is a leading, manufacturer of metal walls, metal roof systems, accessories & more….

#2 Berridge Manufacturing Co.

Domain Est. 1996

Website: berridge.com

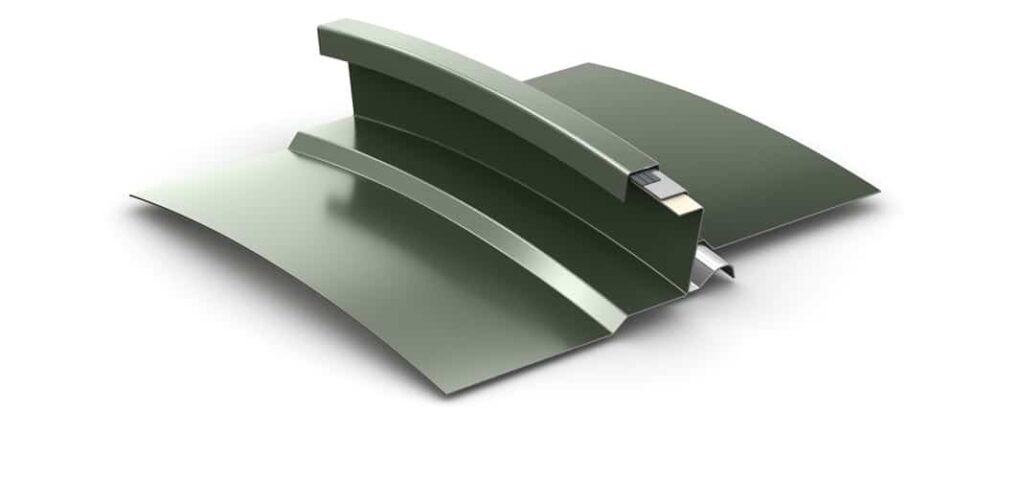

Key Highlights: The Berridge Curved Zee-Lock Panels epitomize architectural innovation, offering a seamless combination of form and function for various real-world metal roof ……

#3 McElroy Metal

Domain Est. 1996

Website: mcelroymetal.com

Key Highlights: McElroy Metal is the leading manufacturer of metal roofing, metal siding, and substructural components with locations across the United States. Learn more….

#4 GAF Roofing

Domain Est. 1996

Website: gaf.com

Key Highlights: As North America’s largest roofing manufacturer, GAF is an industry leader that produces quality, innovative roofing materials….

#5 Drexel Metals

Domain Est. 1996

Website: drexmet.com

Key Highlights: A metal roof provides superior strength and is virtually maintenance-free; making it the premier choice for protecting your home against the elements….

#6 High Snap

Domain Est. 1996

Website: pac-clad.com

Key Highlights: PAC-CLAD high snap-on standing seam metal roofing panel system is used with curved, concave, or convex radius roofs, also ideal for roof transitions….

#7 Curved Metal Roof Panels

Domain Est. 1997

Website: mbci.com

Key Highlights: MBCI offers three curved metal roofing systems that can be installed over a solid deck or open framing. Request a quote today….

#8 Curved Metal Roofing

Domain Est. 2015

Website: westernstatesmetalroofing.com

Key Highlights: Elevate your custom designs with curved metal roofing. Achieve architectural forms, seamless curves, and modern aesthetics without compromising durability….

Expert Sourcing Insights for Curved Steel Roof

H2: Projected Market Trends for Curved Steel Roofs in 2026

The global curved steel roof market is poised for significant transformation by 2026, driven by advancements in architectural design, sustainability demands, and industrial innovation. As construction practices evolve, curved steel roofing—valued for its durability, aesthetic versatility, and structural efficiency—is gaining traction across commercial, industrial, and high-end residential sectors. Below are the key market trends expected to shape the industry in 2026:

1. Rising Demand in Commercial and Public Infrastructure

Curved steel roofs are increasingly favored in airports, sports arenas, exhibition centers, and cultural institutions due to their ability to create expansive, column-free interiors and iconic visual profiles. Governments and private developers are investing in landmark projects, especially in emerging economies, fueling demand for architecturally expressive roofing solutions. This trend is expected to accelerate through 2026, particularly in regions like Asia-Pacific and the Middle East.

2. Advancements in Prefabrication and Modular Construction

The integration of digital fabrication technologies—such as Building Information Modeling (BIM), 3D modeling, and CNC bending—is streamlining the production of curved steel panels. Off-site prefabrication reduces construction time, minimizes waste, and improves precision, making curved steel roofs more cost-effective and accessible. By 2026, modular curved systems are anticipated to dominate new construction projects, especially in urban renewal and industrial developments.

3. Emphasis on Sustainability and Energy Efficiency

Environmental regulations and green building certifications (e.g., LEED, BREEAM) are pushing developers to adopt energy-efficient roofing solutions. Curved steel roofs, especially when combined with cool roofing coatings, photovoltaic integration, and rainwater harvesting systems, contribute to improved thermal performance and reduced carbon footprints. The trend toward net-zero buildings will further boost demand for sustainable curved steel roofing by 2026.

4. Growth in Emerging Markets

Rapid urbanization in countries like India, Indonesia, and Saudi Arabia is driving infrastructure development that favors durable and low-maintenance materials. Curved steel roofs offer resilience against extreme weather and long life cycles, making them ideal for hot, humid, or coastal environments. Increased foreign direct investment and public-private partnerships are expected to expand market penetration in these regions by 2026.

5. Technological Innovation in Coatings and Materials

Developments in anti-corrosion coatings (e.g., zinc-aluminum alloys, PVDF finishes) and high-strength, lightweight steel alloys are enhancing the longevity and performance of curved roofs. These innovations reduce lifecycle costs and maintenance needs, making steel a competitive option against traditional roofing materials. By 2026, smart coatings with self-cleaning or thermal-reflective properties may become standard in premium installations.

6. Customization and Aesthetic Appeal

Architects and developers are increasingly using curved steel roofs to create distinctive, futuristic designs. The flexibility of steel allows for complex geometries and smooth contours, supporting the trend toward biomimicry and organic architecture. As customization becomes more affordable through digital manufacturing, demand for bespoke curved roofing solutions is expected to grow, particularly in luxury residential and boutique commercial developments.

Conclusion

By 2026, the curved steel roof market will be shaped by a confluence of technological innovation, sustainability imperatives, and evolving architectural preferences. With expanding applications across sectors and geographies, the market is projected to experience robust growth, supported by improvements in manufacturing efficiency and material science. Stakeholders who invest in design flexibility, eco-friendly practices, and digital integration will be best positioned to capitalize on these emerging trends.

Common Pitfalls When Sourcing Curved Steel Roofing (Quality and Intellectual Property)

Sourcing curved steel roofing presents unique challenges that, if overlooked, can lead to compromised performance, legal risks, and increased costs. Here are critical pitfalls related to quality and intellectual property (IP) to watch for:

Inadequate Material Quality and Specifications

Suppliers may offer substandard steel that lacks the required tensile strength, corrosion resistance, or coating integrity, leading to premature failure. Always verify material certifications (e.g., ASTM or ISO standards), galvanization levels (e.g., G90), and paint systems (e.g., PVDF or SMP) to ensure long-term durability, especially in harsh environments.

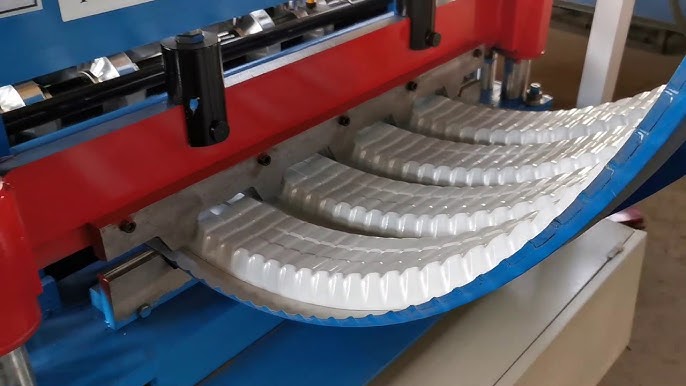

Poor Forming and Curving Precision

Improper rolling or pressing techniques can result in inconsistent curvature, surface deformation, or micro-cracking in the steel’s coating. These flaws compromise both aesthetics and weather resistance. Confirm that suppliers use precision CNC-controlled roll-forming equipment and conduct rigorous in-process quality checks.

Lack of Structural Performance Data

Some suppliers may not provide engineering data or load calculations for curved profiles, making it difficult to verify compliance with local building codes. Request certified performance data, including wind uplift ratings and deflection limits, backed by third-party testing.

Misrepresentation of Coating and Finish Durability

Beware of exaggerated claims about paint longevity or color retention. Inferior finishes can fade, chalk, or peel prematurely. Insist on manufacturer warranties for both the coating and substrate, and verify the finish is suitable for the project’s geographic and environmental conditions.

Intellectual Property (IP) Infringement Risks

Using a curved profile design that is patented or trademarked by another manufacturer exposes your project to legal liability. Always confirm that the supplier owns the rights to the profile design or has proper licensing. Request IP indemnification clauses in contracts to protect against infringement claims.

Incomplete or Unclear Technical Documentation

Missing or ambiguous shop drawings, installation manuals, or warranty terms can lead to installation errors and disputes. Ensure all documentation is comprehensive, project-specific, and includes clear tolerances and handling instructions.

Failure to Verify Supply Chain Authenticity

Counterfeit or unlicensed products may enter the supply chain, especially with popular curved profiles. Source directly from authorized manufacturers or distributors and request batch traceability and product authentication where available.

Addressing these pitfalls through due diligence, supplier vetting, and contractual safeguards ensures a high-quality, compliant, and legally secure curved steel roofing solution.

Logistics & Compliance Guide for Curved Steel Roof

Product Overview

Curved steel roofs are prefabricated structural roofing systems manufactured from high-strength steel, typically galvanized or coated for corrosion resistance. Their curved profile provides enhanced structural integrity, weather resistance, and architectural appeal. Due to their size, weight, and custom fabrication, special handling, transportation, and regulatory considerations are required.

Material Specifications & Compliance Standards

Curved steel roof components must comply with international and regional standards, including:

– ASTM A653/A653M: Standard specification for steel sheet, zinc-coated (galvanized)

– ASTM A792/A792M: Standard for 55% aluminum-zinc alloy-coated steel sheet

– EN 10346: Continuous hot-dip coated steel flat products for cold forming

– ISO 12944: Corrosion protection of steel structures by protective paint systems

– Local Building Codes: Compliance with regional codes (e.g., IBC, Eurocode, AS/NZS) is mandatory for structural performance, wind uplift, and fire resistance.

Fabrication & Quality Control

- All curved roof panels must be fabricated using CNC roll-forming machines to ensure dimensional accuracy.

- Each batch undergoes quality checks for curvature tolerance (±2 mm per meter), coating thickness, and weld integrity (if applicable).

- Third-party inspection certificates (e.g., SGS, BV) should be provided upon request.

Packaging & Handling Requirements

- Panels are bundled securely with edge protectors and moisture-resistant wrapping to prevent surface damage and corrosion.

- Wooden skids or steel cradles must be used to support the curved profile during lifting and transport.

- Handling with nylon slings or spreader bars is required—avoid direct chain or wire contact to prevent coating damage.

Transportation Logistics

- Vehicle Type: Flatbed or low-bed trailers with adequate length and load capacity.

- Load Securing: Use ratchet straps and dunnage to prevent shifting; cover with waterproof tarpaulins.

- Route Planning: Account for oversized load permits if panel length exceeds local limits (typically >12 meters).

- Delivery Schedule: Coordinate site access times to avoid congestion; confirm unloading resources (e.g., crane, forklift) are available.

Import & Export Compliance

- HS Code: 7308.90 (Other structures and parts of structures, of iron or steel)

- Documentation: Commercial invoice, packing list, bill of lading, certificate of origin, and test reports.

- Customs Clearance: Ensure compliance with destination country regulations (e.g., CE marking in EU, CCC in China).

- Duty & Tariff Classification: Verify based on steel type (coated, alloy content) and end use.

On-Site Storage & Installation Preparation

- Store panels on level, elevated ground with protective padding to avoid moisture contact.

- Keep bundled and covered until installation to prevent dust, debris, or UV degradation of coatings.

- Verify site measurements and structural supports match design specifications before unloading.

Safety & Environmental Compliance

- Follow OSHA (or local equivalent) guidelines for lifting and working at heights during installation.

- Dispose of packaging materials (plastic, wood) in accordance with local environmental regulations.

- Use PPE (gloves, eye protection) when handling sharp or coated metal edges.

Warranty & Certification

- Manufacturer typically offers a 10–25 year warranty on coating and structural integrity, subject to proper installation.

- Provide installation certification to validate warranty terms, including fastener type, sealant use, and alignment compliance.

Contact & Support

For logistics inquiries or compliance documentation, contact the supplier’s logistics department at [email protected] or +1 (800) 555-0199. Technical support is available for on-site verification and compliance audits.

Conclusion on Sourcing Curved Steel Roofing

Sourcing curved steel roofing requires a strategic approach that balances quality, cost, engineering specifications, and supplier reliability. After evaluating options, it is evident that selecting the right supplier involves verifying their capacity to accurately form steel to the required radius and profile, using appropriate machinery and techniques such as roll forming or press braking. Working with manufacturers experienced in custom architectural solutions ensures dimensional accuracy, material durability, and compliance with structural and weather resistance standards.

Additionally, logistical considerations—such as transportation of pre-curved panels to the site and coordination with installation teams—play a critical role in project efficiency. Although curved steel roofing may involve higher initial costs due to customization, its long-term benefits, including longevity, low maintenance, and aesthetic appeal, make it a worthwhile investment for specialized architectural designs.

In conclusion, successful sourcing hinges on early engagement with qualified suppliers, detailed technical specifications, and thorough quality control. A well-sourced curved steel roof not only fulfills functional and design requirements but also contributes to the overall structural integrity and visual impact of the building.