The global diesel engine aftermarket, driven by increasing demand for efficient and compliant heavy-duty vehicle maintenance, continues to expand at a steady pace. According to Mordor Intelligence, the diesel engine market is projected to grow at a CAGR of over 4.2% from 2023 to 2028, fueled by rising freight transport needs and stringent emissions regulations. A critical component in modern diesel engines—especially in Cummins platforms—is the diesel exhaust fluid (DEF) injector, essential for selective catalytic reduction (SCR) systems that reduce nitrogen oxide emissions. As emissions standards tighten worldwide, particularly under EPA and Euro VI regulations, demand for high-performance, reliable DEF injectors has surged. This increasing demand has led to the emergence of several specialized manufacturers focusing on compatibility, durability, and precision in DEF injector production. Based on market analysis and performance metrics, the following six manufacturers stand out as leaders in supplying Cummins-compatible DEF injectors, combining innovation, quality control, and global distribution to meet the needs of OEMs and fleet operators alike.

Top 6 Cummins Def Injector Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Manuals and Technical Documents

Domain Est. 1990

Website: cummins.com

Key Highlights: You can access Cummins Owner’s Manuals and wiring diagrams for engine products by ESN with our Engine Manual Lookup tool. Manual Lookup Tool….

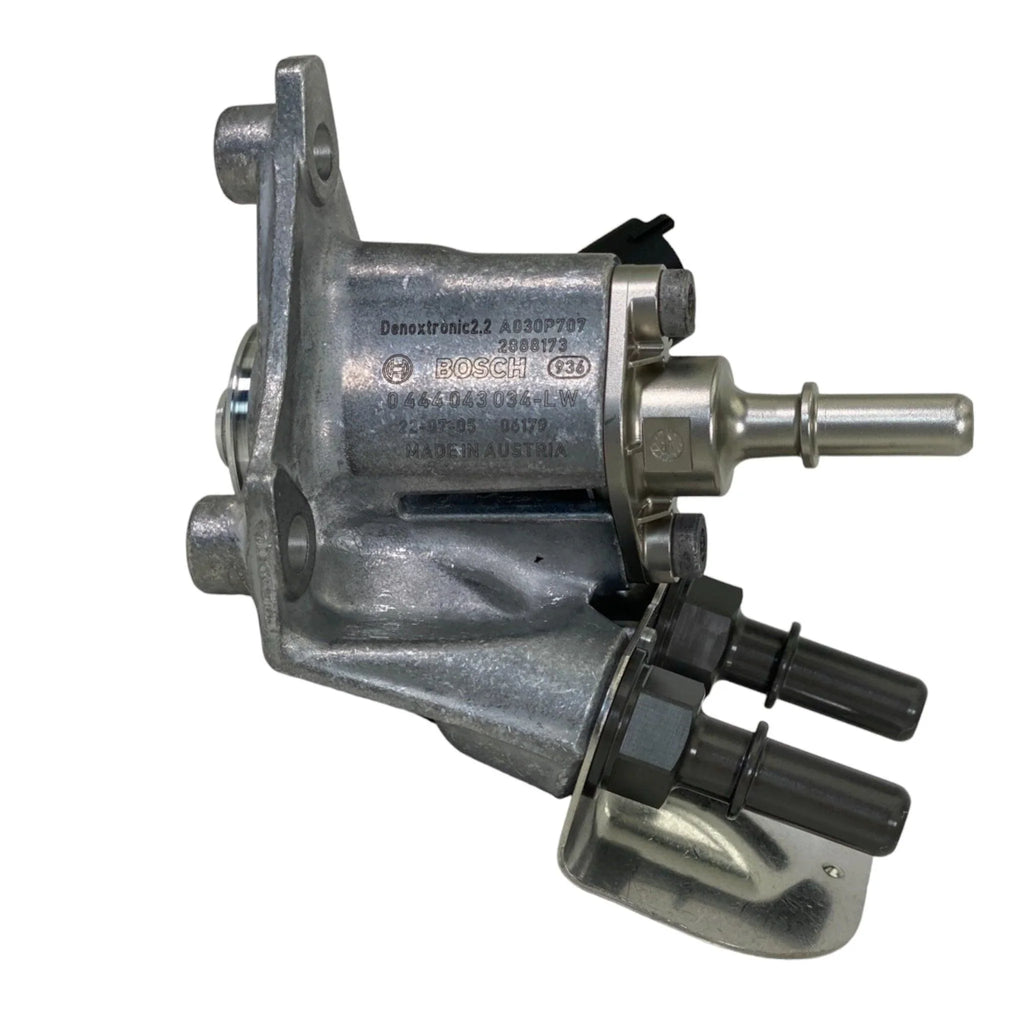

#2 Cummins DEF Doser Injector

Domain Est. 2016

Website: tamerx.com

Key Highlights: In stock Rating 5.0 (4) · $80.87 deliveryTamerx Cummins DEF Doser Injector 2018-2024: OEM 53012607 is built for 2018-2024. Premium quality, fast shipping, and in stock….

#3 Genuine Cummins Parts

Domain Est. 1990

Website: parts.cummins.com

Key Highlights: https://parts.cummins.com is the Genuine online catalog for Holset®, Fleetguard®, Onan and Cummins parts….

#4 Cummins 2880156 / 2880156NX / 2880156RX DEF Doser Injector

Domain Est. 2004

Website: filterserviceandsupply.com

Key Highlights: In stock Free delivery over $500Dinex DinTronic DEF injectors are an exceptional value without sacrificing, quality, fitment, or performance. Free ground shipping within the Contin…

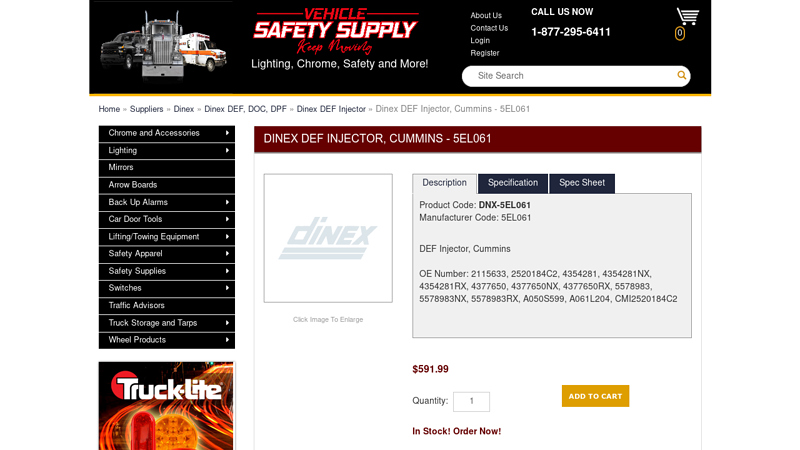

#5 Dinex DEF Injector, Cummins

Domain Est. 2008

Website: vehiclesafetysupply.com

Key Highlights: In stock Free deliveryDinex DEF Injector, Cummins – 5EL061 … In Stock! Order Now! ⚠ Warning : Cancer and Reproductive Harm https://www.p65warnings.ca.gov ……

#6 New RAM 6.7 Cummins DEF Injector (Diesel Exhaust Fluid)

Domain Est. 2010

Website: dalessuperstore.com

Key Highlights: In stock Free deliveryReplace your DEF Injector 4627241AF in 13-19 RAM 6.7 Cummins to maintain optimal emissions. Designed to withstand extreme conditions….

Expert Sourcing Insights for Cummins Def Injector

2026 Market Trends for Cummins DEF Injector

As the global push for cleaner transportation intensifies, the market for Diesel Exhaust Fluid (DEF) injectors—specifically those used in Cummins aftertreatment systems—is poised for significant evolution by 2026. These components are critical to the Selective Catalytic Reduction (SCR) technology mandated in modern diesel engines to meet stringent emissions standards. Several interrelated trends are expected to shape the Cummins DEF injector market in the coming years.

Increasing Stringency of Emissions Regulations

By 2026, global emissions standards, particularly in North America, Europe, and parts of Asia, will become even more rigorous. The U.S. Environmental Protection Agency’s (EPA) Cleaner Trucks Initiative (CTI) and Euro 7 standards in Europe are driving demand for higher precision and reliability in SCR systems. Cummins, as a leading engine manufacturer, will continue to depend on high-performance DEF injectors to ensure compliance. This regulatory pressure will favor OEM and high-quality aftermarket injectors capable of accurate dosing under diverse operating conditions, reducing the tolerance for poor-quality or failing components.

Growth in Heavy-Duty Truck and Off-Highway Equipment Markets

The continued expansion of freight logistics, construction, and mining sectors—despite economic fluctuations—will sustain demand for heavy-duty diesel engines equipped with Cummins SCR systems. The adoption of Cummins-powered Class 8 trucks, buses, and industrial machinery in emerging markets will further increase the installed base of DEF injector-equipped vehicles. As the fleet ages toward 2026, replacement and maintenance needs for DEF injectors will grow, creating a robust aftermarket segment.

Rise of Predictive Maintenance and Connected Diagnostics

By 2026, telematics and onboard diagnostic systems will be more deeply integrated into commercial vehicles. Cummins’ connected engine platforms (e.g., Connected Diagnostics and Remote Programming) will enable real-time monitoring of DEF injector performance. Fleet operators will increasingly rely on predictive maintenance to avoid unplanned downtime. This trend will drive demand for smart injectors or compatible systems that provide early failure warnings, thus increasing the value of OEM and technologically advanced aftermarket injectors with enhanced diagnostics.

Expansion of High-Quality Aftermarket and Remanufactured Solutions

While OEM Cummins DEF injectors will remain the gold standard for reliability, the high cost of replacement will continue to fuel a strong aftermarket. By 2026, remanufactured and third-party injectors with improved engineering, better materials, and compatibility certifications (e.g., OE-spec) will gain market share. Suppliers investing in quality control and warranty support will be well-positioned, especially as independent repair shops and fleet maintenance providers seek cost-effective yet reliable alternatives.

Challenges from Alternative Powertrains

The long-term threat from electric and hydrogen-powered vehicles may temper growth in the diesel engine market. However, by 2026, internal combustion engines—especially those using renewable diesel and biodiesel—will still dominate long-haul and heavy-duty applications. Cummins’ own investments in alternative fuels (e.g., natural gas, hydrogen ICE) do not eliminate the need for SCR systems in many transitional powertrains. Therefore, DEF injector demand will remain resilient, particularly in hybrid or dual-fuel systems where diesel remains a primary energy source.

Focus on Durability and Cold-Weather Performance

DEF injector failures due to crystallization, clogging, and exposure to contaminated fluid remain common pain points. By 2026, manufacturers—including Cummins and its suppliers—will likely emphasize enhanced injector designs that resist DEF deposits and operate reliably in extreme temperatures. Innovations in nozzle materials, heating elements, and dosing algorithms will improve longevity, reducing total cost of ownership and supporting sustainability goals through longer service intervals.

In conclusion, the 2026 market for Cummins DEF injectors will be shaped by tightening emissions rules, fleet growth, digital integration, and aftermarket innovation. While alternative propulsion technologies loom on the horizon, the critical role of SCR systems in current and near-future diesel applications ensures continued demand for high-performance DEF injectors across OEM, replacement, and remanufactured segments.

Common Pitfalls When Sourcing Cummins DEF Injectors (Quality & Intellectual Property)

Sourcing Cummins Diesel Exhaust Fluid (DEF) injectors—critical components in Selective Catalytic Reduction (SCR) systems—can be fraught with risks, especially when quality and intellectual property (IP) concerns are not properly addressed. Falling into these common pitfalls can lead to system failures, regulatory non-compliance, increased downtime, and legal exposure.

1. Purchasing Counterfeit or Non-OEM Parts

One of the most significant risks is unknowingly buying counterfeit DEF injectors. These parts often mimic Cummins branding and packaging but are manufactured without adherence to original equipment specifications.

- Quality Risk: Counterfeits typically use inferior materials and lack precision engineering, leading to poor spray patterns, clogging, and premature failure.

- IP Risk: Distributing or installing counterfeit parts infringes on Cummins’ trademarks and patents, potentially exposing buyers and installers to legal liability.

2. Choosing Low-Cost Aftermarket Alternatives Without Verification

While aftermarket DEF injectors may offer cost savings, many lack proper validation and certification.

- Quality Risk: Substandard manufacturing processes can result in inconsistent performance, unreliable dosing, and damage to the SCR system.

- IP Risk: Some aftermarket manufacturers reverse-engineer Cummins components without licensing, which may violate design patents or utility patents.

3. Sourcing from Unauthorized Distributors or Gray Market Channels

Purchasing from third-party online marketplaces or unverified suppliers increases exposure to non-genuine parts.

- Quality Risk: Lack of traceability and quality control means no assurance of part authenticity or performance reliability.

- IP Risk: Gray market parts may be diverted or reconditioned without Cummins’ authorization, violating distribution agreements and IP protections.

4. Neglecting Part Number and Specification Verification

Cummins DEF injectors vary by engine model, emission standard (e.g., EPA 2010, Euro VI), and calibration requirements.

- Quality Risk: Using an incorrect injector model can cause improper DEF dosing, leading to increased NOx emissions, fault codes, and potential engine derates.

- IP Risk: Unauthorized modifications or adaptations to fit non-approved injectors may infringe on Cummins’ proprietary calibration software and system integration rights.

5. Overlooking Software and Calibration Compatibility

Modern DEF systems rely on integrated software that communicates with the engine control module (ECM).

- Quality Risk: Non-OEM injectors may not support proper calibration, resulting in SCR system malfunctions or diagnostic errors.

- IP Risk: Tampering with or reverse-engineering Cummins’ proprietary software violates copyright and potentially breaches the DMCA (Digital Millennium Copyright Act).

6. Failure to Ensure Compliance with Emissions Regulations

Using non-compliant DEF injectors can compromise the entire emissions control system.

- Quality Risk: Poor injector performance leads to failed emissions tests, fines, and vehicle downtime.

- IP Risk: Circumventing certified emissions components may be interpreted as tampering under EPA or CARB regulations, which also protects Cummins’ certified system IP.

7. Inadequate Warranty and Support from Unverified Suppliers

Non-genuine parts often come with limited or no warranty, and technical support may be nonexistent.

- Quality Risk: Without reliable support, diagnosing and resolving injector issues becomes more difficult and costly.

- IP Risk: Using unsupported components may void Cummins engine warranties and compromise intellectual property-covered service protocols.

Best Practice Recommendation: Always source Cummins DEF injectors through authorized Cummins dealers or certified distributors. Verify part numbers, request certificates of authenticity, and ensure full compliance with emissions and IP regulations to protect your equipment, operations, and legal standing.

Logistics & Compliance Guide for Cummins DEF Injector

This guide outlines key logistics and compliance considerations for handling, transporting, storing, and maintaining Cummins Diesel Exhaust Fluid (DEF) injectors. Adhering to these guidelines ensures optimal performance, regulatory compliance, and system longevity.

Regulatory Compliance

Ensure all operations involving Cummins DEF injectors meet applicable environmental and transportation regulations. Key standards include:

- EPA and CARB Regulations: Confirm DEF injector systems comply with U.S. Environmental Protection Agency (EPA) and California Air Resources Board (CARB) emissions standards under the Clean Air Act.

- ISO 22241 Standards: DEF quality must meet ISO 22241-1 specifications. Use only certified DEF to prevent injector contamination and system failure.

- DOT and Transport Regulations: When shipping injectors or vehicles with installed injectors, follow Department of Transportation (DOT) hazardous materials guidelines, especially if packaging includes residual DEF (classified as non-hazardous but regulated in certain contexts).

Handling and Storage

Proper handling and storage are essential to prevent contamination and ensure injector reliability.

- Clean Environment: Always handle injectors in clean, dry areas. Avoid dust, dirt, and moisture exposure.

- DEF Contamination Prevention: Never expose injector nozzles or connectors to foreign substances. Use protective caps when not in use.

- Temperature Control: Store injectors and associated DEF components between 12°F (−11°C) and 86°F (30°C). Avoid freezing and prolonged exposure to high heat, which can degrade materials.

- Shelf Life: Inspect packaging for expiration dates. Follow Cummins-recommended shelf life for spare parts and avoid using outdated components.

Transportation

Transport DEF injectors safely to prevent mechanical damage and contamination.

- Packaging: Use original Cummins-approved packaging or equivalent protective materials (e.g., anti-static bags, cushioned containers).

- Orientation: Transport injectors in an upright position to prevent fluid leakage or internal damage.

- Documentation: Maintain records of part numbers, batch codes, and compliance certifications for traceability and warranty claims.

Installation and Maintenance

Follow Cummins service guidelines to ensure correct installation and ongoing compliance.

- Trained Technicians: Only certified personnel should install or service DEF injectors using Cummins-recommended tools and procedures.

- Calibration and Testing: After installation, perform system diagnostics and injector calibration using Cummins INSITE™ or equivalent software.

- Preventative Maintenance: Inspect injectors regularly for clogs, leaks, or deposits. Replace according to Cummins maintenance schedules or when fault codes indicate failure.

Environmental and Safety Considerations

- DEF Spill Management: In case of DEF leakage during injector service, clean with water and dispose of waste per local environmental regulations. DEF is non-toxic but can corrode some metals and damage surfaces.

- Recycling and Disposal: Follow Cummins’ end-of-life guidelines for injector disposal. Recycle components where possible through authorized channels to meet environmental compliance.

Documentation and Recordkeeping

- Maintain logs of injector installation dates, service history, replacement parts, and calibration reports.

- Retain compliance documentation, including DEF quality certificates and emissions performance records, for audit readiness.

Adherence to this guide supports reliable operation of Cummins aftertreatment systems and ensures compliance with federal, state, and manufacturer requirements. Always consult the latest Cummins technical bulletins and service manuals for model-specific details.

Conclusion for Sourcing Cummins DEF Injector

Sourcing a Cummins Diesel Exhaust Fluid (DEF) injector requires careful consideration of quality, authenticity, compatibility, and supplier reliability. Given the critical role the DEF injector plays in the Selective Catalytic Reduction (SCR) system—ensuring compliance with emissions standards and optimal engine performance—it is essential to procure components from authorized distributors, OEM-approved suppliers, or reputable aftermarket providers with verifiable track records.

Purchasing genuine Cummins or Cummins-recommended parts ensures durability, correct fitment, and compatibility with the vehicle’s engine management system, reducing the risk of fault codes, reduced fuel efficiency, or environmental compliance issues. Additionally, evaluating pricing, warranty terms, and technical support availability helps mitigate long-term maintenance costs and downtime.

In conclusion, a strategic sourcing approach focused on authenticity, supplier credibility, and total cost of ownership will ensure reliable performance of the Cummins DEF injector, supporting environmental compliance, engine efficiency, and operational uptime.