The global cultured marble market is experiencing steady growth, driven by increasing demand for durable, cost-effective, and aesthetically versatile surfacing solutions in residential and commercial construction. According to Mordor Intelligence, the market is projected to grow at a CAGR of approximately 5.2% from 2023 to 2028, with rising renovation activities and the popularity of seamless, low-maintenance surfaces acting as key growth drivers. As cultured marble installations expand, so does the need for reliable maintenance and restoration—spurring demand for high-quality repair kits. This growing after-sales segment has led to the emergence of specialized manufacturers offering comprehensive solutions for chips, scratches, and surface degradation. In response to industry needs, we’ve identified the top 8 cultured marble repair kit manufacturers leveraging innovation, product performance, and market reach to support longevity and aesthetics in cultured marble surfaces.

Top 8 Cultured Marble Repair Kit Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Commercial Cultured Marble Manufacturer

Domain Est. 2010

Website: imitoday.com

Key Highlights: Leading commercial cultured marble manufacturer for hospitality, multi-family & senior living. Groutless shower surrounds. Made in USA. Marriott approved….

#2 Care for Cultured Marble Surfaces

Website: mmproducts.ca

Key Highlights: DIY Repair Kits: Use a cultured marble repair kit available at most hardware stores. Follow the manufacturer’s instructions carefully. Professional Help ……

#3 Cultured Marble and Cultured Granite Care and Maintenance

Domain Est. 2000

Website: virginiamarble.com

Key Highlights: Gel Coat Repair Kit. Virginia Marble is willing to provide a gel coat repair kit to any customer. The kit includes instructions and the products needed. If ……

#4 Cultured Marble Specialist

Domain Est. 2004

Website: cmsutah.com

Key Highlights: Cultured Marble Specialist manufactures and installs cultured marble products. Contact us today for a quote.Missing: repair kit…

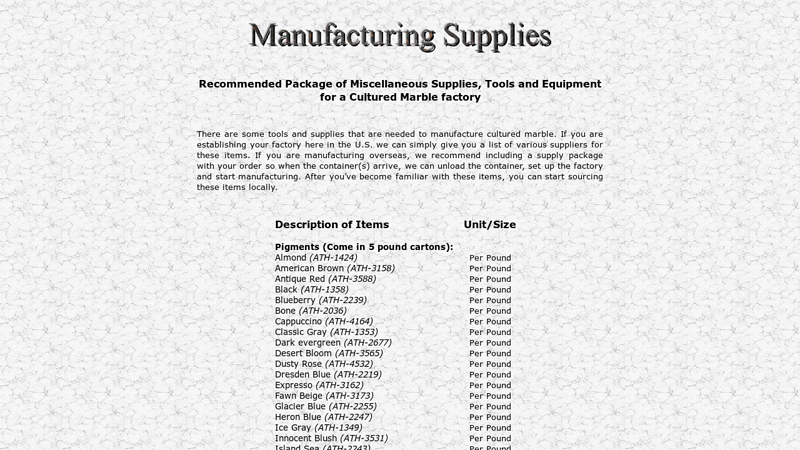

#5 Cultured Marble Manufacturing Supplies

Domain Est. 2005

Website: culturedmarblemolds.com

Key Highlights: Cultured Marble supply prices and mold packages to produce the most fabulous marble, onyx, granite and solid surface products in the world for the bathroom ……

#6 Cultured Marble vs Real Marble

Domain Est. 2008

Website: beyondstonesolutions.com

Key Highlights: Cracks and chips can be repaired with a retail repair kit specifically designed for cultured marble. It may be best, however, to let a ……

#7 MPL Company

Domain Est. 2018

Website: mplcompany.net

Key Highlights: Advanced, durable cultured marble shower panel & pan solutions for high-use shower spaces that look and feel new year after year….

#8 Cultured Marble Customs

Domain Est. 2024

Website: culturedmarblecustoms.com

Key Highlights: At Cultured Marble Customs we redefine luxury with our exquisite range of vanity tops, shower panels, and custom solutions….

Expert Sourcing Insights for Cultured Marble Repair Kit

2026 Market Trends for Cultured Marble Repair Kit

The market for cultured marble repair kits is poised for notable evolution by 2026, driven by shifting homeowner preferences, economic factors, and sustainability concerns. Here are the key trends expected to shape the industry:

1. Rising Demand Due to Cost-Conscious Home Improvements

With home renovation costs continuing to rise and housing inventory remaining tight, more homeowners are opting to refresh existing spaces rather than undergo full remodels. Cultured marble, commonly found in bathrooms and kitchens, often shows wear over time. Repair kits offer an affordable alternative to replacement, making them increasingly attractive. By 2026, this cost-efficiency will drive higher consumer adoption, particularly among DIYers looking to enhance property value without major investment.

2. Growth in DIY Culture and Online Tutorials

The DIY home improvement movement is gaining momentum, fueled by platforms like YouTube, TikTok, and Pinterest. Step-by-step repair videos featuring cultured marble kits are growing in popularity, lowering the perceived difficulty of such projects. By 2026, manufacturers will likely enhance product accessibility through clearer instructions, QR-linked video guides, and beginner-friendly formulations, further expanding their market reach.

3. Innovation in Product Formulations and Ease of Use

To meet consumer demand for professional-looking results, repair kits will evolve with improved materials. Expect advancements in color-matching technology, faster curing resins, and scratch- and stain-resistant finishes. Kits may include smart applicators or pre-mixed components to reduce user error. Brands that prioritize user experience and durability will gain a competitive edge in the 2026 marketplace.

4. Emphasis on Sustainability and Eco-Friendly Materials

Environmental awareness is influencing purchasing decisions across home improvement sectors. By 2026, consumers will increasingly favor repair kits made with low-VOC (volatile organic compounds) resins, recyclable packaging, and non-toxic pigments. Brands highlighting sustainable practices and long-term waste reduction (via repair vs. replacement) will resonate more strongly with eco-conscious buyers.

5. Expansion of E-Commerce and Niche Retail Channels

Online marketplaces like Amazon, Home Depot, and specialty home repair websites will dominate distribution. Cultured marble repair kits will benefit from enhanced product listings, customer reviews, and targeted advertising. By 2026, direct-to-consumer (DTC) models may emerge, allowing brands to offer personalized support and subscription-based refill options for recurring users.

6. Aging Housing Stock Driving Repair Needs

The average age of U.S. homes continues to increase, with many properties from the 1970s–1990s featuring cultured marble fixtures. As these materials degrade, demand for effective, accessible repair solutions will grow. The 2026 market will reflect this demographic reality, with repair kits positioned as essential maintenance tools for older homes.

In conclusion, the 2026 cultured marble repair kit market will be shaped by affordability, DIY empowerment, product innovation, sustainability, and digital commerce. Companies that align with these trends will be well-positioned to capture growing consumer interest in home preservation and value-added improvements.

Common Pitfalls When Sourcing a Cultured Marble Repair Kit (Quality and Intellectual Property)

Sourcing a cultured marble repair kit requires careful consideration to ensure you receive a high-quality product that meets performance expectations and complies with intellectual property (IP) regulations. Below are some common pitfalls buyers and distributors often encounter in both quality and IP aspects.

Poor Quality Materials and Inconsistent Performance

One of the most frequent issues when sourcing cultured marble repair kits is receiving products made from substandard materials. Low-quality resins, fillers, and pigments can lead to mismatched colors, poor adhesion, and premature cracking or yellowing. These deficiencies result in unsatisfactory repairs that fail to blend seamlessly with the existing surface, diminishing customer satisfaction and increasing rework costs.

Suppliers, especially those from unverified sources, may cut corners to reduce manufacturing costs. This can include using outdated formulations or improper curing agents that compromise the durability of the repair. Without proper quality control processes, batches may vary significantly in consistency, making long-term supply reliability a challenge.

Lack of Technical Support and Application Guidance

A high-quality repair kit should come with detailed instructions, technical data sheets, and access to expert support. Many sourced kits—particularly from generic or non-specialist manufacturers—lack comprehensive guidance, leading to improper application. This increases the risk of failed repairs and customer complaints.

Without proper curing times, mixing ratios, or surface preparation instructions, even experienced technicians may struggle to achieve professional results. This pitfall is often overlooked during sourcing but becomes apparent only after the product is in use.

Intellectual Property Infringement Risks

Another significant concern when sourcing repair kits is intellectual property (IP) violations. Some manufacturers replicate proprietary formulations, branding, or packaging from well-known brands without authorization. While these knock-off kits may appear identical and offer lower prices, they can expose buyers to legal liability.

Using or distributing a repair kit that infringes on patented technology or trademarked designs may lead to cease-and-desist orders, product seizures, or lawsuits. Additionally, counterfeit products often lack the rigorous testing and quality assurance of genuine branded kits, further increasing performance risks.

Inadequate Regulatory Compliance and Safety Data

Low-cost suppliers may not provide complete Safety Data Sheets (SDS) or comply with regional regulations such as REACH (EU) or TSCA (USA). This not only poses health and safety risks but can also result in customs delays or import bans. Non-compliant kits may contain restricted chemicals or lack proper labeling, making them unsuitable for professional use in regulated markets.

Final Thoughts

To avoid these pitfalls, it’s crucial to source cultured marble repair kits from reputable suppliers with verifiable quality certifications, transparent manufacturing practices, and a clear IP compliance record. Conducting due diligence—such as requesting samples, reviewing SDS documentation, and verifying brand authenticity—can help ensure you receive a reliable, legally sound product that delivers professional results.

Logistics & Compliance Guide for Cultured Marble Repair Kit

Product Classification & Regulatory Overview

Cultured marble repair kits typically consist of resin-based compounds (such as polyester or epoxy), pigments, hardeners, and application tools. These products are generally classified as chemical repair materials and may be subject to transportation, safety, and environmental regulations depending on formulation and jurisdiction.

Shipping & Transportation Requirements

Repair kits containing reactive resins and hardeners may be regulated under hazardous materials (hazmat) guidelines when shipped by air, sea, or ground. Key considerations include:

– UN Classification: Components with flammable or reactive properties may fall under UN 1866 (Flammable Liquid, N.O.S.) or similar classifications.

– Packaging Standards: Must comply with IATA (air), IMDG (sea), or 49 CFR (U.S. ground) requirements, including leak-proof containers, absorbent materials, and proper closures.

– Labeling & Documentation: Hazard labels (e.g., flammable liquid, corrosive) and Shipper’s Declaration for Dangerous Goods are required if components exceed concentration thresholds.

– Non-Hazmat Options: Kits with low volatile organic compound (VOC) content and non-flammable ingredients may qualify for consumer commodity (ORM-D or limited quantity) exemptions.

Safety Data Sheet (SDS) Compliance

An up-to-date Safety Data Sheet compliant with GHS (Globally Harmonized System) must be provided for each chemical component. The SDS must include:

– Hazard identification

– Composition/information on ingredients

– First-aid and firefighting measures

– Handling and storage instructions

– Exposure controls and personal protective equipment (PPE)

– Regulatory information (e.g., OSHA HCS, REACH, WHMIS)

Labeling & Product Marking

All packaging must feature:

– Product name and usage instructions

– Hazard pictograms and signal words (if applicable)

– Manufacturer or distributor contact information

– Lot number and production date

– Net quantity

– Precautionary statements (e.g., “Use with adequate ventilation”)

– Compliance marks (e.g., CE, UKCA, if sold in relevant markets)

Environmental & Disposal Regulations

- VOC Compliance: Ensure formulations meet regional VOC limits (e.g., U.S. EPA, SCAQMD, EU Directive 2004/42/EC).

- Waste Disposal: Unused product and contaminated materials should be disposed of per local hazardous waste regulations (e.g., RCRA in the U.S.).

- Recycling: Packaging should be labeled with appropriate recycling symbols where applicable.

Import/Export Considerations

- Verify import restrictions in destination countries (e.g., Canada’s DSL, EU’s REACH).

- Provide customs documentation including commercial invoice, packing list, and SDS.

- Ensure compliance with TSCA (U.S.) or equivalent chemical inventories.

Storage & Handling Guidelines

- Store in a cool, dry, well-ventilated area away from ignition sources.

- Keep containers tightly closed when not in use.

- Maintain separation from oxidizers and acids.

- Train personnel on spill response and emergency procedures.

Regulatory Updates & Recordkeeping

- Monitor changes in chemical regulations (e.g., EPA, ECHA).

- Maintain records of SDS, compliance certifications, and shipping documents for minimum of 3–5 years as required.

Adherence to this guide ensures safe distribution, regulatory compliance, and consumer protection for cultured marble repair kits globally.

In conclusion, sourcing a cultured marble repair kit requires careful consideration of the specific damage type, product quality, compatibility with your existing surface, and ease of application. A high-quality kit should include all necessary components—such as color-matched resin, hardener, filler, and application tools—to ensure a seamless and durable repair. Reading customer reviews, verifying manufacturer reputation, and choosing kits designed specifically for cultured marble will enhance the likelihood of a successful restoration. Ultimately, investing in a reliable repair kit not only restores the aesthetic appeal of the surface but also extends the lifespan of the fixture, offering a cost-effective alternative to replacement.