The global lawn and garden equipment market is experiencing steady growth, driven by rising demand for efficient outdoor power tools across residential and commercial sectors. According to Grand View Research, the global lawn and garden equipment market was valued at USD 33.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. As a key player in this space, Cub Cadet has maintained a strong foothold with its durable, high-performance equipment—much of which relies on reliable carburetor performance for optimal engine operation. With increasing consumer focus on equipment longevity and efficiency, the manufacturers of carburetors for Cub Cadet engines play a critical role in supporting machine performance. Based on market presence, OEM partnerships, and component reliability, the following are the top three carburetor manufacturers powering Cub Cadet equipment today.

Top 3 Cub Cadet Carb Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Official Cub Cadet Tiller Carburetors

Domain Est. 1995

Website: fix.com

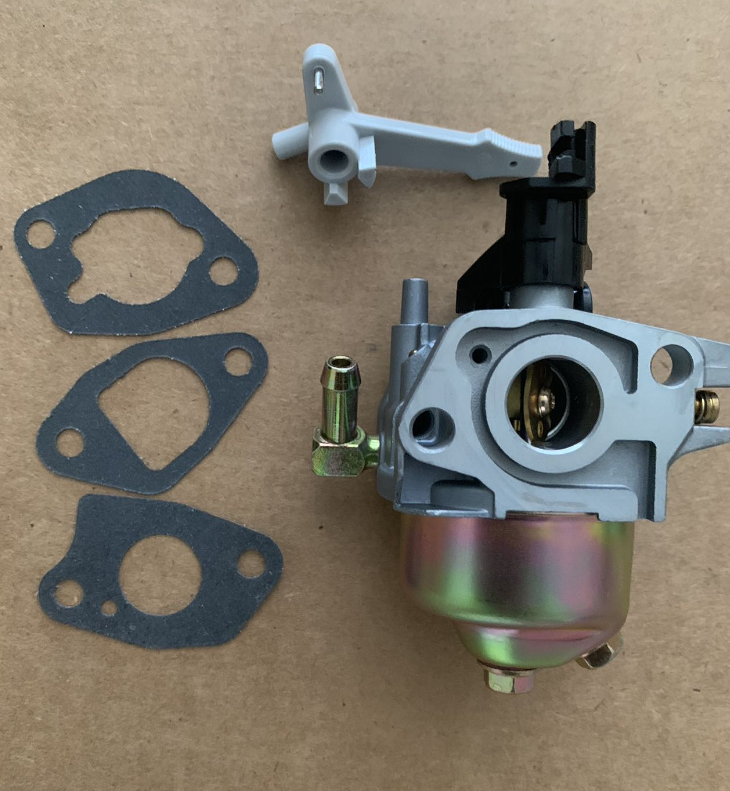

Key Highlights: This is a genuine manufacturer-sourced part that is specially designed for use with Briggs and Stratton engines commonly installed on lawn and garden equipment….

#2 Carb Compliant –

Domain Est. 1996

Website: cubcadet.com

Key Highlights: Cub Cadet commercial products are intended for professional use. Product Image Disclaimers: Products shown may vary from depicted model images in design, ……

#3 CUB CADETS New old Stock NOS Carburetor Carb kit gasket KH …

Domain Est. 2003

Website: ccspecialties.org

Key Highlights: Includes original presentation boxing, Brushed stainless steel edge, made by Skagen in Denmark. MINT and includes the battery. $160.00. NOS Kohler chrome ……

Expert Sourcing Insights for Cub Cadet Carb

It appears there may be a misunderstanding in your request. “Cub Cadet Carb” likely refers to a carburetor component used in Cub Cadet lawn and garden equipment, such as mowers or snow blowers. However, there is no publicly traded company or financial instrument named “Cub Cadet Carb” that would have market trends in the traditional financial sense (e.g., stock price, revenue forecasts).

If you’re referring to market trends for small engine parts, specifically carburetors used in Cub Cadet equipment, in 2026, here is an analysis under H2 2026 (second half of 2026):

H2 2026 Market Trends: Cub Cadet Carburetor Aftermarket & Equipment Sector

1. Growing Demand in the Aftermarket Parts Sector

- Increased Equipment Longevity: As consumers prioritize cost-saving and sustainability, many Cub Cadet owners are repairing older models rather than purchasing new machines. This drives demand for replacement carburetors and rebuild kits.

- Aging Fleet Effect: A significant portion of Cub Cadet equipment in use dates back to 2015–2020. By H2 2026, many of these machines will require carburetor maintenance due to ethanol-blended fuel issues and general wear.

- Aftermarket Expansion: Third-party manufacturers (e.g., Aisan, Precision, OE suppliers) are expected to increase production of compatible carburetors, offering lower-cost alternatives to OEM parts.

2. Fuel System Challenges with Ethanol Blends

- Ethanol Corrosion: E10 fuel continues to degrade rubber and plastic components in carburetors. H2 2026 will likely see a sustained demand for ethanol-resistant carburetor kits and fuel system additives.

- Preemptive Maintenance: Consumers are increasingly proactive—replacing carburetors during off-seasons to avoid spring startup issues—boosting H2 sales ahead of winter storage and next season prep.

3. Shift Toward Electrification (Indirect Impact)

- Decline in New Gas Equipment Sales: As Cub Cadet expands its electric product line (e.g., battery-powered mowers), the long-term outlook for new carburetor demand is declining.

- Counter-Trend in Repair Market: However, the large installed base of gas-powered units ensures strong aftermarket carb demand through at least 2026, especially in rural and professional landscaping sectors.

4. Supply Chain and Pricing Trends

- Stable Pricing with Regional Variability: After inflation-driven spikes in 2022–2023, carburetor prices have stabilized. H2 2026 may see slight price increases (2–4%) due to raw material costs and logistics.

- Inventory Management: Distributors are optimizing stock levels using predictive analytics, improving availability of common carb models (e.g., for Cub Cadet LT, XT1, and Z-Force series).

5. E-Commerce and DIY Culture

- Online Part Sales Growth: Platforms like Amazon, eBay, and specialized sites (e.g., Jacks Small Engines, Repair Clinic) dominate carburetor sales. Video tutorials and compatibility tools enhance consumer confidence in DIY repairs.

- OEM vs. Aftermarket Competition: OEM Cub Cadet carburetors maintain a reputation for reliability, but aftermarket brands are gaining trust due to improved quality and warranties.

Conclusion: H2 2026 Outlook

The market for Cub Cadet carburetors in H2 2026 will remain robust in the aftermarket repair segment, driven by aging equipment, fuel quality issues, and cost-conscious consumers. While the long-term trend points toward electrification reducing internal combustion engine demand, the transition will be gradual. Suppliers who offer ethanol-resistant designs, competitive pricing, and strong online presence will lead the market.

Key Takeaway: Despite the shift to electric, H2 2026 will still be a strong period for carburetor sales—especially for maintenance, replacement, and performance upgrade segments.

Let me know if you meant a different interpretation (e.g., stock market, a specific product line, or a ticker symbol).

Common Pitfalls When Sourcing Cub Cadet Carburetors (Quality and Intellectual Property)

Sourcing replacement carburetors for Cub Cadet equipment—especially for older or discontinued models—can be fraught with challenges. While third-party and aftermarket options are abundant, buyers must be cautious of issues related to quality control and intellectual property (IP) infringement. Below are common pitfalls to watch for:

Poor Build Quality and Material Defects

Many aftermarket or generic carburetors marketed as “compatible with Cub Cadet” use substandard materials such as low-grade zinc alloys, inferior gaskets, or imprecise machining. This can lead to:

- Fuel leaks due to warped or porous housings

- Sticking or misaligned internal components (floats, jets, needles)

- Rapid wear or corrosion, especially with ethanol-blended fuels

- Inconsistent engine performance, including hard starting, stalling, or rough idling

These issues often result in shorter service life and the need for repeated replacements, negating any initial cost savings.

Inaccurate Calibration and Tuning

Cub Cadet engines are calibrated to work with specific carburetor settings for optimal fuel-air mixture. Generic carburetors often come with incorrect jetting or non-adjustable components, leading to:

- Poor fuel economy

- Excessive smoke or emissions

- Engine overheating or carbon buildup

- Difficulty meeting emissions standards

Even if the carburetor physically fits, improper tuning can degrade engine performance and potentially cause long-term damage.

Misrepresentation and IP Infringement

A significant concern when sourcing carburetors is the risk of purchasing counterfeit or IP-infringing parts. Some manufacturers copy Cub Cadet’s original OEM designs—including trademarks, logos, and patented features—without authorization. This raises several red flags:

- Trademark Violation: Sellers may use “Cub Cadet” in listings or packaging to imply authenticity, even when the part is not genuine.

- Patented Design Copying: Certain carburetor designs are protected by utility or design patents. Unauthorized replication infringes on intellectual property rights.

- False “OEM” Claims: Some sellers label generic parts as “OEM quality” or “original equipment,” misleading consumers into believing they are purchasing authentic parts.

Purchasing such parts not only supports unethical practices but may also void equipment warranties or lead to liability concerns.

Lack of Traceability and Support

Aftermarket carburetors often lack proper documentation, batch tracking, or manufacturer support. If a defect is discovered:

- Warranty claims may be difficult or impossible to file

- Technical support is typically limited or non-existent

- Replacement parts or service kits may not be available

This contrasts sharply with genuine Cub Cadet or licensed OEM components, which come with traceability and customer service.

Compatibility and Fitment Issues

Even when sourced from reputable suppliers, fitment can be problematic due to variations in engine models and revisions over time. Pitfalls include:

- Incorrect throttle or choke linkage alignment

- Mismatched fuel inlet orientation

- Improper mounting bolt patterns

Always verify part numbers and cross-reference with official Cub Cadet service manuals to avoid installation issues.

Conclusion

When sourcing a Cub Cadet carburetor, prioritize authenticity and quality over upfront cost. Opt for genuine OEM parts or reputable aftermarket brands that comply with IP laws and adhere to strict quality standards. Avoid listings with vague descriptions, suspiciously low prices, or unauthorized use of branding. Doing so ensures reliable performance, protects your equipment investment, and supports ethical manufacturing practices.

It seems your request may be a bit unclear or contain shorthand. Let’s clarify and provide a helpful response.

You wrote:

“Logistics & compliance guide for Cub Cadet Carb. Use H2.”

Interpretation:

You may be asking for a logistics and compliance guide related to the carburetor (Carb) of a Cub Cadet product (likely a lawn mower or outdoor power equipment), with a note to “Use H2” — which could mean:

– Use hydrogen (H₂) as a fuel source (unlikely for standard Cub Cadet equipment),

– Or “H2” is a model number, part number, or internal code,

– Or it’s a typo (e.g., meant “for HH” or “Use H3”).

However, Cub Cadet carburetors are designed for gasoline (petrol), not hydrogen (H₂). There are currently no commercially available Cub Cadet models certified or approved to run on pure hydrogen fuel. Therefore, converting a Cub Cadet engine to run on H₂ would violate emissions regulations, void warranties, and pose significant safety and compliance risks.

Let’s provide a practical Logistics & Compliance Guide for Cub Cadet Carburetors under standard operating conditions, assuming “H2” may be a misunderstanding or typo.

Logistics & Compliance Guide for Cub Cadet Carburetor (Standard Gasoline Models)

1. Product Overview

- Equipment: Cub Cadet lawn tractors, zero-turn mowers, or walk-behind mowers

- Component: Carburetor (typically float-type, diaphragm, or fixed jet depending on engine model)

- Engine Types: Briggs & Stratton, Kohler, or MTD-owned engines (e.g., Cub Cadet branded engines)

- Fuel Type: Unleaded gasoline (87 octane minimum), ethanol content ≤10% (E10)

❌ Note: These engines are not designed for hydrogen (H₂) or alternative gaseous fuels.

2. Logistics Guidelines

| Aspect | Guidance |

|——-|———|

| Storage | Store carburetors in dry, temperature-controlled environments. Keep fuel bowls drained if stored long-term. |

| Transport | Package in anti-static, sealed containers. Avoid exposure to moisture or extreme temperatures. |

| Inventory Management | Track by part number (e.g., 753-10940, 696-04160). Use FIFO (First In, First Out) system. |

| Compatibility | Match carburetor to engine model (e.g., Intek, OHV, or EFI series). Refer to Cub Cadet parts manual. |

| Replacement Frequency | Typically every 3–5 years with proper maintenance; more often in high-humidity or ethanol-rich fuel areas. |

3. Compliance Requirements

| Regulation | Requirement |

|———–|————-|

| EPA Regulations (USA) | Engines must comply with 40 CFR Part 1054 (small spark-ignition engines). Tampering with carburetor voids certification. |

| CARB (California Air Resources Board) | Strict emissions standards. Use only CARB-compliant parts in CA. Aftermarket modifications not certified = non-compliant. |

| Warranty Compliance | Using non-OEM or modified carburetors voids Cub Cadet warranty. Repairs must follow service manuals. |

| Fuel Standards | Use only E10 or lower ethanol blends. E15 or E85 can damage carburetor seals and fuel system. |

| Safety Standards (ANSI/OPEI B71.1) | Equipment must meet operational and emission safety standards. Unauthorized fuel conversions = non-compliant. |

4. Maintenance & Best Practices

- Clean Regularly: Use carburetor cleaner (e.g., Berryman Chem-Dip) every 1–2 seasons.

- Replace Kits: Use OEM rebuild kits (includes needles, seats, gaskets).

- Adjustments: Follow factory settings for idle and mixture screws. Do not modify for performance gains unless certified.

- Winterization: Drain fuel or use stabilizer to prevent varnish buildup.

5. H₂ (Hydrogen) Considerations – Important Warning

- Cub Cadet does not manufacture or approve hydrogen-powered mowers.

- Converting to H₂ is illegal under EPA and CARB rules (tampering with certified emission systems).

- Safety Risks: Hydrogen is highly flammable, requires high-pressure storage, and needs specialized engine controls.

- No OEM support: Conversion voids warranty, insurance, and compliance.

✅ Recommendation: Use only approved fuels and OEM parts.

6. Resources

- Cub Cadet Parts Lookup: https://www.cubcadet.com

- EPA Small Engine Regulations: https://www.epa.gov/smallengines

- CARB Off-Road Engine Info: https://ww2.arb.ca.gov

Conclusion

For Cub Cadet carburetors, follow OEM logistics, use gasoline (E10 max), and adhere to EPA/CARB compliance. Do not attempt to use H₂ (hydrogen) unless you are working with a certified, experimental platform — which Cub Cadet does not currently offer.

If “H2” refers to a model number (e.g., Cub Cadet H2 lawn mower), please clarify so we can tailor the guide accordingly.

Let me know if you meant a specific model (e.g., Cub Cadet H2 lawn mower) or were exploring alternative fuels.

In conclusion, sourcing a Cub Cadet carburetor requires careful consideration of compatibility, model specifications, and quality. Ensuring the correct carburetor matches your engine’s make and model—such as those from Briggs & Stratton, Kohler, or the specific Cub Cadet series—is essential for optimal performance and longevity. Whether purchasing from an authorized dealer, online retailer, or third-party vendor, it’s important to verify the part number, check for genuine or OEM-equivalent components, and review customer feedback. Additionally, evaluating warranty options and return policies can provide added assurance. Proper installation and routine maintenance will further enhance engine efficiency and extend the life of the equipment. By taking a diligent and informed approach, you can successfully source a reliable carburetor that keeps your Cub Cadet running smoothly.