The global crystal laser etching market is experiencing robust growth, driven by rising demand for personalized and premium decorative products across industries such as corporate gifting, awards, and luxury consumer goods. According to a report by Mordor Intelligence, the global laser engraving market was valued at USD 1.78 billion in 2022 and is projected to grow at a CAGR of 6.8% from 2023 to 2028, with crystal etching emerging as a key segment due to its precision and aesthetic appeal. Advancements in 3D laser technology, coupled with increasing adoption in retail and promotional sectors, have intensified competition among manufacturers to deliver high-quality, customizable solutions. As demand surges, especially in regions like North America and Asia-Pacific, a select group of manufacturers are leading innovation, scalability, and technical expertise in crystal laser etching. Based on production capabilities, technological sophistication, customer reach, and industry reputation, here are the top 10 crystal laser etching manufacturers shaping the future of this niche yet rapidly evolving market.

Top 10 Crystal Laser Etching Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Cristal Laser, Europe’s non linear crystals manufacturer

Website: cristal-laser.com

Key Highlights: Based in France, Cristal Laser is a technology leader that grows and fabricates non-linear optical crystals such as LBO, KTP, KTA, and RTP crystals for electro ……

#2 About Us

Website: crystallasergifts.com

Key Highlights: 3D Laser Gifts is a leading manufacturer of 3D laser etched crystals. We at 3D Laser Gifts use the latest German technology of laser engraving in crystals. We ……

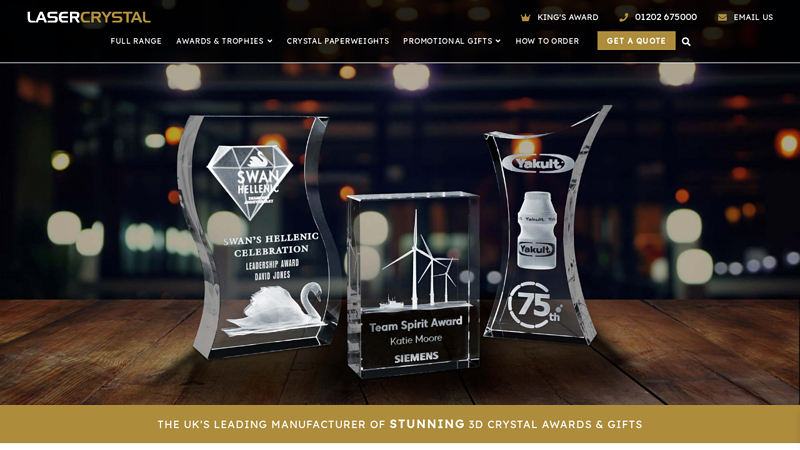

#3 Laser Crystal

Website: lasercrystal.co.uk

Key Highlights: Here at Laser Crystal, we are the UK’s leading manufacturer of high-quality bespoke 3D laser engraved glass awards, trophies and paperweights….

#4 Crystal Sensations: Crystal Awards with Engraving

Website: crystalsensations.com

Key Highlights: Crystal Sensations is a premier designer and manufacturer of high quality trophies and awards for clients all over the globe….

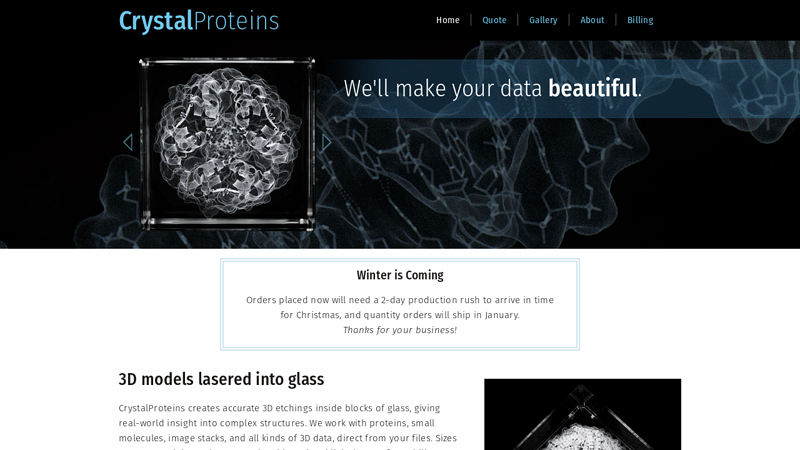

#5 CrystalProteins

Website: crystalproteins.com

Key Highlights: 3D models lasered into glass. CrystalProteins creates accurate 3D etchings inside blocks of glass, giving real-world insight into complex structures….

#6 3D Crystals by ArtPix 3D®

#7 3D Subsurface Laser Engraving

Website: crystal-d.com

Key Highlights: Our 3D subsurface engraving process comes in, allowing us to recreate any image inside a crystal award or gift in two or three dimensions….

#8 Precision Crystal Gifts and Awards

Website: precisioncrystal.com

Key Highlights: As one of the oldest and largest suppliers of sub-surface laser engraving services in the world, Precision Crystal Gifts and Awards possesses the critical ……

#9 3D Crystal

Website: 3d-crystal.com

Key Highlights: 3D laser engraving and marking on all materials by Grüner Laser Products GmbH. 3D Crystal: we guarantee you best reliability and unbeatable Quality….

#10 Personalized 3D Crystal Photos by Beyond Memories®

Website: beyond-memories.com

Key Highlights: Your source for personalized 3D crystal engraving. Beyond Memories® uses the newest innovation of capturing memories in crystals, the perfect gift….

Expert Sourcing Insights for Crystal Laser Etching

H2: 2026 Market Trends for Crystal Laser Etching

The crystal laser etching market is poised for significant evolution by 2026, driven by technological advancements, shifting consumer preferences, and expanding applications. Key trends expected to shape the industry include:

1. Dominance of Personalization and E-Commerce Integration

By 2026, hyper-personalization will remain the cornerstone of the market. Consumers increasingly demand unique, emotionally resonant gifts, and laser-etched crystals perfectly fulfill this need. Online platforms will dominate sales, with seamless integration of 3D preview tools, AI-driven design suggestions, and automated order processing. Subscription models for corporate gifting and milestone celebrations (e.g., monthly employee recognition crystals) will gain traction, fostering recurring revenue.

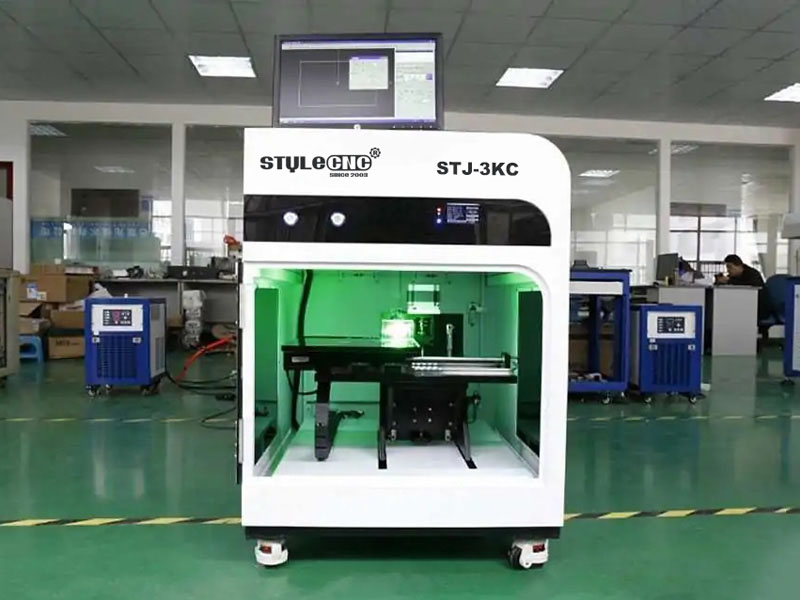

2. Advancements in Laser Technology and Materials

Dual-wavelength and ultrafast (femtosecond) lasers will become more accessible, enabling finer detail, true color etching (beyond monochrome), and faster production speeds. This allows for complex 3D portraits, intricate artwork, and photorealistic images within crystals. Simultaneously, demand for sustainable materials will rise, pushing adoption of recycled optical glass and biodegradable packaging, aligning with eco-conscious consumer values.

3. Expansion into Corporate and Industrial Applications

Beyond gifts, crystal laser etching will see significant growth in B2B sectors. Customized awards and recognition pieces will feature integrated NFC/QR codes linking to digital content (e.g., video messages, employee profiles). In industrial uses, precision etching will be critical for marking high-value optical components, sensors, and security features in semiconductors, driven by demand for traceability and anti-counterfeiting.

4. AI and AR-Driven Design Democratization

Artificial Intelligence will revolutionize design workflows. AI tools will automatically enhance photos for optimal etching, generate artistic interpretations, and suggest layouts. Augmented Reality (AR) apps will allow customers to visualize etched designs on actual crystal blanks in their physical space via smartphones, reducing returns and boosting confidence in online purchases.

5. Consolidation and Niche Specialization

The market will see consolidation among smaller players, while surviving businesses will differentiate through extreme specialization: luxury high-end art pieces, rapid-turnaround corporate solutions, or eco-focused brands. Partnerships with major retailers (e.g., photo printing chains, stationery stores) for in-store kiosks and hybrid online-offline experiences will become more common.

In summary, by 2026, crystal laser etching will transition from a novelty gift to a sophisticated, tech-integrated industry focused on personalization, sustainability, and diverse applications, underpinned by AI, advanced lasers, and e-commerce innovation.

Common Pitfalls in Sourcing Crystal Laser Etching (Quality, IP)

Sourcing crystal laser etching services presents unique challenges, particularly concerning quality consistency and intellectual property (IP) protection. Overlooking these aspects can lead to significant financial loss, reputational damage, and legal complications. Below are key pitfalls to avoid:

Quality Inconsistencies and Material Misrepresentation

One of the most frequent issues is the variability in crystal quality and etching precision. Suppliers may use lower-grade optical materials—such as leaded glass instead of genuine optical crystal—which results in duller images, reduced clarity, and increased internal flaws. Additionally, inconsistent laser focus, incorrect power settings, or subpar 3D modeling software can lead to blurry, distorted, or incomplete engravings. Without clear quality benchmarks and sample validation, buyers risk receiving products that fail to meet aesthetic or functional expectations.

Inadequate Intellectual Property Safeguards

Laser etching often involves the reproduction of proprietary designs, logos, or copyrighted 3D models, making IP protection critical. Many suppliers—especially overseas or low-cost providers—lack robust data security measures or signed non-disclosure agreements (NDAs). This exposes clients to risks of unauthorized duplication, reverse engineering, or resale of designs. Furthermore, absence of clear contractual terms defining IP ownership post-production can result in disputes, particularly if the supplier claims rights to the digital files or finished product design.

Lack of Technical Expertise and Communication

Effective crystal laser etching requires precise calibration and skilled technicians. Sourcing from vendors without proven technical experience can result in poor depth control, unwanted fractures, or surface damage. Miscommunication regarding file formats (e.g., STL, OBJ), resolution requirements, or design specifications often compounds these issues. Without a responsive, technically competent point of contact, resolving problems becomes difficult, leading to delays and rework.

Hidden Costs and Scalability Limitations

Initial quotes may appear competitive but exclude costs for file conversion, setup, or minimum order quantities (MOQs). As projects scale, some suppliers struggle with consistency across larger batches, revealing limitations in equipment capacity or quality control processes. This can undermine brand integrity, especially for corporate gifts or retail products requiring uniformity.

To mitigate these risks, conduct thorough due diligence: request physical samples, verify material certifications, enforce IP agreements, and prioritize suppliers with transparent workflows and strong client references.

Logistics & Compliance Guide for Crystal Laser Etching

Product Overview and Handling

Crystal laser etching involves using high-precision lasers to engrave personalized designs, text, or images into optical-quality crystal blocks. These products are commonly used for awards, corporate gifts, and commemorative items. Due to the fragile nature of crystal and the precision manufacturing process, proper handling, packaging, and compliance with international shipping and safety standards are essential.

Packaging and Shipping Procedures

All etched crystal products must be packaged using shock-absorbent materials such as foam inserts, bubble wrap, and rigid corrugated boxes to prevent breakage during transit. Each crystal should be individually wrapped and secured within the packaging to minimize movement. Use double-boxing for high-value or large items. Clearly label packages as “Fragile” and “This Side Up” to alert carriers. For international shipments, include a detailed packing list and commercial invoice specifying product description, quantity, value, and country of origin.

Import/Export Compliance

Ensure compliance with the import and export regulations of both origin and destination countries. Crystal products generally fall under HS Code 7018 (Glass in the form of cubes, spheres, or other non-geometrical shapes) or 7020 (Other glass). Verify correct classification with local customs authorities. Prohibited or restricted items (e.g., copyrighted imagery, political symbols, or offensive content) must not be etched without proper authorization. Maintain records of customer design approvals for audit purposes.

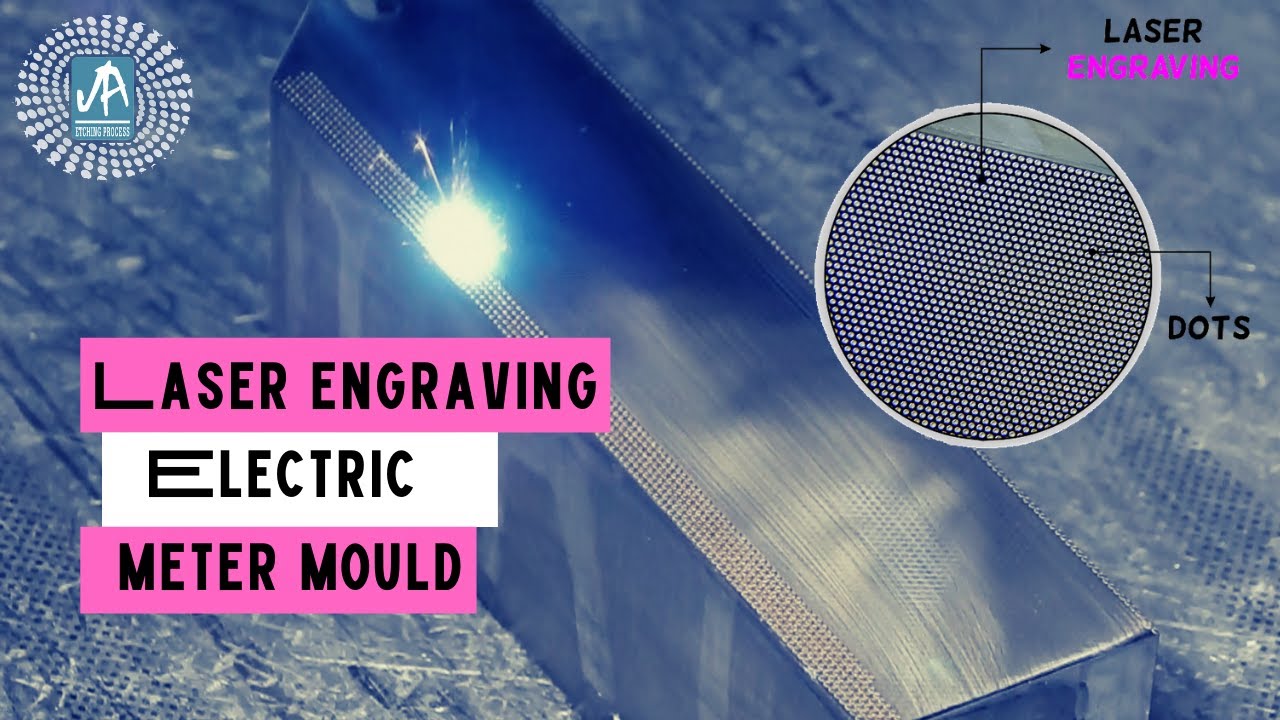

Safety and Workplace Standards

Laser etching operations must comply with OSHA (Occupational Safety and Health Administration) or equivalent national safety standards. Laser equipment should be Class 1 or interlocked Class 4 systems with appropriate warning signage. Operators must wear protective eyewear rated for the laser wavelength used (typically 1064 nm for fiber lasers). Ensure proper ventilation or fume extraction systems are in place to manage any particulates generated during engraving. Conduct regular maintenance and safety training for all personnel.

Environmental and Waste Management

Dispose of damaged or rejected crystal pieces in accordance with local environmental regulations. While optical crystal is inert and non-toxic, recycling through glass reclamation facilities is encouraged. Laser etching produces minimal waste, but any filters from fume extraction systems should be treated as electronic or mixed waste depending on local rules. Document waste disposal procedures to support environmental compliance audits.

Intellectual Property and Data Compliance

Customer-submitted designs may be subject to copyright or trademark laws. Implement a clear user agreement requiring customers to confirm they have rights to the content being etched. Do not reproduce logos, brand names, or artwork without verified permission. Securely store customer design files in compliance with data protection regulations such as GDPR or CCPA. Retain files only for the agreed production period and delete them afterward unless otherwise authorized.

Certification and Labeling Requirements

While crystal laser etched items typically do not require specific product safety certifications (e.g., CE, FCC), business operations related to laser equipment must meet relevant standards such as IEC 60825 for laser safety. Display required compliance labels on laser machinery. For consumer-facing products, include manufacturer information, country of origin, and care instructions where applicable. Custom awards or gifts may require client-specific labeling per contract terms.

Transportation and Carrier Coordination

Use reputable carriers experienced in handling fragile goods. Offer tracking and insurance options for all shipments. For air freight, comply with IATA regulations—ensure packaging meets drop and vibration testing standards. Avoid shipping during extreme weather conditions that may compromise package integrity. Coordinate with logistics partners to provide delivery notifications and signature requirements for high-value items.

Quality Assurance and Documentation

Maintain a quality control checklist for every etched product, verifying design accuracy, clarity of engraving, and absence of cracks or defects. Keep production logs including batch numbers, operator IDs, and inspection results. Provide customers with a certificate of authenticity for premium products upon request. Retain all compliance documentation for a minimum of five years.

Conclusion for Sourcing Crystal Laser Etching

Sourcing crystal laser etching requires a careful evaluation of quality, precision, customization capabilities, and supplier reliability. High-quality crystal combined with advanced laser technology ensures a refined, durable, and visually striking finished product—ideal for awards, corporate gifts, or commemorative items. When selecting a supplier, it is essential to assess their technical expertise, material sourcing, turnaround time, and ability to handle custom designs. Additionally, cost-effectiveness should not compromise craftsmanship. By partnering with reputable manufacturers or specialized vendors who demonstrate consistent results and excellent customer service, businesses can secure premium crystal etchings that leave a lasting impression. Ultimately, successful sourcing hinges on balancing quality, customization, and value to meet both aesthetic and functional objectives.