The global crystal laser engraving market is experiencing robust growth, driven by rising demand for personalized gifting, corporate awards, and high-precision decorative items. According to Grand View Research, the global laser engraving machine market size was valued at USD 861.4 million in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This expansion is fueled by advancements in laser technology, increased automation in manufacturing, and growing adoption across retail, industrial, and creative sectors. As consumer preference shifts toward customized and premium-quality engraved products, manufacturers specializing in crystal laser engraving are scaling capabilities in precision, throughput, and integration with digital design platforms. With China, Europe, and North America leading in both production and consumption, the competitive landscape is evolving rapidly. Based on innovation, output quality, technical specifications, and market reach, the following nine manufacturers stand out as leaders in the crystal laser engraving industry.

Top 9 Crystal Laser Engraving Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Cristal Laser, Europe’s non linear crystals manufacturer

Website: cristal-laser.com

Key Highlights: Based in France, Cristal Laser is a technology leader that grows and fabricates non-linear optical crystals such as LBO, KTP, KTA, and RTP crystals for electro ……

#2 About Us

Website: crystallasergifts.com

Key Highlights: Crystal Laser Gifts is a leading manufacturer of 3D laser etched crystals. We at Crystal Laser Gifts we use the latest German technology of laser engraving ……

#3 Laser Crystal

Website: lasercrystal.co.uk

Key Highlights: Here at Laser Crystal, we are the UK’s leading manufacturer of high-quality bespoke 3D laser engraved glass awards, trophies and paperweights….

#4 3D Crystals by ArtPix 3D®

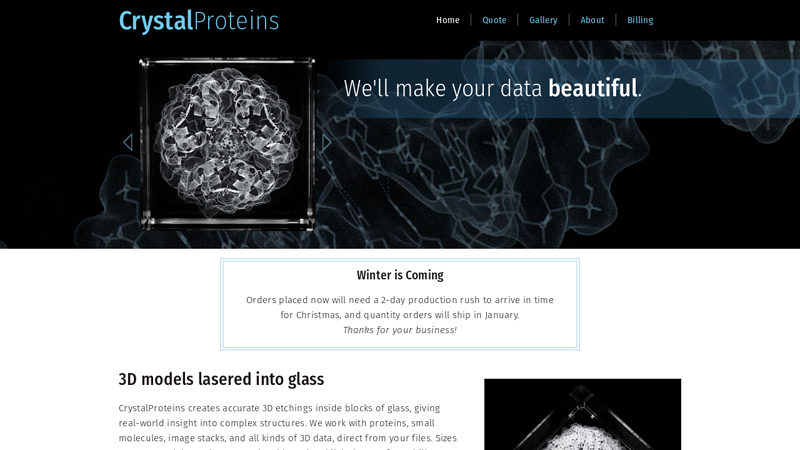

#5 CrystalProteins

Website: crystalproteins.com

Key Highlights: 3D models lasered into glass. CrystalProteins creates accurate 3D etchings inside blocks of glass, giving real-world insight into complex structures….

#6 Personalized 3D Crystal Photos by Beyond Memories®

Website: beyond-memories.com

Key Highlights: Your source for personalized 3D crystal engraving. Beyond Memories® uses the newest innovation of capturing memories in crystals, the perfect gift….

#7 Gravotech

Website: gravotech.us

Key Highlights: Gravotech designs, manufactures, and distributes innovative engraving, marking, and cutting solutions….

#8 3D Subsurface Laser Engraving

Website: crystal-d.com

Key Highlights: Our 3D subsurface engraving process comes in, allowing us to recreate any image inside a crystal award or gift in two or three dimensions….

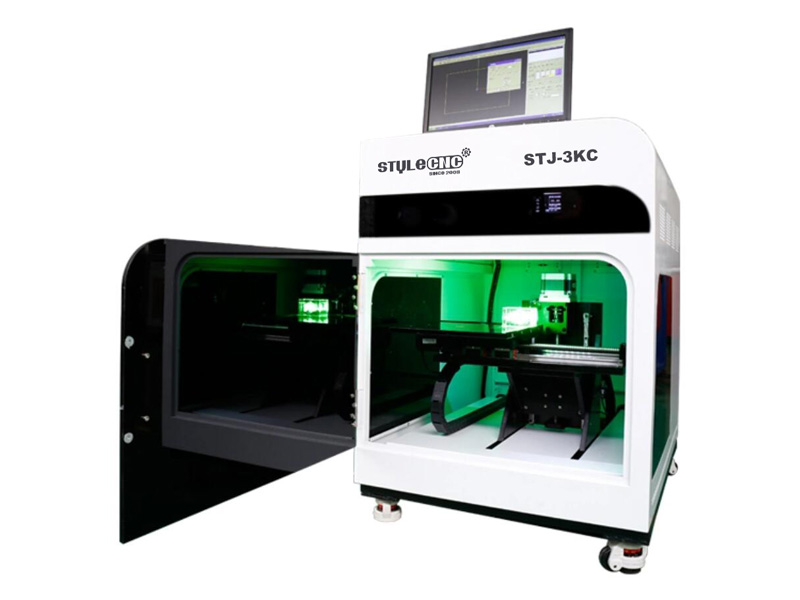

#9 Laser Equipment Supplier

Website: radianlaser.com

Key Highlights: Radian Laser Systems is a laser equipment supplier specializing in high-speed, customizable laser machinery, including fiber, CO2, and galvo lasers….

Expert Sourcing Insights for Crystal Laser Engraving

H2: 2026 Market Trends for Crystal Laser Engraving

The crystal laser engraving market is poised for significant transformation and growth by 2026, driven by technological advancements, rising consumer demand for personalized products, and expanding applications across multiple industries. Here’s an analysis of key trends expected to shape the market in 2026:

-

Increased Demand for Personalized Gifts and Keepsakes

The consumer preference for customized and emotionally resonant products continues to accelerate. By 2026, the gifting sector—especially for weddings, anniversaries, corporate rewards, and memorials—will remain a dominant driver of crystal laser engraving. Enhanced digital platforms and e-commerce integration will allow users to design and order personalized crystal pieces instantly, fueling market expansion. -

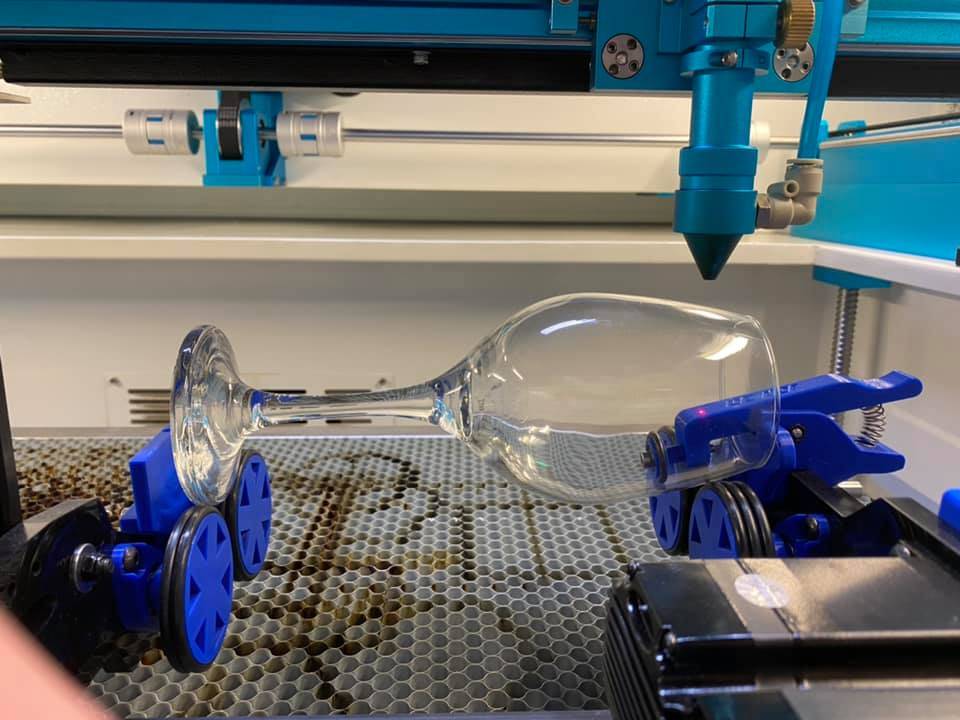

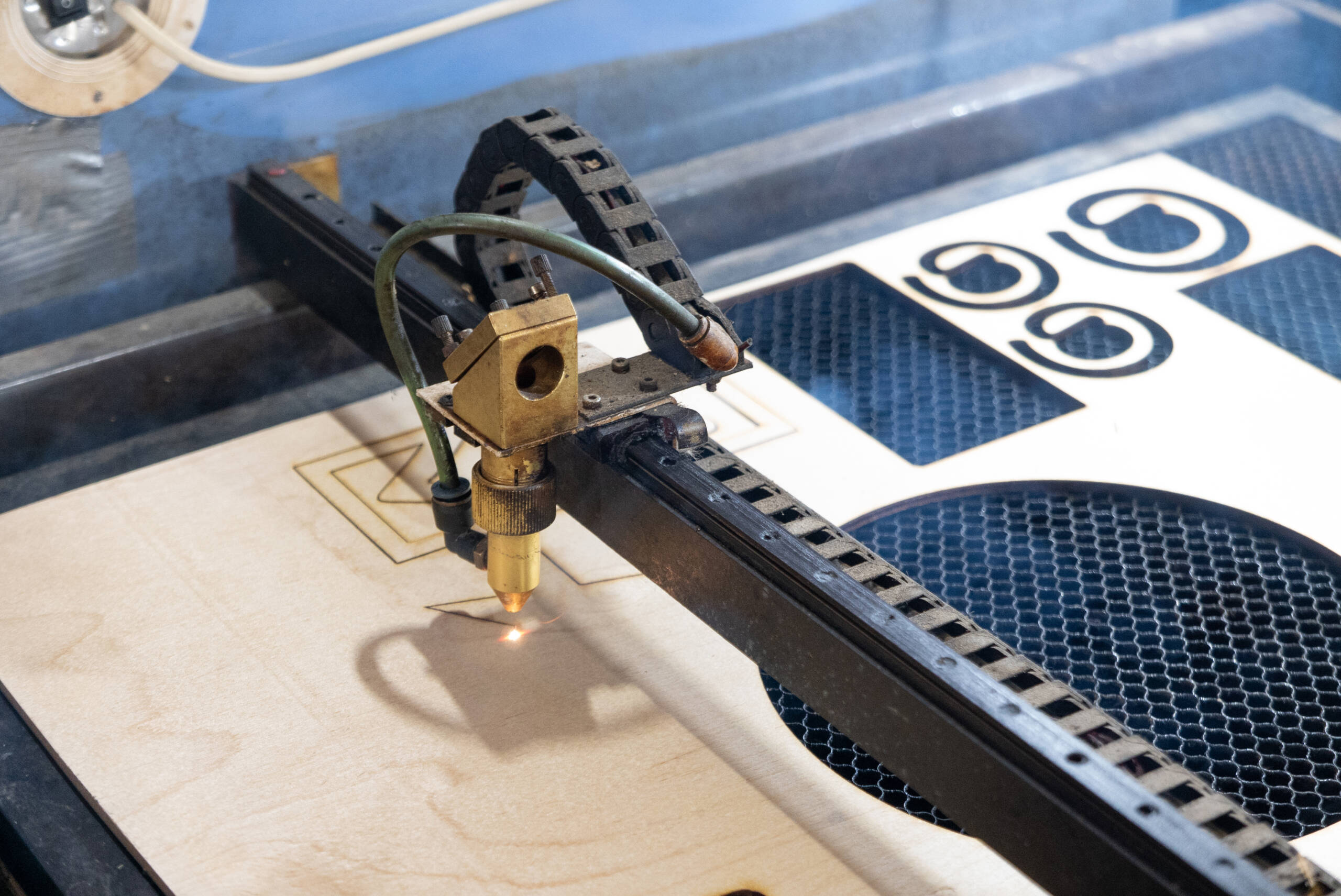

Advancements in Laser Precision and 3D Engraving Technology

Technological improvements in CO₂ and fiber laser systems will enable deeper, more intricate, and three-dimensional engravings within crystal. High-resolution 3D laser internal engraving (also known as subsurface laser engraving) will become more accessible and cost-effective, allowing for photorealistic images and complex geometric designs. These innovations will elevate product quality and open new creative possibilities. -

Expansion into Corporate and Promotional Markets

Businesses are increasingly using engraved crystal awards, trophies, and branded gifts to recognize employees and clients. By 2026, the corporate gifting and recognition market will adopt laser-engraved crystal solutions at scale due to their premium appearance and durability. Customization automation will allow mass personalization, making it feasible for large organizations to order bulk personalized items. -

Integration with AI and Design Automation

Artificial intelligence will play a pivotal role in streamlining the design process. AI-powered tools will enable automatic image optimization, facial recognition for portrait engraving, and real-time 3D previews. This integration will reduce production time, minimize errors, and enhance the user experience on online customization platforms. -

Sustainability and Eco-Conscious Materials

As environmental concerns grow, the industry will see a shift toward sustainably sourced and recyclable crystal materials. Manufacturers will emphasize low-energy laser systems and eco-friendly production practices to appeal to environmentally conscious consumers and B2B clients seeking green certifications. -

Growth in Niche and High-End Applications

Beyond consumer gifts, crystal laser engraving will expand into luxury markets, art installations, and high-tech applications such as data storage in quartz crystals (e.g., 5D optical data storage). While still emerging, these applications could represent high-margin growth opportunities by 2026. -

Globalization and E-Commerce Expansion

Online marketplaces and direct-to-consumer (DTC) models will continue to lower entry barriers for small engraving businesses. Cross-border e-commerce will enable global reach, with regional customization preferences influencing design trends in North America, Europe, and Asia-Pacific markets. -

Competition and Market Consolidation

As the market grows, competition among laser engraving equipment manufacturers and service providers will intensify. This may lead to consolidation, with larger players acquiring niche brands or integrating vertical supply chains to offer end-to-end solutions—from design software to finished products.

In summary, by 2026, the crystal laser engraving market will be characterized by deeper personalization, technological sophistication, and broader application scope. Businesses that leverage automation, sustainability, and digital innovation will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing Crystal Laser Engraving: Quality and Intellectual Property Concerns

Logistics & Compliance Guide for Crystal Laser Engraving

This guide outlines the essential logistics considerations and compliance requirements for businesses involved in crystal laser engraving, including manufacturing, shipping, and international trade.

Shipping and Handling of Engraved Crystal Products

Crystal items are fragile and require special handling to prevent breakage during transit. Use double-wall corrugated boxes with sufficient cushioning such as foam inserts, bubble wrap, or molded pulp. Each engraved crystal should be individually wrapped to protect the surface from scratches. Clearly label packages as “Fragile” and “This Side Up” to alert carriers. Consider using tracked and insured shipping methods, especially for high-value or custom orders. For bulk shipments, palletize securely and stretch-wrap to prevent shifting.

Packaging Labeling and Product Marking

Ensure all packaging includes accurate product descriptions, item quantities, and handling instructions. Include your company name, address, and contact information on the outer box. For retail packaging, product labels should display care instructions (e.g., “Wipe with soft cloth—avoid abrasive cleaners”) and any relevant branding. If the crystal contains lead (common in optical crystal), include a warning label if required by local regulations (e.g., California Proposition 65). Engraved items must not include copyrighted logos or trademarks without proper licensing.

Import and Export Compliance

When shipping engraved crystals internationally, comply with customs regulations in both origin and destination countries. Prepare a commercial invoice detailing product description, value, quantity, and Harmonized System (HS) code—typically 7018.10 for glass sculptures or 7013.99 for glassware. Declare the country of origin accurately. Be aware of potential import duties, value-added tax (VAT), or excise fees. Restricted or prohibited items vary by country; verify that your crystal products (especially if containing electronic components like LED bases) meet local safety and labeling standards.

Safety and Environmental Regulations

Laser engraving operations must comply with occupational safety standards. Use Class 1 or enclosed Class 4 laser systems with proper interlocks and exhaust ventilation to manage fumes from vaporized crystal coatings or adhesives. Provide laser safety training and protective eyewear for operators. Dispose of waste materials (e.g., crystal dust, used filters) in accordance with local environmental regulations, as crystalline silica dust may be hazardous. Ensure electrical components on display bases meet regional safety certifications (e.g., CE, UL, FCC).

Intellectual Property and Copyright Compliance

Only engrave designs, logos, or artwork for which you hold the rights or have obtained proper licensing. Unauthorized reproduction of copyrighted or trademarked material (e.g., sports team logos, movie characters) can lead to legal action. Maintain records of client-provided artwork authorizations. Implement a policy requiring customers to certify they have permission to use requested engravings, especially for corporate or promotional gifts.

Certifications and Industry Standards

Obtain relevant certifications to enhance credibility and ensure compliance. These may include:

– ISO 9001 for quality management

– CE marking for products sold in the European Economic Area

– REACH and RoHS compliance if using electronic bases (restricting hazardous substances)

– Customs-Trade Partnership Against Terrorism (C-TPAT) if shipping frequently to the U.S.

Regularly audit your processes to ensure ongoing adherence to these standards.

Conclusion: Sourcing Crystal Laser Engraving

Sourcing crystal laser engraving services offers a unique opportunity to create elegant, professional, and personalized products suitable for awards, corporate gifts, promotional items, and commemorative keepsakes. The precision and permanence of laser engraving ensure high-quality results that enhance the clarity and brilliance of crystal materials. When selecting a supplier, key considerations include engraving precision, crystal quality, customization capabilities, turnaround time, and cost-effectiveness.

By partnering with reliable and experienced providers—whether domestic or international—businesses can achieve consistent, high-impact results that align with their branding and gifting objectives. Advancements in laser technology have made intricate designs and detailed imagery more accessible, allowing for greater creative flexibility. Additionally, sustainable sourcing and attention to packaging and logistics further support a seamless supply chain.

Ultimately, investing in high-quality crystal laser engraving not only elevates the perceived value of the product but also strengthens client and employee engagement through meaningful, lasting impressions. With careful vendor evaluation and attention to detail, sourcing crystal laser engraving can be a strategic and rewarding decision.