The global crystal engraving machine market is experiencing robust growth, driven by rising demand across consumer electronics, personalized gifting, and industrial marking applications. According to Grand View Research, the global laser engraving machine market—encompassing crystal engraving systems—was valued at USD 1.83 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.7% from 2023 to 2030. Similarly, Mordor Intelligence forecasts a CAGR of over 6.5% during the same period, citing advancements in fiber and CO₂ laser technology and increased automation in precision engraving processes. As industries prioritize high-resolution marking and customized solutions, leading manufacturers are innovating to meet growing global demand. Below are the top 8 crystal engraving machine manufacturers shaping this evolving landscape.

Top 8 Crystal Engraving Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 3D crystal laser engraving machine manufacturer

Website: vitro.de

Key Highlights: Our laser systems are compatible for a wide range of applications. Whether small production, individual production, small and large series production….

#2 3d photo crystal laser engraving machine

Website: arguslaser.net

Key Highlights: Argus Laser is a leading China 3d photo crystal laser engraving machine manufacturer, supplier and exporter. Adhering to the pursuit of perfect quality of ……

#3 Fiber Laser Engraving Machine

Website: haotianlasers.com

Key Highlights: As a leading manufacturer, not a reseller, we specialize in crafting high-quality CO2 laser engraving machines, UV laser marking machines, and fiber laser ……

#4 Crystal & Glass Engraving

Website: gravotech.us

Key Highlights: Engrave and customize glass and crystal pieces and offer your customers unforgettable memories with our glass engraving machines….

#5 IKONICS

Website: ikonics.com

Key Highlights: IKONICS Imaging provides everything needed to start and maintain sandcarving businesses, including photoresist films, sandcarving equipment and supplies, glass ……

#6 Perfect Laser 3D crystal engraving machine

Website: perfectlaser.net

Key Highlights: Perfect Laser offers 3D crystal engraving machine,widely used for 3D crystal engraving and 3D portraits for human image.affordable and easy-to-use….

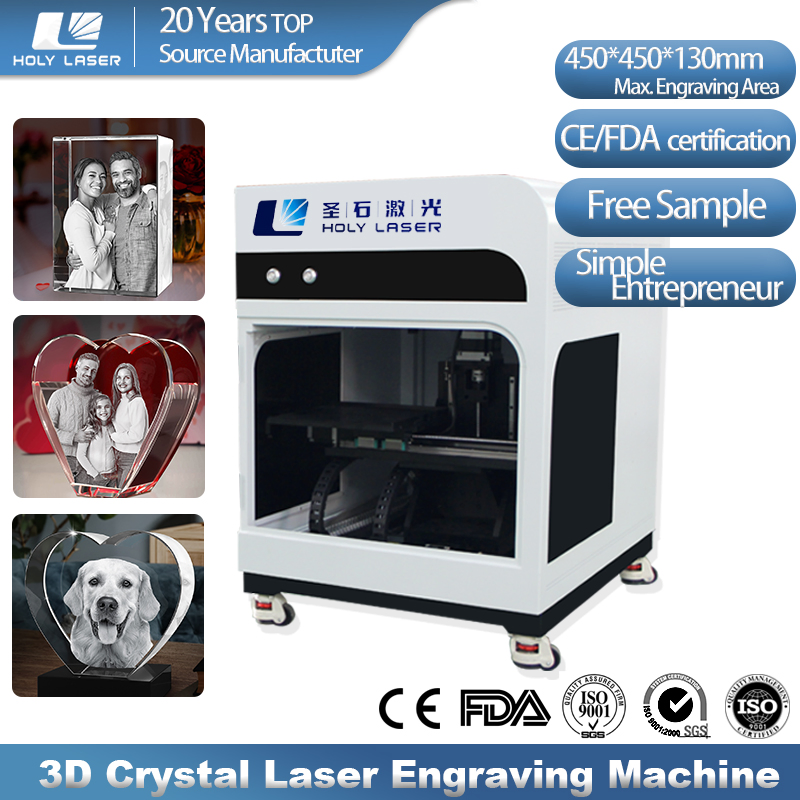

#7 3D Crystal Laser Engraving Machine

Website: sismarlaser.com

Key Highlights: The UV 3D Laser Engraving Machine is ideal for multiple industries and purposes: Personalized Gifts – Keepsakes, portraits, and custom crystal items….

#8 ApexRay HD 3D Crystal Subsurface Laser Engraving Machine

Expert Sourcing Insights for Crystal Engraving Machine

H2: 2026 Market Trends for Crystal Engraving Machines

The global market for crystal engraving machines is poised for significant transformation by 2026, driven by advances in laser technology, rising demand for personalized products, and expansion across diverse industries. This analysis explores key trends shaping the market landscape in the coming years.

1. Technological Advancements and Automation

By 2026, crystal engraving machines are expected to feature greater automation, precision, and integration with AI-driven design software. Fiber and UV laser technologies are becoming standard due to their ability to produce high-resolution, intricate engravings on delicate crystal surfaces without causing micro-fractures. Smart machines with touchscreen interfaces, IoT connectivity, and cloud-based design platforms will enable real-time monitoring and remote operation, improving efficiency for both small businesses and industrial users.

2. Growth in Personalized and Customized Products

The consumer demand for personalized gifts, awards, and luxury décor continues to surge. By 2026, e-commerce platforms and on-demand manufacturing will drive the need for compact, user-friendly crystal engraving systems capable of handling small-batch or single-item production. Customized corporate gifts, wedding souvenirs, and commemorative items will remain key application areas, especially in markets across North America, Europe, and Asia-Pacific.

3. Expansion in Industrial and Commercial Applications

Beyond the gift industry, crystal engraving is gaining traction in sectors such as architecture (for decorative glass elements), medical devices (for precision laser marking), and high-end retail (for brand authentication and luxury packaging). These applications require industrial-grade engraving machines capable of consistent performance and compliance with quality standards, contributing to market diversification.

4. Regional Market Growth

Asia-Pacific, particularly China and India, is expected to emerge as a dominant market by 2026 due to rising disposable incomes, a growing middle class, and increasing investments in manufacturing infrastructure. North America and Europe will continue to lead in technological innovation and premium product adoption, while Latin America and the Middle East present emerging opportunities driven by tourism and event-based gifting.

5. Sustainability and Eco-Friendly Manufacturing

Environmental concerns are influencing equipment design. Future crystal engraving machines will emphasize energy efficiency, reduced material waste, and non-toxic processing methods. Manufacturers are likely to adopt recyclable materials and develop closed-loop systems to align with global sustainability goals.

6. Competitive Landscape and Market Consolidation

The market will see increased competition between established players (e.g., Epilog Laser, Trotec, Gravograph) and emerging regional manufacturers offering cost-effective alternatives. Strategic partnerships, R&D investments, and expansion into niche markets (such as 3D crystal engraving) will define competitive advantage. By 2026, differentiation through software capabilities, after-sales service, and customization options will be critical.

In conclusion, the crystal engraving machine market in 2026 will be shaped by digitalization, personalization trends, and cross-industry adoption. Companies that innovate rapidly and adapt to evolving customer needs will be best positioned to capture growth in this dynamic and expanding market.

Common Pitfalls When Sourcing Crystal Engraving Machines (Quality and Intellectual Property)

Sourcing a crystal engraving machine—especially from international suppliers—can be a cost-effective way to enter or expand in the personalized gifts, awards, or luxury goods market. However, buyers often encounter significant challenges related to product quality and intellectual property (IP) risks. Being aware of these pitfalls can help mitigate costly mistakes.

Poor Build Quality and Component Standards

One of the most common issues when sourcing crystal engraving machines is receiving units with subpar build quality. Many low-cost suppliers use inferior materials and components to cut production costs. This can lead to frequent mechanical failures, inconsistent engraving precision, and shorter machine lifespans. Buyers may find that motors, rails, or laser diodes degrade quickly under regular use, resulting in downtime and increased maintenance costs.

Additionally, inconsistent calibration out of the factory means machines may require extensive adjustments before they produce acceptable results. Without access to reliable technical support or spare parts, resolving these issues becomes difficult and time-consuming.

Inaccurate or Misrepresented Technical Specifications

Suppliers—particularly on online B2B platforms—may exaggerate or fabricate technical capabilities. For example, a machine might be advertised as having “3D internal laser engraving” with high-resolution output, but in reality, it delivers low-detail engravings with alignment issues. Power ratings, engraving speed, and compatibility with different crystal sizes can also be misrepresented.

Always request third-party test reports, videos of the machine in operation, or even independent lab verification before finalizing a purchase. Avoid relying solely on marketing materials provided by the supplier.

Lack of After-Sales Support and Spare Parts Availability

Many budget crystal engraving machines come from manufacturers with limited or no international support infrastructure. Once the machine breaks down, obtaining replacement parts or firmware updates can take weeks or months. In some cases, suppliers disappear entirely after the sale.

Ensure the supplier offers a warranty, has a responsive support team, and can provide spare parts or service locally or through a distributor. Consider the total cost of ownership, not just the initial purchase price.

Intellectual Property Infringement Risks

Sourcing from certain regions, particularly where IP enforcement is weak, increases the risk of purchasing machines that infringe on patented technologies. Some manufacturers clone high-end models from reputable brands, replicating not just the design but also proprietary software algorithms and control systems.

Using such machines could expose your business to legal liability, especially if you operate in a jurisdiction with strong IP protections like the U.S., EU, or Japan. Customs authorities may seize infringing equipment, and original IP holders may pursue legal action against both the manufacturer and end users in some cases.

Always vet the supplier’s IP compliance. Request documentation showing the machine’s design is original or properly licensed. Avoid suppliers who are unwilling or unable to provide transparency on this matter.

Software Limitations and Licensing Issues

Many low-cost crystal engraving machines come with proprietary software that may be unstable, poorly documented, or limited in functionality. Some software may be pirated or lack proper licensing, posing both operational and legal risks.

Ensure the software is compatible with your design workflow (e.g., supports standard file formats like SVG or DXF), offers adequate customer support, and comes with a legitimate license. Open-source or widely supported software platforms are often safer and more sustainable in the long term.

Conclusion

While sourcing a crystal engraving machine from overseas suppliers can offer significant cost savings, it’s essential to carefully evaluate both quality and intellectual property risks. Conduct thorough due diligence, verify specifications with real-world testing, and prioritize suppliers with transparent practices and solid support networks. Skipping these steps can result in operational inefficiencies, legal exposure, and damage to your brand reputation.

Logistics & Compliance Guide for Crystal Engraving Machine

This guide outlines the key logistics and compliance considerations for the shipment, import, and operation of crystal engraving machines across international and domestic markets. Adherence to these guidelines ensures smooth transit, legal compliance, and safe usage.

Packaging and Handling Requirements

Crystal engraving machines are precision instruments and must be packaged securely to prevent damage during transit. Use double-walled corrugated cardboard boxes with internal foam or molded inserts to immobilize the machine. Include desiccant packs to mitigate moisture exposure, especially for sea freight. Clearly label packages with “Fragile,” “This Side Up,” and “Do Not Stack” indicators. Handle with care throughout the logistics chain—avoid dropping, excessive vibration, and exposure to extreme temperatures.

Shipping and Transportation Guidelines

Choose reliable freight carriers experienced in handling sensitive industrial equipment. For international shipments, coordinate between air, sea, or ground transport based on urgency and cost. Ensure all machines are crated and secured on pallets for container or truck loading. Provide detailed packing lists and shipping manifests. Track shipments in real-time and maintain insurance coverage for the full replacement value. Notify recipients in advance of delivery schedules to ensure proper receiving procedures.

Import and Export Compliance

Verify export control regulations in the country of origin (e.g., U.S. EAR or EU Dual-Use Regulations) to determine if the crystal engraving machine requires an export license. Most standard models fall under general exclusions, but high-precision or laser-based systems may be subject to restrictions. For imports, comply with destination country customs requirements. Provide accurate HS (Harmonized System) codes—typically 8479.89 for other machines not elsewhere specified. Submit commercial invoices, bill of lading/airway bill, packing list, and any required certificates of origin.

Electrical and Safety Certification

Ensure the machine meets electrical safety standards of the destination market. In the U.S., look for UL or ETL certification; in Europe, CE marking under the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive is mandatory. Machines must operate safely at local voltage (e.g., 110V/60Hz in North America, 230V/50Hz in Europe). Include multilingual safety labels and user manuals. Comply with local occupational safety regulations regarding laser emissions (e.g., FDA 21 CFR Part 1040.10 in the U.S., IEC 60825 internationally).

Environmental and Waste Disposal Regulations

Follow local environmental regulations for electronic waste (e-waste) disposal at end-of-life. In the EU, comply with the WEEE (Waste Electrical and Electronic Equipment) Directive, which mandates proper recycling and labeling. Avoid shipping machines containing hazardous substances restricted under RoHS (Restriction of Hazardous Substances). Provide customers with disposal instructions and information on authorized take-back programs.

Documentation and Recordkeeping

Maintain comprehensive records for at least five years, including export licenses (if applicable), shipping documents, compliance certifications, and customer delivery confirmations. Provide end-users with operation manuals, safety data sheets (if applicable), and compliance declarations. Accurate documentation supports audits, warranty claims, and regulatory inquiries.

After-Sales Support and Regulatory Updates

Monitor changes in international trade policies, safety standards, and environmental regulations that may affect ongoing compliance. Offer technical support and software/firmware updates to ensure continued safe and compliant operation. Train local distributors on compliance responsibilities and product handling.

Conclusion:

After a thorough evaluation of available options, sourcing a crystal engraving machine is a strategic investment that enhances product customization, improves production efficiency, and supports business growth in markets demanding personalized or premium items. The selection process should prioritize precision, durability, ease of use, software compatibility, and after-sales support. Based on performance requirements, budget considerations, and scalability needs, a CO2 laser engraving machine with 3D crystal engraving capabilities emerges as the most suitable choice for high-quality internal and surface engraving. Additionally, sourcing from reputable suppliers with proven track records ensures reliability and long-term value. Ultimately, integrating a crystal engraving machine strengthens competitive advantage, expands service offerings, and meets the growing demand for bespoke crystal products across industries such as awards, gifts, and luxury goods.