The global glass recycling market is experiencing robust growth, driven by increasing environmental awareness, stringent government regulations on waste management, and rising demand for recycled materials in manufacturing. According to Grand View Research, the global recycled glass market size was valued at USD 31.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This surge is amplified by the construction, packaging, and automotive industries’ growing reliance on cullet—crushed glass—to reduce energy consumption and carbon emissions during production. With recycling rates improving and investment in advanced glass processing technologies on the rise, leading crush glass manufacturers are scaling operations to meet demand. The following list highlights the top eight manufacturers at the forefront of innovation, capacity, and sustainability in the crushed and recycled glass space.

Top 8 Crush Glass Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Crushed Glass Blasting Media Supplier

Domain Est. 1997

Website: agsco.com

Key Highlights: AGSCO offers crushed Glass, an angular media made entirely of recycled glass that can be used in various applications. Request your quote!…

#2 Andela Products

Domain Est. 2001

Website: andelaproducts.com

Key Highlights: Andela Products designs & manufactures the best large-scale glass recycling machines, systems, equipment, and components. In business for over 25 years….

#3 Eye Candy Crush

Domain Est. 2014

Website: thecrushglass.com

Key Highlights: Fresh From The Kiln · Iridescent Sherbet Spoons · Iridescent Sherbet Spoons · Peace Pipe · Peace Pipe · Etched Electroplated Barrel Pipe · 14mm Electroplated Slides ……

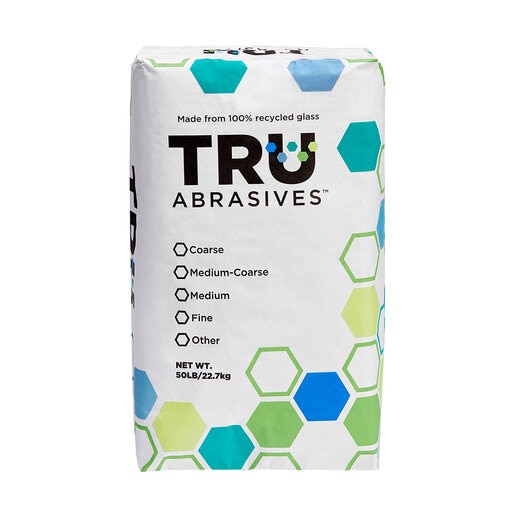

#4 TruAbrasives

Domain Est. 2016

Website: truabrasives.com

Key Highlights: TruAbrasives is the industry leading crushed glass abrasive, superior to other abrasives in a variety of applications for benefits in quality, performance and ……

#5 Daixi glass

Domain Est. 2016

Website: daixiglass.com

Key Highlights: Our company is a leading provider of crushed glass,pool glass beads,glass rock. We can meet various requirements from different types of customers….

#6 Tumbled Crushed Glass For Art

Domain Est. 2017

#7 Crushed Glass

Domain Est. 2020

Website: deepsouthshelling.com

Key Highlights: Crushed Glass for Resin Art. Varieties include Reflective Fire Glass, Classic Fireglass, and our Exclusive Art Glass….

#8 CRUSH GLASS

Domain Est. 2021

Website: crushglasskc.com

Key Highlights: We deliver a Crush Glass recycling bin out to your location on the first scheduled pickup! 3. TO THE CURB. Bring your bin out to the curb by 7 AM on pickup ……

Expert Sourcing Insights for Crush Glass

H2 2026 Market Trends for Crushed Glass

As we approach the second half of 2026, the crushed glass market is poised for significant transformation, driven by tightening environmental regulations, evolving consumer demand for sustainability, and technological advancements in recycling and manufacturing. Here are the key trends shaping the industry:

1. Surge in High-Value Applications Beyond Traditional Uses:

* Construction & Infrastructure Boom: Demand for crushed glass (glasphalt, concrete aggregate, pipe bedding) will intensify, driven by green building certifications (LEED v5+, BREEAM) and municipal mandates requiring recycled content in public projects. Innovations in processing will yield cleaner, more consistent cullet, enhancing performance and acceptance in structural applications.

* Advanced Filtration & Water Treatment: High-purity crushed glass will see accelerated adoption as a superior, sustainable filter media in municipal water and wastewater treatment, outperforming sand due to better flow rates and reduced maintenance. This niche will command premium pricing.

* Emerging Industrial & Specialty Uses: Growth is expected in applications like:

* Abrasive Blasting: Replacing hazardous silica sand.

* Foundry Molds: Utilizing specific glass types for casting.

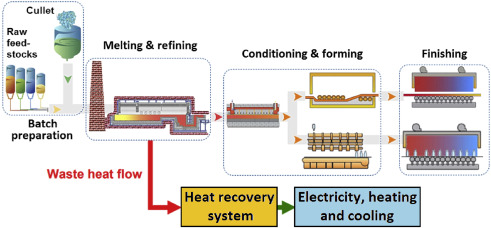

* Ceramics & Glass Manufacturing: Increased use of cullet as a raw material (batch) to lower energy consumption and emissions, supported by carbon pricing mechanisms.

2. Regulatory Pressure as the Primary Growth Catalyst:

* Extended Producer Responsibility (EPR) Schemes: Mandates across the US, EU, and other regions will force brand owners and producers to fund and achieve higher recycling rates, directly increasing the supply of collected glass and demand for processed cullet.

* Landfill Bans & Tipping Fee Hikes: Stricter bans on glass in landfills and significantly increased disposal costs will make recycling economically imperative for municipalities and waste haulers, boosting collection and processing volumes.

* Recycled Content Mandates: Regulations requiring minimum percentages of recycled glass in new bottles (e.g., EU targets, US state laws) will create a guaranteed, high-demand market for high-quality cullet, particularly clear (flint) glass.

3. Supply Chain Consolidation & Quality Imperative:

* “Glass Cliff” Resolution: Investments in advanced sorting technology (AI, NIR, robotics) at MRFs and dedicated glass processors will significantly improve cullet quality by reducing contaminants (ceramics, stones, metals). This is critical for high-value applications.

* Consolidation & Vertical Integration: Expect mergers among processors and partnerships between recyclers, construction firms, and manufacturers to secure supply chains, ensure quality, and capture value across the lifecycle.

* Regionalization of Processing: To reduce transportation costs and carbon footprint, localized glass processing hubs will become more common, especially near high-consumption or high-disposal urban areas.

4. Economic & Market Dynamics:

* Price Volatility & Premium for Quality: Prices will remain volatile but show an overall upward trend. A significant price premium will exist for high-purity, contaminant-free, and color-sorted cullet suitable for container glass manufacturing. Mixed or lower-quality cullet will face price pressure.

* Competition with Virgin Materials: The economic viability of crushed glass hinges on the relative cost of virgin materials (sand, soda ash, limestone) and energy. High energy prices favor cullet use in manufacturing. Carbon pricing mechanisms will further improve cullet’s competitiveness.

* Investment in Innovation: R&D will focus on new applications (e.g., glass foams, geopolymers), improved sorting efficiency, and methods to handle challenging glass types (e.g., borosilicate, laminated).

5. Consumer & Brand Influence:

* Circular Economy Focus: Increased consumer awareness and demand for sustainable packaging will pressure brands to use recycled content, directly boosting demand for high-quality cullet.

* Transparency & Traceability: Brands will require verifiable proof of recycled content and sustainable sourcing, driving demand for certified cullet and traceable supply chains.

Conclusion for H2 2026:

The crushed glass market in H2 2026 will be characterized by strong growth driven by regulation and sustainability goals, a critical shift towards higher quality cullet, and expanding applications beyond traditional landscaping. Success will depend on processors’ ability to deliver consistent, high-purity material, particularly clear glass, and to innovate in both technology and end-use markets. While challenges around collection efficiency and contamination persist, the overall trajectory is positive, positioning crushed glass as a vital component of the circular economy and a strategic material in decarbonizing industries like construction and packaging.

Common Pitfalls in Sourcing Crushed Glass (Quality and Intellectual Property)

Sourcing crushed glass for industrial, construction, or design applications can present several challenges, particularly concerning material quality consistency and intellectual property (IP) risks. Overlooking these factors can lead to product failures, legal disputes, or reputational damage.

Inconsistent Quality and Contamination

One of the most frequent issues in sourcing crushed glass is variability in quality. Suppliers may offer material that contains impurities such as ceramics, stones, metals, or organic residues, especially if the source is mixed post-consumer waste. These contaminants can compromise the performance of the final product—whether used in concrete, filtration systems, or decorative applications. Additionally, inconsistent particle size distribution and angularity affect workability and structural integrity. Without stringent quality control and standardized processing (e.g., optical sorting, magnetic separation), buyers risk receiving subpar material that fails to meet technical specifications.

Lack of Traceability and Certification

Many suppliers do not provide full traceability of the glass source or processing methods. This opacity makes it difficult to verify compliance with environmental regulations or industry standards (e.g., ASTM, LEED). In construction or sustainable building projects, using uncertified or undocumented recycled glass can jeopardize green building certifications and lead to audit failures.

Intellectual Property Infringement Risks

When crushed glass is used in proprietary applications—such as specialty glassphalt, terrazzo, or innovative building materials—there is a risk of inadvertently infringing on patented processes or formulations. Some companies hold IP rights on specific methods of treating, coloring, or integrating crushed glass into composite materials. Sourcing decisions made without IP due diligence may expose the buyer to legal liability, especially if the supplier is using a protected technology without proper licensing.

Supplier Misrepresentation

Some suppliers may misrepresent the origin, purity, or processing history of their crushed glass. For example, labeling mixed-color cullet as “clear crushed glass” or claiming “food-grade” processing without certification can mislead buyers. This misrepresentation affects both product performance and regulatory compliance, particularly in sensitive applications like filtration or architectural finishes.

Inadequate Supply Chain Control

Reliance on intermediaries or brokers without direct oversight of the crushing and sorting process increases the risk of quality deviations. Without clear contractual agreements specifying tolerances, testing protocols, and penalties for non-compliance, buyers have limited recourse when material fails to meet expectations.

To mitigate these pitfalls, buyers should conduct thorough supplier audits, request third-party test reports, establish clear quality agreements, and perform IP landscape analyses when developing new products involving crushed glass.

Logistics & Compliance Guide for Crush Glass

Overview

Crushed glass, also known as cullet, is a recyclable material used in various industries such as construction, glass manufacturing, and abrasives. Due to its physical properties and potential environmental impact, the transportation, handling, and disposal of crushed glass are subject to specific logistics and regulatory compliance requirements. This guide outlines best practices and regulatory considerations to ensure safe, efficient, and compliant operations.

Classification and Hazard Assessment

Crushed glass is generally classified as a non-hazardous recyclable material when uncontaminated. However, it is considered a sharp, abrasive substance and must be handled accordingly. If mixed with hazardous substances (e.g., leaded glass, chemical residues, or contaminants), it may fall under hazardous waste regulations. Always conduct a waste determination in accordance with local, state, and federal guidelines (e.g., EPA regulations in the U.S.).

Packaging and Containment

Use durable, leak-proof containers to prevent spillage and worker injury. Common packaging includes:

– Heavy-duty poly bags within rigid totes or drums

– Sealed bulk containers for large volumes

– Lidded roll-off containers for construction or demolition debris

Ensure containers are clearly labeled as “Crushed Glass” or “Recycled Glass Cullet” and include any relevant handling warnings (e.g., “Sharp Edges – Handle with Care”).

Transportation Requirements

Transport crushed glass in vehicles designed to contain loose materials and prevent debris dispersion. Key considerations include:

– Covering open-top trailers or dump trucks to avoid wind scatter and roadway litter

– Securing loads properly to prevent shifting during transit

– Complying with Department of Transportation (DOT) or local transport regulations for non-hazardous bulk materials

– Maintaining vehicle maintenance records and driver training logs where applicable

Storage Guidelines

Store crushed glass in designated, well-ventilated areas protected from weather when possible. Best practices include:

– Using impermeable surfaces to prevent soil contamination

– Installing containment berms or liners if storing outdoors

– Limiting stockpile height to prevent collapse or erosion

– Posting signage indicating material type and safety precautions (e.g., PPE required)

Worker Safety and PPE

Due to the risk of cuts, eye injuries, and respiratory issues (from fine dust), personnel must use appropriate personal protective equipment (PPE), including:

– Cut-resistant gloves

– Safety goggles or face shields

– Steel-toed boots

– Dust masks or respirators if handling dry, fine-grade cullet

Provide training on safe handling, emergency procedures, and waste segregation.

Regulatory Compliance

Ensure compliance with relevant environmental and occupational safety regulations:

– EPA (U.S.): Follow Resource Conservation and Recovery Act (RCRA) guidelines for waste classification and disposal

– OSHA: Adhere to Hazard Communication (HazCom) and Personal Protective Equipment (PPE) standards

– State/Local Regulations: Some jurisdictions require permits for storage or transportation of recyclable materials

– International Shipments: Comply with IMDG Code or ADR regulations if exporting; verify destination country import requirements

Recycling and End-Use Tracking

Maintain documentation of recycled material destinations, including:

– Recycler or processor name and location

– Quantity shipped

– Certificate of Recycling or Bill of Lading

This supports environmental reporting and may be required for sustainability certifications or regulatory audits.

Spill and Incident Response

Develop a spill response plan specific to crushed glass:

– Small spills: Use brooms, dustpans, and vacuum systems with HEPA filters

– Large spills: Contain area, notify supervisor, and follow site-specific emergency procedures

– Report significant incidents to regulatory bodies if contamination or environmental release occurs

Recordkeeping and Audits

Maintain records for a minimum of three years, including:

– Waste manifests (if regulated)

– Training logs

– Inspection reports

– Shipping and receiving documentation

Regular internal audits help ensure ongoing compliance and operational efficiency.

Conclusion

Proper logistics and compliance management for crushed glass reduce safety risks, minimize environmental impact, and support regulatory adherence. By following this guide, organizations can ensure responsible handling from collection through final recycling or disposal. Stay informed of evolving regulations and update procedures accordingly.

Conclusion on Sourcing Crushed Glass:

Sourcing crushed glass, also known as cullet, presents a sustainable and cost-effective opportunity across various industries, including construction, landscaping, and manufacturing. By utilizing recycled glass, businesses can reduce landfill waste, lower energy consumption in production processes, and support circular economy initiatives. Successful sourcing depends on establishing reliable supply chains with recycling facilities, ensuring consistent quality and appropriate grading of the crushed material. Additionally, compliance with environmental regulations and safety standards is essential. As demand for eco-friendly materials grows, investing in the responsible sourcing of crushed glass not only contributes to environmental conservation but also enhances corporate sustainability profiles and long-term economic efficiency.