The global crumb rubber market is experiencing robust growth, driven by rising demand for sustainable materials in road construction, sports surfaces, and automotive applications. According to Grand View Research, the market was valued at USD 1.87 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. This growth is fueled by increasing focus on recycling end-of-life tires and reducing environmental impact, with crumb rubber emerging as a cost-effective and eco-friendly alternative to virgin materials. As infrastructure development accelerates and regulations promote tire recycling, manufacturers are scaling production and innovating processing technologies to meet evolving industry needs. In this expanding landscape, six key players have distinguished themselves through capacity, quality, and technological advancement, setting the benchmark for performance and sustainability in the crumb rubber sector.

Top 6 Crumb Rubber Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Crumb rubber modified bitumens (CRMB)

Domain Est. 1996

Website: repsol.com

Key Highlights: Repsol has developed an innovative product using end-of-life crumb rubber to improve bitumen performance….

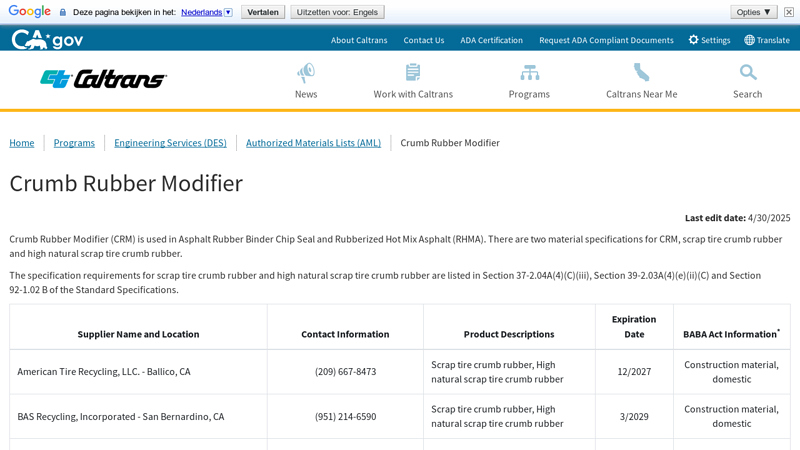

#2 Crumb Rubber Modifier

Domain Est. 1997

Website: mets.dot.ca.gov

Key Highlights: Crumb Rubber Modifier (CRM) is used in Asphalt Rubber Binder Chip Seal and Rubberized Hot Mix Asphalt (RHMA)….

#3 Rubber Crumb Project

Domain Est. 1998

Website: cariri.com

Key Highlights: The commissioned plant can produce rubber crumb and rubber powder, with numerous trial runs conducted. The project is a pivotal element in CARIRI’s commitment ……

#4 Crumb Rubber

Domain Est. 2010

Website: cobaltrubber.com

Key Highlights: Crumb rubber is being used to a greater extent in many states in rubberized asphalt applications and is the largest single use of recycled rubber….

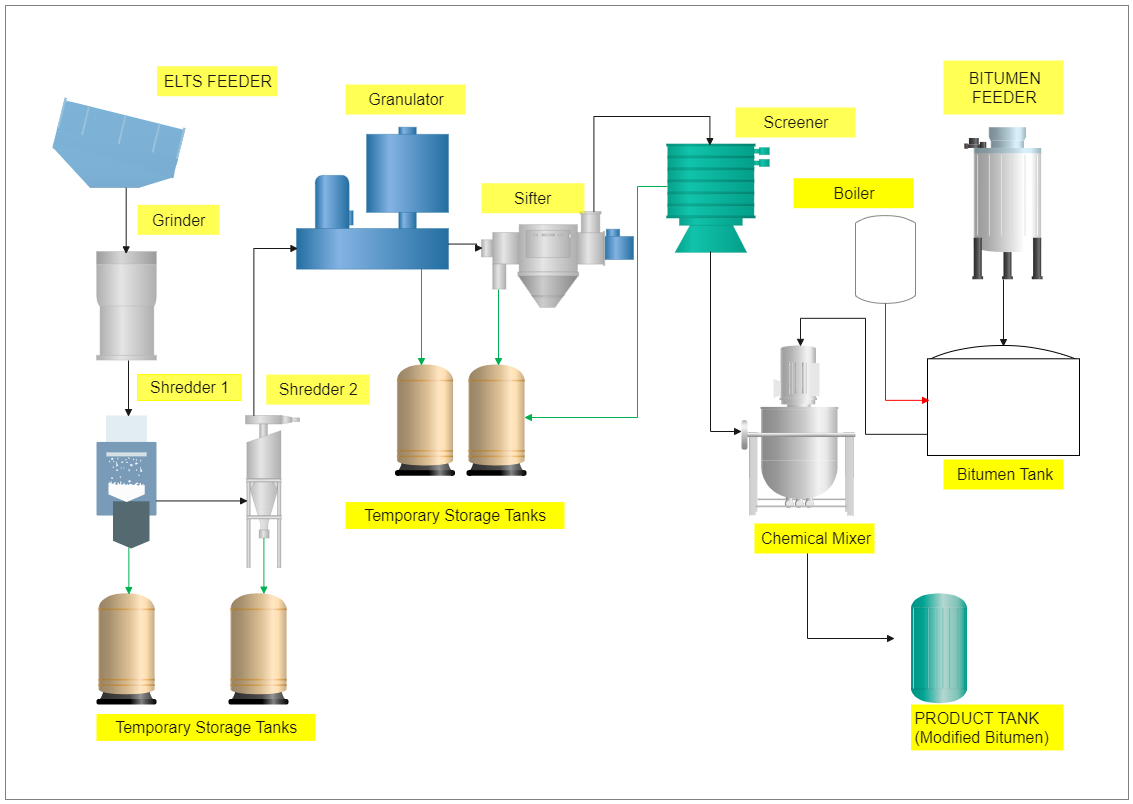

#5 Crumb Rubber Plants

Domain Est. 2012

Website: t2gr.com

Key Highlights: The Crumb Rubber plant is proven to convert whole scrap tires into high quality, uncontaminated crumb rubber. this plant is designed to process from 300kgs to 4 ……

#6 Crumb Rubber

Domain Est. 2012

Website: emterrausa.com

Key Highlights: Recycled crumb rubber can be used in a number of applications including playgrounds, floor mats, soundproof wall barriers, automotive products, roofing, ……

Expert Sourcing Insights for Crumb Rubber

H2: 2026 Market Trends for Crumb Rubber

The global crumb rubber market is poised for significant transformation by 2026, driven by increasing environmental concerns, regulatory support for recycling, and growing demand across key end-use industries. Crumb rubber, derived from recycled tires through mechanical or cryogenic processing, is gaining traction as a sustainable alternative to virgin materials in various applications.

-

Sustainability and Environmental Regulations

By 2026, stringent environmental regulations and global initiatives to reduce tire waste will be major growth drivers. Governments in North America, Europe, and parts of Asia-Pacific are expected to enforce stricter landfill bans on scrap tires, compelling industries to adopt recycled rubber solutions. The circular economy model will further boost investment in tire recycling infrastructure, increasing the supply and quality of crumb rubber. -

Expansion in End-Use Applications

The construction and infrastructure sectors will remain the largest consumers of crumb rubber, particularly in asphalt modification (rubberized asphalt) and athletic flooring. Rubber-modified asphalt improves road durability, noise reduction, and skid resistance, leading to widespread adoption in public infrastructure projects. Additionally, demand in sports surfaces, playgrounds, and molded rubber products will grow due to enhanced safety and performance characteristics. -

Technological Advancements

Innovations in devulcanization and particle size refinement will improve the performance and compatibility of crumb rubber in high-value applications such as automotive components and new tire manufacturing. By 2026, advanced processing technologies are expected to yield finer, cleaner crumb rubber with consistent quality, expanding its usability in sensitive industrial applications. -

Regional Market Dynamics

North America will continue to lead the crumb rubber market, supported by established recycling programs and federal incentives. Europe will follow closely, driven by EU directives on waste management and sustainable public procurement. Meanwhile, the Asia-Pacific region—particularly China and India—will witness rapid growth due to urbanization, infrastructure development, and rising awareness of tire recycling. -

Challenges and Opportunities

Despite positive trends, the market faces challenges such as inconsistent feedstock quality, transportation costs, and public perception around recycled materials. However, partnerships between tire manufacturers, recyclers, and government agencies are expected to streamline supply chains and enhance market credibility.

In conclusion, the crumb rubber market in 2026 will be shaped by sustainability mandates, technological innovation, and expanding application scope. With increasing emphasis on eco-friendly materials, crumb rubber is set to play a critical role in the global transition toward a circular economy.

Common Pitfalls Sourcing Crumb Rubber (Quality, IP)

Sourcing crumb rubber can present several challenges, particularly concerning material quality and intellectual property (IP) considerations. Being aware of these pitfalls is essential for ensuring consistent performance, regulatory compliance, and protection against legal risks.

Inconsistent or Poor Quality

One of the most frequent issues in sourcing crumb rubber is variability in quality due to differences in feedstock (e.g., tire types, age, origin) and processing methods. Poorly processed crumb rubber may contain contaminants like metal, fiber, or excessive moisture. Variations in particle size distribution, surface cleanliness, and polymer integrity can negatively impact performance in applications such as rubber-modified asphalt, sports surfaces, or molded products. Without stringent quality control and standardized specifications (e.g., ASTM standards), buyers risk receiving subpar material that fails to meet technical requirements.

Lack of Traceability and Certification

Many suppliers do not provide full traceability of the source tires or processing history, making it difficult to verify compliance with environmental regulations (e.g., REACH, RoHS) or industry-specific standards. The absence of third-party certifications (e.g., ISO, UL, or Crumb Rubber Product Council seals) increases the risk of sourcing material with hazardous substances or inconsistent properties. This is particularly critical in sensitive applications such as playgrounds or athletic fields where health and safety are paramount.

Intellectual Property Risks

Using crumb rubber in innovative formulations or patented end-products can inadvertently lead to IP infringement. Some processing technologies or proprietary blends (e.g., devulcanization methods, surface treatments) are protected by patents. Sourcing crumb rubber processed using patented techniques—without proper licensing—may expose the buyer to legal liability. Additionally, if a supplier claims exclusive rights to a specific grade or treated crumb rubber, using it in certain applications could violate usage agreements or territorial restrictions.

Inadequate Specifications and Testing Protocols

Buyers often fail to define clear technical specifications or overlook the importance of batch testing. Without agreed-upon parameters for mesh size, ash content, volatile matter, and polymer composition, disputes over material suitability are common. Relying solely on supplier claims without independent verification can result in performance failures and costly rework.

Supply Chain Transparency and Sustainability Claims

Some suppliers make unsubstantiated environmental or sustainability claims (e.g., “green,” “eco-friendly”) without proof of responsible sourcing or processing. This not only poses reputational risks but may also conflict with corporate sustainability goals or public procurement requirements. Ensuring transparency in the supply chain is crucial to avoid greenwashing and ensure alignment with ESG criteria.

Avoiding these pitfalls requires due diligence, clear contractual agreements, rigorous quality assurance processes, and awareness of applicable IP rights in both the sourced material and its intended application.

Logistics & Compliance Guide for Crumb Rubber

Crumb rubber, derived from recycled tires, is widely used in applications such as sports fields, playgrounds, rubberized asphalt, and molded rubber products. Due to its origin and potential environmental and health concerns, transporting and handling crumb rubber requires adherence to specific logistics and regulatory compliance standards. This guide outlines key considerations for safe and compliant management of crumb rubber across the supply chain.

Regulatory Classification and Documentation

Crumb rubber is generally classified as a non-hazardous material in most jurisdictions when processed and handled appropriately. However, regulations vary by country and region. Common classifications include:

- US DOT (Department of Transportation): Typically not regulated as hazardous under 49 CFR when properly processed and free of contaminants. However, shippers must verify with current Material Safety Data Sheets (MSDS) or Safety Data Sheets (SDS).

- EPA (Environmental Protection Agency): Regulates crumb rubber under the Resource Conservation and Recovery Act (RCRA). Processed crumb rubber used beneficially (e.g., in construction) may qualify for regulatory exclusions.

- REACH (EU): Subject to registration under REACH if imported in quantities ≥1 tonne/year. Contains substances of very high concern (SVHCs) such as polycyclic aromatic hydrocarbons (PAHs), requiring communication through the supply chain.

- RoHS & POPs Regulations: Check for compliance with restrictions on hazardous substances, particularly in consumer-facing products.

Ensure up-to-date SDS documentation is available, clearly stating composition, handling instructions, and regulatory status.

Packaging and Containment

Proper packaging prevents contamination, dust generation, and environmental release during transport:

- Use sealed, durable bulk bags (super sacks), poly-lined totes, or covered containers.

- For bulk transport, use enclosed trailers or containers with secure tarping to prevent spillage and dust emissions.

- Label packages clearly with contents (“Recycled Crumb Rubber”), batch number, and any applicable handling symbols (e.g., “Keep Dry,” “Do Not Invert”).

- Minimize exposure to moisture—store and transport under cover to prevent clumping and degradation.

Transportation and Handling

Comply with national and international transport regulations:

- Domestic (US): Follow FMCSA and DOT guidelines for non-hazardous freight. Secure loads to prevent shifting.

- International (IMDG, IATA, ADR): Though generally exempt from hazardous material designation, confirm classification for sea (IMDG), air (IATA), and road (ADR in Europe) transport. Provide accurate commodity descriptions.

- Use enclosed conveyances to reduce particulate dispersion.

- Employ dust suppression measures (e.g., misting, enclosed conveyor systems) during loading/unloading.

- Train personnel in safe handling procedures, including use of PPE (dust masks, gloves, safety glasses).

Storage Requirements

Proper storage prevents fire hazards and environmental contamination:

- Store in dry, well-ventilated areas away from direct sunlight and ignition sources.

- Keep away from oxidizers and flammable materials.

- Use palletized stacking with clear aisle access; avoid excessive pile heights to reduce compaction and heat retention.

- Implement secondary containment if stored outdoors to prevent runoff contamination.

- Monitor for spontaneous combustion in large stockpiles (rare but possible due to residual oils and microbial activity).

Environmental and Health Considerations

- Dust Control: Crumb rubber can generate fine particulates. Use local exhaust ventilation or water sprays during processing.

- Leachate Testing: For outdoor applications (e.g., turf infill), conduct leachate testing per EPA Method 1311 (TCLP) or EU EN 12457 standards to assess potential groundwater impact.

- Worker Safety: Provide respiratory protection where airborne particles are present. Follow OSHA guidelines for particulate exposure (e.g., PELs for rubber processing).

- End-of-Life Management: Plan for recycling or disposal in compliance with local waste regulations. Landfilling may be restricted in some areas.

Import/Export Compliance

- Verify tariff classification (e.g., HS Code 4004.00 for waste or scrap of rubber in many countries).

- Comply with import restrictions in destination countries (e.g., EU’s strict PAH limits in consumer products under REACH).

- Maintain records of origin, processing method, and test results (e.g., PAH, metal content) for customs and regulatory audits.

- Obtain necessary permits for transboundary movement of waste (if classified as such under Basel Convention—note: processed crumb rubber often excluded if used for recycling).

Quality Assurance and Traceability

- Implement batch tracking from source tires to final product.

- Conduct regular testing for contaminants (PAHs, heavy metals, fiber content).

- Maintain certifications (e.g., ISO 9001, ISO 14001) and industry-specific standards (e.g., ASTM F2882 for athletic field infill).

By following this guide, stakeholders in the crumb rubber supply chain can ensure regulatory compliance, promote environmental stewardship, and maintain safe, efficient logistics operations. Regularly consult federal, state, and international regulatory updates to remain compliant.

Conclusion for Sourcing Crumb Rubber

Sourcing crumb rubber presents a sustainable and cost-effective solution for a variety of industrial, construction, and recreational applications. As a recycled material derived from end-of-life tires, crumb rubber contributes to environmental conservation by reducing landfill waste and promoting circular economy principles. Its versatility makes it ideal for use in rubberized asphalt, athletic surfaces, playgrounds, and molded rubber products.

When sourcing crumb rubber, it is essential to consider factors such as quality, consistency, particle size, de-vulcanization level, and environmental safety. Partnering with reputable suppliers who adhere to regulatory standards and utilize environmentally responsible processing methods ensures reliable material performance and minimizes health and environmental risks.

Additionally, local availability, transportation costs, and compliance with regional environmental regulations play a significant role in determining the overall feasibility and sustainability of sourcing strategies. As demand for eco-friendly materials grows and recycling technologies advance, crumb rubber is poised to become an even more integral component in sustainable manufacturing and infrastructure development.

In conclusion, responsible sourcing of crumb rubber not only supports environmental goals but also offers economic and functional benefits, making it a strategic choice for forward-thinking industries committed to sustainability and innovation.