The global textile machinery market is witnessing steady expansion, driven by rising demand for automated and precision-based manufacturing solutions. According to a report by Mordor Intelligence, the textile machinery market is projected to grow at a CAGR of approximately 5.8% from 2024 to 2029. A key contributor to this growth is the increasing adoption of advanced crochet (or crocheting) machines in both industrial and small-scale production settings, particularly for technical textiles, fashion apparel, and home furnishings. As automation and customization become increasingly critical in textile production, manufacturers are turning to high-efficiency crochet machines that offer flexibility, speed, and consistent output. This growing demand has spurred innovation and competition among leading machine producers worldwide. Based on market presence, technological capabilities, and customer feedback, we’ve identified the top 9 crochet machine manufacturers shaping the future of textile automation.

Top 9 Crotchet Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Jiangsu New Victor Industrial Co., Ltd.

Domain Est. 2009

Website: victormac.com

Key Highlights: Jiangsu New Victor Industrial Co., Ltd. is a professional leader China crochet machine, crochet knitting machine, chenille machine manufacturer…

#2 Company Profile

Domain Est. 1999 | Founded: 1992

Website: da-hu.com

Key Highlights: Established in 1992, Taiwan DAHU is a leading manufacturer of high-quality crochet knitting machines, certified with ISO 9001:2015 and CE….

#3 High Speed Automatic Crochet Knitting Machine Series

Domain Est. 2011

Website: kyangyhe.com

Key Highlights: Manufacturer of High Speed Automatic Crochet Machine Series. High speed automatic crochet knitting machine be called for short as crochet machine, is one type ……

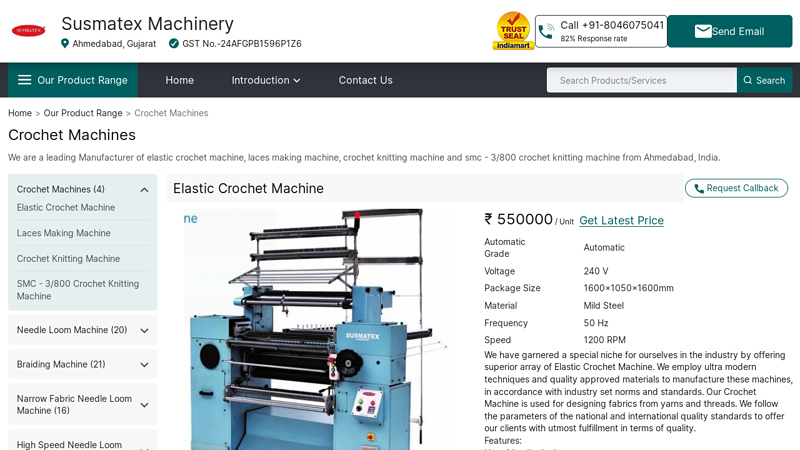

#4 Elastic Crochet Machine Manufacturer from Ahmedabad

Domain Est. 2012

Website: needleloommachines.com

Key Highlights: We employ ultra modern techniques and quality approved materials to manufacture these machines, in accordance with industry set norms and standards….

#5 Homepage

Domain Est. 1989

Website: dmc.com

Key Highlights: Already have your unit? Turn it from a simple box of embroidery supplies into a beautifully organized atelier with our drawer dividers and accessories. Shop now….

#6 Sewing Machines

Domain Est. 1996

Website: merrow.com

Key Highlights: Devised in 1868 in the machine shop built by his grandfather, the first Merrow Crochet Machine was an invention of Mr. Joseph Millard Merrow. These new crochet ……

#7 Ganga Acrowools

Domain Est. 1999

Website: gangaacrowools.com

Key Highlights: Ganga Acrowools Limited located in North west state of Punjab in India today employees 5438 people who as a team produce and deliver over 45,000 Kgs of yarn ……

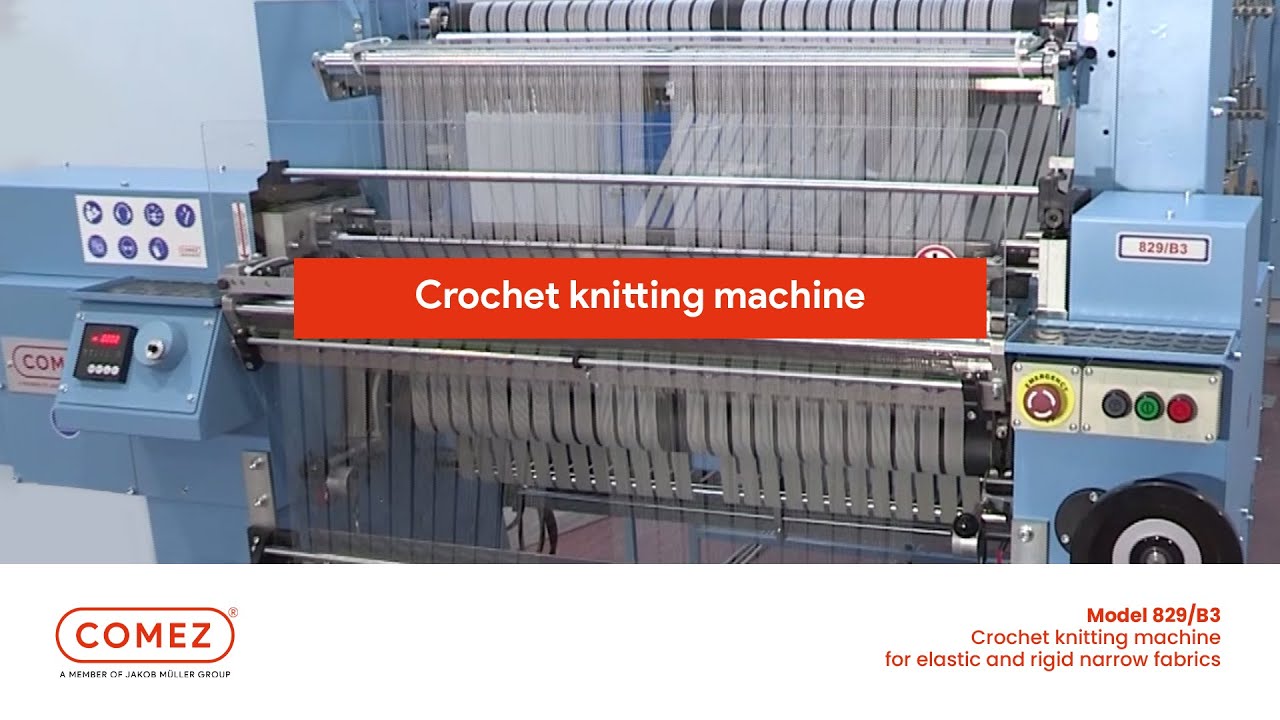

#8 Crochet Knitting Machines

Domain Est. 2001

Website: ledmak.com

Key Highlights: Ledmak Crochet Knitting Machines ensure fast, reliable, and precise production of lace, elastic, and technical fabrics for modern textile needs….

#9 CLOVER

Domain Est. 2009

Website: clover-mfg.com

Key Highlights: Make people around the world happy through handmade. We provide a wide range of high-quality craft supplies….

Expert Sourcing Insights for Crotchet Machine

H2: Projected Market Trends for Crochet Machines in 2026

The global market for crochet machines is poised for notable transformation by 2026, driven by technological innovation, rising consumer interest in handmade textiles, and increasing automation in small-scale manufacturing. This analysis explores key trends expected to shape the crochet machine industry in the coming years.

-

Increased Demand for Home and Hobbyist Use

By 2026, the growing popularity of DIY crafts and sustainable fashion is expected to fuel demand for compact, user-friendly crochet machines targeted at home artisans and hobbyists. Online platforms like Etsy and Instagram have amplified interest in handmade garments, motivating more consumers to adopt semi-automatic or computerized crochet devices for personal use. -

Advancements in Smart and Computerized Machines

Integration of AI and IoT in crochet machines is anticipated to accelerate. By 2026, smart crochet machines with mobile app connectivity, pattern libraries, and automated tension control will become more accessible. These features will appeal to both beginners and experienced crafters, lowering entry barriers and enhancing precision. -

Expansion in Emerging Markets

Asia-Pacific, particularly countries like India and Indonesia, is projected to witness rising adoption of crochet machines due to growing middle-class disposable income and government support for textile entrepreneurship. Localized manufacturing and affordable machine models will drive market penetration in these regions. -

Sustainability and Eco-Friendly Production

As environmental concerns influence consumer choices, manufacturers are expected to emphasize energy-efficient motors, recyclable components, and compatibility with organic or recycled yarns. Crochet machines that support slow fashion and on-demand production will gain a competitive edge. -

Industrial Automation and Small-Scale Manufacturing

While industrial knitting dominates mass textile production, niche markets for custom and artisanal fabrics are creating opportunities for automated crochet systems in micro-factories. By 2026, hybrid machines capable of both crochet and knitting may emerge, offering flexibility for small businesses producing limited-edition apparel. -

E-Commerce and Direct-to-Consumer Sales Growth

Online retail channels will continue to play a central role in distributing crochet machines. Brands are likely to invest in virtual tutorials, augmented reality (AR) product previews, and subscription-based pattern services to enhance customer engagement and drive machine sales.

In conclusion, the 2026 market for crochet machines will be shaped by a convergence of digital innovation, consumer-driven customization, and sustainability. As both hobbyist and commercial applications expand, manufacturers who prioritize accessibility,智能化, and eco-conscious design will be best positioned for growth.

Common Pitfalls When Sourcing Crochet Machines (Quality and Intellectual Property)

Sourcing crochet machines, particularly from international suppliers, involves several potential pitfalls that can impact product quality, business reputation, and legal compliance. Two critical areas to watch are quality consistency and intellectual property (IP) risks.

Quality-Related Pitfalls

Inconsistent Machine Performance

Many low-cost crochet machines, especially from less-regulated manufacturers, suffer from inconsistent tension control, skipped stitches, or mechanical misalignment. This leads to defective or non-uniform textile output, increasing waste and production downtime.

Use of Substandard Materials

Unreliable suppliers may use inferior metals, plastics, or electronic components to cut costs. This results in machines with shorter lifespans, frequent breakdowns, and higher maintenance costs—undermining long-term ROI.

Lack of After-Sales Support and Spare Parts

Some suppliers disappear after delivery or fail to provide technical support, manuals, or replacement parts. This can halt production if a critical component fails and cannot be repaired promptly.

Insufficient Testing and Calibration

Machines may be shipped without proper factory testing or calibration. Buyers then face the burden of troubleshooting and adjustments, delaying production timelines and increasing setup costs.

Intellectual Property (IP) Risks

Rebranded or Counterfeit Machines

A significant risk is sourcing machines that are rebranded copies of patented or trademarked models. These machines may infringe on IP rights held by original equipment manufacturers (OEMs), exposing the buyer to legal liability, especially when importing into IP-protective markets like the EU or U.S.

Unauthorized Use of Proprietary Technology

Some machines incorporate proprietary software, control systems, or mechanical designs without licensing. Purchasing such equipment can inadvertently involve your business in IP infringement disputes, even if unintentional.

Lack of Documentation and Compliance Certificates

Reputable suppliers provide clear documentation, including CE, ISO, or other compliance certifications. Machines lacking these may not meet safety or regulatory standards and could signal IP violations or subpar manufacturing practices.

Difficulty in Enforcement Across Borders

If IP issues arise, enforcing rights or seeking redress against overseas suppliers is complex and costly. Jurisdictional limitations and weak IP enforcement in some countries make resolution difficult.

Mitigation Strategies

To avoid these pitfalls:

– Conduct thorough due diligence on suppliers (audits, references, site visits).

– Request product certifications and verify IP ownership claims.

– Include quality assurance and IP indemnity clauses in contracts.

– Work with legal and technical experts when evaluating machinery purchases.

Proactively addressing these risks ensures reliable machine performance and protects your business from legal and operational setbacks.

Logistics & Compliance Guide for Crotch Machine

Product Classification and Regulatory Compliance

Ensure the Crotch Machine is correctly classified under the appropriate Harmonized System (HS) code for international shipping. Verify compliance with destination country regulations, including medical device standards (if applicable), electrical safety certifications (e.g., CE, UL, FCC), and any required conformity assessments. Maintain technical documentation and Declaration of Conformity for audit readiness.

Packaging and Labeling Requirements

Package the Crotch Machine securely to prevent damage during transit, using shock-absorbent materials and tamper-evident seals where appropriate. Apply clear, multilingual labeling including product name, model number, serial number, manufacturer details, safety warnings, CE/UL marks, and handling instructions (e.g., “Fragile,” “This Side Up”). Include all required regulatory labels per destination market.

Shipping and Transportation Logistics

Utilize certified freight forwarders experienced in handling industrial or medical equipment. Choose shipping methods (air, sea, or ground) based on delivery timelines, cost, and equipment sensitivity. Ensure real-time shipment tracking, temperature control (if needed), and cargo insurance coverage. Comply with IATA, IMDG, or other relevant transport regulations for hazardous components (e.g., batteries).

Import/Export Documentation

Prepare complete documentation for customs clearance, including commercial invoice, packing list, bill of lading/airway bill, certificate of origin, and export license (if required). Verify end-use statements and ensure adherence to export control regulations such as EAR (U.S.) or EU Dual-Use Regulations. Retain records for a minimum of five years.

Duties, Taxes, and Tariff Management

Calculate applicable import duties, VAT, or GST based on the destination country’s tariff schedule. Leverage trade agreements or duty exemptions where eligible (e.g., GSP, USMCA). Partner with local customs brokers to ensure accurate duty assessments and avoid delays or penalties.

End-User Compliance and Installation Support

Verify end-user qualifications if the Crotch Machine requires trained operators or installation by certified technicians. Provide multilingual user manuals, safety guidelines, and compliance training materials. Document installation and commissioning to confirm operational compliance with local standards.

Post-Shipment Monitoring and Recalls

Establish a process for tracking deployed units and managing field safety notices or product recalls. Maintain a compliance incident response plan, including reporting obligations to regulatory authorities and communication protocols with distributors and end-users.

Environmental and Disposal Regulations

Ensure compliance with WEEE, RoHS, and REACH directives (EU) or equivalent regulations in other regions for hazardous substances and end-of-life disposal. Provide take-back programs or recycling instructions for end-users and maintain records of proper disposal.

Conclusion for Sourcing a Crochet Machine

Sourcing a crochet machine requires a strategic approach that balances machine quality, production needs, budget constraints, and long-term operational goals. After evaluating various suppliers, machine types (manual, semi-automatic, and fully automatic), and technical specifications, it is evident that selecting the right machine depends on the scale of production, product complexity, and available expertise.

Automated crochet machines offer higher efficiency and consistency, making them ideal for large-scale manufacturing, while manual or semi-automatic models may suit small businesses or custom production needs. Key considerations such as machine durability, ease of maintenance, yarn compatibility, and after-sales support must be prioritized during the sourcing process.

Sourcing from reputable manufacturers—whether domestic or international—ensures compliance with industry standards and access to technical assistance. Additionally, conducting factory audits, requesting product samples, and comparing total cost of ownership (including shipping, taxes, and training) can significantly reduce risks.

In conclusion, a well-researched and planned sourcing strategy will enable businesses to acquire a crochet machine that enhances productivity, maintains product quality, and supports sustainable growth in the competitive textile and garment market.