The global cotton fabric market continues to experience steady growth, driven by rising consumer demand for sustainable, breathable, and comfortable textiles. According to a 2023 report by Grand View Research, the global cotton fabric market size was valued at USD 58.4 billion and is projected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by increasing awareness of eco-friendly materials, particularly in the apparel and home textiles sectors. Within this landscape, crinkle cotton—a lightweight, textured fabric known for its wrinkle-resistant finish and moisture-wicking properties—has emerged as a preferred choice among designers and manufacturers seeking both aesthetic appeal and functional performance. As sustainability and low-maintenance fabrics gain traction, demand for high-quality crinkle cotton has surged, prompting innovation and competition among leading textile producers. Below, we spotlight the top 7 crinkle cotton fabric manufacturers shaping the industry through quality, scalability, and sustainable practices.

Top 7 Crinkle Cotton Fabric Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 crinkle chiffon fabric Manufacturer & Supplier in China

Domain Est. 2016

Website: dotextile.com

Key Highlights: Crinkle chiffon fabric is a unique fabric which gives a whole new beautiful transition from simple attire to dressy attire. It is special in that it is soft ……

#2 China Crinkle Manufacturer and Supplier, Exporter

Domain Est. 2023

Website: zy-textiles.com

Key Highlights: Are you looking for a reliable crinkle product manufacturer, supplier, and exporter? Look no further! Choose Crinkle, your trusted partner in China….

#3 Cotton Muslin Double Gauze Fabric Manufacturer from Karur

Domain Est. 2024

Website: organicfabricmanufacturer.com

Key Highlights: Cotton double cloth muslin crinkle fabric is a lightweight, breathable, and soft fabric made from 100% cotton. It is often used for clothing, accessories, baby ……

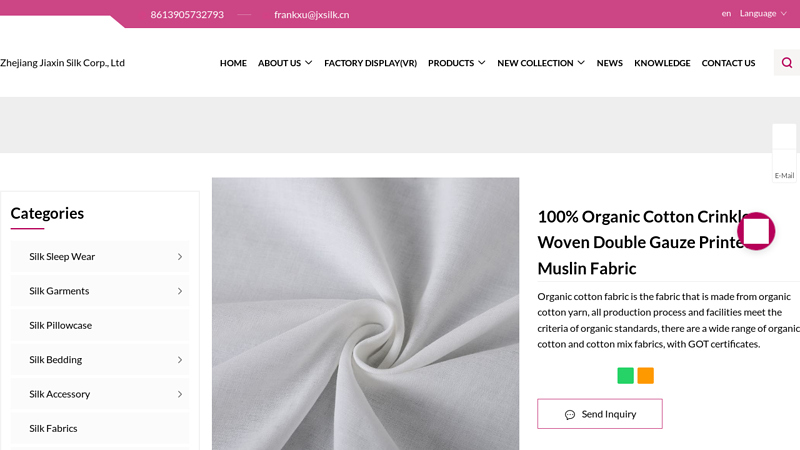

#4 100% Organic Cotton Crinkle Woven Double Gauze Printed Muslin …

Domain Est. 1998

Website: chinesesilk.com

Key Highlights: 100% Organic Cotton Crinkle Woven Double Gauze Printed Muslin Fabric for customers with high quality, appropriate price and good after-sales service….

#5 White Crinkle Japanese Cotton

Domain Est. 2010

Website: merchantandmills.com

Key Highlights: Free delivery over $300 14-day returnsA beautiful pure white Japanese cotton pre washed at the mill which gives it a dry crinkle texture giving your garment structure….

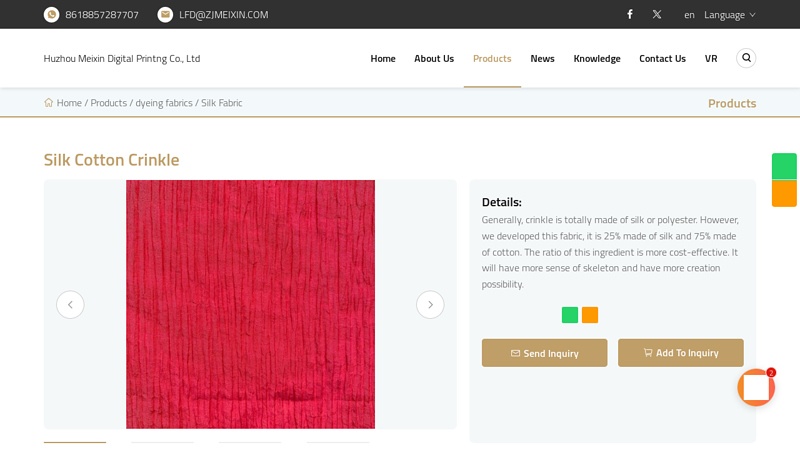

#6 Silk Cotton Crinkle

Domain Est. 2011

Website: zjmeixin.com

Key Highlights: Generally, crinkle is totally made of silk or polyester. However, we developed this fabric, it is 25% made of silk and 75% made of cotton….

#7 All About Crinkle Cotton Clothing

Domain Est. 1999

Website: bluebungalow.com

Key Highlights: Crinkle cotton is a soft that has been treated to have a lasting textured, wrinkly look. Our crinkle cotton collections comes in both woven and knit fabrics….

Expert Sourcing Insights for Crinkle Cotton Fabric

H2: 2026 Market Trends for Crinkle Cotton Fabric

The global market for crinkle cotton fabric is poised for significant evolution by 2026, driven by shifting consumer preferences, sustainability imperatives, and innovation in textile manufacturing. As a textured, breathable, and eco-friendly fabric, crinkle cotton is gaining traction across fashion, home textiles, and activewear sectors. Below are key market trends expected to shape the crinkle cotton fabric industry in 2026:

1. Rising Demand for Sustainable and Low-Impact Textiles

With growing environmental awareness, consumers and brands are increasingly favoring natural, biodegradable fabrics. Crinkle cotton—typically made from 100% cotton without synthetic finishes—aligns with circular fashion principles. By 2026, demand is expected to surge as eco-conscious buyers seek low-water, chemical-free textiles. Certifications like GOTS (Global Organic Textile Standard) will enhance market credibility and drive premium pricing.

2. Expansion in Fashion and Casual Wear Applications

Crinkle cotton’s distinctive texture, wrinkle-resistant properties, and soft hand feel make it ideal for resort wear, summer collections, and minimalist fashion lines. Designers are leveraging its aesthetic versatility for draped silhouettes and relaxed fits. Fast fashion and sustainable brands alike are incorporating crinkle cotton into their 2026 collections, anticipating higher consumer appeal for textured, low-maintenance garments.

3. Growth in Home and Lifestyle Textiles

Beyond apparel, crinkle cotton is gaining popularity in home décor—including curtains, bedspreads, and cushion covers—due to its tactile appeal and durability. The global shift toward comfortable, organic home environments post-pandemic continues to influence demand. By 2026, interior designers are expected to integrate crinkle cotton more frequently into eco-luxury and minimalist design schemes.

4. Technological Advancements in Fabric Finishing

Innovations in mechanical crinkling techniques—such as heat setting and sand-washing without chemical treatments—are improving fabric consistency and scalability. These advancements reduce production costs and environmental impact, making crinkle cotton more accessible. Automation in textile processing will further enhance supply chain efficiency, supporting broader market adoption by 2026.

5. Regional Market Dynamics and Supply Chain Localization

Asia-Pacific, particularly India and China, remains a dominant producer of cotton and crinkle cotton fabric due to raw material availability and manufacturing infrastructure. However, nearshoring trends in Europe and North America may lead to increased regional production to reduce carbon footprints and respond faster to fashion cycles. By 2026, localized supply chains could strengthen resilience and cater to on-demand manufacturing models.

6. Influence of Fast Fashion and Rental Fashion Models

The rise of rental and secondhand clothing platforms is boosting demand for durable, visually distinct fabrics like crinkle cotton. Its ability to retain shape and texture after multiple washes makes it suitable for high-turnover usage. Fast fashion brands are also adopting crinkle cotton for seasonal capsule collections, anticipating consumer interest in affordable, trend-driven textures.

Conclusion

By 2026, the crinkle cotton fabric market is projected to experience steady growth, underpinned by sustainability, functional aesthetics, and manufacturing innovation. Stakeholders across the value chain—from cotton farmers to fashion retailers—will need to align with ethical sourcing, transparent labeling, and adaptive production strategies to capitalize on these emerging trends. As consumer demand for authenticity and eco-responsibility intensifies, crinkle cotton is well-positioned to become a staple in both fashion and lifestyle textile portfolios.

Common Pitfalls When Sourcing Crinkle Cotton Fabric (Quality & Intellectual Property)

Sourcing crinkle cotton fabric can be rewarding, but it comes with specific risks related to both quality consistency and intellectual property (IP) issues. Being aware of these common pitfalls helps buyers avoid costly mistakes.

Inconsistent Crinkle Effect and Fabric Hand Feel

One of the most frequent quality issues is variability in the crinkle texture. Poor processing or inconsistent heat setting during manufacturing can lead to uneven crinkles—some areas may be too flat, while others appear overly wrinkled. This inconsistency affects the final garment’s aesthetic and drape. Additionally, the hand feel might vary between batches, becoming either too stiff or too limp, impacting comfort and perceived quality.

Shrinkage and Dimensional Instability

Crinkle cotton is often pre-shrunk, but not always effectively. Buyers may encounter significant shrinkage after washing, especially if the fabric wasn’t properly heat-set or pre-treated. This can lead to misshapen garments, seam puckering, or sizing inaccuracies, resulting in customer complaints and returns.

Poor Color Fastness and Dye Bleeding

Low-quality dyes or improper dyeing processes can result in poor color fastness. Crinkle cotton fabrics may fade quickly after washing or bleed color onto other garments. This is particularly problematic for dark or vibrant shades and can damage brand reputation if not caught during pre-production testing.

Fabric Weakness and Seam Slippage

The crinkling process—especially mechanical or chemical treatments—can weaken cotton fibers. If not carefully controlled, this leads to reduced tensile strength and increased risk of tearing or seam slippage during wear or washing. Buyers should request fabric strength test reports to verify durability.

Lack of Wash Care Clarity and Performance

Some suppliers fail to provide accurate or tested wash care instructions. Crinkle cotton may lose its texture after improper washing (e.g., high heat drying), resulting in consumer dissatisfaction. Ensuring the supplier provides verified care guidelines based on real wash testing is crucial.

Intellectual Property (IP) Infringement Risks

Sourcing crinkle cotton from unauthorized mills or suppliers using patented finishes (e.g., specific heat-set or resin-based crinkle techniques) can expose buyers to IP litigation. Some crinkle processes are protected by patents or trademarks, especially those associated with branded fabrics like “Seersucker” or proprietary textures. Using these without licensing can lead to legal disputes and supply chain disruptions.

Misrepresentation of Fabric Composition and Origin

Suppliers may mislabel blends as 100% cotton or fail to disclose the use of synthetic fibers or chemical treatments in achieving the crinkle effect. Additionally, false claims about fabric origin can trigger compliance issues, especially in markets with strict import regulations or sustainability standards.

Overlooking Sustainability and Chemical Compliance

Many crinkle finishes involve chemical treatments (e.g., resins or caustic shrinkage processes). Sourcing without verifying compliance with environmental and safety standards (like OEKO-TEX®, REACH, or ZDHC) risks non-compliance, product recalls, or rejection at customs.

Avoiding these pitfalls requires thorough due diligence, clear supplier agreements, third-party lab testing, and attention to both technical specifications and legal considerations.

Logistics & Compliance Guide for Crinkle Cotton Fabric

Product Overview

Crinkle cotton fabric is a textured textile known for its permanently wrinkled or puckered surface, achieved through special finishing techniques such as chemical treatment, heat setting, or mechanical crinkling. It is commonly used in apparel (dresses, blouses, shirts), home textiles (curtains, bedding), and accessories due to its breathable, lightweight, and low-iron properties.

Material Composition & Specifications

- Fiber Content: Typically 100% cotton; may include blends (e.g., cotton-polyester or cotton-viscose) depending on the desired drape and care requirements.

- Weight Range: 80–180 gsm (light to medium weight).

- Width: Standard roll widths of 45″, 58″, or 110″.

- Finish: Permanent crinkle effect, may be pre-shrunk.

- Certifications: Look for GOTS (Global Organic Textile Standard), OEKO-TEX® Standard 100, or BCI (Better Cotton Initiative) if applicable.

Packaging Requirements

- Roll Packaging: Fabric should be rolled onto cardboard tubes (typically 2″, 3″, or 6″ diameter) with protective paper or poly lining to prevent creasing and contamination.

- Bundling: Rolls may be grouped and wrapped in stretch film or polypropylene (PP) woven covers.

- Labeling: Each roll must be labeled with:

- Product code

- Fabric composition

- Width and length

- Batch/lot number

- Care instructions

- Compliance certifications (if any)

- Palletization: Rolls stacked on standard EUR/ISO pallets (1200×800 mm or 1200×1000 mm), secured with strapping and stretch wrap. Max stack height: 1.8m (to prevent crushing).

- Moisture Protection: Use vapor-barrier wrapping or silica gel desiccants if shipping to humid regions.

Transportation & Handling

- Mode of Transport: Sea freight (preferred for bulk), air freight (for urgent samples), or road freight (regional distribution).

- Container Type: Dry van containers (20′ or 40′) for sea freight; ensure containers are clean, dry, and pest-free.

- Temperature & Humidity: Store and transport in dry conditions (RH < 65%). Avoid exposure to direct sunlight and extreme temperatures.

- Stacking: Do not stack heavy items on fabric rolls. Use corner boards for added protection.

- Handling: Use forklifts or pallet jacks to move pallets; avoid dragging to prevent damage.

Import/Export Compliance

HS Code (Harmonized System)

- HS 5208.31 to 5208.39 – Woven cotton fabrics, of yarn of different colors, plain weave.

Note: Final classification may vary based on fabric weight, composition, and finish. Consult local customs authority for precise code.

Required Documentation

- Commercial Invoice

- Packing List

- Bill of Lading (B/L) or Air Waybill (AWB)

- Certificate of Origin

- Textile Declaration (e.g., “100% Cotton” per FTC or EU labeling rules)

- Test Reports (e.g., OEKO-TEX®, REACH, or AZO-free certification)

- Import License (if required by destination country)

Regulatory Compliance

- United States (FTC & CPSC):

- Fiber content labeling required under the Textile Fiber Products Identification Act.

- Comply with flammability standards (e.g., 16 CFR Part 1610) if used in apparel.

-

Ensure compliance with REACH SVHC and Prop 65 if applicable.

-

European Union:

- Follow EU REACH Regulation (EC 1907/2006) – restricts hazardous substances (e.g., azo dyes, formaldehyde).

- Comply with Textile Labeling Regulation (EU) No 1007/2011 – mandatory fiber content labeling.

-

Declare presence of Substances of Very High Concern (SVHC) if above threshold.

-

Canada:

- Textile Labeling Act – accurate fiber disclosure required.

-

Canada Consumer Product Safety Act (CCPSA) – limits on lead and phthalates.

-

Other Regions:

- Check local textile standards (e.g., AS/NZS in Australia/NZ, GB standards in China).

Sustainability & Ethical Compliance

- Environmental Standards:

- Use low-impact dyes and eco-friendly finishing processes.

- Verify wastewater treatment compliance (e.g., ZDHC MRSL).

- Social Compliance:

- Adhere to ILO labor standards.

- Consider SA8000, WRAP, or BSCI certifications.

- Circularity: Design for recyclability; avoid mixed fibers if possible.

Quality Control & Testing

- Pre-Shipment Inspection (PSI): Check for defects (stains, holes, color variation, width inconsistency).

- Lab Testing:

- Colorfastness (to washing, rubbing, light)

- Shrinkage (typically <5% after washing)

- Tensile and tear strength

- pH level (4.0–7.5 for skin safety)

- Azo dyes, formaldehyde, heavy metals (per OEKO-TEX® Class II)

Storage Guidelines

- Warehouse Conditions:

- Temperature: 15–25°C

- Relative Humidity: 50–65%

- Ventilated, clean, and pest-free environment

- Shelf Life: Up to 2 years if stored properly. Rotate stock (FIFO).

- Stacking: Max 5–6 layers high; use pallet racks to avoid floor contact.

Returns & Reverse Logistics

- Defective Goods: Clearly define acceptance criteria for claims (e.g., minimum defect area, documentation required).

- Restocking: Only accepted if packaging is intact and contamination-free.

- Disposal: Recycle or donate unsalvageable fabric; avoid landfill where possible.

Summary

Proper logistics and compliance management for crinkle cotton fabric ensures product integrity, regulatory adherence, and customer satisfaction. Key priorities include accurate labeling, moisture protection, adherence to international textile regulations, and sustainable practices throughout the supply chain. Always verify country-specific requirements before shipment.

In conclusion, sourcing crinkle cotton fabric offers a sustainable, cost-effective, and versatile solution for various textile applications, particularly in fashion and home décor. Its natural texture, breathability, and low maintenance make it an attractive choice for designers and brands aiming for both style and comfort. When sourcing, it is essential to evaluate suppliers based on quality consistency, ethical production practices, and environmental standards. Building strong relationships with reliable manufacturers, considering minimum order quantities, and verifying fabric specifications ensure a successful supply chain. Overall, with growing consumer demand for eco-friendly and timeless textiles, crinkle cotton stands out as a valuable and future-ready material choice.