The global textured and effect paint market has seen robust expansion in recent years, driven by rising consumer demand for decorative finishes in residential and commercial spaces. According to a 2023 report by Grand View Research, the global architectural coatings market was valued at USD 108.9 billion and is projected to grow at a compound annual growth rate (CAGR) of 5.4% from 2023 to 2030, with specialty finishes like crackle effect paints gaining traction due to their aesthetic versatility and ease of application. Similarly, Mordor Intelligence forecasts steady growth in the decorative coatings segment, citing increased investments in interior design and renovations across North America and Europe. As demand for unique surface effects rises, manufacturers specializing in crackle paints are innovating with eco-friendly formulations and enhanced durability. This growth trajectory has intensified competition, leading to a diverse landscape of eight leading crackle effect paint manufacturers shaping industry standards through product quality, performance, and sustainable practices.

Top 8 Crackle Effect Paint Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

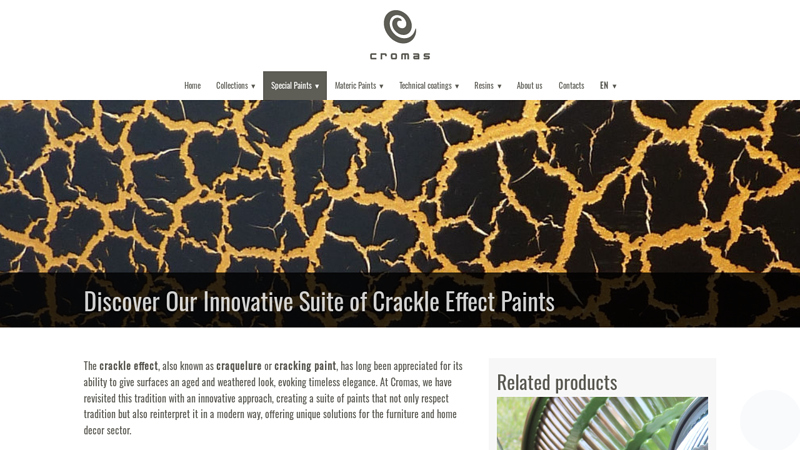

#1 Professional Crackle Paint for Industry and Craftsmanship

Domain Est. 2011

Website: cromas.it

Key Highlights: Crackle paint gives surfaces a cracked and split leather appearance. For industrial and artisanal use. Developed and produced by Cromas srl….

#2 One Step Crackle

Domain Est. 1996

Website: decoart.com

Key Highlights: One Step Crackle | Product DetailsProvides a beautiful aged or modern crackled effect in one easy step. Apply as a topcoat over a dry painted surface….

#3 Crackle Finish Base Coat

Domain Est. 1997

Website: krylon.com

Key Highlights: Create a beautiful crackle effect on your projects with Krylon® Crackle Finish. Crackle Base Coat must be used with Crackle Top Coat….

#4 CRACKLE EFFECT

Domain Est. 1997

Website: italgete.it

Key Highlights: “Antique effect” crackle paint for the decoration and protection of internal and external surfaces. Formulated with special resins….

#5 Montana CRACKLE 400ml

Domain Est. 1999

Website: montana-cans.com

Key Highlights: The CRACKLE spray is high-covering and can be top-coated when fully dry and cured (after 24h) with Montana GOLD, Montana BLACK, Montana WHITE, Montana ACRYLIC ……

#6 Crackle

Domain Est. 1999

Website: modernmasters.com

Key Highlights: Crackle for Latex Paint (DP601). This clear, water base medium offers a consistent crack that works every time. Apply between two layers of flat latex paint ……

#7 Plaster Of Paris For Chalk Paint

Domain Est. 2000

Website: linearcollider.org

Key Highlights: It’s perfect for small to medium projects like picture frames, small furniture pieces, decorative boxes, or accent pieces. The crackle effect it produces looks ……

#8 Crackle Medium

Domain Est. 2001

Website: porterspaints.com

Key Highlights: Porter’s Crackle Medium is an easy to use medium for creating antique and decorative crackle effects on furniture, walls, picture frames and other decorative ……

Expert Sourcing Insights for Crackle Effect Paint

2026 Market Trends for Crackle Effect Paint

The global market for specialty decorative paints is poised for dynamic growth, with crackle effect paint emerging as a niche yet increasingly popular segment. As consumer preferences shift toward personalized and artisanal home aesthetics, crackle effect paint—known for its aged, vintage, and textured finish—is expected to gain traction in both residential and commercial applications. This analysis explores key market trends shaping the crackle effect paint industry in 2026.

Rising Demand for DIY and Home Renovation Projects

A primary driver of the crackle effect paint market in 2026 is the sustained popularity of do-it-yourself (DIY) home improvement. With social media platforms like Pinterest, Instagram, and TikTok fueling creative interior design trends, consumers are increasingly experimenting with textured finishes to add character to furniture, walls, and décor. Crackle effect paint offers an affordable and accessible way to achieve a high-end, vintage look without professional help, making it a staple in the DIY toolkit.

Growth in Sustainable and Low-VOC Formulations

Environmental consciousness is reshaping product development across the paint industry. By 2026, manufacturers of crackle effect paint are expected to prioritize eco-friendly formulations, including water-based, low-VOC (volatile organic compounds), and non-toxic options. This shift aligns with global sustainability goals and consumer demand for healthier indoor air quality, particularly in homes with children and pets. Brands that emphasize green certifications and sustainable packaging are likely to gain a competitive edge.

Expansion in Commercial and Retail Interiors

Beyond residential use, crackle effect paint is finding new applications in boutique hotels, cafes, retail stores, and art installations. Designers are leveraging its unique texture to create focal walls, accent features, and thematic interiors that stand out. The trend toward experiential retail and immersive environments is expected to boost demand for decorative finishes like crackle paint, especially in urban markets where visual storytelling plays a key role in branding.

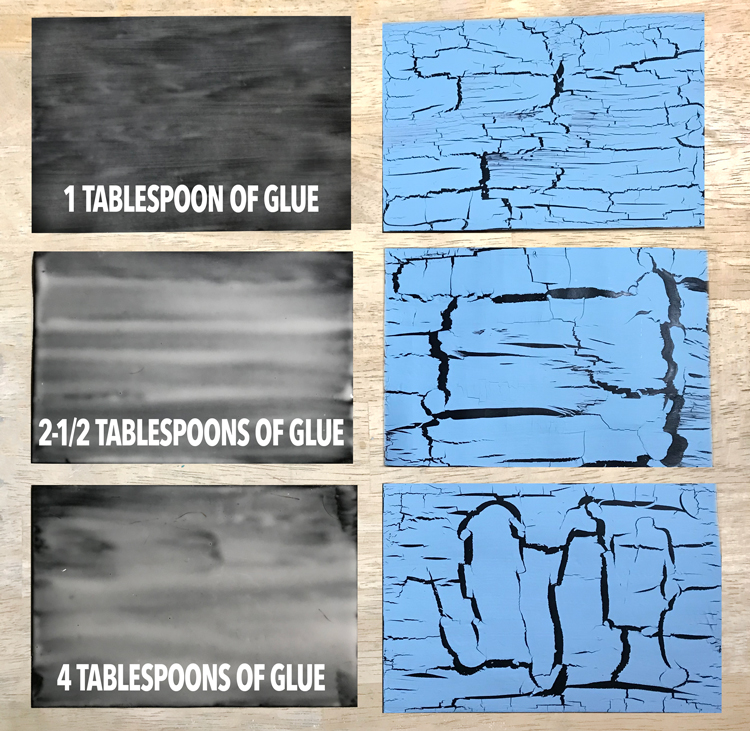

Product Innovation and Customization

To meet diverse consumer tastes, manufacturers are introducing innovative crackle effect variations, such as adjustable crack sizes, color-infused formulas, and hybrid textures that combine crackle with metallic or pearlescent effects. In 2026, expect to see more customizable kits and digital tools (e.g., AR apps) that allow users to preview finishes before application. These advancements will enhance user experience and lower the barrier to entry for novice decorators.

Regional Market Growth

While North America and Western Europe remain strong markets due to high DIY engagement and mature home renovation sectors, Asia-Pacific is projected to witness the fastest growth. Rising disposable incomes, urbanization, and the influence of Western design trends in countries like China, India, and South Korea are driving interest in decorative paints. Localized product offerings and partnerships with regional retailers will be key to capturing this expanding market.

Challenges and Competitive Landscape

Despite growth potential, the crackle effect paint market faces challenges, including inconsistent application results and competition from alternative textured finishes (e.g., lime wash, plaster). To maintain relevance, brands must invest in user education—through tutorials, sample kits, and customer support—while differentiating through quality, ease of use, and innovation.

In conclusion, the 2026 market for crackle effect paint is set for modest yet meaningful expansion, driven by consumer creativity, sustainability, and design innovation. Companies that align with these trends while addressing usability concerns will be well-positioned to succeed in an evolving decorative coatings landscape.

Common Pitfalls When Sourcing Crackle Effect Paint (Quality and Intellectual Property)

Sourcing crackle effect paint can be challenging, especially when balancing quality expectations and intellectual property (IP) considerations. Here are key pitfalls to avoid:

1. Prioritizing Low Cost Over Quality

Many suppliers offer inexpensive crackle paints, but these often deliver inconsistent results. Low-quality formulations may crack unevenly, peel prematurely, or fail to adhere properly to substrates. This leads to rework, customer dissatisfaction, and increased long-term costs. Always request samples and test performance under real application conditions before bulk purchasing.

2. Inadequate Testing of Environmental and Durability Performance

Crackle paints are often used in decorative or architectural applications where exposure to UV light, humidity, or temperature changes is common. Sourcing without verifying weather resistance, flexibility, or colorfastness can result in premature degradation. Ensure the product data sheet includes test results for key durability metrics or conduct third-party testing.

3. Lack of Transparency in Formulation and Compliance

Some suppliers may not disclose full ingredient lists or regulatory compliance (e.g., VOC levels, REACH, RoHS). This poses risks for end-use applications, especially in regulated industries or eco-conscious markets. Always confirm compliance documentation and avoid proprietary “black box” formulations without safety data.

4. Overlooking Intellectual Property (IP) Risks

Using or sourcing crackle effect paints that mimic patented technologies or branded finishes can lead to IP infringement. Some specialty crackle effects are protected by design patents or trade secrets. Ensure your supplier has the right to sell the product and that your use case doesn’t violate existing IP, particularly in commercial or mass-market applications.

5. Relying on Unverified Supplier Claims

Suppliers may exaggerate performance claims or provide misleading application instructions. Claims like “guaranteed crackle every time” or “works on any surface” are often unrealistic. Validate claims through independent testing and consult application experts before scaling up.

6. Insufficient Technical Support and Documentation

Poorly documented mixing ratios, curing times, or substrate preparation requirements can lead to application failures. Choose suppliers who provide detailed technical data sheets (TDS), safety data sheets (SDS), and responsive support to troubleshoot issues during use.

7. Ignoring Scalability and Batch-to-Batch Consistency

Artisanal or small-batch crackle paints may perform well in prototypes but lack consistency in large-scale production. Variations in viscosity, particle size, or chemical composition can alter the crackle effect. Confirm the supplier’s quality control processes and ability to maintain uniformity across batches.

By addressing these pitfalls proactively—focusing on verified quality, regulatory compliance, and IP safety—you can source crackle effect paint that meets both performance standards and legal requirements.

Logistics & Compliance Guide for Crackle Effect Paint

Product Classification & Regulatory Overview

Crackle effect paint is typically classified as a decorative coating product that contains solvents, resins, and additives designed to create a cracked or aged finish. Due to its chemical composition, it may be subject to regulations related to hazardous materials, volatile organic compounds (VOCs), and consumer safety. Key regulatory frameworks include:

– GHS (Globally Harmonized System): Requires proper hazard classification, labeling, and Safety Data Sheet (SDS) documentation.

– REACH (EU Regulation): Mandates registration, evaluation, and restriction of chemical substances.

– TSCA (USA): Regulates the introduction and use of chemical substances under the Toxic Substances Control Act.

– VOC Regulations: Varies by region (e.g., EPA limits in the U.S., EU Directive 2004/42/EC).

Ensure compliance with local and international standards based on destination markets.

Packaging & Labeling Requirements

Proper packaging and labeling are critical for safety and regulatory compliance:

– Container Type: Use leak-proof, chemically resistant containers (typically metal or HDPE plastic) with secure lids to prevent spills and evaporation.

– Hazard Labels: Apply GHS-compliant labels including:

– Pictograms (e.g., flame for flammability, exclamation mark for skin/eye irritation)

– Signal word (“Danger” or “Warning”)

– Hazard statements (e.g., H225: Highly flammable liquid and vapor)

– Precautionary statements (e.g., P210: Keep away from heat/sparks/open flames)

– Product Identification: Include product name, batch/lot number, manufacturer details, net quantity, and expiration date.

– Language Requirements: Labels must be in the official language(s) of the destination country.

Storage & Handling Guidelines

Safe storage and handling minimize risks to personnel and product integrity:

– Storage Conditions: Store in a cool, dry, well-ventilated area away from direct sunlight, heat sources, and incompatible materials (e.g., oxidizers). Ideal temperature range: 10–25°C (50–77°F).

– Flammability Precautions: As many crackle paints are solvent-based and flammable, store in approved flammable storage cabinets if quantities exceed local thresholds.

– Handling Procedures: Use appropriate PPE (gloves, goggles, respirator if needed) during transfer or dispensing. Avoid prolonged skin contact and inhalation of vapors.

– Spill Management: Maintain spill kits (absorbents, containment tools) and train personnel on emergency procedures.

Transportation & Shipping Compliance

Transportation is regulated under hazardous goods frameworks:

– Classification: Determine UN number and hazard class (e.g., UN1263, PAINT, 3, PG II for flammable liquid paints).

– Regulatory Frameworks:

– ADR (Europe): For road transport.

– IMDG Code (Sea): For international maritime shipping.

– IATA DGR (Air): For air freight—note stricter limits and prohibitions on passenger aircraft.

– Packaging: Use UN-certified packaging with proper inner and outer containers. Ensure packages are tested and marked for transport.

– Documentation: Include:

– Safety Data Sheet (SDS), updated and compliant with local regulations

– Transport document with proper shipping name, UN number, class, and packing group

– Dangerous Goods Declaration (for air/sea) if required

– Marking & Placarding: Affix proper hazard labels and transport marks. Vehicles may require placards for bulk shipments.

Environmental & Disposal Regulations

Environmental compliance is essential for end-of-life management:

– Waste Classification: Empty containers may be considered hazardous waste due to residual paint. Follow local guidelines (e.g., EPA, EU Waste Framework Directive).

– Disposal Methods: Do not dispose of in drains or with household waste. Use licensed hazardous waste disposal services.

– Recycling: Investigate container return programs or recycling options for metal cans.

– Spill Reporting: Report significant spills to environmental authorities as required by local law.

Customer & End-User Compliance Support

Ensure downstream compliance and safety:

– Safety Data Sheet (SDS): Provide a current, multi-language SDS with every shipment.

– Usage Instructions: Include clear application and safety guidance on packaging or inserts (e.g., ventilation requirements, curing times).

– Compliance Statements: Supply declarations of conformity (e.g., REACH, RoHS) upon request.

– Training & Support: Offer technical and compliance assistance to distributors and professional users.

Recordkeeping & Audits

Maintain thorough documentation to support compliance:

– Retain SDS, batch records, shipping documents, and regulatory approvals for a minimum of 10 years (or as required locally).

– Conduct regular internal audits to verify adherence to safety, environmental, and transport regulations.

– Stay updated on regulatory changes through industry associations or regulatory monitoring services.

Adhering to this guide ensures safe, legal, and efficient logistics for crackle effect paint across global supply chains.

In conclusion, sourcing crackle effect paint requires careful consideration of several key factors to ensure the desired aesthetic and functional outcomes. It is essential to evaluate the quality of the product, compatibility with the underlying and topcoat paints, and the specific application environment—whether for interior décor, furniture restoration, or artistic projects. Sourcing from reputable suppliers or manufacturers ensures consistency, reliability, and access to technical support. Additionally, comparing various formulations—such as pre-mixed crackle paints versus additive-based systems—allows for greater control over the crackle pattern and finish. Sustainability, ease of application, and drying time are also important aspects to consider. By conducting thorough research and obtaining samples when possible, purchasers can make informed decisions that balance cost, quality, and performance, ultimately achieving a professional and visually appealing crackle effect.