The global cotton wick market is experiencing steady expansion, driven by rising consumer demand for clean-burning, natural materials in candles, aromatherapy products, and personal care applications. According to Grand View Research, the global candle market size was valued at USD 5.34 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 7.1% from 2023 to 2030—fueled in large part by preferences for eco-friendly, sustainably sourced components like cotton wicks. Similarly, Mordor Intelligence projects that increasing disposable incomes, urbanization, and a surge in home fragrance usage across both developed and emerging markets will continue to propel demand for premium candle products, where cotton wicks are favored for their clean, smoke-free burn characteristics. As brands prioritize sustainability and performance, cotton wick manufacturers are scaling production and innovating in braiding techniques and treatments to meet technical and aesthetic standards. In this evolving landscape, the following nine manufacturers have emerged as leaders, demonstrating consistent quality, global reach, and technological advancement in cotton wick production.

Top 9 Cotton Wicks Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Jiya Enterprise

Domain Est. 2023

Website: jiyaenterprise.com

Key Highlights: Jiya Enterprise is one of the leading advanced Cotton Wick Machines and Cotton Wick Manufacturers, Suppliers in Ahmedabad, Gujrat….

#2 Jiya Enterprise, Ahmedabad

Domain Est. 2023

Website: cottonwickmachine.com

Key Highlights: Cotton Wick Making Machine · Rs 1,80,000 / Piece · Round Cotton Wicks · Rs 45 / Pack · Fully Automatic Long cotton wick machine · Rs 1,05,000 / Piece · Pooja ……

#3 S.D. Cotton Wicks Kolkata

Website: sdcottonwicks.in

Key Highlights: S.D. Cotton Wicks is the Manufacturer and Supplier of Twisted Round Cotton Wicks in West Bengal, Wholesale Red & White Round Cotton Wicks in Kolkata, India….

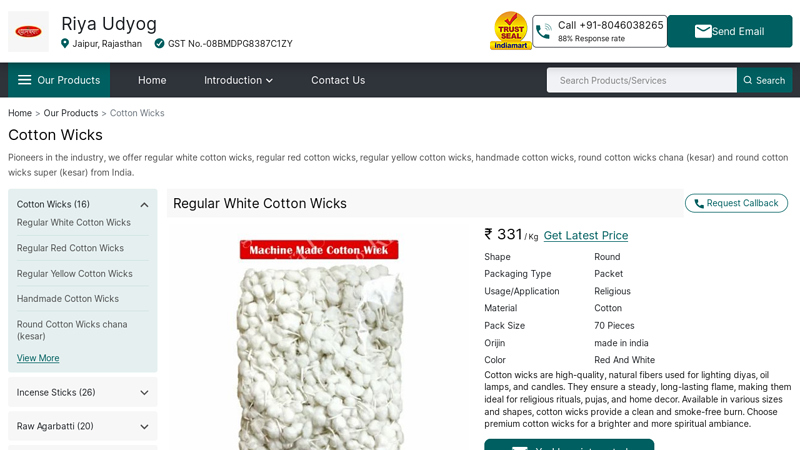

#4 Regular Red Cotton Wicks Manufacturer from Jaipur

Website: riyaudyog.com

Key Highlights: Manufacturer of Cotton Wicks – Regular Red Cotton Wicks, Regular White Cotton Wicks, Super Red Cotton Wicks and Chana Red Cotton Wicks offered by Riya Udyog ……

#5 Candle Wicks

Domain Est. 2002

Website: candlescience.com

Key Highlights: In stock Rating 3.9 (23) Our high-quality, lead-free candle wicks for paraffin wax, and soy, coconut and other natural wax blends, are ideal for beginners and seasoned chandlers …

#6 Cotton Cored Wicks

Domain Est. 2002

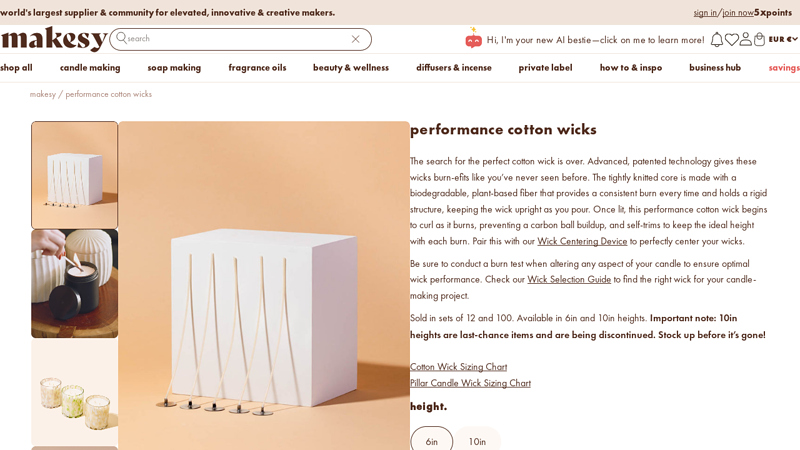

#7 Performance Cotton Wicks

Domain Est. 2014

Website: makesy.com

Key Highlights: Performance cotton wicks include a proprietary and patented knitted core for optimal burn performance. Self-trimming, clean burning, and biodegradable….

#8 Wicks

Domain Est. 2015

Website: wedobraids.com

Key Highlights: Our wick-configurator allows you to easily define key candle parameters – it then automatically lists a number of suitable wicks for testing….

#9 Pooja Cotton Wicks, Pure Cotton Wicks Supplier in Rajasthan

Domain Est. 2024 | Founded: 2017

Website: purecottonwicks.com

Key Highlights: Rachna Traders, Jaipur, Rajasthan, established in 2017, is a leading supplier and trader of high-quality cotton wicks for religious and spiritual purposes. Our ……

Expert Sourcing Insights for Cotton Wicks

2026 Market Trends for Cotton Wicks

The global cotton wick market is poised for steady growth and notable transformation by 2026, driven by evolving consumer preferences, sustainability demands, and innovation in end-use applications. Here are the key trends shaping the market:

1. Surge in Demand for Sustainable and Organic Cotton Wicks

Environmental consciousness is a dominant force, pushing manufacturers and consumers towards eco-friendly alternatives. By 2026, demand for cotton wicks made from certified organic cotton—grown without synthetic pesticides or fertilizers—is expected to rise significantly. Brands across candle-making, skincare, and pharmaceuticals are increasingly adopting organic cotton wicks to align with green certifications and appeal to eco-conscious buyers. This shift is further supported by stricter regulations on chemical usage and supply chain transparency.

2. Innovation in Wick Technology and Performance

Advancements in cotton wick engineering are enhancing burn efficiency, scent throw, and safety. Hybrid cotton wicks—blended with paper, linen, or small amounts of metal for structure—are gaining traction in the premium candle market. These innovations reduce soot, prevent mushrooming, and ensure a cleaner, more consistent burn. Additionally, pre-tabbed and pre-coated cotton wicks tailored for specific wax types (soy, coconut, paraffin) are becoming standard, catering to both DIY enthusiasts and commercial producers.

3. Growth in the Home Fragrance and Luxury Candle Segment

The home fragrance market continues to expand, with candles remaining a top category. As consumers invest more in ambiance and self-care, demand for high-quality cotton wicks—especially in luxury and artisanal candles—will grow. Cotton wicks are preferred for their natural appeal and compatibility with plant-based waxes, a trend aligned with the popularity of wellness-oriented home products. This segment will drive innovation and premium pricing in the cotton wick supply chain.

4. Expansion of E-Commerce and DIY Candle Making

The rise of online marketplaces and social media platforms has fueled the DIY candle-making trend. By 2026, a growing number of hobbyists and small businesses will source cotton wicks directly through e-commerce channels. Suppliers are responding with consumer-friendly packaging, detailed burn guides, and customizable options. This democratization of production supports decentralized manufacturing and increases overall cotton wick consumption.

5. Supply Chain Resilience and Regional Sourcing

Geopolitical uncertainties and past disruptions have prompted companies to reevaluate cotton sourcing strategies. There is a growing emphasis on local or regional cotton production to reduce lead times and ensure ethical labor practices. Countries with strong cotton industries—such as India, the U.S., and Brazil—are expected to strengthen their positions as key suppliers of raw cotton for wick production, fostering more transparent and resilient supply chains.

6. Regulatory and Safety Standards Driving Quality Control

As candle safety becomes a priority, regulatory bodies and industry standards are placing greater emphasis on wick composition. Lead-core wicks are already banned in many regions, and by 2026, stricter guidelines may extend to other metallic additives. Cotton wicks, especially 100% cotton or those with safe plant-based stiffeners, are well-positioned to meet these evolving safety requirements, boosting their market share over synthetic or metal-reinforced alternatives.

In summary, the 2026 cotton wick market will be defined by sustainability, technological refinement, and alignment with premium lifestyle trends. Producers who invest in organic certification, product innovation, and transparent sourcing will be best positioned to capture growth in this dynamic landscape.

Common Pitfalls When Sourcing Cotton Wicks: Quality and Intellectual Property

Sourcing cotton wicks, commonly used in candles, lamps, and cosmetics, involves navigating several potential pitfalls—particularly concerning quality consistency and intellectual property (IP) risks. Being aware of these challenges helps ensure reliable supply and protects your brand.

Quality-Related Pitfalls

Inconsistent Cotton Purity

Not all cotton wicks are created equal. Lower-grade cotton may contain impurities, pesticides, or chemical residues that affect burn performance and consumer safety. Sourcing from suppliers without strict agricultural and processing standards can lead to inconsistent wick performance, such as excessive smoking, poor flame stability, or uneven burning.

Improper Sizing and Tension

Cotton wicks must be precisely sized and braided to meet the requirements of specific applications (e.g., container candles vs. pillar candles). Poorly constructed wicks—either too thick, too thin, or inconsistently braided—can result in tunneling, drowning, or mushrooming of the flame. Suppliers lacking quality control may deliver inconsistent tension or diameter, compromising product reliability.

Inadequate Pre-Treatment or Cording

Many cotton wicks require specific treatments (e.g., carbonization, wax priming, or chemical stiffening) to ensure consistent ignition and burn behavior. Sourcing from manufacturers that skip or poorly execute these steps can result in wicks that fail to meet performance standards. Verify your supplier’s pre-treatment processes and test samples rigorously.

Lack of Certification and Traceability

Reputable cotton wicks should come with certifications such as OEKO-TEX®, GOTS (Global Organic Textile Standard), or pesticide-free documentation. Working with suppliers who cannot provide traceability or third-party testing opens your brand to reputational and compliance risks, especially in eco-conscious or regulated markets.

Intellectual Property (IP) Pitfalls

Inadvertent Use of Patented Wick Designs

Certain braided, flat, or self-trimming cotton wick designs are protected by patents. For example, proprietary wick technologies (such as those with paper or cotton-paper blends, specific plaiting patterns, or integrated sustainers) may be IP-protected. Sourcing generic versions without due diligence can expose your business to infringement claims, especially when importing from regions with weaker IP enforcement.

Supplier Misrepresentation of IP Status

Some suppliers may claim their wicks are “generic” or “patent-free” without proper validation. Relying solely on these claims without independent verification—such as patent searches or legal consultation—can lead to costly disputes or product recalls. Always confirm the IP status of specialized wick types before mass production.

Counterfeit or Unauthorized Production

In regions with lax IP enforcement, manufacturers may produce counterfeit versions of branded or patented wicks. While these may appear identical and offer lower pricing, using them exposes your company to legal liability and supply chain instability. Conduct supplier audits and request proof of licensing where applicable.

Lack of Design Freedom in Custom Wicks

If you develop a custom wick design, ensure that your supplier agreement includes clear ownership of IP rights. Some manufacturers may claim co-ownership or reuse your design for other clients unless contractually prohibited. Define IP rights upfront in sourcing agreements to protect innovation.

Mitigation Strategies

- Request samples and conduct burn testing across multiple batches.

- Audit suppliers for quality certifications, traceability, and ethical sourcing.

- Perform patent landscape searches for specialized wick types.

- Include IP indemnification clauses in supplier contracts.

- Work with legally compliant manufacturers and avoid “too good to be true” pricing that may signal IP infringement.

By proactively addressing these quality and IP pitfalls, businesses can secure reliable, compliant cotton wick supplies that support product performance and brand integrity.

Logistics & Compliance Guide for Cotton Wicks

Product Classification and HS Code

Cotton wicks are typically classified under the Harmonized System (HS) code 5601.21.00, which covers “Wicks for candles, lamps, or similar articles, of cotton, incl. terry towelling or similar terry fabrics.” Accurate classification is essential for international shipping, customs clearance, and duty assessment. Confirm the specific HS code with local customs authorities, as variations may exist by country.

Import and Export Regulations

Ensure compliance with the import/export regulations of both the origin and destination countries. Some countries may impose restrictions or require permits for textile-based products. Verify whether any anti-dumping duties, quotas, or trade agreements apply. Maintain proper documentation, including commercial invoices, packing lists, and certificates of origin.

Packaging and Labeling Requirements

Cotton wicks should be packaged to prevent contamination, moisture damage, and physical compression. Use sealed polybags or moisture-resistant containers for bulk shipments. Label all packages with product description, net weight, batch number, manufacturer details, and safety warnings if applicable (e.g., “Keep away from open flame when not in use”). Include bilingual labeling where required by local regulations.

Transportation and Storage

Ship cotton wicks via standard dry freight methods (air, sea, or ground). Avoid exposure to high humidity, extreme temperatures, or flammable materials during transit. Store in a cool, dry, and well-ventilated area away from ignition sources. Implement FIFO (First In, First Out) inventory practices to maintain product quality.

Safety and Flammability Standards

Although cotton wicks are inherently flammable, they are generally exempt from hazardous materials classification when unprocessed and not treated with accelerants. However, if wicks are pre-treated with chemicals (e.g., metal-core or paraffin-coated), they may fall under dangerous goods regulations (e.g., IATA, IMDG). Confirm treatment status and consult SDS (Safety Data Sheet) if applicable.

Environmental and Sustainability Compliance

Ensure cotton sourcing aligns with legal and ethical standards. Prefer cotton certified under recognized programs such as BCI (Better Cotton Initiative) or organic standards (e.g., GOTS). Comply with REACH (EU), Proposition 65 (California), and other chemical restriction regulations to ensure no harmful substances are present.

Documentation and Traceability

Maintain full traceability from raw material to finished product. Keep records of supplier certifications, batch testing, and shipping documents for at least five years. Prepare for potential audits by regulatory or customs bodies.

Special Considerations for End-Use Applications

If cotton wicks are intended for use in candles, medical devices, or other regulated products, additional compliance may be required (e.g., FDA for medical wicks, ASTM for candle performance). Clearly communicate end-use to avoid misclassification or liability.

Summary

Proper logistics and compliance for cotton wicks involve accurate classification, adherence to trade regulations, safe packaging, and transparent documentation. Proactive management of these factors ensures smooth global distribution and regulatory compliance.

In conclusion, sourcing high-quality cotton wicks requires a careful evaluation of several key factors, including the purity and origin of the cotton, manufacturing standards, wick treatment (e.g., braiding and priming), and environmental and ethical practices of suppliers. Prioritizing natural, pesticide-free, lead-free, and sustainably sourced cotton ensures both performance and safety, especially for use in candles, essential oil diffusers, or other applications requiring clean and consistent burning. Establishing relationships with reliable suppliers who adhere to industry certifications and offer transparency in their production processes is crucial for long-term success. Ultimately, investing time and resources into responsible sourcing not only enhances product quality but also aligns with growing consumer demand for sustainable and ethically produced goods.