The global cotton velour market is experiencing steady growth, driven by rising consumer demand for sustainable, skin-friendly fabrics in the apparel, loungewear, and baby products sectors. According to Grand View Research, the global textile market is projected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030, with natural and organic textiles like cotton velour gaining traction due to increasing environmental and health consciousness. Similarly, Mordor Intelligence highlights a growing preference for premium, soft-touch textiles, particularly in the athleisure and sustainable fashion segments, where cotton velour’s breathability and comfort offer a competitive edge. As brands prioritize ethical sourcing and low-impact materials, demand for high-quality cotton velour from reliable manufacturers has surged. In response, manufacturers are investing in eco-friendly production processes, such as closed-loop water systems and OEKO-TEX® certified dyes, to align with global sustainability standards. This growing momentum underscores the importance of identifying leading producers who combine innovation, scalability, and responsible manufacturing practices. The following list highlights the top 10 cotton velour manufacturers shaping the future of the textile industry.

Top 10 Cotton Velour Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Buy Cotton Velour Fabric from Our Fabric Manufacturer & Factory

Domain Est. 2024

Website: fandafabrics.com

Key Highlights: Discover our premium cotton velour fabric, renowned for its soft, plush texture and breathable comfort. Perfect for apparel, loungewear, and luxurious home ……

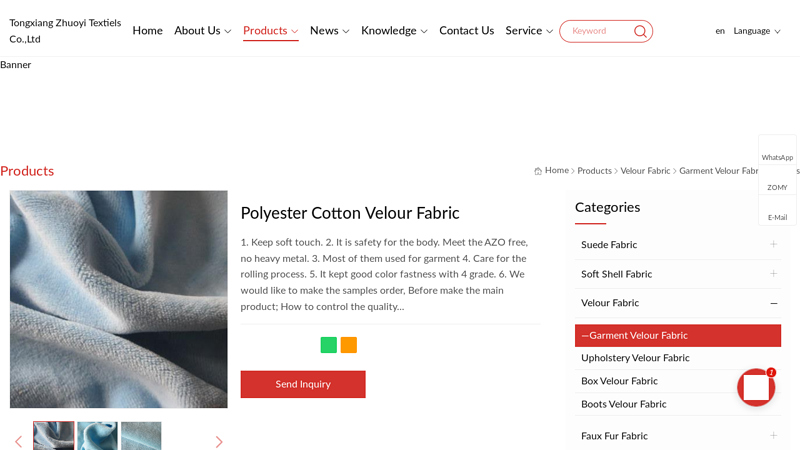

#2 China Polyester Cotton Velour Fabric Manufacturers and Suppliers

Domain Est. 2017

Website: zhuoyifabric.com

Key Highlights: Wholesale polyester cotton velour fabric here from Zhuoyi Textiels – one of the leading polyester cotton velour fabric manufacturers and suppliers in China….

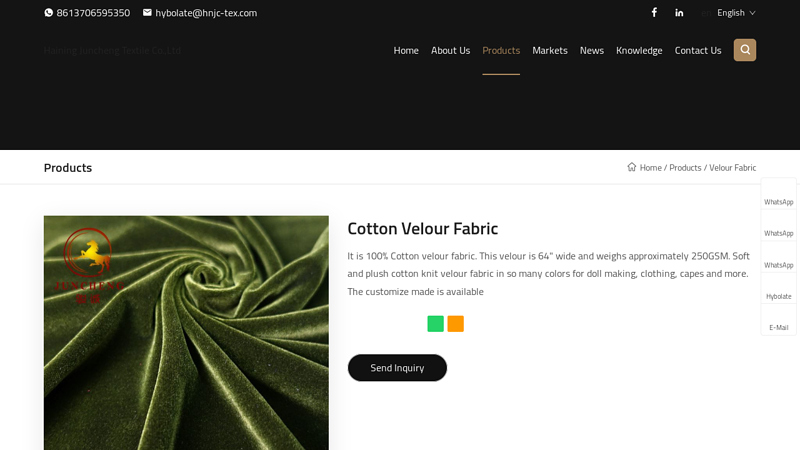

#3 China Cotton Velour Fabric Suppliers and Manufacturers

Domain Est. 2018

Website: supplierfabric.com

Key Highlights: It is 100% Cotton velour fabric. This velour is 64″ wide and weighs approximately 250GSM. Soft and plush cotton knit velour fabric in so many colors for ……

#4 Velour Fabric From Manufacturer

Domain Est. 2023

Website: runtangtex.com

Key Highlights: Quality Velour Fabric (150-600 GSM) by a trusted manufacturer. Materials include Cotton, Polyester, Spandex, and more….

#5 Velour – Cotton

Domain Est. 2000

Website: thefabricofourlives.com

Key Highlights: Velour is a term for a knit or woven fabric that has a soft, dense pile and a decorative sheen. Knit velour is a terry construction that has been sheared ……

#6 Cotton Velour

Domain Est. 2000

Website: azur-scenic.com

Key Highlights: Check out our impressive range of flame-retardant cotton velour fabrics, from extra-heavy stage velour with excellent acoustic properties and a good level ……

#7 Velour Fabric

Domain Est. 2002

Website: canwiltextiles.com

Key Highlights: Velour fabric is a silky, plush fabric that looks and feels a lot like velvet, but it’s actually a much less expensive option….

#8 Organic Cotton Velour Fabric Wholesale

Domain Est. 2008

Website: kinderel.com

Key Highlights: Buy now: cotton velour fabric wholesale. Our unbleached, white color, organic cotton velour is super soft, breathable, silky, and durable….

#9 Add Life / Sustainability

Domain Est. 2016

Website: velourstore.com

Key Highlights: Cotton fiber is strong and maintains its given color over a long time, making our products durable and long-lasting. Fabric made of cotton is soft, breathable ……

#10 Velour Garments

Website: velourgarments.eu

Key Highlights: 14-day returnsHigh Quality Cut and Sew Manufactured Garments, plain blank, Organic Cotton Blend curatedly made in spain….

Expert Sourcing Insights for Cotton Velour

H2 2026 Market Trends for Cotton Velour

As we approach the second half of 2026, the cotton velour market is poised for a period of nuanced growth, driven by evolving consumer preferences, sustainability imperatives, and shifting fashion dynamics. Here’s a breakdown of the key trends shaping the landscape:

1. Sustainability as a Non-Negotiable Driver:

Environmental and social responsibility will be paramount. Consumers will demand greater transparency in sourcing, manufacturing, and supply chains. Expect:

* Rise of Certified Cotton: Increased demand for cotton velour made with GOTS (Global Organic Textile Standard), BCI (Better Cotton Initiative), or recycled cotton content.

* Low-Impact Production: Brands will prioritize mills using water-saving dyeing techniques, renewable energy, and non-toxic dyes to minimize environmental footprint.

* Circularity Focus: Growth in take-back programs, repair services, and designs facilitating disassembly/recycling will gain traction, appealing to eco-conscious consumers.

2. Comfort Meets Elevated Style (“Cozy Luxury”):

The post-pandemic emphasis on comfort remains strong, but with a refined aesthetic. Cotton velour will thrive in:

* Lounge-to-Streetwear Transition: High-quality, minimalist cotton velour pieces (e.g., tailored sets, sleek jackets, elevated joggers) will dominate, blurring lines between home wear and casual outerwear.

* Focus on Texture and Quality: Consumers will value the inherent softness and plush feel of genuine cotton velour over synthetic alternatives, seeking depth of pile and superior hand-feel.

* Neutral & Earthy Palettes: While bold colors exist, core demand will center on sophisticated neutrals (oatmeal, taupe, charcoal, olive, deep burgundy) and muted earth tones, aligning with minimalist and “quiet luxury” trends.

3. Athleisure & Performance-Adjacent Applications:

Cotton velour will maintain relevance in active lifestyles, but with performance enhancements:

* Hybrid Performance: Blends incorporating moisture-wicking or quick-dry fibers (like TENCEL™ Lyocell) will emerge, offering comfort with improved functionality for light activity or layering.

* Focus on Versatility: Pieces designed for multiple uses (e.g., a velour hoodie suitable for travel, casual outings, or light gym sessions) will be favored.

4. Regional Market Diversification & Direct-to-Consumer (DTC) Growth:

Beyond Traditional Hubs: While Europe and North America remain key, growth will accelerate in emerging markets (Asia-Pacific, Latin America) as disposable income rises and awareness of quality textiles increases.

* DTC Dominance:* Independent brands leveraging social media and e-commerce platforms will capture significant market share by offering unique designs, transparent sourcing, and strong brand narratives centered on sustainability and craftsmanship.

5. Challenges & Competitive Pressures:

Cost Volatility: Fluctuations in organic/recycled cotton prices and energy costs will pressure margins, potentially limiting accessibility.

* Synthetic Competition: Polyester and recycled polyester velours (fleece, sherpa) will offer lower-cost alternatives, challenging cotton velour on price, especially in mass-market segments.

* Greenwashing Scrutiny:* Consumers and regulators will increasingly call out vague sustainability claims, demanding verifiable certifications and concrete data.

Conclusion:

H2 2026 will see cotton velour solidify its position as a premium comfort fabric within a highly conscious market. Success will hinge on authentic sustainability practices, innovative yet timeless design, and compelling brand storytelling. Brands that prioritize transparency, quality, and genuine environmental responsibility will lead the market, while those relying solely on low cost or superficial trends will face increasing challenges. The demand for genuine, responsibly-made comfort will define the future of cotton velour.

Common Pitfalls Sourcing Cotton Velour (Quality, IP)

Sourcing cotton velour can present several challenges, particularly when balancing quality expectations and intellectual property (IP) concerns. Being aware of these common pitfalls helps buyers make informed decisions and avoid costly mistakes.

Inconsistent Fabric Quality

One of the most frequent issues is variability in fabric quality across suppliers or production batches. Cotton velour quality depends on factors like cotton fiber grade, yarn count, dyeing techniques, and finishing processes. Poor quality control can result in inconsistencies in color, texture, pile height, or shrinkage, leading to subpar end products.

Misrepresentation of Material Composition

Some suppliers may mislabel blends as 100% cotton velour. For example, fabrics containing polyester or viscose might be passed off as pure cotton to reduce costs. This impacts breathability, softness, and sustainability claims, potentially misleading consumers and damaging brand reputation.

Lack of Ethical and Sustainable Sourcing Verification

Buyers may assume cotton velour is eco-friendly due to its natural fiber base, but without proper certification (e.g., GOTS, OEKO-TEX), the cotton could be sourced from farms using harmful pesticides or unethical labor practices. Failing to verify sustainability claims exposes brands to greenwashing accusations.

Inadequate Testing and Certification

Skipping independent lab testing for colorfastness, pilling resistance, and shrinkage can result in product failures post-production. Cotton velour used in apparel or home textiles must meet industry standards; sourcing without proper certification increases the risk of recalls or customer complaints.

Overlooking Intellectual Property Rights

Using proprietary velour weaves, patterns, or finishes without proper licensing can lead to IP infringement. Some manufacturers develop unique textures or manufacturing techniques protected by patents or design rights. Unauthorized use may result in legal disputes or supply chain disruptions.

Failure to Audit Supplier IP Compliance

Suppliers may claim originality but use copied designs or machinery that infringes on third-party IP. Without auditing a supplier’s design sources and manufacturing processes, brands risk associating with counterfeit or unlawfully produced materials.

Poor Communication of Technical Specifications

Ambiguous or incomplete fabric specifications—such as pile density, GSM (grams per square meter), or finishing treatments—can lead to receiving a product that doesn’t meet design requirements. Clear technical documentation is essential to ensure consistency and alignment with product goals.

Relying on Visual Samples Only

Approving cotton velour based solely on small swatches without testing full production runs can be misleading. Lighting, sample preparation, and scale may hide defects or performance issues that only appear in bulk manufacturing.

Avoiding these pitfalls requires due diligence, clear communication, third-party verification, and respect for intellectual property throughout the sourcing process.

Logistics & Compliance Guide for Cotton Velour

Cotton velour is a soft, plush fabric commonly used in apparel, home textiles, and accessories. Its unique texture and composition require careful attention during logistics and compliance processes. This guide outlines key considerations for the safe, efficient, and compliant handling of cotton velour throughout the supply chain.

Sourcing & Material Compliance

Ensure that cotton velour used in production meets international and regional textile standards:

– Verify cotton origin and adherence to sustainable sourcing guidelines (e.g., BCI – Better Cotton Initiative, Organic Content Standard).

– Confirm compliance with REACH (EU), CPSIA (USA), and other applicable chemical regulations (e.g., restricted substances like Azo dyes, formaldehyde).

– Provide proper labeling per FTC (Federal Trade Commission) requirements in the U.S., including fiber content (e.g., “100% Cotton” or “80% Cotton, 20% Polyester”).

– If exported, comply with country-specific textile labeling laws (e.g., UK, Canada, Japan).

Packaging & Storage

Protect cotton velour from damage during storage and transit:

– Use breathable, non-abrasive packaging (e.g., polybags with ventilation) to prevent moisture buildup and odor retention.

– Avoid tight compression to preserve the fabric’s pile and texture; loose folding or rolling is preferred.

– Store in a dry, temperature-controlled environment away from direct sunlight to prevent fading and mildew.

– Keep off the floor using pallets and protect from dust and pests.

Transportation & Handling

Follow best practices for shipping cotton velour domestically and internationally:

– Use clean, dry containers or trucks with moisture barriers to prevent water damage.

– Minimize vibration and compression; stack cartons carefully to avoid crushing lower layers.

– For air or sea freight, comply with ISPM 15 regulations if wooden pallets are used (heat-treated and stamped).

– Provide clear handling instructions (e.g., “Fragile,” “Do Not Stack”) on outer packaging.

Import/Export Documentation

Ensure accurate documentation for cross-border shipments:

– Prepare commercial invoice, packing list, and bill of lading/air waybill with detailed description (e.g., “Cotton Velour Fabric, 300gsm, Width 150cm”).

– Assign correct HS code (e.g., 5801.32 for velvet and velour of cotton, depending on construction and use).

– Include certificates of origin if claiming preferential tariffs under trade agreements (e.g., USMCA, RCEP).

– Submit required compliance documentation (e.g., FDA prior notice for textiles in contact with skin, if applicable).

Sustainability & End-of-Life Compliance

Adhere to environmental regulations and promote circularity:

– Follow WEEE, SCIP, or other eco-directives if cotton velour contains electronic components (e.g., smart garments).

– Support recycling programs and provide care instructions to extend product life.

– Comply with extended producer responsibility (EPR) schemes in regions like the EU.

Quality Assurance & Testing

Implement pre-shipment quality checks:

– Conduct fabric tests for colorfastness, pilling, shrinkage, and tensile strength per ISO or AATCC standards.

– Inspect for defects such as snags, uneven dyeing, or contamination.

– Maintain records of test results for audit and compliance purposes.

By following this guide, businesses can ensure the safe, legal, and sustainable movement of cotton velour through the global supply chain while minimizing risks and maintaining product integrity.

In conclusion, sourcing cotton velour requires a strategic approach that balances quality, cost, sustainability, and ethical considerations. It is essential to partner with reliable suppliers who adhere to industry standards and provide consistent fabric quality, including the desired softness, weight, and durability. Evaluating factors such as manufacturing location, production capacity, lead times, and compliance with environmental and labor regulations will help ensure a resilient and responsible supply chain. Additionally, staying informed about market trends and fabric innovations can enhance competitiveness. Ultimately, successful sourcing of cotton velour supports not only product excellence but also brand integrity and long-term sustainability goals.