The global cotton print fabric market is experiencing steady growth, driven by rising consumer demand for sustainable, breathable, and versatile textiles in apparel, home furnishing, and fashion industries. According to a report by Grand View Research, the global printed fabric market was valued at USD 19.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030, with cotton remaining one of the most preferred natural fibers due to its comfort and eco-friendly profile. Additionally, increasing investments in digital printing technologies and a surge in demand from emerging economies are accelerating production capabilities among leading manufacturers. As sustainability and customization gain traction, cotton print fabric producers are innovating to meet evolving market needs—making it essential to spotlight the top eight manufacturers leading the charge in quality, scalability, and technological advancement.

Top 8 Cotton Print Fabric Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

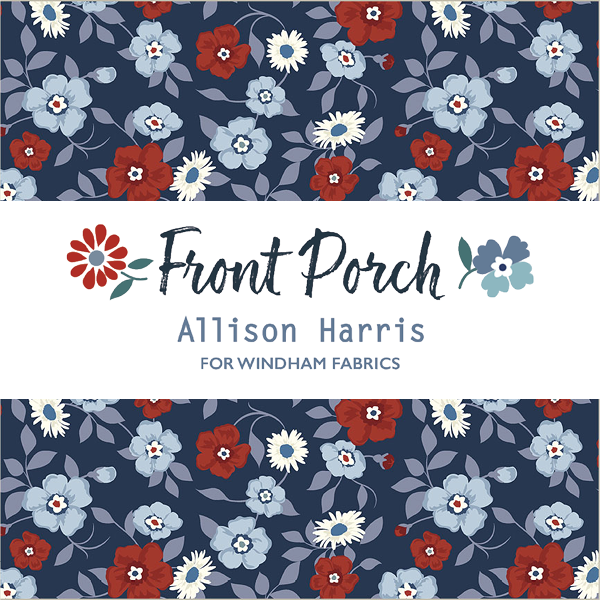

#1 Windham Fabrics: Shop High

Domain Est. 2003

Website: windhamfabrics.com

Key Highlights: Explore our wide range of premium fabrics for quilt shops and manufacturers. From soft cotton and colorful batiks to warm and cozy fleece, find the perfect ……

#2 Cotton Incorporated

Domain Est. 1996

Website: cottoninc.com

Key Highlights: Cotton Incorporated is your resource for all things cotton: · Performance Technologies · Fabric Developments · Fiber Economic Analysis · Cotton Sustainability….

#3 Robert Kaufman Fabrics

Domain Est. 1997 | Founded: 1942

Website: robertkaufman.com

Key Highlights: Wholesale supplier of quality textiles and fabrics for quilting, fashion and manufacturing since 1942 … Cotton Pique Print Wide, Cotton Plaids, Cotton Poly ……

#4 Cotton Fabric

Domain Est. 1999

Website: fabricmartfabrics.com

Key Highlights: 30-day returnsCotton Fabric ; Main Color. Black (13) ; Content. 100% Cotton (194) ; Type. Broadcloth (26) ; Pattern / Design. Abstract (12)….

#5 Novelty Cotton Fabric

Domain Est. 2002

#6 Organic Cotton Plus

Domain Est. 2003

Website: organiccottonplus.com

Key Highlights: Organic Cotton Fabric and Eco-Friendly Crafting Supplies. GOTS Certified products including organic cotton Flannel, Jersey, Interlock, Canvas, Fleece……

#7 Elliott Berman Textiles: High

Domain Est. 2008

Website: elliottbermantextiles.com

Key Highlights: Free delivery 15-day returnsElliott Berman Textiles is your destination for exclusive, high-end apparel fabrics from Italy and France. Shop a curated selection of luxury designer ….

#8 Cotton+Steel Fabrics

Domain Est. 2013

Website: cottonandsteelfabrics.com

Key Highlights: Fabrics: Canvas, Cotton, Double Gauze, Knit, Lawn, Rayon, Unbleached Cotton. Designers: Designers: Alex Roda, Alex Roda, Feel the Void Grounded….

Expert Sourcing Insights for Cotton Print Fabric

H2: 2026 Market Trends for Cotton Print Fabric

The global cotton print fabric market is poised for notable transformation by 2026, driven by evolving consumer preferences, sustainability imperatives, technological advancements, and shifting supply chain dynamics. This analysis outlines key trends expected to shape the industry in the coming years.

1. Rising Demand for Sustainable and Organic Cotton Print Fabrics

Environmental concerns are reshaping consumer behavior, with increasing demand for eco-friendly textiles. By 2026, the market is expected to see a significant shift toward organic cotton print fabrics, which are grown without synthetic pesticides and consume less water. Certification standards such as GOTS (Global Organic Textile Standard) and OEKO-TEX are becoming key differentiators. Brands are likely to emphasize transparency and traceability in sourcing, appealing to environmentally conscious consumers.

2. Growth in Digital Printing Technologies

Digital textile printing is set to revolutionize cotton print fabric production. By 2026, digital printing is expected to account for a larger share of the market due to its advantages in customization, reduced waste, and faster turnaround times. This technology supports on-demand production, minimizing overstock and aligning with the growing fast-fashion and micro-trend cycles, while also offering intricate designs with high color accuracy.

3. Expansion in Emerging Markets

Asia-Pacific, particularly countries like India, China, and Bangladesh, will continue to dominate cotton print fabric production and consumption. However, rising disposable incomes and urbanization in regions such as Southeast Asia, Africa, and Latin America are creating new consumer bases. Local apparel industries in these regions are increasingly incorporating printed cotton fabrics, fueled by cultural demand for vibrant, traditional designs.

4. Influence of Fashion E-Commerce and Customization

The proliferation of online fashion retail platforms enables greater access to niche and designer cotton print fabrics. By 2026, direct-to-consumer (DTC) models and mass customization options—such as personalized prints—are expected to gain traction. Consumers are increasingly seeking unique, statement pieces, driving demand for limited-edition and bespoke cotton prints.

5. Supply Chain Resilience and Regionalization

Post-pandemic and geopolitical disruptions have prompted brands to re-evaluate supply chain dependencies. In 2026, there will be a growing trend toward regional production hubs to reduce lead times and enhance agility. Nearshoring and onshoring of cotton fabric printing activities are likely in North America and Europe, supported by automation and local sustainability regulations.

6. Integration of Smart Textiles and Functional Finishes

While still emerging, the convergence of cotton print fabrics with functional technologies—such as moisture-wicking, UV protection, or antimicrobial finishes—is gaining momentum. Though traditional printed cotton remains dominant, hybrid products that combine aesthetics with performance are expected to capture niche market segments, particularly in activewear and children’s clothing.

7. Regulatory and Compliance Pressures

Stricter environmental regulations, especially in the EU and North America, will influence cotton print fabric manufacturing processes. By 2026, compliance with chemical restrictions (e.g., REACH, ZDHC) and carbon footprint reporting will be essential for market access. This could lead to increased investment in cleaner dyeing processes and water recycling systems.

Conclusion

By 2026, the cotton print fabric market will be characterized by innovation, sustainability, and regional diversification. Success will depend on manufacturers’ ability to adapt to digital transformation, meet eco-conscious consumer demands, and navigate complex regulatory landscapes. Companies that invest in sustainable practices, adopt agile production models, and leverage digital platforms are likely to lead the market in the coming years.

Common Pitfalls When Sourcing Cotton Print Fabric (Quality & Intellectual Property)

Sourcing cotton print fabric involves balancing aesthetic appeal, durability, cost, and legal compliance. Overlooking key pitfalls—especially in quality and intellectual property (IP)—can lead to production delays, customer dissatisfaction, or even legal disputes. Here are the most common issues to avoid:

Inconsistent Fabric Quality and Construction

One of the top challenges in sourcing cotton print fabric is ensuring consistent quality across batches. Buyers often face variations in weight, weave, shrinkage, and hand feel due to differences in cotton sourcing, yarn count, and manufacturing processes. Low-quality cotton or improper finishing can result in fabrics that pill, tear, or shrink excessively after washing.

Poor Color Fastness and Print Durability

Many suppliers offer vibrant prints that fade or bleed after the first wash. This is often due to the use of low-grade dyes or improper fixation processes. Without proper color fastness testing (e.g., for washing, light, and rubbing), the final product may not meet consumer expectations or industry standards.

Lack of Pre-Production Sampling and Approval

Skipping or rushing the sampling phase can lead to major quality mismatches. Without approving physical strike-offs or lab dips, buyers risk receiving fabrics with incorrect colors, misaligned patterns, or subpar print resolution. Always insist on pre-production samples verified under the same lighting and conditions as the end use.

Misalignment in Print Registration and Repeat Patterns

Printed fabrics require precise registration, especially for complex patterns or large repeats. Poor alignment during printing—due to machinery issues or inexperience—can result in blurred edges, off-grain designs, or mismatched pattern repeats, leading to wasted yardage and production delays.

Intellectual Property Infringement Risks

Using copyrighted or trademarked designs—even unintentionally—can result in legal action, shipment seizures, or costly recalls. A common pitfall is sourcing from suppliers who offer “inspired by” prints that closely mimic popular designer or artist patterns. Always verify that the print design is either original, properly licensed, or in the public domain.

Lack of Design Ownership and Licensing Clarity

Even if a supplier creates a custom print, ownership rights may not automatically transfer to the buyer. Without a clear contract specifying IP ownership or licensing terms, brands may be unable to reuse or modify the design, or could face disputes if the supplier sells the same print to competitors.

Failure to Audit Supply Chain for Compliance

Some suppliers subcontract printing or finishing to third-party facilities not vetted by the buyer. This increases the risk of unauthorized production, quality deviations, and IP leaks. Ensure full transparency in the supply chain and conduct audits to confirm ethical practices and IP protection.

Inadequate Testing and Certification

Cotton print fabrics used in apparel or home textiles may need to meet specific safety and environmental standards (e.g., OEKO-TEX®, GOTS). Overlooking required certifications can result in non-compliant products, especially when selling in regulated markets like the EU or North America.

Overlooking Minimum Order Quantities and Lead Times

Printed fabrics often have higher MOQs due to setup costs for screens or digital printing. Failing to plan for long lead times or bulk commitments can strain cash flow and inventory management, particularly for small or emerging brands.

Conclusion

Avoiding these pitfalls requires due diligence, clear communication, and contractual safeguards. Prioritize supplier vetting, enforce sampling and testing protocols, and secure proper IP rights to ensure a smooth, compliant, and high-quality cotton print fabric sourcing process.

Logistics & Compliance Guide for Cotton Print Fabric

Overview

Cotton print fabric—woven or knitted cotton material with patterned designs applied via printing techniques—is widely used in apparel, home textiles, and accessories. Moving this product across borders involves navigating complex logistics and regulatory requirements. This guide outlines key considerations for the international shipment and compliance of cotton print fabric.

Classification & Tariff Codes

Accurate product classification is critical for customs clearance and duty assessment.

– HS Code (Harmonized System): Typically falls under Chapter 52 (Cotton). Common codes include:

– 5208.33 – Printed cotton fabric, weighing ≤ 200 g/m²

– 5208.39 – Printed cotton fabric, weighing > 200 g/m²

– (Note: Final classification depends on fabric weight, composition, weave, and regional trade agreements.)

– Verify country-specific tariff lines (e.g., HTSUS in the U.S., CN in the EU) to determine applicable duties and restrictions.

Country of Origin Requirements

- Rules of origin must be documented to qualify for preferential tariffs under trade agreements (e.g., USMCA, EU GSP).

- For cotton print fabric, origin is typically determined by:

- The location where the fabric is both spun and woven

- The transformation of yarn into fabric (substantial transformation rule)

- Labels must comply with destination country regulations (e.g., “Made in India” for U.S. import).

Textile Regulations & Labelling

Compliance with labeling laws is mandatory in most markets:

– Fiber Content: Must disclose cotton percentage (e.g., “100% Cotton” or “Cotton/Polyester Blend”).

– Care Instructions: Required in regions like the U.S. (FTC Care Labeling Rule) and EU.

– Country of Origin Labeling: Enforced in the U.S., Canada, and other jurisdictions.

– Eco-Labels & Certifications: Brands may require GOTS (Global Organic Textile Standard), OEKO-TEX®, or Bluesign® certification for sustainability claims.

Chemical & Safety Compliance

Printed fabrics may contain dyes, pigments, and finishing agents subject to chemical regulations:

– REACH (EU): Restricts substances of very high concern (SVHCs); requires communication along the supply chain.

– CA Prop 65 (California, USA): Requires warning labels if fabric contains listed carcinogens or reproductive toxins.

– AZO Dyes Ban: Prohibited in the EU (REACH Annex XVII) and China if they release harmful aromatic amines.

– Formaldehyde Limits: Must comply with limits under OEKO-TEX® Standard 100 or national regulations.

Phytosanitary & Environmental Considerations

- Cotton is a natural fiber derived from plants; while not typically subject to phytosanitary certificates for finished fabric, raw cotton shipments may be.

- Some countries monitor for pests or contaminants in raw materials, so ensure cleanliness and storage integrity.

- Sustainable sourcing (e.g., BCI – Better Cotton Initiative) may be required by importers or retailers.

Packaging & Marking Requirements

- Use durable packaging (e.g., polybags, cardboard tubes, or bales) to prevent moisture, dirt, and physical damage.

- Mark outer packages with:

- Product description and HS code

- Quantity (yards/meters), weight, and roll numbers

- Country of origin

- Handling symbols (e.g., “Do Not Stack,” “Keep Dry”)

- Avoid prohibited materials (e.g., certain wood packaging requiring ISPM 15 treatment).

Import Documentation

Ensure complete and accurate documentation for customs:

– Commercial Invoice (with full product description, value, and INCOTERMS)

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin (preferential or non-preferential, as required)

– Test Reports or Certifications (e.g., GOTS, OEKO-TEX®)

– Import License (if required by destination country)

Restricted Markets & Trade Policies

- Monitor sanctions and embargoes (e.g., U.S. restrictions on cotton from Xinjiang, China under UFLPA).

- Conduct due diligence on supply chain to avoid forced labor risks; provide supply chain mapping if requested.

- Some countries impose quotas or anti-dumping duties on textile imports—verify current status.

Transportation & Handling

- Use temperature- and humidity-controlled containers when shipping long distances to prevent mildew or shrinkage.

- Avoid folding printed fabrics sharply to prevent creasing; roll where possible.

- Insure shipments against loss, damage, or delay.

Conclusion

Successfully shipping cotton print fabric internationally requires strict adherence to classification, labeling, chemical safety, and documentation standards. Proactive compliance reduces delays, avoids penalties, and supports sustainable and ethical trade practices. Always consult local customs authorities or a licensed customs broker for up-to-date requirements in target markets.

In conclusion, sourcing cotton print fabric requires a careful evaluation of quality, supplier reliability, sustainability practices, cost-efficiency, and compliance with industry standards. By establishing clear specifications, conducting thorough supplier assessments, and fostering strong supplier relationships, businesses can ensure a consistent supply of high-quality cotton print fabric that meets both aesthetic and functional requirements. Additionally, considering ethical and environmental factors not only supports responsible sourcing but also enhances brand reputation and long-term sustainability. With a strategic and informed approach, companies can secure a competitive advantage in the textile market while meeting the evolving demands of consumers and regulators alike.