The global mica powder market has witnessed steady expansion, driven by rising demand for natural and shimmer-enhancing ingredients in the cosmetics industry. According to Grand View Research, the global mica market was valued at USD 1.17 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing consumer preference for premium, visually appealing beauty products such as eyeshadows, highlighters, and nail polishes—categories where cosmetic-grade mica powder plays a pivotal role. Moreover, with growing emphasis on ethically sourced raw materials, manufacturers are investing in traceability and sustainable mining practices to meet regulatory and consumer expectations. As the clean beauty movement gains momentum, demand for high-purity, non-toxic, and responsibly produced mica has elevated the importance of reliable suppliers. In this competitive landscape, a select group of manufacturers have emerged as leaders, combining quality, compliance, and innovation. Based on market presence, product range, certifications, and ethical sourcing initiatives, here are the top 7 cosmetic mica powder manufacturers shaping the industry.

Top 7 Cosmetic Mica Powder Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sun Chemical

Domain Est. 1995

Website: sunchemical.com

Key Highlights: Sun Chemical develops a wide range of pigments and color materials for architectural, automotive and industrial coatings, cosmetics, plastics, printing inks, ……

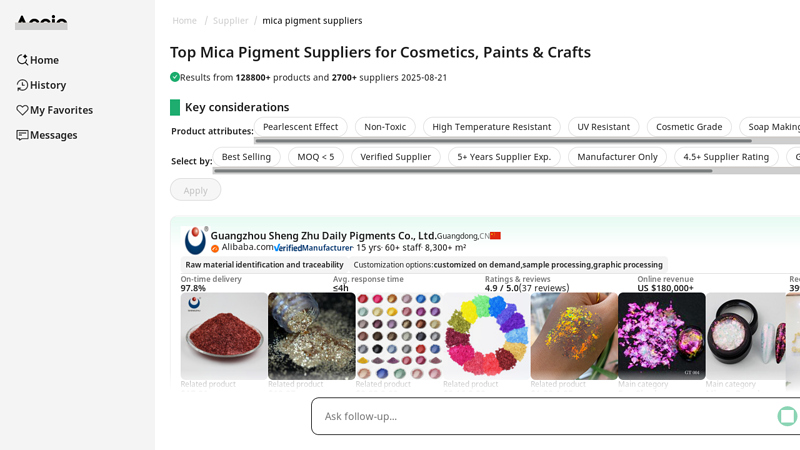

#2 Top Mica Pigment Suppliers for Cosmetics, Paints & Crafts

Domain Est. 1997

Website: accio.com

Key Highlights: Need reliable mica pigment suppliers? Discover 2700+ verified manufacturers offering custom solutions for cosmetics, paints, and crafts….

#3 Miyoshi America

Domain Est. 2015

Website: miyoshiamerica.com

Key Highlights: Miyoshi America, Inc., along with the Miyoshi Kasei Group of companies, is the global leader in the development and manufacture of surface treated pigments….

#4 Presperse

Domain Est. 2023

Website: letsmakebeauty.com

Key Highlights: Free delivery over $49At Presperse – Let’s Make Beauty, we provide the highest-quality cosmetic ingredients in formats and sizes tailored for Contract Manufacturers, Private Label …

#5 Pearl Ex Powdered Pigments

Domain Est. 1997

Website: jacquardproducts.com

Key Highlights: 5-day delivery 14-day returnsPearl Ex is a safe, inert pigment that exhibits extreme colorfastness and stability. The different particle sizes produce different effects….

#6 Prismatic Powders

Domain Est. 2001

Website: prismaticpowders.com

Key Highlights: $13.95 delivery 30-day returnsWorld’s Largest Custom Powder Coating Color Selection. Prismatic Powders offers the world’s largest selection of powder coating colors and styles….

#7 Koel Colours: Pigment Manufacturing Company

Domain Est. 2008

Website: koelcolours.com

Key Highlights: We are one of the leading Pigments Manufacturing Company. Specialized in manufacturing of a wide range of Colour Dyes, Pigments and Specialty Ingredients….

Expert Sourcing Insights for Cosmetic Mica Powder

H2: 2026 Market Trends for Cosmetic Mica Powder

The cosmetic mica powder market in 2026 is poised for significant evolution, driven by shifting consumer preferences, technological advancements, and intensified regulatory scrutiny. Key trends shaping the landscape include:

1. Dominance of Ethical & Sustainable Sourcing:

By 2026, traceability and ethical sourcing will be paramount. Consumers and brands are demanding full transparency regarding mica origins to combat child labor and unsafe mining practices, particularly in traditional regions like India. Expect widespread adoption of certified ethical mica (e.g., through initiatives like the Responsible Mica Initiative – RMI) and blockchain-enabled traceability systems. Brands will increasingly shift toward lab-grown (synthetic) mica and alternative biodegradable effect pigments to ensure sustainability and ethical compliance.

2. Rise of Synthetic & Alternative Effect Pigments:

Synthetic fluorphlogopite (lab-grown mica) will gain substantial market share due to its consistent quality, purity, and ethical advantages. Innovations in bio-based and biodegradable pearlescent pigments (e.g., derived from cellulose or algae) will also emerge as sustainable alternatives, appealing to eco-conscious consumers and reducing environmental impact compared to mined minerals.

3. Clean Beauty & Clean Label Demand:

The clean beauty movement will continue to influence formulation choices. Demand will grow for cosmetic mica that is free from heavy metals (lead, arsenic, mercury), talc, and contaminants. Suppliers will emphasize purity testing (e.g., via ICP-MS) and provide detailed Certificates of Analysis. “Naturally derived” but responsibly sourced mica will be highly valued, even as synthetic options rise.

4. Technological Advancements in Particle Engineering:

Innovations in particle size, shape, and surface treatment will enable enhanced sensory properties, improved dispersion, and next-generation visual effects (e.g., color-shift, ultra-matte finishes, 3D depth). Nano-engineered micas will offer improved stability and performance in water-based and long-wear formulations, supporting the growth of innovative makeup and skincare products.

5. Regulatory Harmonization and Stricter Standards:

Global regulations (e.g., EU SCCS, US FDA) will likely tighten around heavy metal limits and contaminant thresholds for cosmetic-grade mica. Compliance with INCI naming, GMP standards, and regional safety assessments will be non-negotiable. This will drive consolidation among suppliers and increase costs, favoring established players with robust quality control.

6. Growth in Emerging Markets & Premiumization:

Asia-Pacific and Latin America will see rising demand due to expanding middle classes and growing beauty consciousness. Simultaneously, premium and luxury beauty segments will drive demand for high-purity, specialty-effect micas in high-performance and “clean” formulations, supporting price premiums for premium grades.

7. Integration with Multifunctional Formulations:

Mica will increasingly be used not only for aesthetics but also as a functional ingredient—enhancing texture, providing soft-focus effects in skincare-infused makeup, and improving adherence in sun care and color cosmetics. This blurring of categories will expand mica’s application scope beyond traditional makeup.

In summary, by 2026, the cosmetic mica powder market will be defined by ethical integrity, technological innovation, and regulatory rigor. Success will depend on suppliers’ ability to deliver sustainable, traceable, and high-performance mica solutions that align with evolving consumer values and formulation demands.

Common Pitfalls When Sourcing Cosmetic Mica Powder (Quality & Intellectual Property)

Sourcing cosmetic mica powder involves navigating complex challenges related to both product quality and intellectual property (IP) protection. Overlooking these areas can lead to regulatory non-compliance, supply chain disruptions, brand damage, and legal disputes. Below are the most common pitfalls to avoid:

Quality-Related Pitfalls

1. Inadequate Purity and Contaminant Screening

Many suppliers, especially those in less-regulated markets, may provide mica powder containing harmful contaminants such as heavy metals (lead, arsenic, mercury), asbestos, or residual solvents. Failure to demand and verify comprehensive Certificates of Analysis (CoA) from accredited third-party labs increases the risk of unsafe formulations.

2. Inconsistent Particle Size and Color Batch-to-Batch

Cosmetic performance relies heavily on consistent particle size distribution and color. Poorly controlled manufacturing processes can result in variations that affect product texture, shimmer, and formulation stability. Relying on suppliers without robust quality control systems can compromise end-product consistency.

3. Lack of Ethical Sourcing and Traceability

Mica mining is associated with child labor and unethical practices, particularly in regions like India and Madagascar. Sourcing from unverified suppliers exposes brands to reputational risks and non-compliance with ESG (Environmental, Social, Governance) standards. Failing to demand full supply chain transparency and third-party certifications (e.g., Responsible Mica Initiative) is a major pitfall.

4. Mislabeling or False “Natural” Claims

Some suppliers misrepresent synthetic or coated micas as “natural” or “pure.” This can mislead formulators and result in non-compliant marketing claims. Always verify the INCI name and confirm whether the mica is mineral-based, synthetic fluorphlogopite, or color-treated.

5. Insufficient Stability and Compatibility Testing

Not all mica powders are compatible with various cosmetic bases (e.g., anhydrous oils, water-based serums). Sourcing without requesting compatibility and stability data can lead to formulation issues such as clumping, separation, or color shift over time.

Intellectual Property (IP)-Related Pitfalls

1. Unlicensed Use of Proprietary Color Formulations

Certain vibrant or unique mica blends are patented or trademarked by specialty chemical companies (e.g., L’Oréal, Sensient, BASF). Sourcing generic versions that replicate these protected formulations can result in IP infringement and legal action, even if the supplier claims the product is “similar.”

2. Lack of IP Clauses in Supplier Agreements

Failing to include clear IP ownership and confidentiality terms in sourcing contracts leaves brands vulnerable. Suppliers may claim rights over custom-developed blends or reuse formulations for competing clients, eroding competitive advantage.

3. Reverse Engineering Without Legal Clearance

Attempting to replicate a competitor’s mica-based product without conducting a freedom-to-operate (FTO) analysis risks infringing on existing patents, especially for coated pigments or effect additives. Legal due diligence is essential before commercialization.

4. Overlooking Trademarked Color Names

Colors like “Electric Blue” or “Rose Gold” may be trademarked when used in specific cosmetic contexts. Sourcing mica powders with such names without verifying trademark status can lead to cease-and-desist letters or rebranding costs.

5. Supplier Claims of “Custom Blends” Without IP Assignment

Suppliers may offer custom mica blends but retain IP rights unless explicitly transferred. Brands assuming ownership without written agreements may face restrictions or fees when scaling production or switching manufacturers.

To mitigate these risks, establish a vetting process that includes third-party testing, supply chain audits, legal review of formulations, and robust contractual protections. Prioritize transparency, compliance, and due diligence at every stage of sourcing.

Logistics & Compliance Guide for Cosmetic Mica Powder

Regulatory Classification and Compliance Requirements

Cosmetic mica powder is classified as a color additive under the regulatory frameworks of major markets such as the United States (FDA), the European Union (EC Regulation 1223/2009), and other international jurisdictions. In the U.S., mica used in cosmetics must comply with FDA color additive regulations (21 CFR Part 73, Subpart B), specifically 21 CFR 73.2110, which mandates certification by the FDA’s Color Certification Program. Each batch must be submitted for certification unless it is labeled “not for use in the area of the eye” and meets non-certified specifications.

In the EU, mica (CI 77019) is listed in Annex IV of the EU Cosmetics Regulation and is permitted for use in cosmetics without pre-market authorization, provided it meets strict purity criteria regarding heavy metals (e.g., lead ≤10 ppm, arsenic ≤3 ppm, mercury ≤1 ppm) and is free from asbestos contamination. Suppliers must provide a Certificate of Analysis (CoA) confirming compliance with these limits.

Additionally, compliance with Good Manufacturing Practices (GMP) as outlined in ISO 22716 is required to ensure product safety and quality throughout production and handling.

Responsible Sourcing and Ethical Supply Chain

Due to concerns over child labor and unsafe mining practices—particularly in regions like India—sourcing cosmetic mica powder responsibly is a critical compliance and ethical obligation. Companies must implement due diligence processes in line with the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas.

Key actions include:

- Conducting supply chain mapping to trace mica back to the mine of origin.

- Engaging only with suppliers who are members of recognized initiatives such as the Responsible Mica Initiative (RMI) or have third-party certifications (e.g., SMETA, SA8000).

- Requiring supplier declarations and audit reports demonstrating adherence to social and environmental standards.

- Implementing regular audits and risk assessments, especially for operations in high-risk regions.

Failure to ensure ethical sourcing can result in reputational damage, regulatory scrutiny, and non-compliance with emerging legislation such as Germany’s Supply Chain Due Diligence Act (LkSG) and proposed EU Corporate Sustainability Due Diligence Directive (CSDDD).

Labeling and Product Documentation

Accurate labeling of cosmetic mica powder is essential for regulatory compliance and consumer safety. In the U.S., cosmetic products containing certified color additives must list the color using its approved name (e.g., “Mica” or “CI 77019”) on the ingredient list in descending order of predominance. The label must also include the manufacturer’s name and place of business, net quantity, and any necessary warning statements.

In the EU, Annex VI of the Cosmetics Regulation requires that all ingredients be listed using the International Nomenclature of Cosmetic Ingredients (INCI) name. Mica must be declared as “Mica (CI 77019)” in the ingredient list. If the product contains nanomaterials, this must be indicated by the word “nano” in parentheses after the ingredient name (e.g., “Mica (nano) (CI 77019)”).

Additional documentation required includes:

- Safety Data Sheet (SDS) compliant with REACH (Regulation EC 1907/2006) and CLP (Regulation EC 1272/2008).

- Product Information File (PIF) for EU market access, including safety assessment, manufacturing information, and proof of compliance.

- Batch-specific CoA verifying purity, particle size, and absence of contaminants.

Storage, Handling, and Transportation

Proper logistics practices are essential to maintain the integrity and safety of cosmetic mica powder during storage and transport.

Storage:

– Store in a cool, dry, and well-ventilated area away from direct sunlight and moisture to prevent clumping or degradation.

– Use sealed, non-reactive containers (e.g., HDPE or laminated foil bags) to prevent contamination and maintain sterility.

– Maintain segregation from incompatible materials (e.g., strong oxidizers, acids) and ensure compliance with local fire and safety regulations.

Handling:

– Personnel must wear appropriate PPE (e.g., dust masks, gloves, safety goggles) to minimize inhalation of fine particles and skin contact.

– Use local exhaust ventilation in areas where mica powder is handled in bulk to control airborne dust.

– Follow GMP and internal SOPs to prevent cross-contamination.

Transportation:

– Classify mica powder as a non-hazardous material under DOT (49 CFR), IATA, and IMDG regulations when shipped in consumer or industrial cosmetic quantities.

– Package in UN-certified containers if required by volume or carrier specifications.

– Provide accurate shipping documentation, including commercial invoice, packing list, and CoA.

– For international shipments, ensure compliance with import regulations of the destination country, including customs declarations and potential import permits.

Environmental and Disposal Compliance

While mica is chemically inert and non-toxic in its natural form, environmental compliance must address dust emissions during processing and proper end-of-life disposal.

- Dust emissions during manufacturing and packaging must be controlled through filtration systems (e.g., HEPA filters) to comply with OSHA and local air quality regulations.

- Waste mica powder should be disposed of in accordance with local waste management regulations. In most cases, it can be disposed of as non-hazardous solid waste.

- Avoid release into waterways; sedimentation controls may be required for large-scale operations.

- Recycle packaging materials where possible to support sustainability goals.

Companies should conduct periodic environmental audits and maintain records of waste disposal to demonstrate compliance with environmental protection laws.

In conclusion, sourcing cosmetic-grade mica powder requires careful consideration of quality, safety, ethical practices, and regulatory compliance. It is essential to partner with reputable suppliers who provide certified, pure, and contaminant-free mica that meets international cosmetic standards such as FDA, EU Cosmetics Regulation, and ISO certifications. Due to growing concerns over unethical mining practices, particularly involving child labor, prioritizing suppliers who offer responsibly sourced and traceable mica—ideally from verifiable, fair-trade, or recycled sources—is crucial for maintaining brand integrity and consumer trust. Additionally, conducting regular audits, requesting material safety data sheets (MSDS), and performing batch testing can ensure consistent product quality and compliance. Ultimately, a transparent and sustainable sourcing strategy not only supports safe and high-performing cosmetic formulations but also aligns with the increasing consumer demand for ethically produced beauty products.