The global market for sheet metal cutting machines is experiencing steady expansion, driven by rising demand across manufacturing, automotive, and construction industries. According to Grand View Research, the global metal cutting machine tools market was valued at USD 18.9 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 7.1% from 2023 to 2030. This growth is fueled by increased adoption of CNC technology, automation, and the need for precision in industrial fabrication. As the demand for efficient and high-accuracy cortadora de lámina (sheet metal cutter) solutions intensifies, manufacturers are innovating to deliver advanced machinery that supports higher productivity and reduced operational costs. In this competitive landscape, three leading manufacturers have emerged at the forefront, combining technological excellence, global reach, and proven performance to meet evolving industry needs.

Top 3 Cortadora De Lamina Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Serie CP835

Domain Est. 1994

Website: tools.cp.com

Key Highlights: Serie CP835 – Cortadoras de lámina – Para los operadores que trabajan en aplicaciones de mantenimiento general, como el corte de esquinas y círculos ……

#2 Máquinas cortadoras láser para metal

Domain Est. 2000

Website: blmgroup.com

Key Highlights: Maquina para corte láser de fibra para láminas metalicas, libremente accesible. Área de trabajo desde: 3000 x 1500 mm a 6000 x 2000 mm. Fuente láser de fibra…

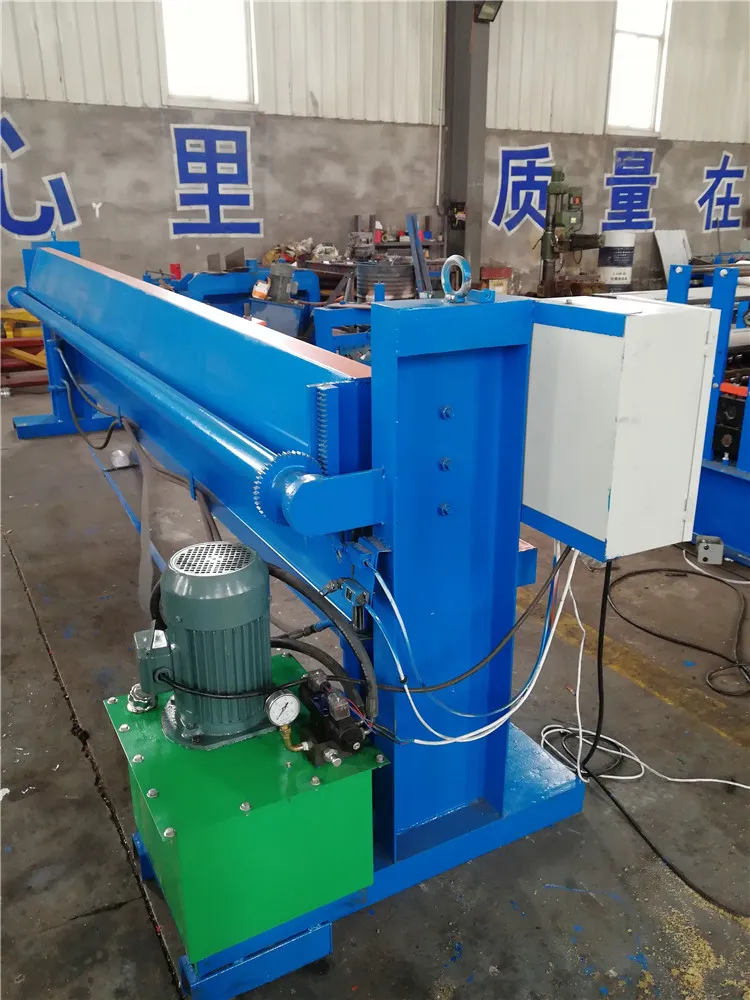

#3 Cortadoras para cortar lamina

Domain Est. 2002

Website: americanmachinetools.com

Key Highlights: Estas máquinas son todas fabricadas en los Estados Unidos. GARY cortadora de lamina. Cortadora de garganta robusta de 24 pulgadas con ajuste rápido de la parte ……

Expert Sourcing Insights for Cortadora De Lamina

2026 Market Trends for Cortadora De Lamina

The market for Cortadora de Lamina (sheet metal cutting machines) is poised for significant transformation by 2026, driven by technological innovation, rising industrial automation, and evolving manufacturing demands. This analysis explores key trends shaping the industry, including technological advancements, regional market dynamics, sustainability initiatives, and the growing need for precision and efficiency in metal fabrication.

Technological Advancements and Automation

By 2026, automation and smart manufacturing will dominate the cortadora de lamina sector. The integration of AI-driven controls, IoT-enabled monitoring, and cloud-based diagnostics will enhance machine performance, predictive maintenance, and operational efficiency. CNC (Computer Numerical Control) and fiber laser cutting technologies are expected to lead, offering higher precision, faster cutting speeds, and reduced waste. Additionally, hybrid machines combining laser and plasma cutting capabilities will gain traction, allowing manufacturers to process a wider range of materials with a single system.

Growth in Demand Across Key Industries

Industries such as automotive, aerospace, construction, and renewable energy are driving demand for advanced sheet metal cutting solutions. Electric vehicle (EV) production, in particular, requires intricate metal components, increasing the need for high-precision cutting machines. Similarly, the construction sector’s shift toward prefabricated metal structures is boosting demand for automated and portable cutting systems, especially in emerging markets.

Regional Market Expansion

Latin America, especially countries like Mexico, Brazil, and Colombia, is expected to see increased adoption of cortadoras de lamina due to industrial modernization and foreign investment in manufacturing. In Asia-Pacific, China and India remain dominant markets, supported by robust infrastructure development and government initiatives promoting “smart manufacturing.” Meanwhile, North America and Western Europe will focus on upgrading existing facilities with energy-efficient and digitally integrated systems to maintain competitive advantage.

Sustainability and Energy Efficiency

Environmental regulations and corporate sustainability goals will influence machine design and operation. By 2026, manufacturers will prioritize energy-efficient motors, reduced material waste through optimized nesting software, and recyclable components. Fiber laser technology, which consumes less power than CO2 lasers, will become the standard, further supporting green manufacturing practices.

Competitive Landscape and Innovation

The market will witness increased competition among key players such as Amada, Bystronic, TRUMPF, and local manufacturers offering cost-effective alternatives. Innovation will focus on user-friendly interfaces, remote operation capabilities, and modular designs that allow for easy upgrades. Additionally, the rise of Industry 4.0 will push vendors to offer comprehensive software ecosystems that integrate seamlessly with enterprise resource planning (ERP) and product lifecycle management (PLM) systems.

Conclusion

The 2026 outlook for cortadora de lamina is one of dynamic growth and technological evolution. As industries demand faster, smarter, and more sustainable manufacturing solutions, the sheet metal cutting market will respond with advanced automation, enhanced precision, and greater connectivity. Companies that invest in innovation and adapt to regional and environmental needs will be best positioned to lead in this competitive landscape.

Common Pitfalls When Sourcing a Cortadora De Lámina (Quality, IP)

Sourcing a Cortadora de Lámina (sheet metal cutter) involves several critical considerations, particularly regarding quality standards and intellectual property (IP). Failing to address these aspects can lead to operational inefficiencies, legal risks, and financial losses. Below are some common pitfalls to avoid.

1. Compromising on Build Quality and Material Standards

One of the most frequent mistakes is selecting a machine based solely on price without evaluating its construction quality. Low-cost Cortadoras de Lámina may use substandard steel, inferior bearings, or poorly calibrated cutting mechanisms, leading to:

- Inconsistent cuts and material waste

- Higher maintenance and downtime

- Shorter machine lifespan

Tip: Verify the machine’s compliance with international standards (e.g., ISO, CE) and inspect real-world performance through factory audits or third-party testing.

2. Overlooking Precision and Tolerance Specifications

Not all sheet metal cutting machines offer the same precision. Some suppliers may exaggerate specifications such as cutting tolerance or speed. Poorly manufactured machines can introduce dimensional inaccuracies, especially when cutting thin or high-strength materials.

Pitfall: Assuming advertised tolerances are accurate without validating them through sample testing.

Solution: Request cutting samples using your target materials and perform metrology checks before finalizing the purchase.

3. Ignoring Intellectual Property (IP) Risks

Many low-cost Cortadoras de Lámina, especially from certain regions, may infringe on patented technologies. Using or importing such equipment could expose your company to:

- Legal actions from original equipment manufacturers (OEMs)

- Seizure of machines at customs

- Reputational damage

Red Flag: Suppliers offering “identical” or “OEM-replica” machines at a fraction of the original price—this often indicates IP violations.

Best Practice: Source from manufacturers with transparent IP ownership or proper licensing. Conduct due diligence, including patent searches and supplier background checks.

4. Inadequate After-Sales Support and Spare Parts Availability

Even high-quality machines will require maintenance and replacement parts. Sourcing from suppliers with poor after-sales support can result in long downtimes.

Pitfall: Not verifying spare parts inventory, technical documentation, or availability of trained service technicians.

Solution: Ensure the supplier provides a comprehensive service package, including manuals, training, and a clear warranty policy.

5. Misunderstanding Power and Safety Compliance

Different regions have varying electrical and safety standards (e.g., NEMA in the U.S., IEC in Europe). A machine built for one market may not comply with regulations in another.

Risk: Non-compliant machines may fail safety inspections or pose hazards to operators.

Prevention: Confirm that the Cortadora de Lámina meets local safety and electrical codes before shipment.

Conclusion

To avoid costly mistakes when sourcing a Cortadora de Lámina, prioritize verified quality, compliance, and IP integrity over initial price. Conduct thorough supplier evaluations, demand performance proof, and ensure legal and technical alignment with your operational needs.

Logistics & Compliance Guide for Cortadora De Lamina

Transporting and operating a Cortadora De Lamina (sheet metal cutting machine) involves careful attention to logistics and regulatory compliance to ensure safety, efficiency, and legal adherence. This guide outlines key considerations for shipping, handling, installation, and compliance for industrial sheet metal cutting equipment.

1. Pre-Shipment Preparation

- Machine Inspection: Conduct a full inspection of the Cortadora De Lamina before shipment. Document any existing damage and ensure all components are securely fastened.

- Disassembly (if required): Remove blades, control panels, or fragile components if recommended by the manufacturer for safe transport.

- Packaging: Use original manufacturer packaging or custom-built crates with shock-absorbing materials. Clearly label with “Fragile,” “This Side Up,” and “Heavy Equipment.”

- Weight & Dimensions: Record and verify machine weight, dimensions, and center of gravity for proper loading and carrier requirements.

2. Domestic & International Shipping

- Carrier Selection: Use freight carriers experienced in handling industrial machinery. Ensure they provide lift-gate service if needed.

- Documentation:

- Commercial Invoice

- Packing List

- Bill of Lading (BOL)

- Certificate of Origin (for international shipments)

- Export Declaration (if applicable)

- Customs Compliance (International):

- Classify the machine under the correct HS Code (e.g., 8462.21 for CNC metal-cutting machines).

- Comply with destination country’s import regulations and tariffs.

- Provide Spanish-English bilingual manuals if required.

- Insurance: Secure full transit insurance covering damage, theft, and delays.

3. Import & Regulatory Compliance

- Electrical Standards: Verify the machine meets local voltage (e.g., 220V/380V), frequency (50/60 Hz), and plug standards. Use transformers or adapters if necessary.

- Safety Certifications:

- Ensure CE marking (EU), UL/CSA (North America), or NOM (Mexico) certification is valid.

- Provide Declaration of Conformity (DoC) for customs clearance.

- EMC & RoHS (Europe): Confirm electromagnetic compatibility and restriction of hazardous substances compliance.

- Local Industrial Regulations: Comply with occupational safety standards (e.g., OSHA in the U.S., NOM-019-STPS in Mexico).

4. Receiving & Handling

- Delivery Site Readiness: Ensure clear access with appropriate flooring strength, door clearance, and overhead space.

- Unloading Equipment: Use forklifts, pallet jacks, or cranes with sufficient load capacity. Follow manufacturer’s handling instructions.

- Inspection at Delivery: Check for shipping damage before signing the delivery receipt. Document and report issues immediately.

5. Installation & Commissioning

- Site Preparation: Level foundation or mounting surface; ensure adequate ventilation and dust extraction.

- Electrical Connection: Install by a certified electrician using proper grounding and circuit protection.

- Calibration & Testing: Perform initial alignment, blade tensioning, and test cuts under supervision.

- Operator Training: Train personnel on safe operation, emergency stops, and maintenance procedures.

6. Ongoing Compliance & Maintenance

- Safety Inspections: Conduct regular checks of guards, emergency systems, and blade condition.

- Maintenance Records: Keep logs of servicing, blade replacements, and repairs.

- Regulatory Updates: Stay informed about changes in local industrial safety and environmental laws.

- Waste Management: Follow proper disposal protocols for metal shavings, lubricants, and worn parts.

7. Documentation & Recordkeeping

Maintain the following records:

– Machine manuals (in local language)

– Certificates of compliance

– Shipping and customs documents

– Maintenance and inspection logs

– Training records for operators

By following this logistics and compliance guide, businesses can ensure the safe, legal, and efficient deployment of a Cortadora De Lamina across regional and international operations.

Conclusion on Sourcing a Cortadora de Lámina (Sheet Metal Cutter):

After evaluating various suppliers, equipment types, and technical specifications, sourcing a cortadora de lámina requires a balanced approach that considers cutting precision, production volume, material compatibility, durability, and total cost of ownership. Whether opting for manual, mechanical, or CNC-controlled models, it is essential to align the machine’s capabilities with the specific needs of the fabrication process. Key factors such as blade quality, cutting capacity, safety features, and after-sales service play a critical role in long-term operational efficiency.

Sourcing from reputable manufacturers—either locally or internationally—can ensure reliability and compliance with industry standards. Additionally, evaluating warranty terms, training availability, and spare parts accessibility will help minimize downtime and maintenance costs. Ultimately, investing in the right cortadora de lámina enhances productivity, improves cut quality, and supports scalable growth in metalworking operations. A well-informed sourcing decision today lays the foundation for improved manufacturing performance tomorrow.