The global demand for durable, cost-effective roofing solutions has driven significant growth in the roofing sealants and tapes market, particularly for products addressing common issues like leaks in corrugated roofing systems. According to Mordor Intelligence, the global roof coating market was valued at USD 10.7 billion in 2023 and is projected to grow at a CAGR of 5.8% through 2029, fueled by rising construction activities and increased focus on building maintenance and energy efficiency. A key segment within this market—corrugated roof stop leak tape—has gained prominence due to its ease of application, weather resistance, and long-term performance in industrial, commercial, and residential buildings. As metal roofing remains a preferred choice in both emerging and developed markets, manufacturers specializing in high-performance adhesive tapes are expanding product innovation and geographic reach. This growing demand has elevated competition among suppliers, making it essential to identify the leading manufacturers delivering proven, data-backed solutions in durability, tensile strength, and waterproofing efficiency. The following analysis highlights the top eight companies shaping this niche through technology, scalability, and market presence.

Top 8 Corrugated Roof Stop Leak Tape Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 GAF Roofing

Domain Est. 1996

Website: gaf.com

Key Highlights: As North America’s largest roofing manufacturer, GAF is an industry leader that produces quality, innovative roofing materials….

#2 Eternabond AlumiBond Roof and Leak Repair Tape

Domain Est. 2002

Website: lakefrontsupply.com

Key Highlights: ETERNABOND is the only MicroSealant in a tape form available that will stop virtually any leak or water proof any surface in minutes. From the manufacturer to ……

#3 High

Domain Est. 2016

Website: astraladhesives.com

Key Highlights: Astral Adhesives offers top bonding solutions, sealants &adhesive products designed for durability and performance in diverse industrial applications….

#4 Henry

Domain Est. 1994

Website: henry.com

Key Highlights: Protect every critical point on the roof and prevent costly failures with premium single-ply systems from Henry. … Prevent leaks, mold, and costly call-backs in ……

#5 Waterproofing Tape

Domain Est. 1995

Website: tha.sika.com

Key Highlights: Sika offers a wide range of self-adhesive waterproofing tapes or multi-purpose waterproofing tapes which is used to cover roof joints, roof leak repair,sealing ……

#6 Koolseal

Domain Est. 1996

Website: koolseal.com

Key Highlights: The leader in cool roofs for more than a century. Repair your roof and seal leaks with these dependent line of Kool Seal products.Missing: corrugated stop…

#7 Roof Repair & Sealing Tape

Domain Est. 2000

Website: thermacote.com

Key Highlights: Experience immediate and durable roof repair with Thermacote’s Roof Repair Tape. Designed for easy application and lasting protection. Seal leaks today!Missing: corrugated stop…

#8 EPDM Coatings

Domain Est. 2003

Website: epdmcoatings.com

Key Highlights: EPDM Coatings provide rubber roof sealants/coatings for roof leaks repair. Cost effective and DIY solution for residential and commercial roofing projects….

Expert Sourcing Insights for Corrugated Roof Stop Leak Tape

H2: 2026 Market Trends for Corrugated Roof Stop Leak Tape

The global market for Corrugated Roof Stop Leak Tape is poised for significant evolution by 2026, driven by a confluence of economic, environmental, technological, and regulatory factors. Key trends shaping the landscape include:

1. Rising Demand from Construction & Infrastructure Sectors:

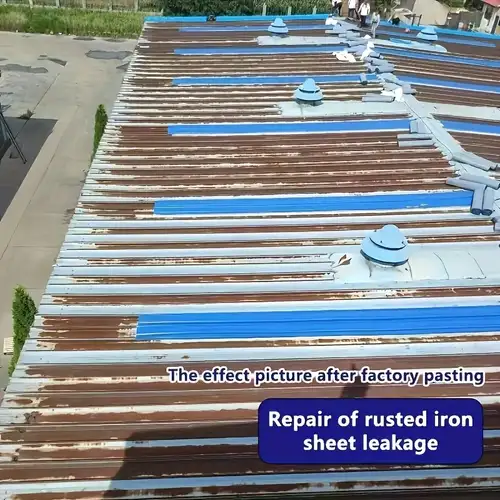

Accelerated urbanization, particularly in emerging economies across Asia-Pacific, Latin America, and Africa, is fueling demand for affordable, durable roofing solutions. Corrugated metal roofs remain popular for industrial, agricultural, and residential buildings due to their cost-effectiveness and ease of installation. This directly boosts the need for effective sealing solutions like stop leak tape to extend roof lifespan and prevent water damage.

2. Emphasis on Preventive Maintenance and Building Longevity:

Building owners and facility managers are increasingly prioritizing preventive maintenance to reduce long-term repair costs and avoid business disruptions. Stop leak tape is gaining recognition as a cost-efficient, non-invasive solution for sealing joints, seams, and fastener penetrations on existing corrugated roofs, aligning with this shift toward proactive upkeep.

3. Growth in Green Building and Energy Efficiency Standards:

Regulations and certifications like LEED, BREEAM, and regional energy codes are promoting building envelope integrity. Effective sealing reduces air leakage and improves thermal performance. High-performance stop leak tapes with enhanced insulation properties and sustainability credentials are becoming more attractive to meet these standards.

4. Advancements in Tape Technology and Materials:

By 2026, expect wider availability of next-generation tapes featuring:

– Improved Adhesion: Stronger bonding to diverse substrates (metal, plastic, aged coatings) even under thermal cycling.

– Enhanced Durability: Greater resistance to UV degradation, temperature extremes, and mechanical stress.

– Eco-Friendly Formulations: Increased use of low-VOC (Volatile Organic Compounds), recyclable, or bio-based materials to meet sustainability goals.

– Easier Application: Tapes with improved handling, conformability, and faster cure times to reduce labor costs.

5. Expansion of E-commerce and Direct-to-Consumer Channels:

Online platforms are making stop leak tape more accessible to DIY homeowners, small contractors, and remote areas. Manufacturers and distributors are investing in digital marketing, detailed product information, and online tutorials, broadening the market reach beyond traditional trade channels.

6. Regional Market Diversification:

While North America and Europe maintain strong demand due to aging infrastructure and high maintenance standards, the fastest growth is expected in the Asia-Pacific region (driven by China, India, and Southeast Asia) and parts of the Middle East and Africa, where rapid construction and climate resilience needs are paramount.

7. Increased Competition and Brand Differentiation:

As the market grows, competition intensifies. Leading brands are differentiating through product innovation, performance guarantees, technical support, and bundling solutions (e.g., tape with primers or sealants). Price sensitivity remains, but performance and reliability are becoming key purchase drivers.

Conclusion:

By 2026, the corrugated roof stop leak tape market will be characterized by higher performance expectations, sustainability demands, and technological innovation. Success will depend on manufacturers’ ability to deliver reliable, eco-conscious solutions that meet evolving building standards and cater to both professional and DIY user segments across diverse global markets.

Common Pitfalls When Sourcing Corrugated Roof Stop Leak Tape (Quality & IP)

Sourcing corrugated roof stop leak tape can be fraught with challenges, especially when balancing cost, performance, and intellectual property (IP) concerns. Avoiding these common pitfalls is crucial to ensure long-term roof integrity and legal compliance.

Poor Adhesive Performance and Substrate Adhesion

Many low-cost tapes fail due to inadequate adhesive formulation. Tapes may use low-tack adhesives or inappropriate polymers that cannot withstand thermal cycling, UV exposure, or moisture. This leads to premature delamination, shrinkage, or complete failure, especially on dusty, oily, or aged roofing substrates. Always verify adhesive specifications for peel strength, shear resistance, and temperature range.

Inadequate UV and Weather Resistance

Not all tapes are created equal when exposed to sunlight. Inferior tapes may degrade rapidly under UV radiation, becoming brittle or losing adhesion within months. Look for tapes with proven UV stabilizers and long-term weathering test data (e.g., ASTM G154 or QUV testing) to avoid short service life and repeated maintenance costs.

Mismatched Tape Profile and Roof Profile

Corrugated roofs come in various profiles (e.g., 7/12, 12/12, trapezoidal). Using a flat or generic tape without proper profile conformity creates gaps and poor sealing. Ensure the tape is specifically designed for corrugated metal roofs and matches the roof’s pitch and rib dimensions for effective water shedding and adhesion.

Lack of Breathability or Vapor Transmission

Some tapes create a complete vapor barrier, trapping moisture underneath and accelerating corrosion of metal roofs. High-quality tapes should allow controlled vapor transmission (breathability) to prevent condensation buildup while still repelling liquid water. Check for MVTR (Moisture Vapor Transmission Rate) specifications.

Misleading or Inaccurate Product Claims

Suppliers may exaggerate performance claims—such as “lifetime warranty” or “extreme temperature resistance”—without independent testing to back them up. Be wary of vague marketing terms. Request third-party test reports and performance certifications (e.g., FM Global, UL, or ISO standards) to validate claims.

IP Infringement and Copycat Products

The market is flooded with counterfeit or cloned tapes that mimic well-known branded products (e.g., resembling tapes like Sika, 3M, or Vulkem). These infringe on patented formulations, designs, or trademarks, exposing buyers to legal risks. Sourcing from unauthorized suppliers or obscure manufacturers may result in IP violations, poor quality, and lack of technical support.

Insufficient Technical Support and Warranty

Low-cost suppliers often lack engineering support or fail to provide clear installation guidelines. Without proper application instructions (surface prep, temperature conditions, overlap requirements), even good-quality tape can fail. Additionally, missing or unenforceable warranties leave buyers without recourse if the product underperforms.

Compromised Material Thickness and Consistency

Thinner tapes may appear cost-effective but offer reduced durability and puncture resistance. Inconsistent coating thickness or scrim reinforcement leads to weak spots. Verify material build (carrier, adhesive thickness, reinforcement layer) against industry benchmarks to ensure reliability.

By recognizing these pitfalls, buyers can make informed decisions, prioritize certified and IP-compliant products, and ensure long-term performance and legal safety in their roofing projects.

Logistics & Compliance Guide for Corrugated Roof Stop Leak Tape

Product Overview

Corrugated Roof Stop Leak Tape is a self-adhesive, weather-resistant sealing tape designed for quick and effective repair of leaks on corrugated metal, fiberglass, and plastic roofing panels. It features a durable backing (typically aluminum or UV-resistant polymer) with a high-strength adhesive layer, enabling long-term protection against water, UV exposure, and temperature fluctuations.

Packaging & Labeling

- Standard Packaging: Supplied in rolls (e.g., 5m, 10m, or 25m lengths) wound on a cardboard core, individually wrapped in polyethylene film.

- Outer Cartons: Packaged in sturdy corrugated cardboard boxes with quantity and product details clearly printed.

- Labeling Requirements:

- Product name and model number

- Net dimensions (length x width)

- Batch/lot number and manufacturing date

- Storage conditions (e.g., “Store in a cool, dry place away from direct sunlight”)

- Safety warnings and handling instructions

- Manufacturer and distributor information

- Compliance marks (e.g., CE, UKCA, if applicable)

Storage Conditions

- Temperature Range: Store between 5°C and 30°C (41°F to 86°F).

- Humidity: Keep in a dry environment; avoid condensation.

- UV Exposure: Protect from direct sunlight and prolonged UV exposure to prevent adhesive degradation.

- Shelf Life: Typically 12–24 months from date of manufacture when stored properly. Check manufacturer’s specification sheet for exact duration.

Transportation Guidelines

- Mode of Transport: Suitable for road, sea, and air freight (non-hazardous classification).

- Handling: Handle with care to avoid crushing or puncturing rolls. Use pallets for bulk shipments to prevent damage.

- Stacking: Limit stack height to 1.5 meters (5 feet) on pallets to avoid compression of lower layers.

- Climate Control: Avoid exposure to extreme temperatures or moisture during transit (e.g., do not leave in unventilated containers or trucks for extended periods).

Regulatory Compliance

- REACH (EU): Complies with Registration, Evaluation, Authorisation and Restriction of Chemicals (EC 1907/2006). No SVHC (Substances of Very High Concern) above threshold limits.

- RoHS (EU): Compliant with Directive 2011/65/EU on restriction of hazardous substances (lead, cadmium, mercury, etc.).

- CE Marking: Required for products sold in the European Economic Area (EEA), indicating conformity with health, safety, and environmental standards.

- UKCA Marking: Required for sale in Great Britain (England, Wales, Scotland) post-Brexit; replaces CE marking where applicable.

- California Prop 65: Product does not contain chemicals known to the State of California to cause cancer or reproductive harm, or includes appropriate warning labels if required.

- TSCA (USA): Complies with the Toxic Substances Control Act; all components are listed or exempt.

Safety & Handling

- PPE Recommendations: Gloves recommended during application; avoid prolonged skin contact.

- Ventilation: Apply in well-ventilated areas, especially in confined spaces.

- Flammability: Non-flammable under normal conditions; keep away from open flames during storage.

- Spill & Disposal: No special procedures for spills. Dispose of waste tape and packaging in accordance with local regulations. Do not incinerate unless in approved facilities.

Import & Export Documentation

- HS Code: 3919.10 (Plastic adhesive tapes, width ≤ 20 cm) – confirm based on material composition and destination.

- Commercial Invoice: Must include product description, quantity, value, country of origin, and Incoterms (e.g., FOB, CIF).

- Packing List: Detailed breakdown of contents per shipment.

- Certificate of Conformity (CoC): May be required for customs clearance in certain markets (e.g., EU, GCC).

- Bill of Lading / Air Waybill: Essential for freight tracking and delivery.

Environmental & Sustainability

- Recyclability: Backing material may be recyclable depending on composition (e.g., aluminum). Adhesive residue may limit recyclability; consult local facilities.

- Eco-Friendly Claims: If applicable, ensure claims (e.g., “low VOC,” “recyclable packaging”) are substantiated and compliant with advertising standards (e.g., FTC Green Guides).

Quality Assurance

- Inspection: Each batch is subject to quality control checks for adhesive strength, dimensional accuracy, and visual defects.

- Documentation: Available upon request: Material Safety Data Sheet (MSDS/SDS), Technical Datasheet, and Test Certificates.

- Traceability: Full batch traceability maintained for 5 years post-manufacture.

Contact Information

For compliance inquiries, safety data, or logistics support, contact:

[Manufacturer/Distributor Name]

Email: [email protected]

Phone: +1 (555) 123-4567

Website: www.company.com/compliance

Conclusion: Sourcing Corrugated Roof Stop Leak Tape

After evaluating various options for sourcing corrugated roof stop leak tape, it is clear that selecting the right product involves balancing quality, durability, cost, and availability. High-performance tapes—such as butyl rubber, aluminum-reinforced, or UV-resistant acrylic tapes—offer long-term sealing solutions for corrugated metal roofs, effectively preventing leaks, resisting weathering, and reducing maintenance needs.

When sourcing, it is essential to consider reputable suppliers or manufacturers that provide proven adhesion, elongation, and weather resistance specifications. Purchasing from established building supply distributors, industrial hardware retailers, or directly from manufacturers ensures authenticity and access to technical support. Additionally, bulk sourcing can offer cost advantages, particularly for large-scale or repeat-use applications.

Ultimately, investing in a high-quality corrugated roof stop leak tape from a reliable source not only enhances roof integrity but also extends service life, delivering both immediate and long-term value. Proper selection and sourcing contribute significantly to effective, low-maintenance roofing solutions in residential, commercial, and industrial settings.