The global copper shot market is experiencing steady growth, driven by rising demand in industrial applications such as plumbing, electrical conductivity, and antimicrobial surface coatings. According to Grand View Research, the global copper market size was valued at approximately USD 169.4 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030, with industrial metals like copper shot benefiting from infrastructure development and renewable energy expansions. As demand for high-purity copper forms increases—especially in HVAC, brazing, and metal fabrication—reliable manufacturers of copper shot are becoming critical supply chain partners. Below is a data-informed overview of the top eight copper shot manufacturers leading innovation, scalability, and quality in this evolving market.

Top 8 Copper Shot Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Jiangsu Shengshi Jiuhao Material Technology Co., LTD

Domain Est. 2015

Website: china-springshot.com

Key Highlights: Copper shot, find quality Copper shot Products,Copper shot Manufacturers, Copper shot Suppliers and Exporters atJiangsu Shengshi Jiuhao Material Technology Co.,…

#2 China Copper Shot Manufacturers, Suppliers, Factory

Domain Est. 2017

Website: renwa-abrasive.com

Key Highlights: As one of the leading copper shot manufacturers and suppliers in China, we warmly welcome you to buy or wholesale copper shot in stock here from our factory ……

#3 Copper Shot, Copper Cut Wire Shot Manufacturer

Domain Est. 2008

Website: jxabrasives.com

Key Highlights: Buy copper shot from JX Abrasives Manufacturer in China, 0.6-3.0 mm copper cut wire shot, 100-200 HV, for polishing, peening of hardware parts….

#4 Copper Shot (Cu Shot)

Domain Est. 2022

Website: attelements.com

Key Highlights: ATT specializes in producing high purity Copper Shot with the highest possible density and smallest possible average grain sizes….

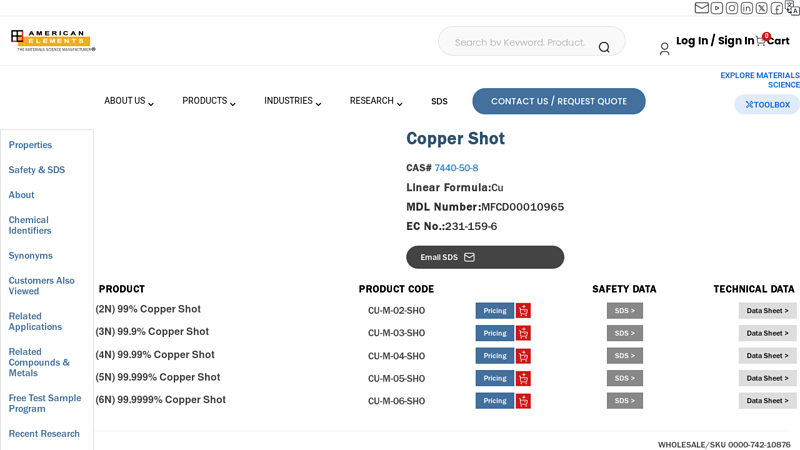

#5 Copper Shot

Domain Est. 1998

Website: americanelements.com

Key Highlights: American Elements specializes in producing high purity Copper Shot with the highest possible density and smallest possible average grain sizes….

#6

Domain Est. 2018

Website: gknpm.com

Key Highlights: Consumer Goods & Electronics. We manufacture high-precision metal components for consumer products, from electronic housings to mechanical parts. Our expertise ……

#7 Boss

Domain Est. 2018

Website: bossshotshells.com

Key Highlights: 12 Gauge Boss Copper. Rated 4.97 out of 5 stars. · Price range: $40.00 through $415.00 ; 20 Gauge 3″ MAG 1 1/8oz. Copper Shotshells. Rated 4.69 out of 5 stars….

#8 Copper Metal Shot, Lab Grade 500G

Domain Est. 2018

Website: congeriem.com

Key Highlights: Copper Metal Shot, Lab Grade 500G ; CAS#: 7440-50-8 ; Chemical Formula: Cu ; Molecular Weight: 63.55….

Expert Sourcing Insights for Copper Shot

H2: Market Trends for Copper Shot in 2026

As we approach 2026, the market for copper shot—a specialized form of copper used primarily in industrial applications such as plumbing, HVAC systems, ammunition, and increasingly in emerging green technologies—is undergoing significant transformation. Driven by shifts in global supply dynamics, technological innovation, and policy changes, several key trends are shaping the copper shot market in the second half of the decade.

-

Rising Demand from Green Energy Infrastructure

Copper shot, due to its high conductivity and malleability, plays a critical role in renewable energy systems. With global investments in solar power, wind energy, and electric vehicle (EV) charging infrastructure accelerating in 2026, demand for copper-based components, including shot for grounding and electrical connections, is on a steady upward trajectory. The push for decarbonization in North America, Europe, and parts of Asia is making copper shot an indispensable material in energy transition projects. -

Supply Constraints and Geopolitical Influences

Copper supply chains remain vulnerable to geopolitical tensions and mining disruptions. Major copper-producing countries such as Chile and Peru are experiencing labor unrest and environmental regulations that affect output. As a result, prices for refined copper, including processed forms like copper shot, have remained volatile in H2 2026. This has prompted manufacturers to seek alternative sourcing strategies, including recycling and nearshoring production. -

Growth in Recycling and Sustainable Sourcing

Amid increasing environmental regulations and corporate sustainability goals, the recycled copper market—including recycled copper shot—is expanding rapidly. In 2026, nearly 40% of copper used in industrial applications in developed markets is estimated to come from recycled sources. Copper shot, often derived from scrap wiring and industrial offcuts, benefits from this trend due to its ease of reprocessing and high recovery value. -

Technological Advancements in Manufacturing

Innovations in metal shot production, such as precision granulation and contamination control, are enhancing the quality and consistency of copper shot. These advancements support high-performance applications in electronics and aerospace, where purity and particle uniformity are critical. Automated sorting and AI-driven quality control systems are becoming standard in leading production facilities. -

Expansion into Emerging Markets

Developing economies in Southeast Asia, Africa, and Latin America are investing heavily in urban infrastructure and electrification. This is creating new demand centers for copper shot, particularly in construction and utility projects. Localized production and distribution hubs are emerging to reduce logistics costs and meet regional needs. -

Competitive Pricing and Market Consolidation

The copper shot market is witnessing consolidation among suppliers, with larger metallurgical firms acquiring niche producers to strengthen vertical integration. This trend is leading to improved economies of scale but also reducing competition, which could affect pricing flexibility for smaller buyers.

Conclusion

By H2 2026, the copper shot market is characterized by strong demand from clean energy and infrastructure sectors, tempered by supply volatility and sustainability pressures. Companies that invest in recycling, supply chain resilience, and high-purity production technologies are best positioned to capitalize on these evolving dynamics. As electrification and industrial modernization continue to accelerate globally, copper shot remains a critical, high-value component in the foundation of the 21st-century economy.

Common Pitfalls Sourcing Copper Shot (Quality, IP)

Sourcing copper shot—a form of small, spherical copper pieces used in applications like ammunition, catalysts, and industrial processes—requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these aspects can lead to performance issues, supply chain disruptions, or legal liabilities.

Quality-Related Pitfalls

1. Inconsistent Purity and Composition

One of the most common quality issues is receiving copper shot that does not meet specified purity standards. Impurities such as lead, iron, or sulfur can compromise performance, especially in sensitive applications like pyrotechnics or electronics. Suppliers may offer “commercial grade” copper without clear certification, leading to batch-to-batch inconsistencies. Always demand certified mill test reports (MTRs) and verify compliance with standards such as ASTM B301 or ISO 1337.

2. Poor Sphericity and Size Distribution

Copper shot is often valued for its spherical shape and uniform size, which affect flow characteristics and packing density. Poor manufacturing processes can result in irregular shapes, surface oxides, or inconsistent diameters. This can lead to clogging in automated equipment or uneven reaction rates. Ensure suppliers provide detailed particle size distribution (PSD) data and conduct incoming inspections using sieving or imaging techniques.

3. Oxidation and Surface Contamination

Exposure to moisture or improper storage can cause surface oxidation, forming copper oxide layers that hinder performance in chemical or electrical applications. Some suppliers may not use protective packaging or controlled environments during storage and transport. Specify requirements for packaging (e.g., vacuum-sealed, desiccant-containing containers) and test for surface cleanliness upon receipt.

4. Lack of Traceability and Certification

Without full traceability—from mine to finished product—there is increased risk of receiving material from unethical or non-compliant sources. This is especially critical in regulated industries. Insist on full supply chain documentation, including country of origin, refining history, and compliance with environmental and labor standards (e.g., RMI, LBMA).

Intellectual Property (IP) Pitfalls

1. Unauthorized Use of Proprietary Manufacturing Processes

Some copper shot is produced using patented atomization or coating techniques. Sourcing from suppliers who use such processes without licensing exposes your company to IP infringement claims, especially if the end product is sold in jurisdictions with strong IP enforcement. Conduct due diligence on the supplier’s process legitimacy and request documentation of IP rights or freedom-to-operate opinions.

2. Reverse Engineering and Trade Secret Risks

When specifying custom copper shot (e.g., alloy composition or surface treatment), there is a risk that suppliers may reverse-engineer or retain knowledge for competitive advantage. This is particularly dangerous if the shot is part of a proprietary product. Use robust non-disclosure agreements (NDAs) and limit technical disclosures to only what is necessary.

3. Inadequate IP Clauses in Contracts

Many procurement agreements fail to clearly define IP ownership, especially regarding process improvements or custom formulations developed during collaboration. Without explicit terms, suppliers may claim rights to innovations, limiting your freedom to source elsewhere. Ensure contracts include clauses assigning IP to your organization or granting exclusive, perpetual licenses.

4. Counterfeit or Grey Market Materials

Unverified suppliers may offer branded or specification-matched copper shot at lower prices, but these may be counterfeit or diverted from other supply chains. These materials often lack proper IP authorization and may not meet quality standards. Source only from authorized distributors or directly from reputable manufacturers, and verify authenticity through batch tracking and certification.

By proactively addressing these quality and IP pitfalls, organizations can ensure reliable performance, regulatory compliance, and legal safety in their copper shot sourcing strategy.

Logistics & Compliance Guide for Copper Shot

Overview and Product Classification

Copper shot refers to small, spherical or granular pieces of copper metal typically used in industrial applications such as shot peening, weighting, radiation shielding, or as raw material in metal fabrication. Due to its metallic composition and potential environmental impact, copper shot is subject to specific logistics and regulatory compliance requirements globally and regionally.

Shipping and Transportation Requirements

Copper shot is generally classified as a non-hazardous material for transport under international shipping regulations (e.g., IMDG Code for sea, IATA DGR for air, and 49 CFR for road/rail in the U.S.), provided it is dry and not contaminated with hazardous substances. However, shippers must ensure proper packaging to prevent spillage, corrosion, or contamination. Use sealed containers or moisture-resistant bags within durable outer packaging. Label packages with contents, weight, and handling instructions (e.g., “Keep Dry,” “Protect from Moisture”).

International Trade and Export Controls

Export of copper shot may be subject to trade regulations depending on destination country and volume. While copper is not typically a controlled strategic material, some countries impose export quotas, tariffs, or reporting requirements. Verify compliance with the Export Administration Regulations (EAR) in the U.S. (typically classified under ECCN 9A991 for unalloyed copper forms) or equivalent regulations in other jurisdictions (e.g., EU Dual-Use Regulation). Obtain necessary export licenses if required by the destination country or international sanctions lists.

Environmental and Safety Compliance

Copper is a heavy metal and can be toxic to aquatic life. Spills or improper disposal may violate environmental regulations such as the U.S. EPA’s Clean Water Act or the EU’s REACH and RoHS directives. Handle copper shot to prevent release into waterways or soil. Provide Safety Data Sheets (SDS) compliant with GHS standards, indicating potential environmental hazards and safe handling procedures. Implement spill containment and cleanup protocols at storage and handling sites.

Storage and Handling Best Practices

Store copper shot in a dry, well-ventilated area away from acids, oxidizers, and moisture to prevent corrosion and hydrogen gas generation. Use non-reactive containers and avoid prolonged skin contact; wear appropriate PPE (gloves, eye protection) during handling. Ensure storage areas comply with local fire and occupational safety codes, particularly if stored in large quantities.

Documentation and Recordkeeping

Maintain accurate shipping manifests, bills of lading, SDS, export documentation, and customs declarations. Record inventory movements and disposal activities to support traceability and regulatory audits. For international shipments, ensure Harmonized System (HS) code accuracy (e.g., 7404.00 for copper waste and scrap, or 7401.10 for copper cathodes and sections—specific classification depends on form and purity).

Regulatory Monitoring and Updates

Stay informed about changes in environmental regulations, trade policies, and transportation safety standards affecting copper products. Subscribe to updates from relevant authorities such as the U.S. Department of Commerce, EPA, OSHA, or ECHA in the EU. Conduct periodic compliance reviews to ensure ongoing adherence to legal and industry requirements.

In conclusion, sourcing copper shot requires careful consideration of several key factors including purity, size specifications, supplier reliability, and compliance with industry standards. Whether for use in ammunition reloading, industrial applications, or specialized manufacturing processes, high-quality copper shot ensures optimal performance and safety. Evaluating suppliers based on reputation, cost-effectiveness, lead times, and sustainability practices further supports a strategic sourcing decision. Ultimately, establishing a consistent and reputable supply chain for copper shot contributes to operational efficiency, product consistency, and long-term cost savings.