The global copper pipe repair clamp market is experiencing steady growth, driven by rising demand across residential, commercial, and industrial plumbing sectors. According to a report by Mordor Intelligence, the global plumbing market—of which pipe repair solutions are a critical component—is projected to grow at a CAGR of over 5.5% from 2023 to 2028. A key factor fueling this expansion is the increasing need for cost-effective, quick-fix solutions to combat pipe leaks, corrosion, and structural failures—especially in aging infrastructure. Copper pipe repair clamps are particularly favored for their durability, ease of installation, and compatibility with widely used copper piping systems. Grand View Research further supports this trend, noting that the global pipe repair clamp market is expected to grow significantly, underpinned by urbanization, infrastructure modernization, and stringent regulatory standards for water conservation and leak prevention. As demand rises, manufacturers are innovating with improved sealing technologies, corrosion-resistant materials, and versatile clamp designs. In this competitive landscape, the following nine companies have emerged as leading manufacturers of copper pipe repair clamps, recognized for product quality, global reach, and technical innovation.

Top 9 Copper Pipe Repair Clamp Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

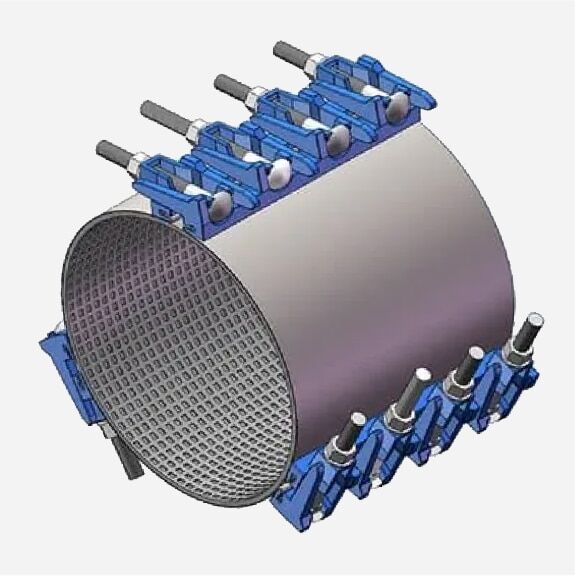

#1 Pipeline Repair Fittings & Couplings Manufacturer

Domain Est. 1998

Website: jcmindustries.com

Key Highlights: JCM repair fitting selection includes a wide variety of product designs whose common core purpose is to return damaged piping systems to their original service ……

#2 REPAIR CLAMPS

Domain Est. 1995

Website: romac.com

Key Highlights: Stainless steel repair clamp with cast iron lugs. Nominal Sizes 1/2 – 2 inches. Working Pressure Up to 150 psi. Pipe Compatibility Steel and copper pipe….

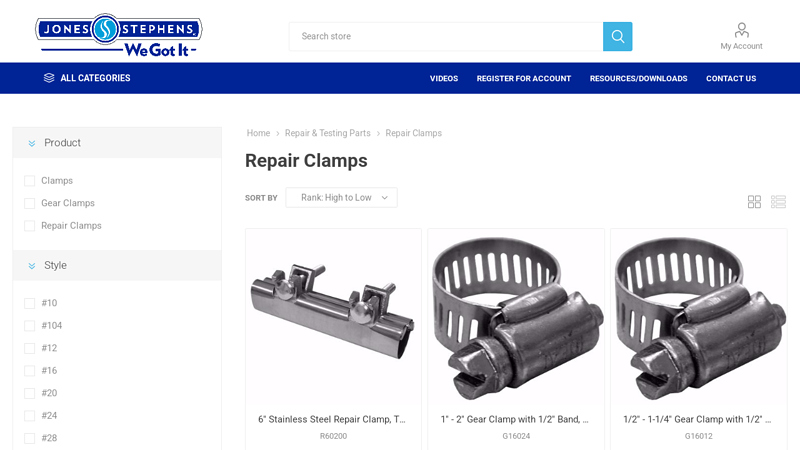

#3 Repair Clamps

Domain Est. 1999

Website: jonesstephens.com

Key Highlights: Repair Clamps ; 6″ Stainless Steel Repair Clamp, Two Bolt, 2″ IPS. R60200 ; 1″ – 2″ Gear Clamp with 1/2″ Band, All Stainless, Box of 100. G16024 ; 1/2″ – 1-1/4″ ……

#4 Smith-Blair 246 Pipe Repair Clamp

Domain Est. 1999

Website: xylem.com

Key Highlights: A repair clamp designed to repair pin holes, punctures or splits in rigid pipe, like Steel, plastic, or Copper tube….

#5 Pipe Repair Clamps Distributor

Domain Est. 1999

Website: bricebarclay.com

Key Highlights: Free delivery over $1,000 30-day returnsBriceBarclay is a premier pipe repair clamps distributor. We offer a wide range of pipeline repair clamps to repair pit holes, splits, and c…

#6 Repair Clamps

Domain Est. 2000

Website: aymcdonald.com

Key Highlights: At AY McDonald Mfg. Co., we carry a full line of repair clamps that live up to industry standards and designed to last….

#7 Pipe Repair

Domain Est. 2000

Website: muellercompany.com

Key Highlights: Mueller Co. has created and offers a complete line of pipe repair products for all types of pipe material including: service saddles, tapping sleeves, and ……

#8 Pipe Repair Clamps

Domain Est. 2005

Website: pipemanproducts.com

Key Highlights: Pipe Repair Clamps are made for every type of pipe on the market from Copper to Steel, PVC, Ductile Iron, Cast Iron and HDPE….

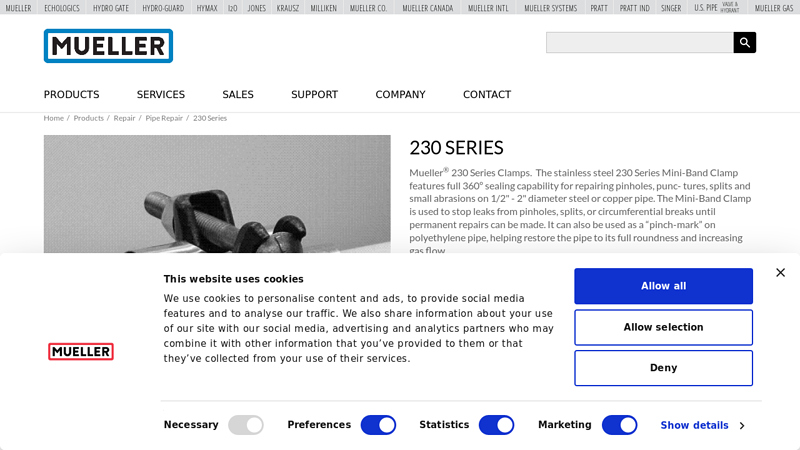

#9 230 Series

Domain Est. 2011

Website: muellergas.com

Key Highlights: The Mini-Band Clamp is used to stop leaks from pinholes, splits, or circumferential breaks until permanent repairs can be made. It can also be used as a “pinch- ……

Expert Sourcing Insights for Copper Pipe Repair Clamp

H2: 2026 Market Trends for Copper Pipe Repair Clamp

As we approach 2026, the global market for copper pipe repair clamps is undergoing significant transformation, shaped by evolving infrastructure demands, technological advancements, and sustainability initiatives. These clamps—used to temporarily or permanently repair leaks and structural weaknesses in copper piping—remain essential across residential, commercial, and industrial plumbing systems. Several key trends are expected to influence market dynamics in 2026:

1. Rising Demand in Residential and Commercial Construction

The ongoing expansion of urban infrastructure, particularly in emerging economies across Asia-Pacific, Latin America, and Africa, is driving demand for reliable plumbing solutions. With increased investments in housing and commercial real estate, copper pipe repair clamps are seeing steady adoption due to their ease of installation and cost-effectiveness compared to full pipe replacement.

2. Growth in Retrofit and Maintenance Projects

Aging water infrastructure in North America and Europe is prompting municipalities and building owners to prioritize repair and maintenance over costly overhauls. Copper pipe repair clamps offer a non-invasive, quick-fix solution ideal for retrofitting older buildings, contributing to market growth. The push for water conservation also reinforces demand, as timely repairs reduce water loss.

3. Advancements in Clamp Materials and Design

Manufacturers are innovating with corrosion-resistant materials such as stainless steel and reinforced polymers to enhance clamp durability and compatibility with various pipe types. In 2026, smart clamps equipped with leak-detection sensors are emerging in high-end applications, enabling predictive maintenance—particularly in industrial and smart building environments.

4. Emphasis on Sustainability and Water Efficiency

Environmental regulations and water scarcity concerns are pushing industries and governments to minimize water waste. Copper pipe repair clamps support sustainability goals by extending the lifespan of existing piping systems, reducing the need for new materials and lowering the carbon footprint associated with full replacements.

5. Competitive Pricing and Market Fragmentation

The market remains highly competitive, with numerous regional and global players offering cost-effective solutions. In 2026, price sensitivity among contractors and DIY consumers is driving demand for affordable, reliable clamps, especially in e-commerce channels. However, premium brands are differentiating through quality certifications and warranty offerings.

6. Regional Market Variations

While North America and Europe remain key markets due to aging infrastructure, the Asia-Pacific region is expected to register the highest growth rate in 2026, fueled by rapid urbanization and public water system upgrades in countries like India and Indonesia. Government initiatives for clean water access are further accelerating adoption.

In conclusion, the copper pipe repair clamp market in 2026 is poised for moderate but steady growth, driven by infrastructure modernization, sustainability imperatives, and product innovation. Companies that focus on durability, ease of use, and integration with smart technologies will likely gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Copper Pipe Repair Clamps (Quality and IP)

When sourcing copper pipe repair clamps, especially for critical plumbing or industrial applications, buyers often encounter challenges related to product quality and intellectual property (IP) concerns. Overlooking these factors can lead to system failures, safety hazards, and legal complications. Below are common pitfalls to avoid:

Poor Material Quality and Durability

One of the most frequent issues is receiving repair clamps made from substandard materials. Low-quality copper or alloy blends may corrode quickly, lack structural integrity, or fail under pressure. Some suppliers use thin-walled clamps or inferior rubber gaskets that degrade prematurely, leading to leaks. Always verify material specifications (e.g., ASTM B75 for copper) and request third-party test reports or certifications to ensure durability and compatibility with existing piping systems.

Inaccurate Sizing and Fit

Copper pipe repair clamps must match the outer diameter of the pipe precisely. Many low-cost suppliers offer poorly manufactured clamps with inconsistent internal diameters, leading to improper seals. This misalignment can cause leaks or make installation difficult. Ensure suppliers provide accurate dimensional data and consider ordering samples before bulk purchases.

Lack of Pressure and Temperature Ratings

Not all repair clamps are rated for the same operating conditions. Some generic or uncertified clamps may not meet required pressure (PSI) or temperature thresholds, especially in hot water or high-pressure systems. Always confirm that the clamp carries appropriate ratings and complies with standards such as ASME A112.19.3 or NSF/ANSI 61 for drinking water applications.

Counterfeit or Non-Compliant Products

Suppliers, particularly in online marketplaces, may offer counterfeit versions of branded repair clamps. These products often mimic logos and packaging but fail to meet original performance standards. This not only compromises safety but can also violate intellectual property rights. Be cautious of unusually low prices and verify authenticity through official distributors or certifications.

Intellectual Property Infringement Risks

Manufacturers sometimes replicate patented clamp designs without authorization, especially in regions with weak IP enforcement. Sourcing such products—knowingly or unknowingly—can expose your business to legal liability, including infringement claims or supply chain disruptions. Conduct due diligence on suppliers, request proof of IP compliance, and avoid vendors offering “compatible” or “equivalent” versions of patented designs without proper licensing.

Insufficient Documentation and Traceability

Reputable suppliers provide detailed product documentation, including material traceability, test results, and compliance certificates. Many low-cost suppliers lack this transparency, making it difficult to verify quality or defend against liability in case of failure. Prioritize vendors who offer full traceability and clear technical support.

Conclusion

Sourcing copper pipe repair clamps requires careful evaluation of both product quality and IP compliance. Avoiding these common pitfalls ensures reliable performance, regulatory compliance, and legal safety. Always work with trusted suppliers, validate certifications, and conduct thorough due diligence before finalizing procurement.

Logistics & Compliance Guide for Copper Pipe Repair Clamp

Product Classification & Regulatory Overview

Copper Pipe Repair Clamps are mechanical fittings used to seal leaks or reinforce damaged sections in copper piping systems. They are commonly used in plumbing, HVAC, and industrial applications. While generally considered mechanical repair components rather than permanent fittings, they must still comply with regional plumbing codes and safety standards. Key regulations include the International Plumbing Code (IPC), Uniform Plumbing Code (UPC), and relevant standards from organizations such as ASTM, ASME, and NSF.

Material Compliance & Certification Requirements

Copper Pipe Repair Clamps must be constructed from materials compatible with potable water and resistant to corrosion. Common materials include brass, copper, and stainless steel components with rubber sealing gaskets. To be compliant in the U.S., clamps used in drinking water systems should meet NSF/ANSI 61 certification for health effects related to drinking water system components. In Canada, compliance with CSA B125.1 is required. Manufacturers should provide certification documentation and traceability of materials used.

Packaging & Labeling Standards

Repair clamps should be packaged to prevent damage during transit and protect against moisture and corrosion. Each package must include clear labeling with:

– Product name and model number

– Size(s) and compatible pipe diameter

– Material specifications

– Compliance markings (e.g., NSF 61, UPC)

– Manufacturer or distributor information

– Date of manufacture or batch number

Bulk shipments should include safety data sheets (SDS) if applicable and comply with OSHA Hazard Communication Standard (HazCom) if lubricants or protective coatings are used.

Shipping & Transportation Logistics

Copper Pipe Repair Clamps are generally non-hazardous and can be shipped via standard freight methods (LTL, FTL, parcel). However, proper packaging must ensure product integrity—use of corrugated boxes, palletization, and stretch wrapping is recommended. For international shipments, compliance with International Maritime Dangerous Goods (IMDG) Code is not typically required unless lubricants or adhesives are included. Ensure adherence to Incoterms® 2020 for clarity on responsibilities between buyer and seller.

Import/Export Compliance

For cross-border trade:

– Classify the product under the correct Harmonized System (HS) Code, typically 7412.20 (copper pipe fittings) or 7307.99 (other tube or pipe fittings, other materials).

– Verify country-specific import regulations (e.g., CE marking for EU, WRAS approval for UK, WaterMark for Australia).

– Prepare commercial invoices, packing lists, and certificates of origin.

– Comply with U.S. Customs and Border Protection (CBP) requirements, including Section 321 entry for low-value shipments.

Storage & Handling Guidelines

Store repair clamps in a dry, climate-controlled environment to prevent oxidation and rubber degradation. Avoid direct exposure to UV light or extreme temperatures. Keep packaging sealed until point of use. Handle with clean gloves to avoid contaminating rubber seals. Implement a first-in, first-out (FIFO) inventory system to minimize aging-related performance issues.

Environmental & Disposal Considerations

Repair clamps are primarily composed of recyclable metals and elastomers. At end-of-life, disassemble components where possible: metal parts can be recycled through standard scrap metal channels, while rubber seals should be disposed of in accordance with local solid waste regulations. No special hazardous waste classifications apply under RCRA or EU WEEE directives.

Quality Assurance & Traceability

Maintain documentation for each production batch, including material certifications, test reports, and inspection records. Implement a quality management system (e.g., ISO 9001) to ensure consistent product performance. Traceability allows for effective recalls or field corrections if compliance issues arise.

Warranty & Customer Support

Provide clear warranty terms indicating coverage period, conditions for use, and limitations. Support customers with installation guidelines and troubleshooting to ensure code-compliant usage. Maintain a record of field performance to support ongoing compliance and product improvement.

In conclusion, sourcing copper pipe repair clamps requires careful consideration of quality, compatibility, durability, and cost-effectiveness. These clamps serve as a reliable and efficient solution for repairing leaks in copper piping systems, offering a quick fix without the need for extensive pipe replacement. When selecting a supplier or product, it is important to prioritize corrosion-resistant materials, proper sizing, and compliance with plumbing standards to ensure long-term performance. Whether for residential, commercial, or industrial applications, investing in high-quality copper pipe repair clamps from reputable suppliers not only enhances the integrity of the plumbing system but also reduces maintenance time and costs. Ultimately, a well-sourced repair clamp contributes to a safer, more reliable, and sustainable plumbing infrastructure.