The global gasket sealants market is experiencing steady expansion, driven by rising demand across automotive, industrial machinery, and manufacturing sectors. According to a 2023 report by Mordor Intelligence, the global gasket sealant market was valued at USD 2.17 billion and is projected to grow at a CAGR of 5.2% from 2024 to 2029. This growth is fueled by the increasing need for high-performance sealing solutions that can withstand extreme temperatures and pressures—particularly in engine applications where reliability is critical. Copper head gasket sealants, known for their superior heat conductivity and durability, have become a preferred choice in high-stress environments such as internal combustion engines. With automotive production rebounding and industrial maintenance standards becoming more stringent, manufacturers are innovating to meet performance and efficiency benchmarks. As competition intensifies, a handful of key players have emerged as leaders in the copper head gasket sealant space, setting industry standards for formulation, application, and reliability.

Top 9 Copper Head Gasket Sealant Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

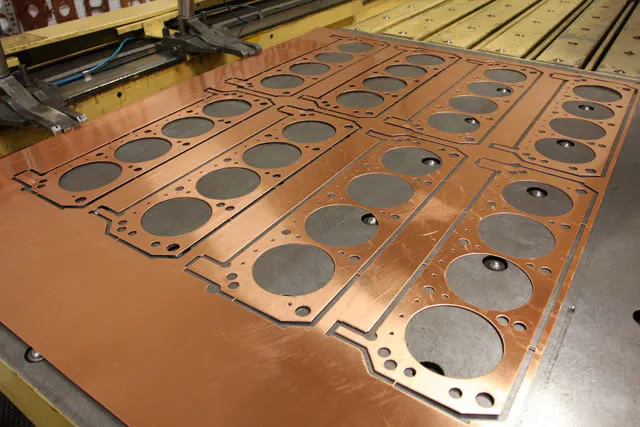

#1 Cometic Gasket

Domain Est. 1996

Website: cometic.com

Key Highlights: Cometic manufactures gaskets and engine sealing solutions for Automotive, Powersport, V-Twin, Marine, and OEM, as well as Remanufactured Engine, Agricultural, ……

#2 Permatex® Copper Spray

Domain Est. 1995

Website: permatex.com

Key Highlights: Permatex Copper Spray-A-Gasket Hi-Temp Sealant is a fast-drying, metallic copper sealant that helps dissipate heat, preventing gasket burnout and improving heat ……

#3 Permatex Copper Spray

Domain Est. 1996

Website: wurthusa.com

Key Highlights: Permatex Copper Spray-A-Gasket Hi-Temp Sealant is a fast-drying, metallic copper sealant that helps dissipate heat, preventing gasket burnout and improving heat ……

#4 Spray copper coat & copper head gaskets

Domain Est. 2002

Website: v8buick.com

Key Highlights: I just got my new copper head gaskets from SCE, when I ordered them they said to coat them with copper coat, and that’s it, ready to go it seals great……

#5 Performance

Domain Est. 2003

Website: gasgacinch.com

Key Highlights: Performance Gasgacinch Gasket Sealer remains flexible and makes it easier to assemble and disassemble the engine or transmission….

#6 Head gasket sealant?

Domain Est. 2003

Website: k20a.org

Key Highlights: They recommend a sealant. I’m thinking maybe Permatex Copper High Temperature Spray-A-Gasket Sealant. Anybody got a better recommendation? Or should I just ……

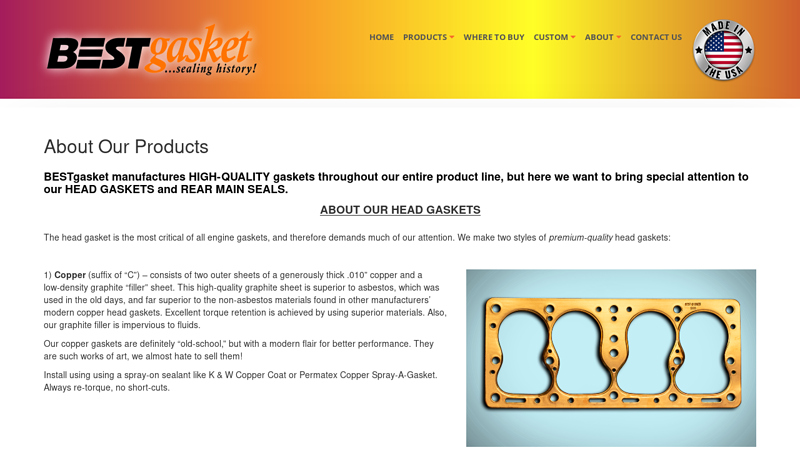

#7 about our head gaskets

Domain Est. 2004

Website: bestgasket.com

Key Highlights: Install GraphTite™ head gaskets using using a spray-on sealant like K & W Copper Coat or Permatex Copper Spray-A-Gasket. Always re-torque, no short-cuts ……

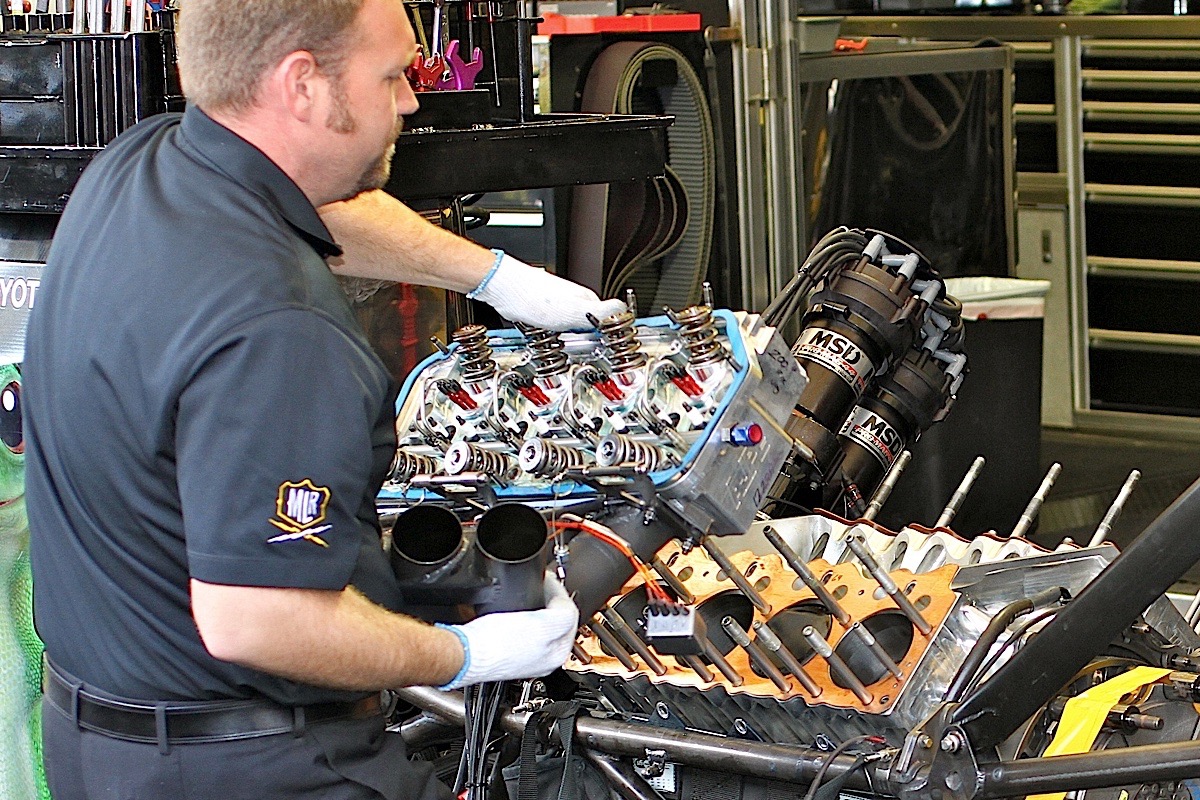

#8 Clark Copper Head Gaskets

Domain Est. 2020

Website: clarkcoppergaskets.com

Key Highlights: More than 40 years of manufacturing and supplying top engine builders and race teams. Others may make copper gaskets but ours are what legends are made from….

#9 Need Info on correctly sealing a copper head gasket with o

Website: toymods.org.au

Key Highlights: I’m after any information on the correct way of installing O-rings and a copper head gasket, i found this site useful for the preparation and installation of ……

Expert Sourcing Insights for Copper Head Gasket Sealant

H2: 2026 Market Trends for Copper Head Gasket Sealant

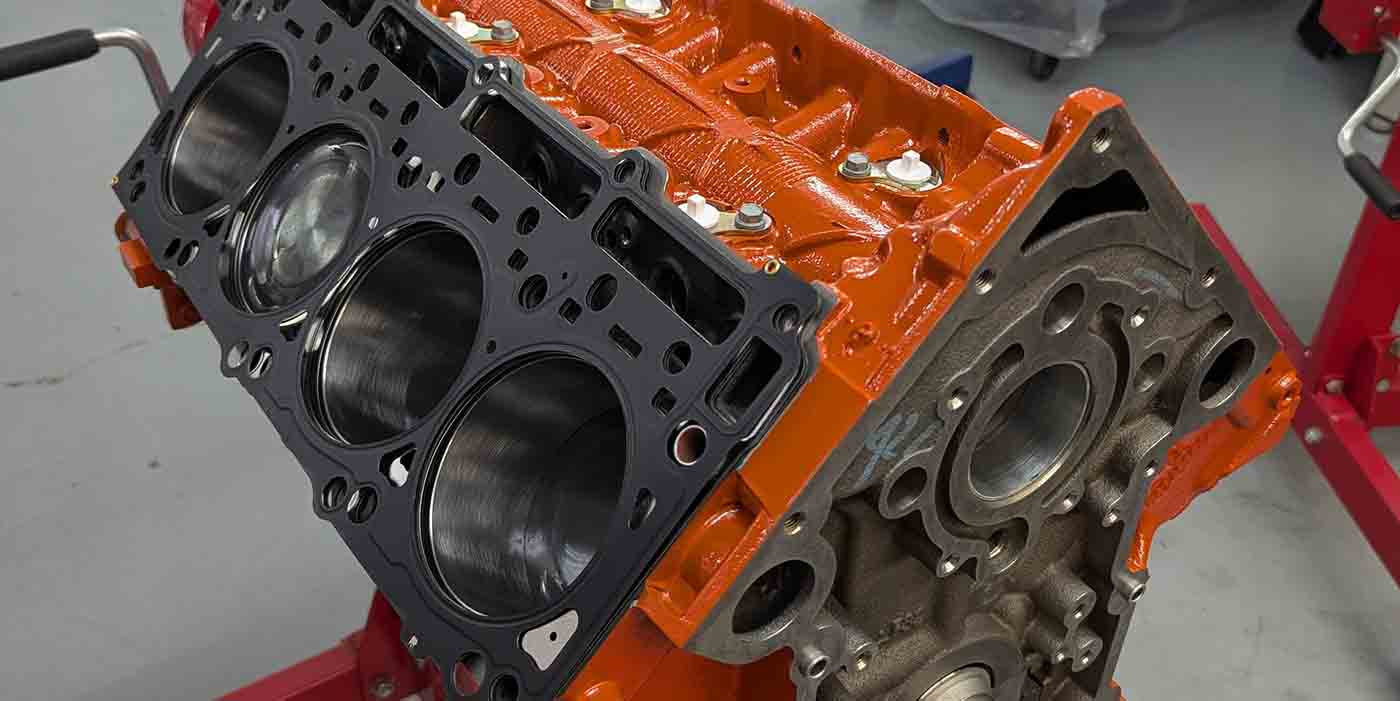

The global market for copper head gasket sealant is poised for steady growth and transformation by 2026, driven by evolving automotive technologies, increasing demand for durable engine repair solutions, and advancements in sealant formulations. Several key trends are expected to shape the industry landscape over the coming years.

1. Rising Demand in Automotive Aftermarket Sector

By 2026, the automotive aftermarket is anticipated to remain a primary growth driver for copper head gasket sealants. As vehicle lifespans extend due to improved manufacturing and maintenance practices, the need for reliable, cost-effective repair solutions like head gasket sealants will continue to rise. Particularly in emerging economies, where vehicle ownership is growing but access to new engines or replacements is limited, copper-based sealants offer an affordable and effective fix for head gasket leaks.

2. Technological Advancements in Sealant Formulations

Manufacturers are investing heavily in R&D to enhance the thermal resistance, durability, and compatibility of copper head gasket sealants. By 2026, next-generation formulations are expected to integrate nano-copper particles and advanced polymers, improving sealing performance under extreme temperature and pressure conditions. These innovations will expand the applicability of sealants beyond conventional internal combustion engines to high-performance and heavy-duty applications.

3. Shift Toward Multi-Material Compatibility

Modern engines increasingly utilize diverse materials such as aluminum, cast iron, and composites. Copper head gasket sealants are being reformulated to ensure compatibility across these materials without causing galvanic corrosion. This trend toward universal compatibility will broaden market appeal and increase adoption across different vehicle types, including passenger cars, commercial vehicles, and off-road machinery.

4. Environmental and Regulatory Pressures

As environmental regulations tighten globally, particularly in regions like the EU and North America, there is growing scrutiny on volatile organic compounds (VOCs) in automotive chemicals. Sealant manufacturers are expected to respond by developing low-VOC or VOC-free copper-based products. This shift will not only ensure regulatory compliance but also appeal to environmentally conscious consumers and service centers.

5. Expansion in Emerging Markets

Asia-Pacific, Latin America, and Africa are expected to witness significant market growth by 2026 due to rising vehicle fleets, underdeveloped recycling infrastructures, and a preference for repair over replacement. Countries like India, Brazil, and Indonesia will see increased demand for copper head gasket sealants as local mechanics and DIY users adopt these products for engine maintenance.

6. E-Commerce and Direct-to-Consumer Sales Growth

The distribution landscape is evolving, with online platforms gaining prominence. By 2026, a growing share of copper head gasket sealant sales is expected to occur through e-commerce channels, driven by convenience, competitive pricing, and detailed product information. Brands that invest in digital marketing and online customer education will hold a competitive edge.

7. Integration with Preventive Maintenance Programs

Fleet operators and industrial users are increasingly adopting preventive maintenance strategies. Copper head gasket sealants are being promoted not only as repair solutions but also as part of proactive engine care. This shift in positioning is expected to open new sales channels and increase per-vehicle consumption.

In conclusion, the 2026 market for copper head gasket sealant will be characterized by innovation, geographic expansion, and adaptation to environmental and technological changes. Companies that prioritize product efficacy, sustainability, and market accessibility will be best positioned to capitalize on these emerging trends.

Common Pitfalls When Sourcing Copper Head Gasket Sealant (Quality & IP)

Sourcing Copper Head Gasket Sealant effectively requires careful attention to both product quality and intellectual property (IP) considerations. Overlooking these areas can lead to performance failures, legal risks, and supply chain disruptions. Below are the key pitfalls to avoid:

Quality-Related Pitfalls

- Assuming Generic Formulations Are Equivalent: Not all copper-based sealants are created equal. Pitfall: Selecting the cheapest option without verifying its specific formulation, curing profile, temperature resistance, and chemical compatibility with engine materials (aluminum, cast iron, specific gasket types). This can result in leaks, premature failure, or damage to sensitive engine components.

- Neglecting Performance Testing & Certification: Pitfall: Failing to demand or verify independent test data (e.g., ASTM standards, OEM specifications like GM 6277M, Ford WSK-M2C152-A2) or certifications. Relying solely on supplier claims without proof increases the risk of receiving substandard product that cannot withstand real-world operating conditions (high pressure, thermal cycling, oil/coolant exposure).

- Overlooking Shelf Life and Storage Requirements: Pitfall: Ignoring the product’s shelf life and specific storage conditions (temperature, humidity). Copper sealants can degrade, thicken, or separate if stored improperly or used beyond their shelf life, drastically reducing effectiveness and sealing integrity.

- Inadequate Supplier Qualification: Pitfall: Sourcing from suppliers without a proven track record in automotive or high-performance sealants, lacking robust quality management systems (e.g., ISO 9001), or failing to conduct on-site audits. This increases the risk of inconsistent batches and unreliable supply.

- Misunderstanding Application Requirements: Pitfall: Choosing a sealant not specifically designed for head gasket applications (e.g., using a general-purpose RTV). Head gaskets face extreme demands; using an inappropriate sealant leads to catastrophic engine failure.

Intellectual Property (IP)-Related Pitfalls

- Unintentional Infringement of Formulation Patents: Pitfall: Sourcing a sealant that replicates a patented chemical formulation (e.g., specific polymer base, curing agent system, or additive package) without a license. This exposes the buyer to significant legal liability, injunctions, and damages, even if the sealant is technically suitable.

- Using Trademarked Product Names Incorrectly: Pitfall: Referring to sourced sealant using a competitor’s well-known trademark (e.g., “like Permatex #1” or “equivalent to OEM X”). This constitutes trademark infringement and can mislead customers, leading to legal action and reputational damage.

- Sourcing Counterfeit or “Knock-off” Products: Pitfall: Acquiring products that falsely bear a brand name or packaging mimicking a protected design. These are illegal, often dangerously low quality, and directly infringe on trademarks and potentially trade dress rights. The buyer shares liability for distributing counterfeit goods.

- Ignoring Licensing Agreements: Pitfall: Failing to verify if a “compatible” or “approved” sealant requires a specific license from the OEM or patent holder for its use in certain applications or with specific gaskets. Using it without authorization breaches IP rights.

- Weak or Absent IP Clauses in Contracts: Pitfall: Supplier contracts lacking clear indemnification clauses for IP infringement, warranties regarding freedom to operate, and specifications defining formulation ownership (especially for custom blends). This leaves the buyer financially exposed if IP disputes arise.

By proactively addressing these quality and IP pitfalls through rigorous supplier vetting, demanding verifiable specifications and test data, respecting intellectual property rights, and using well-drafted contracts, organizations can secure reliable, high-performing Copper Head Gasket Sealant while minimizing legal and operational risks.

H2: Logistics & Compliance Guide for Copper Head Gasket Sealant

1. Product Overview & Classification

- Product Name: Copper Head Gasket Sealant (Typically solvent-based or anaerobic formulations containing copper particles).

- Primary Use: High-temperature, high-pressure sealant for automotive, marine, and industrial engine head gaskets, exhaust manifolds, and other critical flanges.

- Hazard Classification (GHS/CLP): Typically classified due to:

- Flammability: Often Highly Flammable Liquid and Vapour (H225).

- Health Hazards: May cause skin irritation (H315), serious eye irritation (H319), may cause respiratory irritation (H335), may cause drowsiness or dizziness (H336). Specific classification depends on solvent base (e.g., toluene, xylene, acetone).

- Environmental Hazards: Toxic to aquatic life with long-lasting effects (H410) is common.

- UN Number: Usually UN 1133 (PAINT, flammable, or PAINT RELATED MATERIAL, flammable) or UN 1263 (PETROLEUM PRODUCTS, N.O.S. (e.g., Solvents)) – VERIFY with specific SDS.

- Proper Shipping Name (PSN): “FLAMMABLE LIQUID, N.O.S. (Copper Head Gasket Sealant)” or similar – VERIFY with SDS.

- Packing Group: Typically PG II (Medium Danger) or PG III (Low Danger) – VERIFY with SDS.

- Transport Hazard Class: Class 3 (Flammable Liquids).

2. Regulatory Compliance

- Safety Data Sheet (SDS): MANDATORY. Ensure you have the latest, supplier-provided SDS (Section 15: Regulatory Information) for the exact product. This is the primary source for classification, transport info, and handling procedures. Review Sections 2 (Hazards), 4 (First Aid), 7 (Handling), 8 (Exposure Controls), 9 (Physical Properties), 14 (Transport).

- GHS/CLP Compliance: Ensure product labeling (primary container and outer packaging) meets GHS/CLP requirements: Pictograms (Flame, Exclamation Mark, Health Hazard, Environment), Signal Word (Danger/Warning), Hazard Statements (H225, H315, etc.), Precautionary Statements (P210, P233, P305+P351+P338, etc.), Supplier Info.

- Transport Regulations:

- Road (ADR): Comply with ADR regulations. Requires:

- Proper classification, packaging, marking, and labeling (Class 3 diamond label, UN number, PSN).

- Transport Document (Dangerous Goods Note – DGN) specifying UN number, PSN, Class, PG, quantity, and tunnel code (likely C/D/E).

- Appropriate packaging (e.g., UN-certified metal/plastic containers, securely closed, leak-proof, with sufficient absorbent material if in combination packaging). Overpacks often required.

- Driver training (ADR certificate).

- Vehicle marking (orange plates for loads > certain thresholds – check ADR limits).

- Air (IATA DGR): EXTREMELY RESTRICTIVE. Flammable liquids (Class 3) are generally prohibited as cargo on passenger aircraft. Limited quantities might be permitted on cargo aircraft under strict conditions (Packing Instruction 3 for small quantities, limited to 1L per inner pack, 5L per outer pack, specific packaging, quantity limits per package/consignment). Consult IATA DGR and airline regulations BEFORE considering air freight. Often impractical.**

- Sea (IMDG Code): Comply with IMDG Code. Similar requirements to ADR for classification, packaging, marking, labeling, and documentation (Dangerous Goods Declaration). Stowage and segregation rules apply (e.g., keep away from heat, oxidizers). Consider ventilation on container ships.

- Road (ADR): Comply with ADR regulations. Requires:

- REACH/CLP (EU): Ensure registration (if applicable) and full compliance with CLP labeling/notification. Consider SVHC (Substances of Very High Concern) screening if required.

- TSCA (USA): Ensure compliance with Toxic Substances Control Act requirements.

- Local Regulations: Check specific national/state/provincial regulations (e.g., EPA, DOT in USA; Environment Agency in UK; provincial regulations in Canada).

3. Packaging & Handling

- Primary Container: Use original, UN-certified, leak-proof containers (usually metal tubes or plastic bottles) with secure closures. Ensure no damage.

- Secondary Packaging/Overpack:

- Place primary containers in strong, rigid outer packaging (e.g., fiberboard box, wooden crate).

- Use sufficient, non-flammable absorbent material (e.g., vermiculite, specialized absorbent pads) to contain leaks from all primary containers within the package. Critical for preventing fire spread.

- Ensure packaging is strong enough to withstand normal handling (stacking, drops).

- UN Certification: The complete packaging system (primary + secondary + absorbent) often needs to meet UN performance standards (e.g., 4G, 1A2, 1H2). Verify with packaging supplier/SDS.

- Labeling & Marking:

- Outer Packaging: Clearly display:

- Proper Shipping Name (PSN) & UN Number.

- Class 3 Flammable Liquid hazard label (red diamond).

- Orientation arrows (if required).

- Limited Quantity mark (if applicable – e.g., “Y” for ADR/IMDG, “LTD QTY” for IATA).

- Shipper/Consignee information.

- Ensure labels are weather-resistant.

- Outer Packaging: Clearly display:

4. Storage

- Location: Designated, well-ventilated, cool, dry area away from direct sunlight, heat sources, sparks, and open flames. FLAMMABLE LIQUID STORAGE CABINET (FM/UL listed) is HIGHLY RECOMMENDED.

- Segregation: Store away from:

- Oxidizing agents (e.g., peroxides, nitrates – Class 5.1).

- Corrosives (Acids/Bases – Class 8).

- Incompatible materials listed on SDS.

- Containment: Use spill trays or bunds to contain potential leaks.

- Security: Prevent unauthorized access.

- Duration: Follow supplier recommendations; avoid long-term storage.

5. Transportation

- Carrier Selection: Use carriers experienced in handling Class 3 dangerous goods. Provide them with the complete SDS and DGN.

- Loading/Unloading:

- Ensure vehicle is suitable (fire extinguisher, grounding/bonding if required for large quantities).

- Handle packages carefully to prevent damage, puncture, or leakage. No dropping or rolling.

- Secure packages to prevent movement during transit.

- Ground/bond during transfer if large volumes are involved (e.g., drum transfer).

- Documentation: Ensure accurate and complete transport documents (DGN, DGD) are with the driver/consignment.

- Emergency Information: Provide the carrier with emergency contact details and the SDS.

6. Emergency Procedures

- Spill:

- Eliminate ignition sources (NO SMOKING, NO SPARKS).

- Ventilate area.

- Contain spill with inert absorbent (sand, vermiculite, specialized pads). DO NOT USE SAWDUST (flammable).

- Collect contaminated material in a suitable, labeled, UN-approved container for hazardous waste disposal.

- Decontaminate area.

- Report significant spills to authorities as required.

- Fire:

- Evacuate area. Alert emergency services (specify flammable liquid fire).

- Use dry chemical, CO2, or foam extinguishers. Water may be ineffective and spread the fire.

- Cool exposed containers with water spray from a safe distance.

- First Aid: Refer to SDS Section 4. Have eyewash station and safety shower readily accessible in handling/storage areas.

- Emergency Contacts: Display local emergency numbers and supplier emergency contact (from SDS Section 1).

7. Key Considerations & Best Practices

- SDS is King: Always consult the specific SDS for the product you are handling. Classification and requirements can vary significantly between formulations.

- Quantity Matters: Regulations (especially air transport and vehicle marking) have thresholds based on total quantity. Know your shipment size.

- Training: Ensure all personnel involved in handling, storage, and transport are adequately trained in hazards, procedures, and emergency response.

- Waste Disposal: Dispose of used containers, absorbents, and spill material as hazardous waste according to local regulations. Never pour down drains.

- Record Keeping: Maintain records of SDS, training, shipments (DGN/DGD), and disposal.

- Consult Experts: When in doubt, consult with your supplier, a dangerous goods safety advisor (DGSA), or regulatory specialists.

Disclaimer: This guide provides general information. Regulations are complex and subject to change. Always obtain and follow the specific Safety Data Sheet (SDS) for your product and consult with qualified regulatory experts or dangerous goods consultants for definitive compliance requirements.

In conclusion, sourcing a reliable copper head gasket sealant is critical for ensuring engine integrity, preventing leaks, and maintaining optimal performance under high-temperature and high-pressure conditions. When selecting a copper-based sealant, it is essential to prioritize high-quality, temperature-resistant products from reputable manufacturers. Factors such as chemical compatibility, ease of application, curing time, and adherence to industry standards should be carefully evaluated. Sourcing from trusted suppliers with verifiable product specifications and technical support helps mitigate the risk of engine failure and costly repairs. Ultimately, investing in a premium copper head gasket sealant not only enhances durability and reliability but also contributes to the longevity and efficiency of the engine system.