The global cooker hood market is experiencing robust growth, driven by rising demand for energy-efficient kitchen appliances and increasing awareness of indoor air quality. According to a 2023 report by Mordor Intelligence, the global kitchen hood market was valued at USD 6.8 billion and is projected to grow at a CAGR of 5.2% from 2023 to 2028. This expansion is further supported by Grand View Research, which attributes market growth to the surge in residential and commercial construction, particularly in emerging economies, alongside the growing popularity of modular kitchens and smart ventilation systems. With copper emerging as a preferred material due to its superior heat conductivity, antimicrobial properties, and aesthetic appeal, demand for copper cooker hoods is gaining momentum. As manufacturers focus on combining performance with design innovation, a select group of industry leaders has risen to the forefront. Here are the top six copper cooker hood manufacturers shaping the future of premium kitchen ventilation.

Top 6 Copper Cooker Hood Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

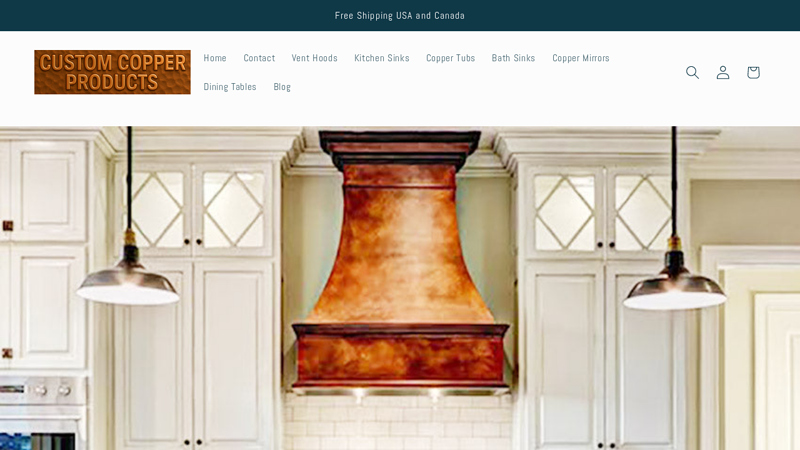

#1 Kitchen Hoods

Domain Est. 2023

Website: customcopperhoodsinc.com

Key Highlights: Custom Copper Hoods, Inc. specializes in custom kitchen hoods in Illinois. Let us create the perfect vent hood to fit your style and needs!…

#2 Custom Range Hoods, Metal Kitchen Hoods

Domain Est. 1996

Website: rangecraft.com

Key Highlights: We build the highest quality custom kitchen range hoods in the world! Materials: copper, steel, brass & more! Made in U.S.A…..

#3 CopperHoods: Custom Metal Range Hoods

Domain Est. 2004

Website: copperhoods.com

Key Highlights: Family-crafted custom copper range hoods that transform your kitchen into a work of art. Blending Midwestern charm, unmatched craftsmanship, and speedy ……

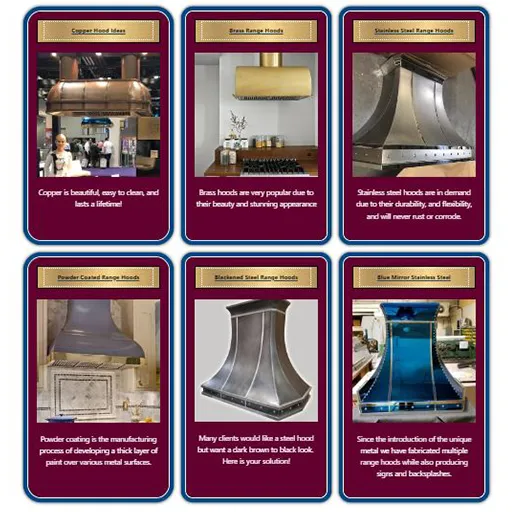

#4 Custom Range Hoods & Metal Kitchen Products

Domain Est. 2013

Website: worldcoppersmith.com

Key Highlights: Transform your kitchen with a handcrafted range hood from CopperSmith®, available in copper, brass, stainless steel, or powder-coated finishes. Our hoods ……

#5 Kitchen Extractor Hood

Domain Est. 2013

Website: mycustomcopper.com

Key Highlights: We developed along the years a massive range of copper cooker hood designs with limited guarantee on ventilation equipment. Buying direct from ……

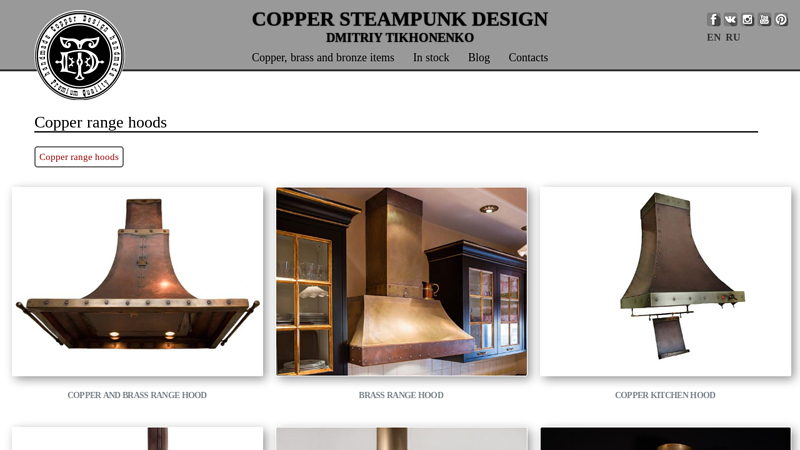

#6 Copper range hoods

Domain Est. 2017

Website: copper-steampunk-design.com

Key Highlights: Copper and brass range hoods made by our designers and artisans is an important functional element of your kitchen….

Expert Sourcing Insights for Copper Cooker Hood

H2: 2026 Market Trends for Copper Cooker Hoods

The global market for copper cooker hoods is poised for notable transformation by 2026, driven by shifting consumer preferences, advancements in kitchen appliance technology, and growing emphasis on sustainable and aesthetically pleasing home design. Copper, long valued for its antimicrobial properties, durability, and luxurious appearance, is increasingly being integrated into premium kitchen ventilation systems. The following key trends are expected to shape the copper cooker hood market in 2026:

1. Rising Demand for Premium and Custom Kitchen Appliances

Homeowners, particularly in high-income markets such as North America, Western Europe, and parts of Asia-Pacific, are increasingly investing in luxury kitchen renovations. Copper cooker hoods are gaining traction as statement pieces that combine functionality with high-end design. Customization options—such as hand-finished copper surfaces, artisanal detailing, and integration with smart home systems—are expected to drive demand among affluent consumers.

2. Sustainability and Health-Conscious Consumerism

Copper’s naturally antimicrobial properties make it an appealing material for kitchen environments where hygiene is paramount. As consumers become more health-conscious, especially post-pandemic, copper’s ability to inhibit bacterial growth on surfaces adds functional value beyond aesthetics. This health-driven appeal is likely to boost adoption in both residential and commercial kitchens.

3. Integration with Smart Kitchen Ecosystems

By 2026, copper cooker hoods are expected to increasingly incorporate smart technology, such as motion sensors, voice control, automatic airflow adjustment based on cooking intensity, and integration with IoT-enabled kitchen appliances. While the copper exterior maintains a classic, elegant look, internal components are becoming smarter and more energy-efficient, balancing tradition with innovation.

4. Growth in Emerging Markets

While currently dominant in developed regions, the copper cooker hood market is projected to expand in emerging economies—including China, India, and the GCC countries—due to rising disposable incomes, urbanization, and the popularity of Western-style kitchens. Local manufacturers may begin offering more affordable copper-finished or copper-clad models to cater to this demand.

5. Challenges in Material Sourcing and Cost

Despite its appeal, the high cost of raw copper and fluctuations in commodity prices could constrain market growth. Manufacturers may respond by using copper plating or veneers over more affordable base materials (e.g., stainless steel), offering the visual benefits of copper at a lower price point. Recycling and sustainable sourcing practices are expected to gain importance to address environmental concerns.

6. Influence of Interior Design Trends

Interior design movements such as industrial, rustic luxury, and artisanal craftsmanship continue to favor raw, warm metallic finishes. Copper cooker hoods align well with these aesthetics, making them a popular choice in open-plan kitchens and loft-style homes. Designers are likely to promote copper as a timeless alternative to stainless steel and matte black finishes.

Conclusion

By 2026, the copper cooker hood market will be shaped by a convergence of luxury, health, and technology. While challenges related to cost and material availability persist, ongoing innovation and evolving consumer tastes are expected to sustain growth, particularly in premium segments. As smart functionality and sustainable materials become standard expectations, copper’s unique blend of beauty and practicality positions it as a material of choice for high-end kitchen ventilation solutions.

Common Pitfalls When Sourcing Copper Cooker Hoods (Quality & IP)

Sourcing copper cooker hoods can be challenging due to the premium nature of the material and the complexity of manufacturing. Buyers must be vigilant to avoid compromising on quality or inadvertently infringing on intellectual property. Below are key pitfalls to watch for:

Poor Material Quality and Thickness

One of the most frequent issues is receiving hoods made from substandard copper. Some suppliers may use copper that is too thin (e.g., less than 0.6mm), leading to warping, denting, or poor heat resistance over time. Others may use copper alloys with low copper content or apply only a thin copper veneer over a cheaper substrate like steel or aluminum. This undermines both aesthetics and durability.

Tip: Always request material certifications and verify copper thickness. Conduct spot inspections or third-party testing if sourcing in large volumes.

Inadequate Surface Finishing and Protection

Copper naturally oxidizes, developing a patina. While this is desirable in some design contexts, uncontrolled oxidation can lead to unsightly stains or uneven coloration. Poorly finished hoods may lack protective coatings (e.g., lacquer or wax), leading to rapid tarnishing and maintenance issues.

Tip: Clarify the finishing process—whether polished, brushed, or sealed—and ensure the protective treatment is durable and food-safe.

Misrepresentation of “Handmade” or “Artisan” Claims

Many copper hoods are marketed as handmade or artisan-crafted to justify higher prices. However, some suppliers outsource mass-produced units and falsely label them as custom or hand-formed. This affects both craftsmanship quality and authenticity.

Tip: Request factory audits, production videos, or visit the workshop to verify craftsmanship claims firsthand.

Intellectual Property (IP) Infringement Risks

Copper cooker hood designs—especially ornate, custom, or branded models—may be protected by design patents, trademarks, or copyrights. Sourcing counterfeit or look-alike products from unauthorized manufacturers can expose buyers to legal liability, customs seizures, or reputational damage.

Tip: Verify design ownership. If sourcing a design resembling a well-known brand, ensure the supplier has proper licensing or that the design is in the public domain.

Lack of Compliance with Safety and Ventilation Standards

Even with beautiful copper exteriors, hoods must meet ventilation performance and electrical safety standards (e.g., UL, CE, or local building codes). Some suppliers focus on aesthetics while neglecting internal components like motors, filters, or ducting, resulting in poor functionality or non-compliance.

Tip: Require test reports for airflow (CFM), noise levels, and electrical safety. Ensure the entire assembly—not just the copper shell—meets required certifications.

Hidden Costs and Supply Chain Delays

Copper is a volatile commodity, and lead times for handcrafted hoods can be lengthy. Suppliers may offer low initial quotes but later impose price increases due to copper market fluctuations or extended production timelines.

Tip: Lock in pricing in contracts, clarify lead times, and include penalties for delays. Factor in import duties and logistics when comparing quotes.

Avoiding these pitfalls requires due diligence, clear specifications, and strong supplier vetting. Investing time upfront ensures a high-quality, compliant, and legally sound product.

Logistics & Compliance Guide for Copper Cooker Hood

This guide outlines the key logistics and compliance considerations for the import, distribution, and sale of Copper Cooker Hoods. Adherence to these requirements ensures regulatory compliance, smooth supply chain operations, and consumer safety.

Product Classification and Tariff Codes

Identify the correct Harmonized System (HS) code for the Copper Cooker Hood to determine applicable import duties, taxes, and regulatory controls. Typical classifications may fall under:

– HS Code 7323.93 (Stainless steel kitchenware) – may apply if primarily steel with copper finish.

– HS Code 8516.60 (Electric cooking hoods) – most common for powered cooker hoods.

– HS Code 7418.20 (Copper kitchenware) – if predominantly copper material.

Consult local customs authorities or a licensed customs broker for accurate classification based on product specifications.

Import Regulations and Documentation

Ensure all required documentation is prepared prior to shipment:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Product Compliance Certificates (e.g., CE, UKCA, ETL, RoHS)

– Test Reports (EMC, electrical safety, material composition)

– Import License (if required by destination country)

Verify import restrictions or prohibitions related to copper content, electrical safety standards, or energy efficiency requirements in the target market.

Electrical and Safety Compliance

Copper Cooker Hoods with electrical components (fan, lighting) must meet regional safety standards:

– European Union: CE marking per Low Voltage Directive (LVD 2014/35/EU), EMC Directive (2014/30/EU), and RoHS (2011/65/EU).

– United Kingdom: UKCA marking with compliance to UK LVD, EMC, and RoHS regulations.

– United States: ETL or UL listing under UL 507 (Standard for Electric Fans) and UL 867 (Electrostatic Air Cleaners, if applicable).

– Canada: CSA or cETL certification under CSA C22.2 No. 113 (Household Cooking Appliances).

Ensure all electrical components are rated for the destination market’s voltage and frequency (e.g., 120V/60Hz for North America, 230V/50Hz for EU).

Energy Efficiency and Environmental Standards

Comply with energy labeling and efficiency regulations:

– EU Energy Label: Subject to EU Energy Labelling Regulation (EU) 2017/1369; cooker hoods require an energy efficiency class (A to G), airflow, sound power level, and grease filtration efficiency.

– US ENERGY STAR: While not currently mandatory, ENERGY STAR-qualified models may have market advantages.

– EPA Volatile Organic Compounds (VOC) Regulations: Ensure finishes and coatings comply with low-VOC requirements, especially in California (e.g., CARB Phase 2).

Material and Environmental Compliance

Verify compliance with environmental and chemical regulations:

– REACH (EU): Registration, Evaluation, Authorisation and Restriction of Chemicals—ensure no restricted substances in copper alloys or coatings.

– RoHS (EU/UK): Restriction of Hazardous Substances—limit lead, cadmium, mercury, and other hazardous materials.

– Copper Sourcing: Confirm responsible sourcing practices; adherence to OECD Due Diligence Guidance may be required.

Packaging and Labeling Requirements

Packaging must meet regulatory and sustainability standards:

– Include bilingual or multilingual labels (as required).

– Display compliance marks (CE, UKCA, ETL, etc.), model number, voltage, wattage, and manufacturer/importer details.

– Include user manuals with safety instructions, installation guidelines, and maintenance procedures in the local language.

– Use recyclable materials and comply with packaging waste directives (e.g., EU Packaging Waste Directive 94/62/EC).

Transportation and Handling

Plan logistics with care for fragile and heavy items:

– Use sturdy, protective packaging to prevent damage to copper finishes and internal components.

– Label packages as “Fragile” and “This Side Up”.

– Ensure stackability and compatibility with standard pallet sizes (e.g., EUR/EPAL pallets in Europe, 48”x40” in the US).

– Choose carriers experienced in handling high-value kitchen appliances.

Customs Clearance and Duties

Prepare for customs valuation and duty assessment:

– Duties vary by country and HS code (e.g., 3–8% in the EU, potentially higher in other regions).

– Factor in VAT/GST, which is typically applied to the landed cost (product value + insurance + freight + duties).

– Utilize preferential trade agreements (e.g., UK-EU Trade and Cooperation Agreement) if applicable.

Post-Import Compliance and Market Surveillance

After import, maintain compliance through:

– Recordkeeping of test reports, certifications, and declarations of conformity for at least 10 years (EU/UK).

– Monitoring for product recalls or non-compliance notifications via RAPEX (EU) or equivalent systems.

– Providing technical support and warranty service per local consumer protection laws.

Conclusion

Successfully managing the logistics and compliance of Copper Cooker Hoods requires proactive planning, accurate documentation, and adherence to regional regulations. Partnering with experienced freight forwarders, compliance consultants, and certification bodies will ensure a smooth market entry and ongoing legal operation.

In conclusion, sourcing a copper cooker hood requires careful consideration of several key factors, including material authenticity, design compatibility, durability, and maintenance requirements. Copper offers a unique blend of aesthetic appeal and natural antimicrobial properties, making it an excellent choice for high-end kitchen environments. When sourcing, it is essential to verify the quality of the copper—opting for solid or high-grade copper finishes—and to partner with reputable suppliers or manufacturers to ensure craftsmanship and longevity. Additionally, considering customization options, pricing, lead times, and after-sales support will help in making a well-informed decision. Ultimately, a responsibly sourced copper cooker hood not only enhances the visual impact of a kitchen but also represents a sustainable and timeless investment in home design.