The global metal roofing market is experiencing robust growth, driven by rising demand for durable, energy-efficient, and aesthetically versatile roofing solutions. According to Grand View Research, the market was valued at USD 29.8 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 6.7% from 2024 to 2030. A key trend fueling this expansion is the increasing preference for architectural metal roofing with premium finishes, including copper-colored coatings that mimic the elegance of natural copper without the high cost or maintenance. These finishes offer enhanced corrosion resistance, reflectivity, and long-term color retention, making them a favored choice for both residential and commercial applications. As sustainability and curb appeal become decisive factors in construction decisions, manufacturers specializing in copper-hued metal roofing are gaining prominence. Based on market reach, product innovation, and coating technology, the following eight manufacturers stand out as leaders in delivering high-performance copper-colored metal roofing systems worldwide.

Top 8 Copper Colored Metal Roofing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Berridge Manufacturing Co.

Domain Est. 1996

Website: berridge.com

Key Highlights: For over 50 years Berridge has worked to set the standard by designing, developing and manufacturing superior architectural metal products and technology….

#2 MetalMax

Domain Est. 1998

Website: metalmax.com

Key Highlights: MetalMax is a leading manufacturer of high-quality metal roofing and siding with locations in Tennessee, Texas, New Hampshire, Georgia, Florida, and Oregon….

#3 Tri County Metals, Florida

Domain Est. 2003

Website: tricountymetals.com

Key Highlights: As a privately owned metal roofing manufacturer, we produce seven different metal roof panel profiles, complete custom trim solutions, specialty trim, and a ……

#4 Copper Metal Roofing & Siding

Domain Est. 2007

Website: copperroofingsupply.com

Key Highlights: We manufacturer copper siding and roofing panels. Whether you’re designing a timeless architectural masterpiece or enhancing your home’s curb appeal….

#5

Website: metalsales.us.com

Key Highlights: Metal Sales is the nation’s largest manufacturer of metal roofing, wall, and building systems. We are the most awarded and highly recognized provider of metal ……

#6 Architectural

Domain Est. 1995

Website: reverecopper.com

Key Highlights: Revere’s iconic bare/bright Classic Copper is firmly established as the premier roofing and wall cladding product, complemented by aesthetic options for every ……

#7 Copper Metal Coil and Sheet Metal

Domain Est. 2014

Website: metalalliance.com

Key Highlights: Copper coil and flat sheet from Metal Alliance is skillfully made in the USA with superior flatness and surface quality for peak performance….

#8 12 Standard Copper Colors For Metal Roofing & Wall Panels

Domain Est. 2015

Website: westernstatesmetalroofing.com

Key Highlights: Copper colored metal is designed to mimic the look of an old copper roof. These faux copper colors come in a variety of aged copper finishes that look authentic ……

Expert Sourcing Insights for Copper Colored Metal Roofing

2026 Market Trends for Copper Colored Metal Roofing

The global construction and architectural design sectors are undergoing a transformation driven by sustainability demands, technological advancements, and evolving aesthetic preferences. Within this context, copper colored metal roofing is emerging as a high-growth segment in the roofing industry. As we approach 2026, several key trends are shaping the market for copper colored metal roofing, reflecting shifts in material science, consumer behavior, and regulatory frameworks.

Rising Demand for Aesthetic and Durable Roofing Solutions

Homeowners and commercial developers are increasingly prioritizing roofing materials that combine visual appeal with long-term durability. Copper colored metal roofing offers the luxurious, warm appearance of natural copper without the high cost and maintenance. Advances in coating technologies—such as Kynar 500® and polyvinylidene fluoride (PVDF)—have enabled steel and aluminum substrates to mimic the rich patina of real copper while resisting fading, chalking, and corrosion. By 2026, demand for these aesthetically enhanced metal roofing products is expected to grow significantly, particularly in residential renovations and high-end architectural projects.

Sustainability and Energy Efficiency Driving Adoption

Environmental concerns are reshaping building material choices. Copper colored metal roofing supports green building initiatives due to its recyclability, energy-reflective properties, and long lifespan (often exceeding 50 years). In 2026, stricter energy codes and incentives for energy-efficient construction—such as those under LEED and ENERGY STAR certifications—are expected to boost adoption. Additionally, cool metal roofing variants with solar reflectance technology will gain traction, helping reduce urban heat island effects and lower cooling costs, especially in warmer climates.

Growth in Residential and Light Commercial Sectors

While historically used in institutional and luxury residential buildings, copper colored metal roofing is becoming more accessible to mid-range homeowners. Manufacturers are expanding product lines with cost-effective alternatives like stone-coated steel and pre-patinated finishes, making the copper aesthetic more attainable. The trend toward modern farmhouse, rustic, and urban industrial architectural styles—popular in North America and Europe—will further drive residential demand. By 2026, the residential segment is projected to dominate the market, supported by increasing home renovation activity and new construction in suburban and rural areas.

Regional Market Expansion and Supply Chain Innovations

North America and Western Europe remain key markets, but growth is accelerating in Asia-Pacific and Latin America, where urbanization and infrastructure development are rising. Localized manufacturing and improved supply chain logistics are enabling faster delivery and reduced costs for copper colored roofing products. In addition, digital tools such as augmented reality (AR) visualization platforms are helping architects and homeowners preview roofing designs before installation, enhancing customer confidence and driving sales.

Technological Integration and Smart Roofing Trends

By 2026, integration with smart home systems and solar-ready roofing designs will become more common. Copper colored metal roofs are being engineered to accommodate photovoltaic panels seamlessly, with color-matching solar shingles and mounting systems. This convergence of aesthetics and functionality positions copper colored metal roofing as a preferred choice for eco-conscious consumers seeking sustainable, high-performance homes.

Conclusion

The 2026 market for copper colored metal roofing is poised for robust growth, fueled by aesthetic appeal, sustainability, and technological innovation. As consumer preferences shift toward durable, energy-efficient, and visually distinctive building materials, manufacturers and contractors who embrace these trends will be well-positioned to capture market share. With continued advancements in coatings, design flexibility, and integration with renewable energy systems, copper colored metal roofing is set to become a standard in modern, resilient construction.

Common Pitfalls When Sourcing Copper-Colored Metal Roofing: Quality and Intellectual Property Concerns

Logistics & Compliance Guide for Copper Colored Metal Roofing

Product Overview and Specifications

Copper colored metal roofing is a pre-finished steel or aluminum product coated with a specialized paint system designed to replicate the aesthetic of natural copper. These panels typically feature a durable polymer coating such as PVDF (polyvinylidene fluoride) or SMP (silicone-modified polyester) to ensure long-term color stability, corrosion resistance, and weatherability. Key specifications include panel profile (e.g., standing seam, corrugated, tile), thickness (gauge), coating type, and ASTM standards compliance (e.g., ASTM A792 for steel, ASTM B209 for aluminum).

Regulatory and Building Code Compliance

All copper colored metal roofing products must comply with local, state, and national building codes. Key standards include:

– International Building Code (IBC) and International Residential Code (IRC): Ensure structural, wind uplift, and fire resistance requirements are met.

– FM Approvals and UL Class A Fire Rating: Required for roofing materials in many commercial and high-risk fire zones.

– ASTM Standards: Verify material quality and performance (e.g., ASTM D7449 for coating adhesion, ASTM G154 for UV resistance).

– Energy Efficiency: Products may need to meet Energy Star or Cool Roof Rating Council (CRRC) requirements for solar reflectance and thermal emittance.

Always confirm project-specific requirements with local authorities having jurisdiction (AHJ).

Environmental and Sustainability Compliance

Copper colored metal roofing should meet environmental regulations and sustainability benchmarks:

– VOC Emissions: Comply with EPA and SCAQMD regulations for low volatile organic compound (VOC) coatings.

– Recyclability: Most metal roofing is 100% recyclable; provide documentation on recycled content (e.g., under LEED v4 credits).

– RoHS and REACH Compliance: Ensure coating materials are free from restricted hazardous substances, especially for export or public projects.

Shipping and Handling Logistics

- Packaging: Panels are typically bundled with protective film, edge protectors, and moisture-resistant wrapping. Use wooden skids or steel straps to secure loads.

- Transportation: Use flatbed trucks with adequate tie-downs. Avoid sharp impacts and exposure to moisture during transit.

- On-Site Storage: Store panels horizontally on level, raised surfaces to prevent warping or water accumulation. Keep protective film intact until installation to avoid scratches or staining.

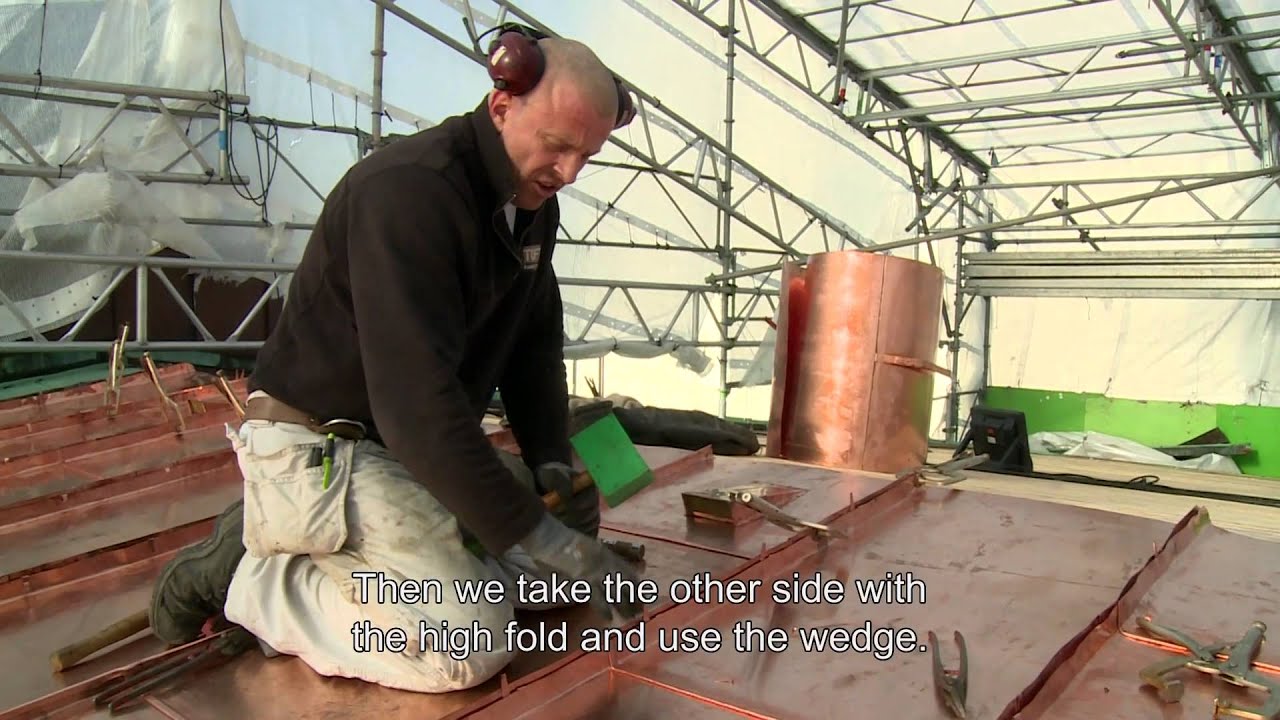

Installation Best Practices and Safety

- Training and Certification: Installers should be manufacturer-certified and trained in proper fastening, seaming, and flashing techniques.

- Safety Protocols: Follow OSHA guidelines for fall protection, ladder safety, and handling of sharp materials.

- Weather Conditions: Avoid installation during high winds, rain, or extreme temperatures that may compromise sealants or coatings.

Warranty and Manufacturer Requirements

Most copper colored metal roofing systems include a limited lifetime or 30–50 year warranty covering finish integrity, chalk resistance, and corrosion. To maintain warranty validity:

– Use only approved fasteners and accessories.

– Adhere strictly to manufacturer installation guidelines.

– Submit installation certification or inspection reports if required.

Documentation and Certification Submission

For compliance verification, maintain and submit the following:

– Product data sheets and test reports (e.g., wind uplift, fire rating).

– Material Safety Data Sheets (MSDS/SDS) for coatings.

– Certificates of compliance with ASTM, IBC, and environmental standards.

– Installation affidavits and warranty registration forms.

Disposal and End-of-Life Management

At end-of-life, copper colored metal roofing should be deconstructed and recycled through certified metal recyclers. Avoid landfill disposal to comply with environmental regulations and support circular economy principles. Provide recycling documentation when required by municipal or project sustainability standards.

In conclusion, sourcing copper-colored metal roofing offers a practical and aesthetically appealing solution for both residential and commercial projects. While natural copper provides a distinctive, long-lasting patina and premium appearance, copper-colored alternatives—such as painted or coated steel and aluminum—deliver similar visual appeal at a more accessible price point. When selecting a material, it is essential to consider factors such as durability, climate resistance, maintenance requirements, cost, and sustainability. Working with reputable suppliers and manufacturers ensures quality product performance and proper installation support. Ultimately, copper-colored metal roofing combines timeless beauty with modern functionality, making it a valuable investment that enhances curb appeal and property value over time.