The global cookware and kitchen appliance market has witnessed steady expansion over the past decade, driven by rising disposable incomes, urbanization, and increasing demand for energy-efficient home appliances. According to a 2023 report by Mordor Intelligence, the global kitchen appliances market is projected to grow at a CAGR of approximately 4.8% from 2023 to 2028. As integral components of ovens and built-in cookers, high-quality door seals play a crucial role in ensuring thermal efficiency, safety, and durability. This growing emphasis on appliance performance and energy conservation has amplified the demand for reliable cooker door seal manufacturers. Fueled by advancements in sealing materials and stringent regulatory standards, the market for precision-engineered gaskets and seals is expanding, particularly in regions with robust construction and appliance manufacturing sectors. Below, we spotlight the top 10 cooker door seal manufacturers leading innovation, quality, and global supply in this specialized niche.

Top 10 Cooker Door Seal Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Shop OEM Wall Oven Seals and Gaskets

Domain Est. 1995

Website: fix.com

Key Highlights: $12.99 deliveryShop for the OEM replacement Seals and Gaskets you need to repair your Wall Oven. Fix.com offers genuine manufacturer parts, repair help, and same-day ……

#2 Official Whirlpool WP701650 Oven Door Seal

Domain Est. 1999

Website: partselect.com

Key Highlights: Rating 5.0 (1) · $12.99 deliveryOEM WP701650 – Oven Door Seal – replacement. We offer authentic parts, and the expert advice you need to complete the repair. Same–day shipping …

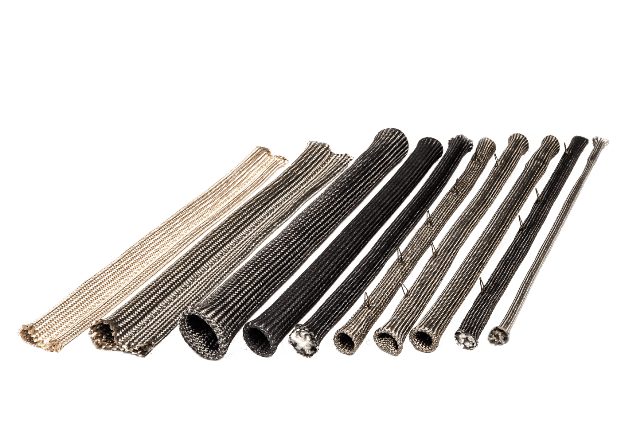

#3 Oven Door Gaskets and Seals

Domain Est. 2009

Website: davlyngroup.com

Key Highlights: Davlyn Group Oven Door Gaskets provide the perfect commercial and industrial sealing solution for ovens, dryers, boilers, and furnaces….

#4 Door Gasket Archives

Domain Est. 1996

#5 Door Gasket for Rofco Oven

Domain Est. 1999

Website: pleasanthillgrain.com

Key Highlights: In stock Rating 4.8 (8) Replacement door gasket for Rofco stone oven. Gasket available for B5, B10, B20, B30 or B40 oven….

#6 Furrion Chef Collection Replacement Electric RV Oven Door Seal …

Domain Est. 2007

#7 Allpoints

Domain Est. 2008

Website: allpointsfps.com

Key Highlights: Find restaurant equipment parts and commercial kitchen replacement parts of the highest quality and at a low price, with same-day shipping options….

#8 Oven Door Seals & Gaskets

Domain Est. 2009

Website: cookerspareparts.com

Key Highlights: Buy oven door seals. We stock a huge range of oven gaskets and door seals for all the top cooker brands. Great prices – buy online now….

#9 Oven Door Seal Profile

Domain Est. 2016

Website: exactseal.com

Key Highlights: At Exactseal, we specialize in manufacturing high-quality oven door seal profiles. These are essential for maintaining the efficiency and safety of ovens….

#10 Oven Door Seals

Domain Est. 2017

Website: sealextrusions.com

Key Highlights: Oven door seals are typically made from silicone rubber. Silicone rubber is a flexible, durable material that can withstand elevated temperatures….

Expert Sourcing Insights for Cooker Door Seal

H2: 2026 Market Trends for Cooker Door Seals

The global market for cooker door seals is poised for notable transformation by 2026, driven by advancements in appliance technology, increasing consumer demand for energy efficiency, and evolving safety standards. Several key trends are expected to shape the industry landscape over the coming years.

1. Rising Demand for Energy-Efficient Appliances

As governments and consumers prioritize energy conservation, cooker manufacturers are focusing on improving thermal efficiency. High-performance door seals play a critical role in minimizing heat leakage, directly impacting energy consumption. By 2026, demand for advanced sealing materials—such as silicone and EPDM rubber with enhanced thermal resistance—is projected to grow, especially in regions with strict energy regulations like the European Union and North America.

2. Growth in Smart and Connected Kitchen Appliances

The proliferation of smart ovens and integrated kitchen ecosystems is influencing design requirements for cooker components. Door seals are increasingly being engineered to maintain integrity under variable temperature cycles and frequent door openings associated with smart cooking programs. This trend is driving innovation in durable, flexible sealing solutions compatible with next-generation appliances.

3. Shift Toward Sustainable and Recyclable Materials

Environmental concerns are pushing manufacturers to adopt eco-friendly materials. By 2026, there will be a heightened focus on recyclable, non-toxic, and biodegradable seal materials. Companies investing in sustainable production processes and compliant with regulations such as REACH and RoHS are likely to gain a competitive edge.

4. Expansion in Emerging Markets

Rapid urbanization and rising disposable incomes in Asia-Pacific, Latin America, and Africa are fueling demand for modern kitchen appliances. As household penetration of electric and gas cookers increases, so does the need for replacement and OEM door seals. Localized manufacturing and cost-effective seal solutions will be critical for market penetration in these regions.

5. Aftermarket and Replacement Demand

Cooker door seals degrade over time due to heat exposure and wear, leading to a steady aftermarket for replacements. Online retail growth and e-commerce platforms are making it easier for consumers to source compatible seals, boosting the replacement segment. By 2026, this aftermarket is expected to account for a significant share of overall revenue.

6. Technological Innovation in Seal Design

Manufacturers are investing in precision-engineered seals with improved heat resistance, longer lifespan, and better adhesion. 3D modeling and simulation tools are being used to optimize seal geometry for various cooker models, ensuring tighter fits and enhanced performance.

In conclusion, the 2026 cooker door seal market will be shaped by a confluence of regulatory, technological, and consumer-driven factors. Companies that innovate sustainably, cater to smart appliance integration, and expand in high-growth regions will be best positioned for success.

Common Pitfalls When Sourcing Cooker Door Seals (Quality and IP)

Sourcing cooker door seals involves several critical considerations, especially regarding quality and Ingress Protection (IP) ratings. Failing to address these aspects can lead to performance issues, safety hazards, and non-compliance. Below are common pitfalls to avoid:

Poor Material Quality

Using substandard materials such as low-grade silicone or rubber compromises seal durability and heat resistance. Inferior seals degrade quickly under high temperatures, leading to warping, cracking, and loss of effectiveness.

Inadequate Heat Resistance

Cooker door seals must withstand continuous exposure to high temperatures. Sourcing seals with insufficient thermal resistance results in premature failure, reduced energy efficiency, and potential safety risks.

Incorrect Ingress Protection (IP) Rating

Selecting a seal that does not meet the required IP rating (e.g., IPX7 for moisture resistance) can allow steam, water, or debris to enter the appliance. This can damage internal components and create electrical hazards.

Poor Dimensional Accuracy

Seals that do not precisely match the door’s dimensions will not form a proper seal. This leads to heat leakage, inefficient cooking, and increased energy consumption.

Lack of Compliance with Safety Standards

Using seals that are not certified to relevant standards (e.g., UL, CE, or IEC) may result in non-compliance with regional safety regulations, leading to product recalls or legal issues.

Insufficient Compression and Elasticity

A seal must maintain consistent compression and rebound properties over time. Poor-quality seals lose elasticity, leading to gaps and reduced sealing performance after repeated use.

Overlooking Long-Term Durability Testing

Failing to test seals under simulated long-term use (thermal cycling, humidity, mechanical stress) may result in unexpected field failures and increased warranty claims.

Sourcing from Unverified Suppliers

Procuring from suppliers without proper quality management systems (e.g., ISO 9001) increases the risk of receiving inconsistent or counterfeit products.

Avoiding these pitfalls ensures reliable, safe, and compliant cooker door seals that enhance appliance performance and customer satisfaction.

Logistics & Compliance Guide for Cooker Door Seal

Product Classification and HS Code

Identify the correct Harmonized System (HS) code for cooker door seals to ensure accurate customs declaration and tariff application. Typically classified under HS 7326 (Other articles of iron or steel) or 4016 (Other articles of rubber), depending on primary material composition. Confirm with local customs authorities or a trade compliance expert.

Packaging and Labeling Requirements

Package cooker door seals in sealed, moisture-resistant materials to prevent deformation or contamination. Label each package with: product name, part number, quantity, batch/lot number, country of origin, and compliant safety symbols (e.g., CE mark if applicable). Ensure multilingual labeling for international shipments where required.

Import/Export Documentation

Prepare essential shipping documents including commercial invoice, packing list, bill of lading/airway bill, and certificate of origin. For regulated markets, include conformity declarations (e.g., EU Declaration of Conformity) and material safety data sheets (MSDS) if applicable.

Regulatory Compliance

Ensure seals meet regional safety and performance standards such as:

– European Union: Compliant with REACH and RoHS regulations; CE marking if part of a safety-critical assembly.

– United States: Meets EPA and CPSC guidelines for consumer products; compliance with California Proposition 65 if applicable.

– United Kingdom: UKCA marking post-Brexit; adherence to UK REACH.

Verify compliance through accredited third-party testing when necessary.

Transportation and Storage Conditions

Ship in dry, temperature-controlled environments to prevent rubber degradation or metal corrosion. Store in clean, ventilated areas away from direct sunlight, ozone sources, and extreme temperatures. Use pallets for bulk shipments to maintain structural integrity.

Customs Clearance and Duties

Anticipate potential import duties based on the destination country’s tariff schedule. Utilize Free Trade Agreements (FTAs) where eligible to reduce duty costs. Engage a licensed customs broker to handle clearance, especially for high-volume or complex routes.

Environmental and Disposal Compliance

Adhere to WEEE (Waste Electrical and Electronic Equipment) directives if seals are part of end-of-life appliances. Provide disposal guidance for non-hazardous materials and ensure recyclability per local environmental laws.

Recordkeeping and Audit Readiness

Maintain records of compliance certifications, test reports, shipment documentation, and supplier declarations for a minimum of five years. Be prepared for regulatory audits by ensuring traceability from raw material to final product.

Conclusion for Sourcing Cooker Door Seal:

After evaluating various suppliers, materials, and cost considerations, it is clear that sourcing a reliable and high-quality cooker door seal is essential for ensuring appliance safety, energy efficiency, and customer satisfaction. The ideal seal must be heat-resistant, durable, and compatible with the specific cooker model to prevent heat loss and maintain optimal performance.

Sourcing from reputable manufacturers who comply with industry standards (such as ISO or CE certification) ensures product reliability and longevity. Additionally, balancing cost-effectiveness with quality is crucial to maintain profitability without compromising on safety or functionality. Establishing long-term relationships with flexible and responsive suppliers can also enhance supply chain efficiency and support timely replacements or scaling of operations.

In conclusion, a strategic sourcing approach—prioritizing quality, compatibility, compliance, and supplier reliability—will ensure the consistent availability of effective cooker door seals, ultimately contributing to improved product performance and customer trust.