The global conveyor system market is experiencing robust growth, driven by rising automation across manufacturing, logistics, and food processing industries. According to Grand View Research, the global conveyor systems market size was valued at USD 7.4 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This expansion is fueled by increasing demand for efficient material handling solutions, especially in e-commerce fulfillment and automated production lines. Within this landscape, padded chain conveyors—known for their gentle handling of delicate products such as bottled goods, packaged foods, and electronics—have emerged as a critical solution for minimizing product damage and optimizing line efficiency. As industries prioritize uptime and product integrity, demand for high-performance padded chain systems continues to rise. In this evolving market, a select group of manufacturers have distinguished themselves through innovation, durability, and engineering precision. Based on performance metrics, global reach, and technological advancements, here are the top 9 conveyor padded chain manufacturers shaping the future of material handling.

Top 9 Conveyor Padded Chain Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

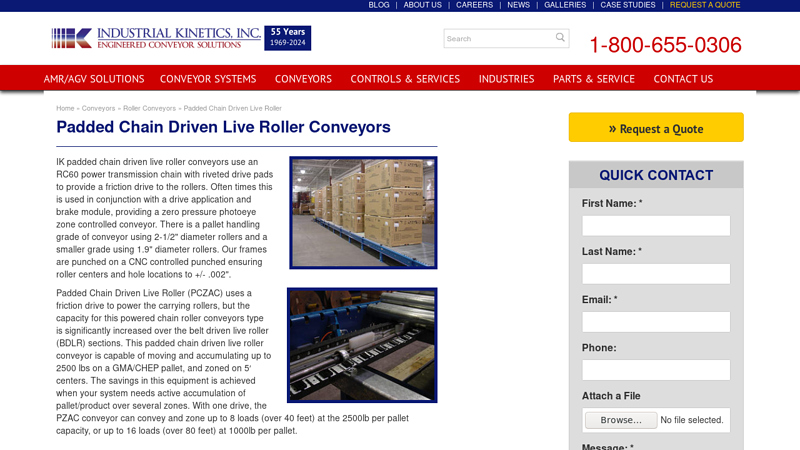

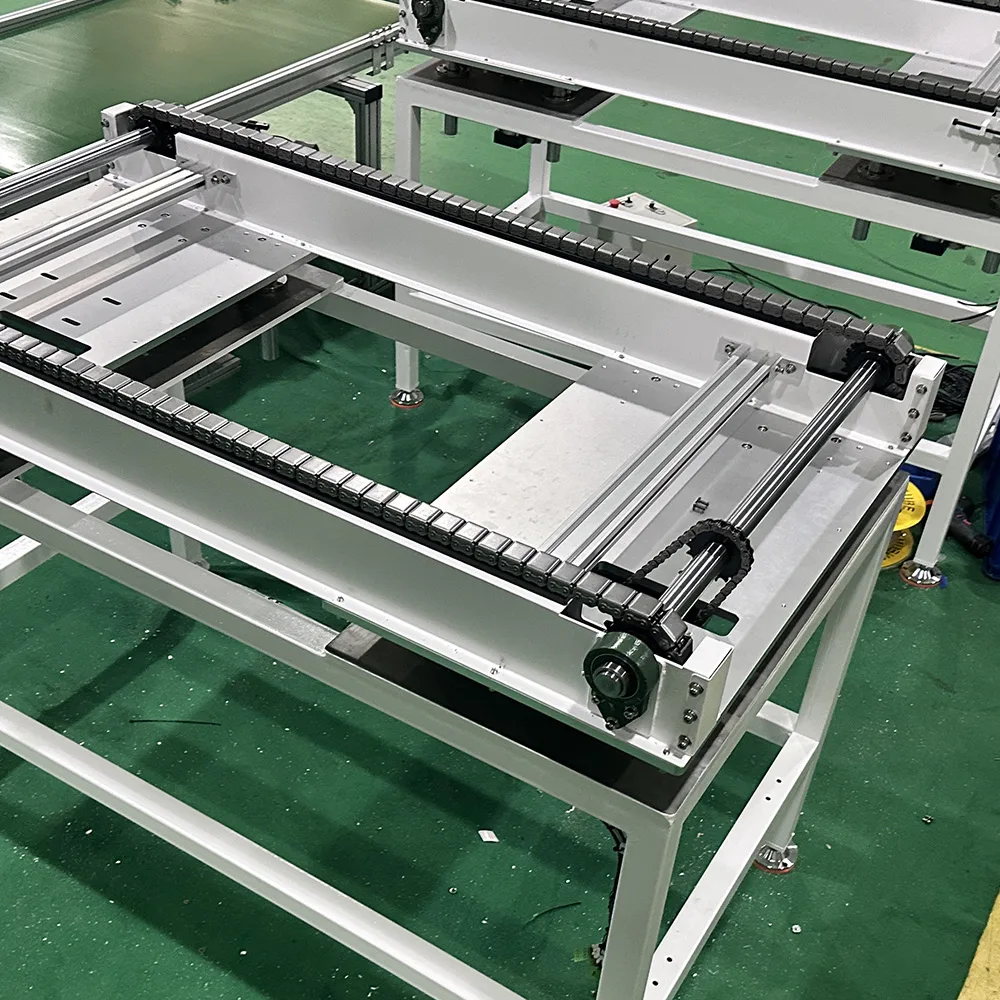

#1 Padded Chain Driven Live Roller Conveyors

Domain Est. 1996

Website: iki.com

Key Highlights: Our Padded Chain Driven Live Roller Conveyor uses an RC60 power transmission chain with riveted drive pads to provide a friction drive to the rollers….

#2 Appliance Manufacturing Conveyor Solutions

Domain Est. 1997

Website: titanconveyors.com

Key Highlights: Titan Conveyors has been supplying conveyor systems to appliance manufacturers in North America for over 25 years. Explore our extensive features and ……

#3 Chain Conveyors by Ultimation Industries

Domain Est. 1998

Website: ultimationinc.com

Key Highlights: Ultimation is one of the leading chain conveyor manufacturers and can design and engineer custom conveyors, as well as providing fast-ship “off the shelf” ……

#4 Chain Conveyor

Domain Est. 1989

Website: omni.com

Key Highlights: Chain Conveyor (CC) is used to move products that wouldn’t normally convey on rollers. They are ideal for wrong-way pallets, racks, automobile frames, or other ……

#5 Driver Pad (ALR) & Driver Pad Chain

Domain Est. 1996

Website: shinglebelting.com

Key Highlights: Shingle ALR driver pad is a special hollow, D-shaped Veethane extrusion with perforations. It is installed on the customer’s chain-driven roller accumulation ……

#6 Chain Conveyors

Domain Est. 1997

Website: webb-stiles.com

Key Highlights: Explore custom chain conveyors designed by Webb-Stiles for heavy loads, complex layouts, and precision part handling….

#7 Rapid Industries

Domain Est. 1998

Website: rapidindustries.com

Key Highlights: Rapid Industries is your one stop shop for Conveyor Systems, Inspections, Turn-Key Solutions, Automated Equipment & Structural Fabrications….

#8 Chain Conveyor

Domain Est. 2002

Website: lathrupindustries.com

Key Highlights: A chain conveyor is a durable and rugged transportation conveyor, used to move products along a production line. Chain is used to convey pallets, racks, ……

#9 Chain Conveyor

Domain Est. 2021

Website: bifaconveyor.com

Key Highlights: FlexLink is a well-known supplier of chain conveyor systems, providing modular conveying solutions, which are widely used in manufacturing and assembly lines….

Expert Sourcing Insights for Conveyor Padded Chain

2026 Market Trends for Conveyor Padded Chain

The Conveyor Padded Chain market is poised for significant evolution by 2026, driven by increasing automation, sustainability demands, and advancements in materials science. These specialized chains, featuring protective polymer or rubber padding on standard roller chain components, are critical in industries where product protection, noise reduction, and smooth material handling are paramount. Key trends shaping the market include:

Growing Demand in Food & Beverage and Packaging Sectors

The food & beverage and packaging industries remain the largest drivers of conveyor padded chain adoption. By 2026, heightened focus on hygiene, traceability, and production efficiency will accelerate demand. Padded chains minimize product damage during high-speed bottling, canning, and case packing operations. Regulatory standards such as FDA compliance and HACCP will continue to favor materials that are non-toxic, easy to clean, and resistant to bacterial growth, pushing manufacturers toward advanced, food-grade padding compounds.

Shift Toward Sustainable and Low-Maintenance Materials

Sustainability will be a core market differentiator. By 2026, there will be a stronger preference for padded chains made with recyclable or bio-based polymers. Reduced lubrication requirements and longer service life will be key selling points, as end-users seek to lower their total cost of ownership (TCO) and environmental footprint. Self-lubricating or dry-running padded chains with enhanced wear resistance will gain traction, especially in clean environments like pharmaceuticals and electronics.

Integration with Smart Manufacturing and IIoT

As Industry 4.0 adoption expands, conveyor systems—including padded chains—are becoming part of intelligent production networks. By 2026, expect increased integration of sensors into or near padded chain assemblies to monitor wear, tension, temperature, and alignment in real time. This predictive maintenance capability will reduce unplanned downtime and optimize replacement cycles, improving overall equipment effectiveness (OEE) in smart factories.

Regional Expansion in Asia-Pacific and Emerging Markets

The Asia-Pacific region, particularly China, India, and Southeast Asia, will see robust growth in demand for conveyor padded chains due to expanding manufacturing bases, rising consumer goods production, and modernization of logistics infrastructure. Localized production and supply chain resilience will drive investment in regional manufacturing of both chains and padding materials, reducing lead times and import dependency.

Innovation in Padding Technologies and Customization

Material innovation will play a crucial role. By 2026, expect wider use of high-performance thermoplastics (e.g., TPU, TPE) and engineered composites offering superior abrasion resistance, temperature tolerance, and noise dampening. Customization will become standard—chains tailored to specific load profiles, conveyor speeds, and environmental conditions (e.g., washdown, extreme temperatures) will differentiate leading suppliers in a competitive landscape.

In summary, the 2026 Conveyor Padded Chain market will be defined by smarter, more sustainable, and highly specialized solutions. Companies that invest in material R&D, digital integration, and industry-specific applications will be best positioned to capture growth in this evolving niche.

Common Pitfalls When Sourcing Conveyor Padded Chain (Quality, IP)

Sourcing conveyor padded chain involves more than just finding a supplier with the lowest price. Overlooking critical quality and intellectual property (IP) factors can lead to operational failures, safety risks, and legal exposure. Below are key pitfalls to avoid:

Poor Material Quality and Durability

One of the most frequent issues is selecting padded chains made from substandard materials. Low-quality polymers or elastomers used for padding may degrade quickly under heat, oils, UV exposure, or repeated impact. This leads to premature wear, chain failure, and increased downtime. Always verify material specifications (e.g., FDA compliance for food-grade lines, resistance to chemicals or temperatures) and request durability test data.

Inconsistent Padding Adhesion

A common quality flaw is inadequate bonding between the padding and the chain links. Over time, vibration and load stress can cause the padding to delake, exposing metal components and risking product damage—especially in industries like beverage or electronics. Ensure the supplier uses proven bonding techniques (e.g., overmolding or mechanical interlock) and inquire about adhesion strength testing.

Lack of Dimensional Accuracy

Improperly manufactured padded chains may have inconsistent link or pad dimensions, leading to misalignment, tracking issues, or jamming in the conveyor system. This reduces efficiency and increases maintenance. Request samples or dimensional certifications to confirm conformity to specified tolerances.

Misrepresentation of Intellectual Property (IP) Compliance

Some suppliers may offer padded chains that closely resemble patented designs from reputable manufacturers (e.g., chains designed by major OEMs like Rexnord, IWIS, or Tsubaki). Using such “copycat” products can expose your company to IP infringement claims, especially in regulated markets. Always verify that the chain design does not violate existing patents and request documentation of IP clearance or design ownership.

Absence of Traceability and Certification

Reputable suppliers provide traceability through batch numbers, material certifications (e.g., RoHS, REACH), and quality assurance documentation. Sourcing from vendors without proper traceability increases the risk of receiving inconsistent or non-compliant products—particularly problematic in food, pharmaceutical, or export-sensitive industries.

Insufficient Testing and Validation Data

Suppliers may claim high performance without supporting data. Without access to real-world testing results—such as load capacity, wear resistance, or noise reduction metrics—buyers cannot validate performance claims. Request third-party test reports or case studies from similar applications before committing to large orders.

Overlooking After-Sales Support and Warranty

Low-cost suppliers may lack technical support or warranty coverage. If a padded chain fails prematurely, the absence of responsive service can result in extended downtime. Confirm warranty terms, availability of replacement parts, and access to engineering support before finalizing procurement.

Avoiding these pitfalls requires due diligence: vet suppliers thoroughly, demand transparency in materials and design, and prioritize long-term reliability over initial cost savings.

Logistics & Compliance Guide for Conveyor Padded Chain

Overview

Conveyor padded chains are specialized components used in material handling systems to transport delicate or sensitive products without damage. Proper logistics and compliance procedures are essential to ensure safe handling, regulatory adherence, and uninterrupted operations. This guide outlines best practices for shipping, storage, documentation, and regulatory compliance.

Packaging and Handling

Use robust, moisture-resistant packaging to protect padded chains from environmental damage during transit. Secure chains on pallets using straps or shrink wrap to prevent shifting. Avoid stacking heavy items on top. Handle with forklifts or pallet jacks to prevent abrasion or deformation of padding material. Always lift by the pallet—not the chain—to avoid structural stress.

Transportation Requirements

Ship via freight carriers experienced in industrial handling equipment. Clearly label packages with orientation arrows and “Fragile – Do Not Crush” warnings. For international shipments, ensure compliance with Incoterms (e.g., FOB, CIF) and coordinate customs documentation in advance. Maintain a temperature-controlled environment if the padding material is sensitive to heat or cold (e.g., rubber or polyurethane).

Storage Conditions

Store in a clean, dry, and temperature-stable environment (ideally 10°C to 30°C / 50°F to 86°F). Keep away from direct sunlight, ozone sources (e.g., motors), and chemicals that may degrade elastomeric padding. Elevate pallets off the floor to prevent moisture absorption. Limit storage duration; rotate stock using a first-in, first-out (FIFO) system to prevent material aging.

Regulatory Compliance

Ensure conveyor padded chains meet relevant industry standards such as:

– CE Marking (for EU markets) per Machinery Directive 2006/42/EC

– REACH and RoHS compliance for restricted substances in materials

– OSHA guidelines (in the U.S.) for workplace safety and machine guarding

– ISO 5293:2002 for conveyor chain performance specifications

Provide technical documentation, including Declarations of Conformity and material safety data sheets (MSDS), with each shipment.

Import/Export Documentation

For cross-border shipments, prepare:

– Commercial invoice with detailed product description and HS code (e.g., 8431.31 for parts of conveyor systems)

– Packing list with weight, dimensions, and quantity

– Certificate of Origin

– Any required permits or licenses (e.g., for controlled materials)

Verify destination country-specific requirements—some regions mandate additional testing or certification.

Quality Assurance & Traceability

Implement batch tracking for all padded chains. Retain production records, inspection reports, and test certifications for a minimum of five years. Conduct periodic audits to ensure ongoing compliance with quality standards (e.g., ISO 9001). Report and document any non-conformities to support corrective actions.

Environmental & Sustainability Considerations

Dispose of damaged or end-of-life padded chains according to local waste regulation. Recycle metal components where possible; consult local authorities on proper disposal of polymer padding materials. Prefer suppliers with sustainable manufacturing practices and environmental management systems (e.g., ISO 14001 certified).

Emergency Procedures

In case of shipping damage or compliance concerns:

– Isolate affected products immediately

– Notify supplier and carrier within 24 hours

– Document damage with photos and inspection reports

– Initiate return or replacement per contractual terms

– Report safety-related issues to regulatory bodies if required (e.g., CPSC in the U.S.)

Contact & Support

For compliance inquiries, logistics support, or documentation requests, contact:

[Your Company Name] Logistics & Compliance Team

Email: [email protected]

Phone: +1 (555) 123-4567

Available Monday–Friday, 8:00 AM – 5:00 PM [Your Time Zone]

In conclusion, sourcing a conveyor padded chain requires careful consideration of application requirements, material specifications, load capacity, environmental conditions, and compatibility with existing systems. Evaluating suppliers based on quality standards, lead times, after-sales support, and cost-effectiveness is essential to ensure reliable and long-term performance. By selecting the right padded chain from a reputable supplier, businesses can enhance operational efficiency, reduce wear and maintenance costs, and improve product handling across their conveyor systems. A well-informed sourcing decision ultimately contributes to increased productivity and process reliability in material handling operations.