The global conveyor belt market is experiencing robust growth, driven by rising automation, expanding manufacturing output, and increasing demand from key industries such as mining, automotive, and e-commerce logistics. According to a report by Mordor Intelligence, the conveyor belt market was valued at USD 6.32 billion in 2023 and is projected to reach USD 8.57 billion by 2029, growing at a CAGR of 5.1% during the forecast period. Similarly, Grand View Research highlights accelerating adoption of material handling systems in warehouse automation and intralogistics as key market drivers, with the global conveyor systems market expected to expand at a CAGR of over 5.5% through 2030. As industries prioritize efficiency, throughput, and operational reliability, the role of high-performance conveyor belt manufacturers becomes increasingly critical. In this landscape, a select group of global manufacturers leads innovation, offering specialized belt types—from modular plastic and rubber-covered belts to high-tension steel-cord and heat-resistant variants—tailored to diverse industrial applications. The following list highlights the top 10 conveyor belt manufacturers shaping the future of material handling with advanced engineering, global reach, and data-backed market influence.

Top 10 Conveyor Belt Types Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Esbelt

Domain Est. 1996

Website: esbelt.com

Key Highlights: We are industrial conveyor belt manufacturer of lightweight thermoplastic conveyor belts for a wide range of applications, in food, agro, or industrial ……

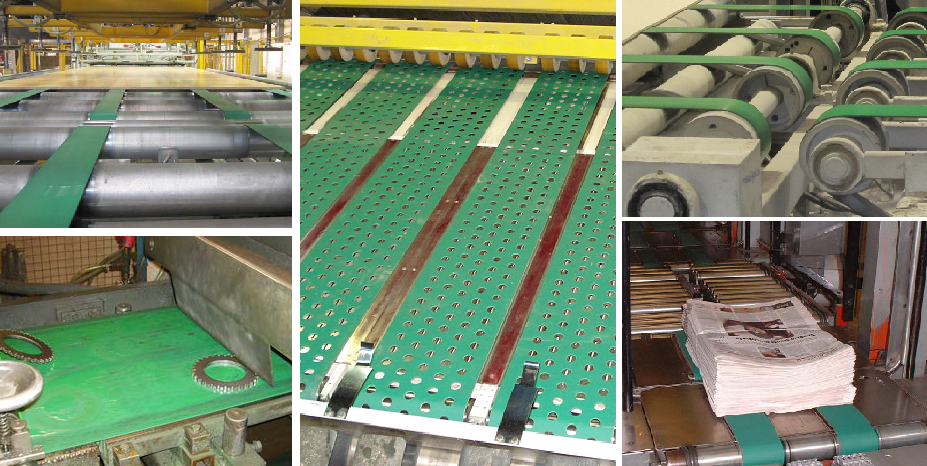

#2 Belt Conveyor Systems

Domain Est. 1998

Website: ultimationinc.com

Key Highlights: Ultimation is one of the top conveyor belt manufacturers. Our simple and versatile belt conveyor systems use two or more pulleys to drive looped belts….

#3 MAFDEL Belts

Domain Est. 2001

Website: mafdel-belts.com

Key Highlights: Mafdel designs and manufactures thermoweldable belts and conveyor belts intended for continuous industrial handling….

#4 Conveyor Belts

Domain Est. 2011

Website: conveyor-belts.semperitgroup.com

Key Highlights: Semperit is a global provider of tailormade conveyor belt technology. Enhance your business with custom, innovative and reliable solutions….

#5 Conveyor Belts and Processing Belts

Domain Est. 1996

Website: forbo.com

Key Highlights: Siegling Transilon conveyor and processing belts ensure efficient flow of materials and economic work processes in light materials handling….

#6 Pipe type conveyor belts

Domain Est. 1996

Website: trelleborg.com

Key Highlights: The Pipe type conveyor belt is suitable for use in tougher conditions and requires application of special tubular-type conveyors….

#7 Volta Belting

Domain Est. 1999

Website: voltabelting.com

Key Highlights: Elevate your poultry processing operations with Volta Belting’s innovative conveyor belt solutions, designed for superior hygiene and efficiency….

#8 Conveyor Belting

Domain Est. 2007

Website: dornerconveyors.com

Key Highlights: Conveyor belts are on the front lines of your conveyor system. They come in scores of varieties, from lightweight to heavy-duty, and in a range of surface ……

#9 Conveyor Belt Systems

Domain Est. 2018

Website: continental-industry.com

Key Highlights: Continental offers steel cord conveyor belts, textile conveyor belts, solid woven conveyor belts, steel mesh conveyor belts, conveyor belts for steep-incline ……

#10 Fenner Dunlop Conveyor Belting (EMEA)

Domain Est. 2023

Website: fennerdunlopemea.com

Key Highlights: Every Fenner Dunlop conveyor belt comes with a robust 2-year guarantee against premature failure due to faulty workmanship or materials, even in demanding ……

Expert Sourcing Insights for Conveyor Belt Types

2026 Market Trends for Conveyor Belt Types

The global conveyor belt market is undergoing significant transformation driven by automation, sustainability demands, and evolving industrial needs. As we approach 2026, several key trends are shaping the demand and development of different conveyor belt types across industries such as manufacturing, logistics, mining, and food processing.

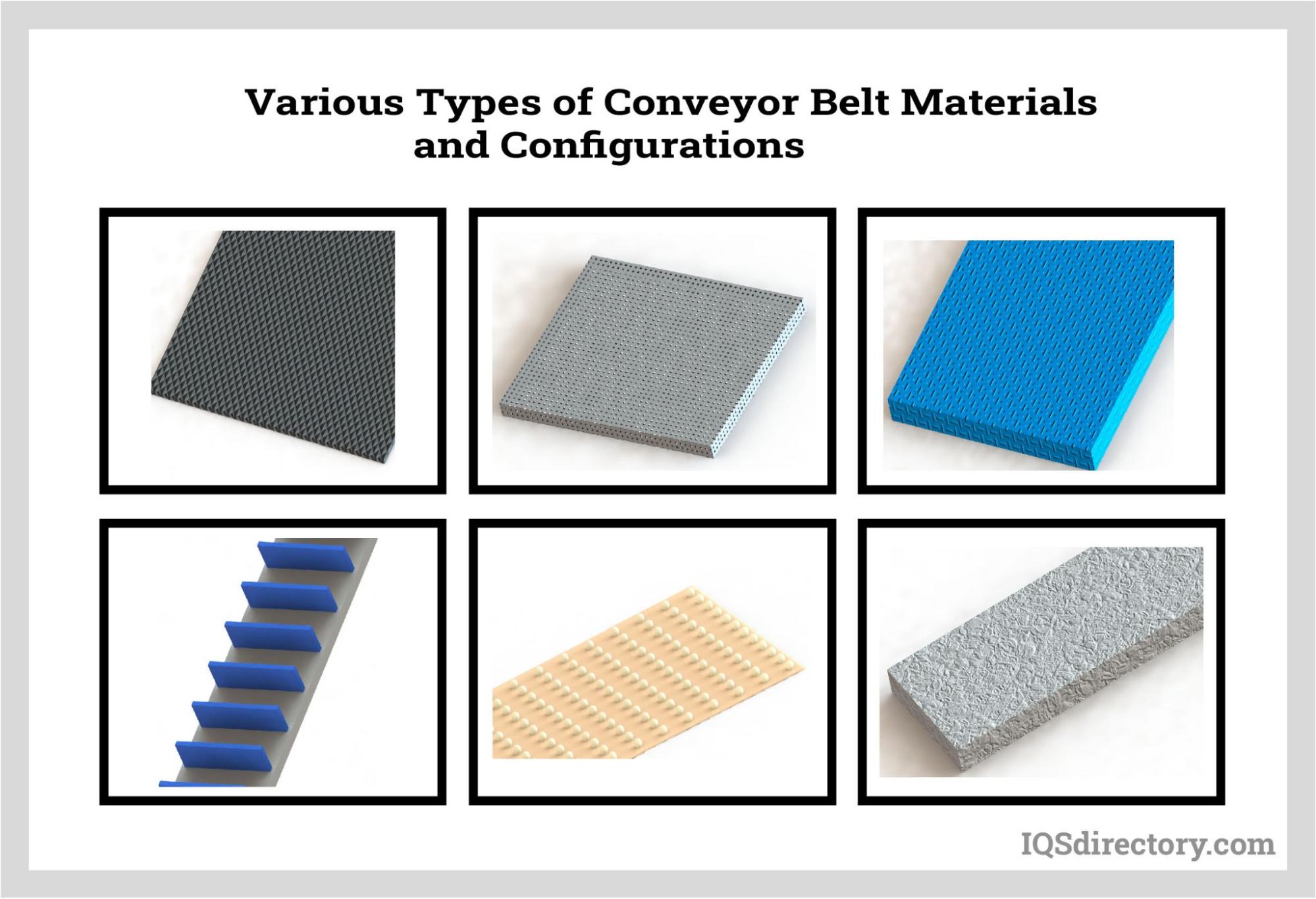

Increasing Demand for Modular Plastic Belts in Automation and Hygiene-Critical Sectors

Modular plastic conveyor belts are experiencing robust growth, particularly in food and beverage, pharmaceuticals, and e-commerce fulfillment centers. Their hygienic design, ease of cleaning, and resistance to chemicals make them ideal for environments requiring strict sanitation. Additionally, their flexibility in configuration supports complex automated material handling systems, including robotic integration. By 2026, advancements in lightweight, high-strength polymers will likely enhance their load capacity and energy efficiency, further expanding their application in high-speed sorting and packaging lines.

Rising Adoption of Steel Cord and High-Tensile Belts in Heavy-Duty and Long-Distance Applications

In mining, aggregate, and bulk material handling, steel cord and high-tensile fabric belts continue to dominate due to their superior strength and durability. As mining operations move toward deeper reserves and remote locations, the demand for belts capable of long-distance, high-capacity transportation is increasing. Innovations in rubber compound formulations and steel cord adhesion technologies are expected to improve belt lifespan and reduce maintenance costs by 2026. Moreover, integration with IoT-enabled monitoring systems for real-time wear and strain detection will enhance operational safety and reliability.

Growth in Specialty and Customized Conveyor Belts for Industry 4.0 Integration

The shift toward smart factories is driving demand for conveyor belts embedded with sensors and connected systems. By 2026, belts with built-in condition monitoring capabilities—such as temperature, vibration, and alignment sensors—will become more common, enabling predictive maintenance and reducing unplanned downtime. Custom solutions tailored for specific applications, such as low-temperature belts for cold storage or anti-static belts for electronics manufacturing, will gain traction as companies seek optimized performance and safety.

Sustainability Driving Innovation in Recyclable and Eco-Friendly Belt Materials

Environmental regulations and corporate sustainability goals are pushing manufacturers to develop conveyor belts with lower environmental impact. By 2026, belts made from recycled rubber, bio-based polymers, or fully recyclable materials are expected to enter mainstream markets. Energy-efficient belt designs that reduce rolling resistance and motor load will also be prioritized, contributing to lower carbon footprints in logistics and manufacturing operations. Leading suppliers are likely to emphasize circular economy models, offering take-back and recycling programs.

Expansion of Lightweight and Flexible Belts in E-Commerce and Parcel Handling

The booming e-commerce sector demands fast, adaptable, and space-efficient material handling systems. Lightweight PVC and PU belts, including curve belts and inclined conveyors, are increasingly used in parcel sorting hubs. These belts offer flexibility in routing, easy installation, and quiet operation. By 2026, enhanced durability and static-dissipative properties will make them even more suitable for high-throughput distribution centers, supporting the trend toward same-day and next-day delivery.

In summary, the conveyor belt market in 2026 will be characterized by technological innovation, customization, and sustainability. Modular plastic and specialty belts will grow rapidly in automated and hygienic environments, while high-tensile and smart belts will dominate heavy industries. Eco-conscious materials and intelligent integration will be key differentiators for manufacturers aiming to capture market share in an increasingly competitive and regulated landscape.

Common Pitfalls When Sourcing Conveyor Belt Types (Quality, IP)

Sourcing the right conveyor belt is critical for operational efficiency, safety, and long-term cost savings. However, several common pitfalls—especially concerning quality and intellectual property (IP)—can lead to performance issues, downtime, or legal complications. Being aware of these challenges helps ensure a successful procurement process.

Overlooking Material and Construction Quality

One of the most frequent mistakes is selecting a conveyor belt based solely on price without assessing the actual material composition and construction. Low-quality belts may use inferior rubber, fabric, or steel cords, leading to premature wear, tearing, or delamination. Buyers should verify specifications such as tensile strength, elongation, abrasion resistance, and environmental suitability (e.g., oil, heat, or chemical resistance) to ensure durability.

Ignoring Industry Standards and Certifications

Choosing a conveyor belt that doesn’t meet relevant industry standards (e.g., ISO, CEMA, or RMA) is a significant risk. Belts lacking proper certification may not perform reliably under expected loads or conditions. For applications in food processing, mining, or hazardous environments, compliance with FDA, ATEX, or other regulatory standards is essential. Always request documentation proving conformity.

Misjudging Application Requirements

Sourcing the wrong type of belt—such as using a light-duty belting in a heavy mining operation—leads to frequent breakdowns and safety hazards. Factors like load weight, speed, incline angle, operating temperature, and exposure to moisture or chemicals must be precisely evaluated. Failure to match the belt type (e.g., PVC, rubber, modular, or timing belts) to the application results in poor performance and increased maintenance.

Falling for Counterfeit or Imitation Products

In global supply chains, counterfeit conveyor belts are a growing concern. These products mimic reputable brands but use substandard materials and lack proper performance testing. Sourcing from unauthorized distributors or unclear suppliers increases the risk of receiving fake products that compromise safety and efficiency. Always verify supplier authenticity and request traceability documentation.

Intellectual Property (IP) Infringement Risks

Using or sourcing conveyor belts that replicate patented designs, tread patterns, or splice technologies can expose companies to legal action. Some manufacturers produce “compatible” belts that closely imitate proprietary products, potentially violating IP rights. To avoid infringement, ensure that the belt design does not copy protected innovations and that suppliers provide legal assurances of IP compliance.

Inadequate Due Diligence on Suppliers

Relying on suppliers without proper vetting—especially in low-cost regions—can lead to quality inconsistencies and lack of after-sales support. It’s crucial to audit suppliers’ manufacturing processes, quality control systems, and track record. Absence of clear communication, poor responsiveness, or refusal to provide test reports are red flags.

Neglecting Total Cost of Ownership

Focusing only on the upfront purchase price ignores long-term costs associated with maintenance, energy consumption, and downtime. A higher-quality belt with better durability and efficiency may have a higher initial cost but offers significant savings over time. A lifecycle cost analysis helps avoid the pitfall of false economies.

Skipping Prototype Testing or Sample Evaluation

Implementing a new belt type without testing a sample under real operating conditions is risky. Performance can vary significantly based on installation, alignment, and environmental factors. Requesting and evaluating a sample ensures compatibility and helps identify potential issues before full-scale procurement.

By avoiding these common pitfalls—particularly those related to quality assurance and intellectual property—organizations can make informed sourcing decisions that enhance reliability, safety, and compliance.

Logistics & Compliance Guide for Conveyor Belt Types

Understanding the logistics and compliance considerations for different conveyor belt types is essential for efficient operations, regulatory adherence, and workplace safety. This guide outlines key factors across common belt types used in industrial and commercial applications.

Roller Bed Conveyor Belts

Roller bed conveyor belts are widely used for transporting heavy or large loads over long distances. Their logistics and compliance aspects include:

- Load Capacity & Structural Compliance: Must meet load-bearing standards (e.g., ISO 21183-1 for light conveyor belts or CEMA standards in North America). Structural design must comply with local occupational safety regulations (e.g., OSHA in the U.S.).

- Installation & Maintenance: Requires precise alignment during installation to avoid belt misalignment and premature wear. Regular inspections are mandated under safety compliance programs.

- Logistics Considerations: Heavy-duty construction increases shipping weight and handling requirements. On-site assembly may require specialized tools and trained personnel.

Modular Plastic Conveyor Belts

Common in food processing, packaging, and washdown environments, modular plastic belts offer flexibility and hygiene benefits.

- FDA & Food Safety Compliance: Must be made from FDA-compliant, non-toxic materials, especially in food and pharmaceutical applications. Belts should meet 3-A Sanitary Standards where applicable.

- Cleanability & Sanitation: Design must allow for easy cleaning and drainage to comply with HACCP and GMP guidelines. Avoid harborage points for bacteria.

- Logistics Advantages: Lightweight and modular – easy to transport, reconfigure, and replace sections without full system downtime. Ideal for facilities with frequent changeovers.

Rubber Conveyor Belts

Used in mining, aggregate, and heavy manufacturing, rubber belts must withstand abrasive, high-impact conditions.

- Fire Resistance & MSHA/ISO Compliance: In mining applications, belts must meet flame-resistance standards such as MSHA 30 CFR Part 18 (U.S.) or ISO 340 and ISO 284 for fire and electrical conductivity.

- Splicing & Joint Safety: Mechanical or vulcanized splices must adhere to safety guidelines to prevent failure. Documentation of splice procedures may be required for audits.

- Transport & Storage: Large rolls require careful handling; improper storage (e.g., exposure to sunlight, extreme temperatures) can degrade rubber quality and violate manufacturer warranties.

Cleated & Incline Conveyor Belts

These belts feature raised sections (cleats or sidewalls) to transport products vertically or on steep inclines.

- Product Containment & Safety Guards: Must include proper guarding to prevent material slippage, complying with machinery safety directives (e.g., EU Machinery Directive 2006/42/EC).

- Angle & Speed Compliance: Incline angles and belt speeds should be tested and documented to ensure stability, especially with loose or irregular loads.

- Logistics Planning: Cleated belts are often custom-designed, requiring lead time for manufacturing and careful coordination during delivery and installation.

Sanitary & Flexible Spiral Conveyor Belts

Used in high-hygiene or space-constrained environments (e.g., baking, freezing), these belts demand special compliance attention.

- Grade 304/316 Stainless Steel Components: Must meet food-grade material standards. All belt components should be corrosion-resistant and suitable for frequent washdowns.

- Drainage & Slope Compliance: Design must prevent water pooling to comply with food safety codes. Slopes and curves should be engineered to avoid product jamming.

- Logistics Challenges: Spiral conveyors are often pre-assembled and bulky, requiring careful route planning and crane or forklift access during delivery and installation.

General Compliance & Logistics Best Practices

Regardless of belt type, the following practices support compliance and efficient logistics:

- Documentation & Traceability: Maintain material certifications (e.g., FDA, MSHA, ISO), installation records, and maintenance logs for audits.

- Worker Training: Ensure personnel are trained in safe operation, lockout/tagout (LOTO) procedures, and emergency stop usage as required by OSHA or local regulations.

- Environmental Considerations: Dispose of worn belts according to local environmental regulations; some rubber or PVC belts may require special recycling or hazardous waste handling.

Selecting the right conveyor belt involves balancing performance needs with logistical feasibility and regulatory requirements. Always consult industry standards and involve compliance officers during system design and procurement.

Conclusion on Sourcing Conveyor Belt Types

When sourcing conveyor belt types, it is essential to consider the specific operational requirements of the application, including material characteristics, environmental conditions, load capacity, speed, and maintenance needs. Different conveyor belt materials—such as rubber, PVC, PU, fabric, steel, or silicone—offer unique advantages depending on industry demands, whether in manufacturing, mining, food processing, or logistics.

Proper selection enhances efficiency, reduces downtime, and extends the service life of the conveyor system. Key factors such as belt strength, surface finish, temperature resistance, and compliance with industry standards (e.g., FDA, USDA, or fire safety regulations) must be carefully evaluated. Additionally, sourcing from reputable suppliers who provide technical support, quality certifications, and after-sales service ensures reliability and long-term performance.

In conclusion, a strategic and informed approach to sourcing conveyor belts—rooted in application-specific needs and supplier credibility—leads to optimized material handling operations, improved safety, and cost-effective solutions across diverse industrial environments.