The global conveyor belt pulley market is experiencing robust growth, driven by rising automation, expanding industrial manufacturing, and increasing demand across mining, logistics, and aggregate sectors. According to a report by Mordor Intelligence, the conveyor system market is projected to grow at a CAGR of over 5.8% from 2024 to 2029, with conveyor pulleys representing a critical component in system efficiency and durability. Grand View Research further supports this trajectory, estimating the global conveyor systems market size to reach USD 12.6 billion by 2030, expanding at a CAGR of 6.1%, fueled by advancements in material handling technologies and the push for operational optimization in heavy industries. As demand intensifies, selecting high-performance pulley manufacturers has become a strategic imperative for maximizing uptime, reducing maintenance costs, and enhancing productivity. In this evolving landscape, the following ten manufacturers stand out for their engineering excellence, global footprint, and innovation in pulley design and materials.

Top 10 Conveyor Belt Pulley Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 BRECOflex: Timing Belt Manufacturer

Domain Est. 1996

Website: brecoflex.com

Key Highlights: BRECOflex CO., L.L.C. manufacturers timing belts, pulleys and drive components for linear drives, conveying & power transmission applications….

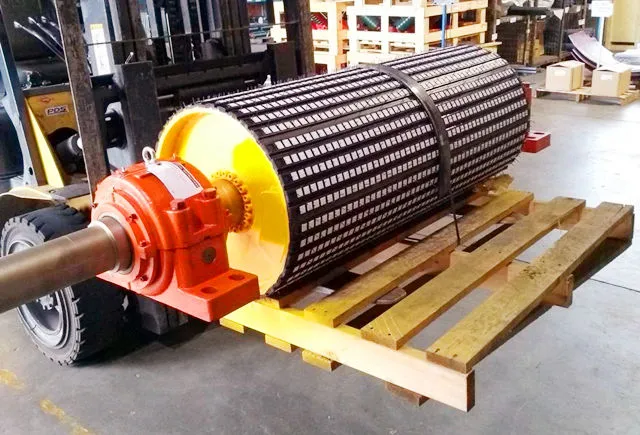

#2 Conveyor Pulleys

Domain Est. 1998

Website: pcimfg.com

Key Highlights: Designed using gauge wall tubing or heavy wall pipe. Features our Trapezoidal Crown technology to maximize belt life and improve conveyor performance….

#3 Mol Belting

Domain Est. 1998

Website: molbelting.com

Key Highlights: We are a manufacturer, fabricator, and solution-provider of conveyor belting, motorized pulleys, and conveyance accessories for an array of industries around ……

#4 Conveyor Pulleys

Domain Est. 1995

Website: martinsprocket.com

Key Highlights: Martin’ s heavy-duty conveyor pulley product line meets the demanding requirements of industries such as: sand and gravel quarries, coal mines, unit packaging….

#5 Conveyor Belting

Domain Est. 1998

Website: beltpower.com

Key Highlights: Investing in high-quality conveyor belting is essential for maximizing operational efficiency and minimizing downtime….

#6 Conveyor Belt Pulleys

Domain Est. 1999

Website: woodsage.com

Key Highlights: Woodsage produces high-quality conveyor belt pulleys, including drive, tail and idler conveyor pulleys manufactured to UPS-spec for longer lasting service ……

#7 Volta Belting

Domain Est. 1999

Website: voltabelting.com

Key Highlights: Elevate your poultry processing operations with Volta Belting’s innovative conveyor belt solutions, designed for superior hygiene and efficiency….

#8 Motorized Pulleys & Belt Conveyor Rollers

Domain Est. 2003

Website: rulmecacorp.com

Key Highlights: A full range of Motorized Pulleys for the Food Processing and Unit Handling Industry developed for various demanding applications such as airport logistics, ……

#9 PPI-We keep it moving

Domain Est. 2016

Website: ppi-global.com

Key Highlights: PPI produces pulleys for all conveyor applications. From the Pro Duty to the Herringbone wing, we have the product material handlers need to keep their ……

#10 Head & Tail Pulleys

Domain Est. 2020

Website: conveyorbeltcompany.com

Key Highlights: We provide both crowned head pulleys and heavy duty fabricated tail pulleys, available in a wide range of standard sizes….

Expert Sourcing Insights for Conveyor Belt Pulley

H2: 2026 Market Trends for Conveyor Belt Pulleys

The conveyor belt pulley market is poised for significant evolution by 2026, driven by industrial automation, material handling demands, and technological advancements. Key trends shaping the landscape include:

1. Rising Demand from Key Industries:

The mining, aggregate, and manufacturing sectors remain primary drivers. Increased global infrastructure projects and mineral extraction activities, particularly in emerging economies, will boost demand for robust and high-capacity pulleys. The e-commerce boom continues to fuel growth in logistics and warehousing, necessitating efficient conveyor systems where pulleys are critical components.

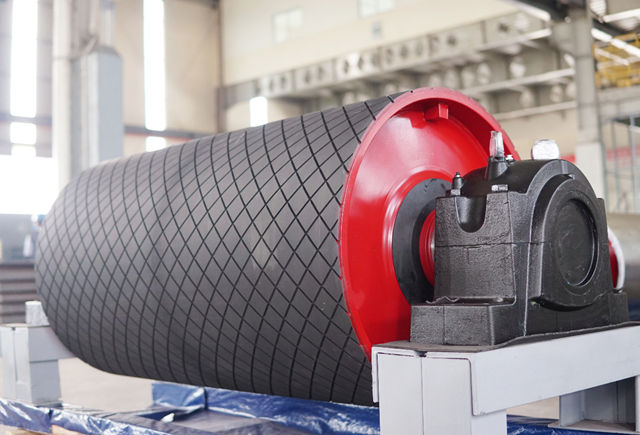

2. Focus on Durability and Efficiency:

End-users are prioritizing pulleys with extended service life and reduced maintenance. This trend promotes the adoption of advanced materials (e.g., high-strength steel, wear-resistant coatings) and innovative designs that minimize energy loss and belt slippage. Manufacturers are investing in precision engineering to enhance alignment and reduce downtime.

3. Integration of Smart Technologies:

The Industrial Internet of Things (IIoT) is making inroads into conveyor systems. By 2026, expect greater integration of smart pulleys equipped with embedded sensors for real-time monitoring of temperature, vibration, and load. This predictive maintenance capability enhances system reliability and reduces unplanned outages.

4. Sustainability and Energy Efficiency:

Environmental regulations and corporate sustainability goals are pushing demand for energy-efficient pulley designs. Lightweight yet strong materials, low-friction bearings, and optimized surface finishes contribute to reduced power consumption across conveyor networks.

5. Regional Market Shifts:

Asia-Pacific, particularly China and India, will lead market growth due to rapid industrialization and infrastructure development. North America and Europe will see steady demand driven by modernization of existing facilities and adoption of automation. Latin America and Africa offer emerging opportunities linked to mining and agriculture.

6. Supply Chain Resilience and Localization:

Post-pandemic disruptions have prompted manufacturers to diversify supply chains and localize production. This trend is expected to continue, with regional manufacturing hubs reducing lead times and enhancing responsiveness to market demands.

In conclusion, the 2026 conveyor belt pulley market will be characterized by innovation, digital integration, and a strong emphasis on reliability and sustainability, supporting broader industrial efficiency goals.

Common Pitfalls When Sourcing Conveyor Belt Pulley (Quality, IP)

Sourcing conveyor belt pulleys requires careful evaluation to ensure long-term reliability, safety, and performance. Many buyers fall into common traps that compromise system efficiency and increase maintenance costs. Below are key pitfalls to avoid, particularly concerning quality and intellectual property (IP) concerns.

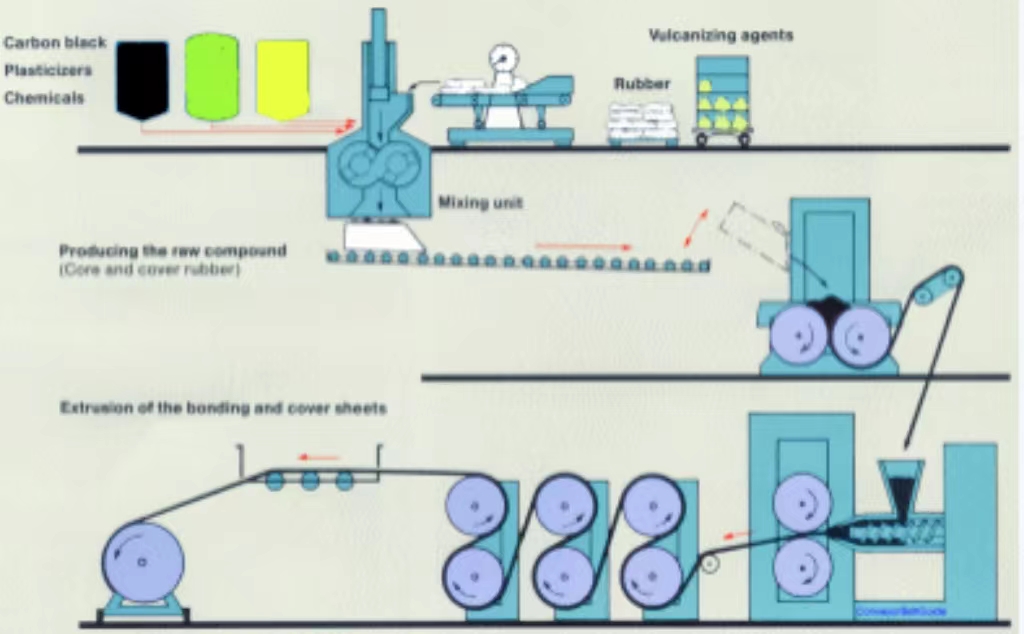

Poor Quality Materials and Manufacturing

One of the most frequent issues is selecting pulleys made from substandard materials or manufactured using inadequate processes. Low-quality steel, improper welding techniques, or insufficient surface treatments (like lagging or coating) can lead to premature wear, corrosion, and structural failure. Always verify material certifications and manufacturing standards (e.g., ISO, ASME) to ensure durability under operational loads.

Inadequate IP Protection and Counterfeit Products

Sourcing from regions with weak intellectual property enforcement can expose buyers to counterfeit or reverse-engineered pulleys. These copies often mimic reputable brands but lack engineering integrity, leading to performance issues and safety risks. Always work with authorized distributors or manufacturers and request proof of IP ownership or licensing, especially for proprietary designs.

Misalignment with Application Requirements

Pulleys must be matched precisely to the conveyor system’s specifications—diameter, face width, shaft size, and load capacity. Choosing an off-the-shelf pulley without proper engineering review can result in belt slippage, increased energy consumption, or mechanical failure. Customization should be verified through technical documentation and design validation.

Lack of Certified Testing and Documentation

Reputable suppliers provide test reports, including dynamic balancing, non-destructive testing (NDT), and load testing. Skipping verification of these documents may result in receiving untested or non-compliant components. Ensure all pulleys come with a Certificate of Conformance and traceable quality records.

Overlooking Environmental and Safety Standards

Pulleys used in hazardous or extreme environments (e.g., mining, food processing) must meet specific IP (Ingress Protection) ratings and industry regulations (e.g., ATEX, FDA). Failing to confirm these ratings can lead to equipment failure or non-compliance with safety standards, risking downtime and liability.

Insufficient Supplier Vetting

Choosing suppliers based solely on price increases the risk of poor quality and IP violations. Conduct thorough due diligence, including site audits, customer references, and review of quality management systems (e.g., ISO 9001). Transparent supply chains reduce the likelihood of counterfeit or subpar components.

Avoiding these pitfalls ensures reliable conveyor system performance and protects your organization from operational, legal, and financial risks.

Logistics & Compliance Guide for Conveyor Belt Pulley

Overview of Conveyor Belt Pulleys

Conveyor belt pulleys are critical components in material handling systems, used to drive, guide, and support conveyor belts in industries such as mining, manufacturing, and bulk material handling. Proper logistics planning and regulatory compliance are essential due to their size, weight, and international shipping requirements.

Packaging and Handling Requirements

Conveyor belt pulleys are heavy, often ranging from several hundred kilograms to multiple tons. They must be securely packaged to prevent damage during transit. Use wooden crates or steel skids with protective wrapping to shield shafts and bearing surfaces. Clearly label packages with weight, center of gravity, lifting points, and orientation arrows. Avoid direct ground contact during storage and transport.

Transportation Modes and Considerations

Select transportation based on pulley dimensions and destination:

– Road Transport: Ideal for regional delivery. Use heavy-duty flatbed trailers with secure lashing. Oversized loads may require permits and escort vehicles.

– Rail Transport: Suitable for long-distance, heavy shipments within continental networks. Confirm loading gauge clearance and crane availability at origin and destination.

– Sea Freight: Preferred for international shipments. Pulleys are typically shipped as breakbulk cargo or in open-top containers. Provide detailed cargo dimensions for stowage planning. Use waterproof wrapping to prevent saltwater corrosion.

Import and Export Compliance

Ensure compliance with international trade regulations:

– HS Code Classification: Use HS Code 8431.31 (parts of conveyor machinery) for customs declarations. Verify country-specific codes to avoid delays.

– Export Controls: Check if pulleys contain controlled materials or technologies (rare in standard pulleys, but verify for specialized designs).

– Documentation: Prepare commercial invoice, packing list, bill of lading/airway bill, certificate of origin, and any required export licenses.

Regulatory and Safety Standards

Adhere to regional and international standards:

– ISO Standards: Follow ISO 12048 for pulley design and safety. Comply with ISO 9001 for quality management during manufacturing.

– CE Marking (EU): Required for pulleys sold in the European Economic Area. Ensure conformity with Machinery Directive 2006/42/EC.

– OSHA & ANSI (USA): Comply with OSHA 29 CFR 1910.212 for machinery guarding and ANSI/ASME B20.1 for safety standards in material handling equipment.

Customs Clearance and Duties

Prepare for customs inspections by providing accurate technical specifications and material declarations. Be aware of:

– Duty Rates: Vary by country; check local tariff schedules.

– Anti-Dumping Measures: Some regions impose additional duties on imported industrial components from specific countries.

– Pre-Arrival Processing: Submit documentation electronically for faster clearance (e.g., ACE in the U.S., AES in the EU).

Environmental and Sustainability Compliance

- REACH (EU): Declare substances of very high concern (SVHC) in materials used, such as coatings or lubricants.

- RoHS Compliance: Ensure no restricted hazardous substances in electrical components (if pulley is motorized).

- Packaging Waste Directive: Use recyclable packaging materials and provide disposal instructions.

On-Site Receiving and Installation Support

Coordinate with the end-user for:

– Unloading Equipment: Confirm availability of cranes or forklifts with sufficient lifting capacity.

– Site Access: Verify road conditions, bridge weight limits, and overhead clearance.

– Technical Support: Provide installation manuals and, if needed, arrange for on-site supervision.

Record Keeping and Traceability

Maintain records of:

– Manufacturing certifications (material test reports, weld inspections)

– Shipping and customs documentation

– Certificates of compliance (CE, ISO, etc.)

This ensures traceability and supports warranty or audit requirements.

Conclusion

Efficient logistics and strict compliance are vital for the successful delivery and deployment of conveyor belt pulleys. Proactive planning, accurate documentation, and adherence to international standards will minimize delays, reduce costs, and ensure safety and regulatory conformity across the supply chain.

Conclusion for Sourcing Conveyor Belt Pulleys

In conclusion, sourcing conveyor belt pulleys requires a strategic approach that balances quality, cost, durability, and supplier reliability. Selecting the right pulley—whether drive, tail, or idler—depends on factors such as the operating environment, load capacity, belt type, and material compatibility. It is essential to partner with reputable suppliers who adhere to industry standards, offer customization options, and provide technical support and after-sales service.

Conducting thorough supplier evaluations, considering total cost of ownership rather than initial price, and ensuring compliance with safety and performance standards are critical steps toward minimizing downtime and extending the lifespan of the conveyor system. By prioritizing these aspects, organizations can ensure efficient, reliable, and cost-effective material handling operations in the long term.

Ultimately, effective sourcing of conveyor belt pulleys contributes significantly to overall operational efficiency, reduced maintenance costs, and improved system performance across industries such as mining, manufacturing, logistics, and aggregate processing.