The global conveyor systems market is experiencing robust growth, driven by rising automation across manufacturing, logistics, and e-commerce sectors. According to a report by Mordor Intelligence, the market was valued at USD 8.62 billion in 2023 and is projected to reach USD 12.21 billion by 2029, growing at a CAGR of 5.9% during the forecast period. Similarly, Grand View Research estimates continued expansion due to increased demand for efficient material handling solutions in industries such as automotive, food and beverage, and pharmaceuticals. As companies prioritize operational efficiency and supply chain optimization, investment in advanced conveyor technologies is accelerating. This surge has intensified competition among manufacturers, fostering innovation in modular designs, energy efficiency, and smart integration with warehouse management systems. Against this backdrop, identifying the top conveyor manufacturers becomes crucial for businesses seeking reliable, scalable, and technologically advanced material handling solutions.

Top 10 Conveyer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Endura

Domain Est. 2001

Website: endura-veyor.com

Key Highlights: Endura-Veyor, Inc. is a leading US manufacturer of high-quality container dumpers, hinged steel belt, drag chain, fabric belt, and magnetic separator conveyors….

#2 QC Conveyors

Domain Est. 2013

Website: qcconveyors.com

Key Highlights: QC Conveyors is a trusted conveyor manufacturer providing custom systems for industrial and automation applications. Fast lead times and expert support….

#3 Conveyor Equipment Manufacturers Association

Domain Est. 1996

Website: cemanet.org

Key Highlights: Leading manufacturers of conveyors and conveying systems in the Americas who design, produce and install all types of conveying machinery and conveyor ……

#4 FMH Conveyors: Conveyor Manufacturer

Domain Est. 2014

Website: fmhconveyors.com

Key Highlights: FMH Conveyors is a leading conveyor company improving your truck loading and unloading efficiency, productivity, and safety in conveyance solutions….

#5 CHAIN WE MACHINERY CO., LTD.

Domain Est. 2015

Website: conveyor-manufacturer.com

Key Highlights: 1 stop service includes planning, designing, manufacturing and after-sales. 30 + years of experience in conveyor designing. 18000 m 2 manufacturing area….

#6 Span Tech Conveyors

Domain Est. 2017

Website: spantechconveyors.com

Key Highlights: Explore Span Tech’s custom conveyors for packaging, food, pharma, and more—built for efficiency, flexibility, and increased productivity….

#7 Shuttleworth

Domain Est. 1996

Website: shuttleworth.com

Key Highlights: Shuttleworth designs and manufactures conveyor systems & material handling systems for a variety of industries & applications….

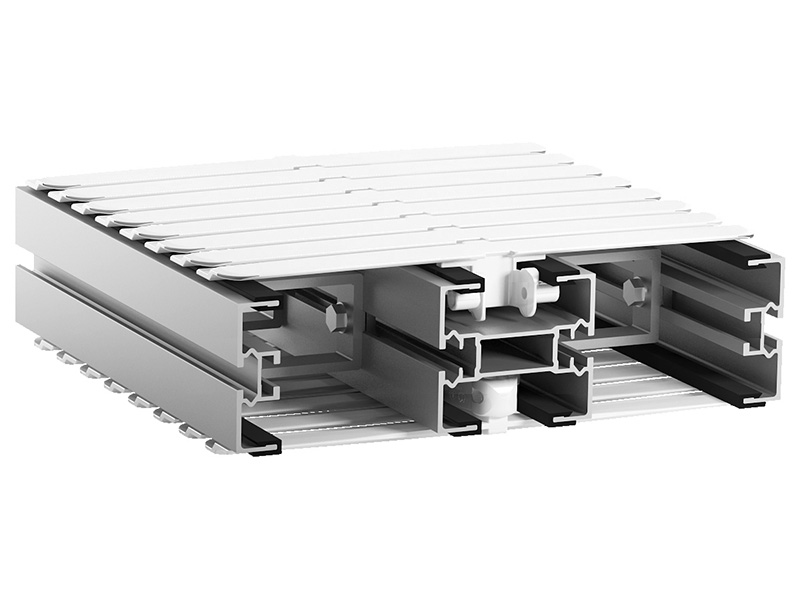

#8 Flexlink

Domain Est. 1997

Website: flexlink.com

Key Highlights: FlexLink is a leading company in the production of automated conveyors systems and robotic palletizing cells for several industries….

#9 SRS Conveyors

Domain Est. 2002 | Founded: 1962

Website: srsconveyors.com

Key Highlights: Since 1962 SRS Conveyors have been designing, manufacturing, Installing and servicing material handling systems around the world….

#10 Conveyor Systems

Domain Est. 2013

Website: nerconconveyors.com

Key Highlights: Nercon designs and manufactures conveyor systems to keep consumer packaged goods moving in ways that are faster, more reliable and more efficient. About Us….

Expert Sourcing Insights for Conveyer

2026 Market Trends for Conveyor Systems

The global conveyor systems market is poised for significant transformation by 2026, driven by advancements in automation, rising e-commerce demand, and the integration of smart technologies across industries. This analysis explores the key trends expected to shape the conveyor market over the next few years.

Growth in Automation and Industry 4.0

Manufacturing and logistics sectors are increasingly adopting Industry 4.0 principles, emphasizing connectivity, data exchange, and intelligent automation. Conveyor systems are evolving from simple material transport mechanisms into intelligent, integrated components of smart factories. By 2026, conveyors equipped with IoT sensors, real-time monitoring, and predictive maintenance capabilities are expected to dominate new installations. This shift enables greater operational efficiency, reduced downtime, and improved scalability.

E-Commerce and Warehouse Automation

The rapid expansion of e-commerce continues to fuel demand for high-speed, flexible conveyor solutions in distribution centers and fulfillment warehouses. As consumers expect faster delivery times, companies are investing heavily in automated sortation systems, cross-belt conveyors, and dynamic routing technologies. By 2026, conveyors integrated with robotics and AI-driven sorting algorithms will be standard in major logistics hubs, especially in North America, Europe, and Asia-Pacific.

Sustainability and Energy Efficiency

Environmental regulations and corporate sustainability goals are pushing manufacturers to develop energy-efficient conveyor systems. Lightweight materials, regenerative drives, and low-friction components are becoming increasingly common. The market is expected to see growth in modular, recyclable conveyor designs that reduce lifecycle environmental impact. By 2026, energy-efficient conveyors will be a key differentiator for suppliers targeting green-certified facilities.

Customization and Modular Design

Industries such as food & beverage, pharmaceuticals, and automotive require conveyors that meet strict hygiene, precision, or load-bearing standards. As a result, demand for customizable and modular conveyor systems is rising. These systems allow quick reconfiguration for different products or production lines, enhancing flexibility. The trend toward plug-and-play modules is expected to accelerate, enabling faster deployment and easier maintenance.

Regional Market Dynamics

Asia-Pacific is projected to be the fastest-growing region for conveyor systems by 2026, driven by industrialization in India and Southeast Asia, along with strong investments in automated manufacturing in China. North America and Europe will continue to lead in adopting high-tech conveyors, particularly in automated warehouses and smart factories. Latin America and the Middle East are emerging markets with growing infrastructure and logistics development.

Conclusion

By 2026, the conveyor systems market will be defined by intelligence, adaptability, and sustainability. Companies that innovate in smart integration, energy efficiency, and modular design will be best positioned to capture market share. As global supply chains demand greater speed and reliability, conveyors will play a central role in the future of industrial automation.

Common Pitfalls in Sourcing Conveyor Systems: Quality and Intellectual Property Risks

When sourcing conveyor systems—especially from international or third-party suppliers—businesses often encounter significant challenges related to quality control and intellectual property (IP) protection. Overlooking these areas can lead to operational disruptions, legal disputes, and financial losses. Below are key pitfalls to avoid.

Quality-Related Pitfalls

Inconsistent Manufacturing Standards

Suppliers, particularly in regions with less stringent regulatory oversight, may not adhere to international quality standards (e.g., ISO, CE). This can result in conveyors that fail prematurely or do not meet safety requirements, leading to downtime and increased maintenance costs.

Lack of Rigorous Supplier Vetting

Failing to conduct thorough audits or site visits can mean partnering with suppliers who lack proven quality management systems. Relying solely on certifications without verification increases the risk of receiving substandard equipment.

Inadequate Testing and Validation

Some suppliers may skip comprehensive performance testing under real-world conditions. Without witnessing prototype testing or reviewing test reports, buyers risk deploying systems that underperform in their specific operational environment.

Poor Documentation and Traceability

Incomplete or missing documentation—such as material certifications, assembly records, or maintenance manuals—can complicate quality assurance, compliance audits, and troubleshooting down the line.

Intellectual Property (IP) Risks

Unprotected Design Specifications

Sharing detailed engineering drawings or proprietary configurations without proper non-disclosure agreements (NDAs) or IP clauses exposes your innovations to misuse. Suppliers may replicate or resell your designs to competitors.

Co-Development Without Clear IP Ownership

When working with suppliers on custom conveyor solutions, ambiguous contracts can lead to disputes over who owns the resulting IP. Without explicit agreements, the supplier may claim rights to design improvements or modifications.

Counterfeit or Reverse-Engineered Components

Some suppliers may use counterfeit or unauthorized components that infringe on third-party patents or trademarks. This not only affects system reliability but can also expose the buyer to legal liability for IP infringement.

Lack of IP Clauses in Contracts

Failing to include enforceable IP protection terms in sourcing agreements—such as assignment of IP rights, restrictions on reverse engineering, and confidentiality obligations—leaves your designs vulnerable, especially in cross-border transactions.

Mitigation Strategies

- Conduct due diligence on suppliers, including quality audits and site inspections.

- Require compliance with recognized industry standards and request test reports.

- Use detailed contracts with robust IP protections, including NDAs and IP assignment clauses.

- Limit the disclosure of sensitive design information to only what is necessary.

- Consider working with legal counsel experienced in international IP law when sourcing globally.

By proactively addressing these quality and IP pitfalls, organizations can secure reliable, compliant conveyor systems while protecting their intellectual assets.

Logistics & Compliance Guide for Conveyor Systems

This guide outlines key logistics considerations and compliance requirements for the installation, operation, and maintenance of conveyor systems in industrial and commercial environments.

Design and Installation

Ensure conveyor systems are designed to meet the specific material handling needs of your facility, including load capacity, speed, and environmental conditions. All installations must comply with local building codes and industrial safety standards such as OSHA (Occupational Safety and Health Administration) in the U.S. or equivalent regional regulations. Secure all necessary permits prior to installation and use certified professionals for assembly and integration.

Safety Compliance

Conveyor systems must adhere to safety standards such as ANSI/ASME B20.1 (Safety Standard for Conveyors and Related Equipment). Required safety features include emergency stop buttons, guarding around moving parts, warning signage, and lockout/tagout (LOTO) procedures. Conduct regular safety audits and provide mandatory training for all personnel operating or working near conveyors.

Operational Logistics

Develop standard operating procedures (SOPs) for conveyor use, including startup, shutdown, and material flow protocols. Schedule routine maintenance to prevent downtime and ensure consistent performance. Use asset tracking systems to monitor conveyor health and predict maintenance needs through condition-based monitoring.

Regulatory Documentation

Maintain comprehensive documentation including equipment manuals, risk assessments, inspection logs, maintenance records, and compliance certifications. This documentation must be readily available for internal audits and regulatory inspections.

Environmental and Energy Compliance

Ensure conveyor systems meet energy efficiency standards and minimize environmental impact. Use energy-efficient motors and consider variable frequency drives (VFDs) to reduce power consumption. Address noise levels in accordance with local environmental regulations and implement dust or debris containment measures where applicable.

Transportation and Supply Chain Integration

When sourcing or relocating conveyor systems, plan logistics carefully to accommodate size, weight, and disassembly requirements. Coordinate with freight carriers experienced in handling industrial equipment and ensure proper packaging and securing during transit. Align conveyor operations with broader supply chain workflows to optimize throughput and inventory management.

Training and Workforce Compliance

Provide documented training for all operators and maintenance staff covering safe operation, hazard recognition, and emergency response. Retain training records to demonstrate compliance with labor and safety regulations.

Incident Reporting and Continuous Improvement

Establish a procedure for reporting and investigating conveyor-related incidents or near misses. Use findings to update safety protocols, improve system design, and reinforce compliance across the organization. Regularly review and update this logistics and compliance guide to reflect changes in regulations or operations.

Conclusion for Sourcing Conveyor Systems:

In conclusion, sourcing a conveyor system requires a comprehensive evaluation of operational needs, material handling requirements, budget constraints, and long-term maintenance considerations. Selecting the right conveyor involves balancing quality, reliability, and cost-effectiveness while ensuring compatibility with existing production processes. By partnering with reputable suppliers, conducting thorough market research, and prioritizing energy efficiency and scalability, organizations can enhance productivity, reduce downtime, and achieve a strong return on investment. Ultimately, a well-sourced conveyor system not only streamlines material flow but also supports sustainable growth and operational excellence.