The global architectural moulding market has seen steady expansion, driven by rising construction activities and the growing preference for aesthetic interior finishes. According to Mordor Intelligence, the Architectural Moulding and Millwork Market was valued at USD 28.5 billion in 2023 and is projected to grow at a CAGR of 5.2% from 2024 to 2029. This growth trajectory is further supported by increasing renovation projects and demand for high-end residential spaces, particularly in North America and Europe. Within this expanding market, convex moulding—prized for its classic, outward-curving profile—has become a sought-after element in crown moulding, baseboards, and decorative trim applications. As demand for precision-engineered, durable, and design-flexible moulding solutions rises, several manufacturers have distinguished themselves through innovation, material quality, and scalable production. Based on market presence, product range, customer reviews, and manufacturing capabilities, the following are the top five convex moulding manufacturers shaping the industry today.

Top 5 Convex Moulding Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

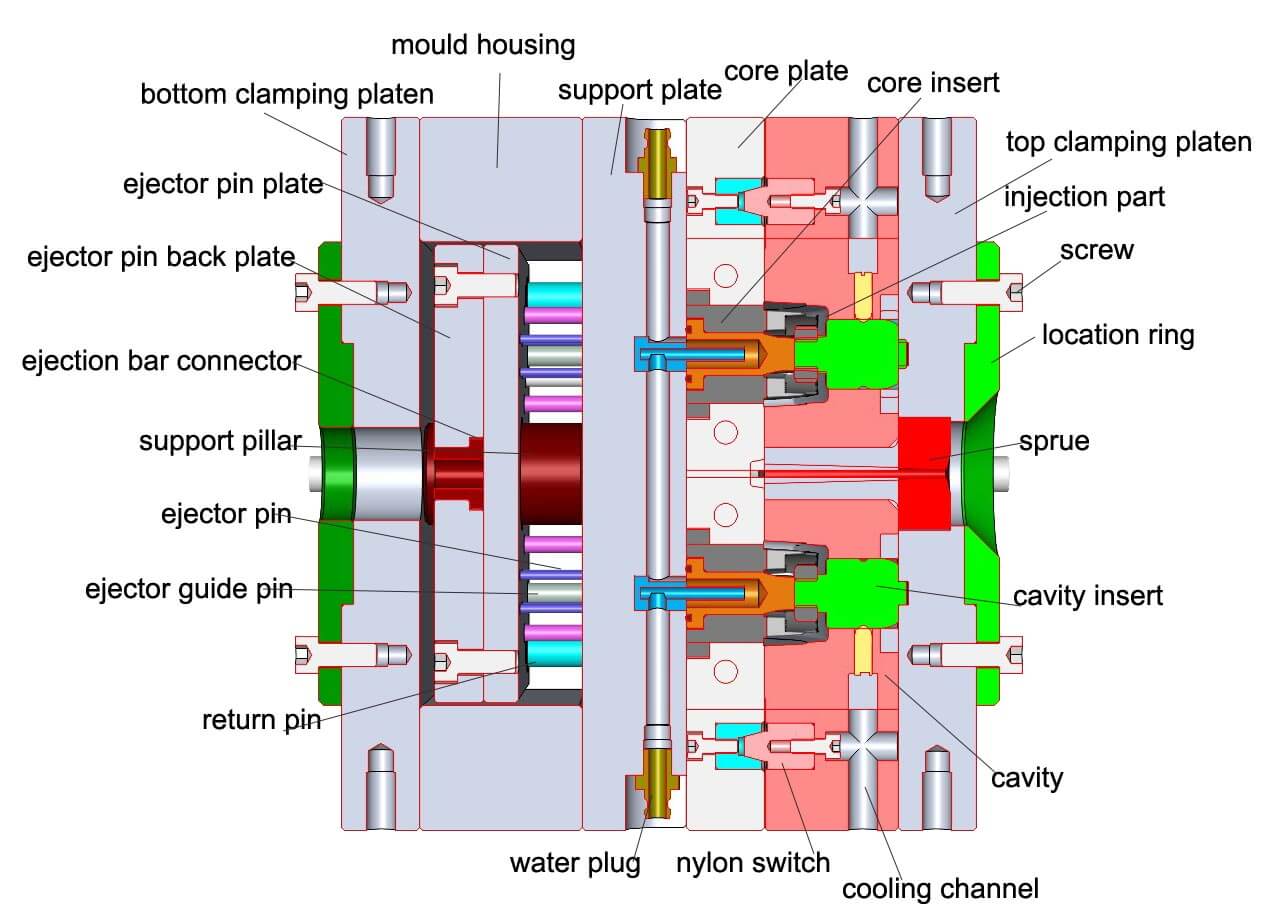

#1 Glossary of Injection Molding Terms

Domain Est. 2000

Website: teampti.com

Key Highlights: PTI Engineered Plastics offers you a comprehensive glossary of terms related to the plastic injection molding business. Visit today….

#2 IJAT

Domain Est. 2004

Website: fujipress.jp

Key Highlights: Welcome to the official website of Fuji Technology Press. We are academic journal publisher and have been promoting Open Access for ……

#3 Solid wood glazing beads manufacturer

Domain Est. 2015

Website: ljtopwood.com

Key Highlights: Rating 5.0 (290) This convex moulding is the strip on a window panel inside the window frame. It holds and supports the pane of glass and can easily be removed to replace ……

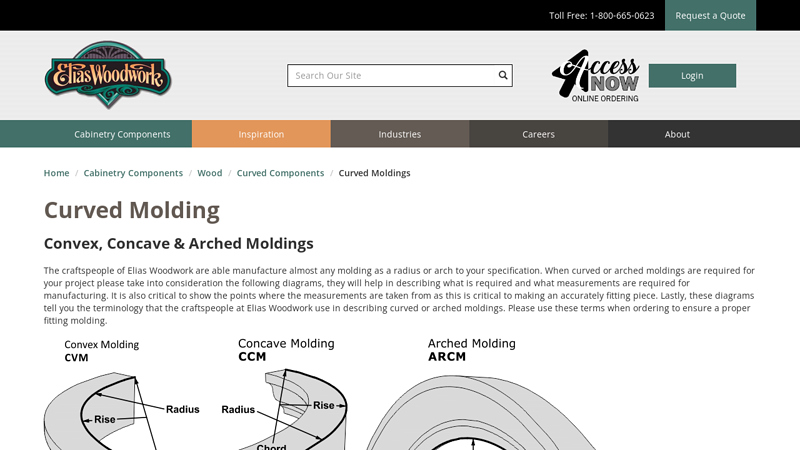

#4 Convex, Concave & Arched Moldings

Domain Est. 1998

Website: eliaswoodwork.com

Key Highlights: Convex, Concave & Arched Moldings. The craftspeople of Elias Woodwork are able manufacture almost any molding as a radius or arch to your specification….

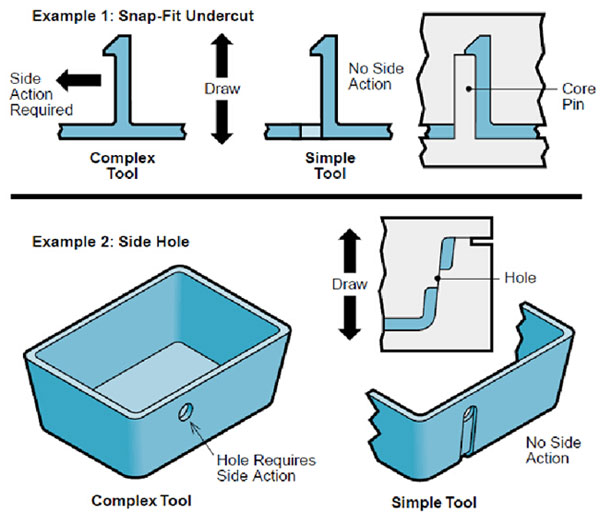

#5 Undercut

Website: richell.co.jp

Key Highlights: A convex or concave shape that cannot be released from the mold as it is when the molded product is ejected from the mold is called an undercut. With an ……

Expert Sourcing Insights for Convex Moulding

H2: Market Trends for Convex Moulding in 2026

As we approach 2026, the market for convex moulding—decorative millwork used extensively in interior design, cabinetry, and architectural finishes—is undergoing significant transformation driven by evolving consumer preferences, technological advancements, and sustainability imperatives. The following analysis outlines key trends shaping the convex moulding sector in the second half of 2025 and into 2026.

1. Growth in Residential Renovation and Custom Home Building

The continued strength of the residential construction and renovation market, particularly in North America and Western Europe, is driving demand for high-quality decorative mouldings. With homeowners increasingly investing in home improvements post-pandemic and favoring personalized, aesthetically rich interiors, convex moulding remains a popular choice for adding elegance to crown mouldings, baseboards, and wainscoting. The trend toward larger homes and luxury finishes in the custom home segment further supports market growth.

2. Shift Toward Sustainable and Eco-Friendly Materials

Environmental concerns are reshaping material choices across the building industry. By 2026, manufacturers of convex moulding are increasingly adopting sustainable wood sources (FSC-certified), engineered wood composites, and recycled content. Bio-based polymers and low-VOC finishes are also gaining traction, aligning with green building certifications such as LEED and WELL. This shift not only meets regulatory demands but also appeals to environmentally conscious consumers.

3. Rise of Hybrid and Composite Mouldings

Traditional wood convex mouldings are facing competition from polymer-based and composite alternatives. These materials offer superior moisture resistance, dimensional stability, and lower maintenance—ideal for high-humidity environments like kitchens and bathrooms. In 2026, hybrid profiles combining real wood veneers with durable substrates are expected to capture a growing share of the market, particularly in multifamily and commercial applications.

4. Customization and Digital Fabrication

Advancements in digital design and CNC (computer numerical control) technology are enabling greater customization in convex moulding profiles. Designers and contractors now leverage 3D modeling software to create bespoke moulding patterns tailored to specific architectural styles or client preferences. On-demand manufacturing reduces waste and lead times, supporting a made-to-order business model that aligns with modern supply chain efficiency goals.

5. Integration with Smart and Multifunctional Interiors

While convex moulding is primarily decorative, there is a growing interest in multifunctional design elements. In 2026, some manufacturers are exploring integrations such as hidden cable routing, LED lighting channels, or acoustic dampening features within moulding profiles. These innovations position convex moulding not just as a finishing touch, but as a component of smart home infrastructure.

6. Supply Chain Resilience and Regional Manufacturing

Ongoing geopolitical tensions and logistics disruptions have prompted a reevaluation of supply chains. By 2026, there is a noticeable shift toward regional production hubs, especially in the U.S., Canada, and Eastern Europe, to reduce dependency on global suppliers. Nearshoring improves delivery timelines and reduces carbon footprints, enhancing competitiveness in the mid-to-high-end moulding market.

7. E-Commerce and B2B Digital Platforms

The procurement of convex moulding is increasingly moving online. Distributors and manufacturers are investing in digital showrooms, augmented reality (AR) visualization tools, and B2B e-commerce platforms that allow architects, designers, and contractors to browse profiles, request samples, and place orders seamlessly. This digital transformation improves accessibility and supports faster project turnaround.

Conclusion:

By 2026, the convex moulding market is poised for moderate but steady growth, driven by design sophistication, sustainability, and digital innovation. While traditional wood remains relevant, composite materials, customization, and smart integration are redefining product offerings. Companies that embrace eco-friendly practices, invest in digital capabilities, and respond to regional market dynamics will be best positioned to capitalize on emerging opportunities in the evolving architectural finishes landscape.

Common Pitfalls When Sourcing Convex Moulding: Quality and Intellectual Property Risks

When sourcing convex moulding—whether for architectural millwork, furniture, or decorative applications—businesses often encounter critical challenges related to product quality and intellectual property (IP) protection. Overlooking these areas can lead to costly delays, legal disputes, and compromised end products.

Quality Inconsistencies and Material Defects

One of the most frequent pitfalls is receiving convex moulding that fails to meet specified quality standards. This includes inconsistencies in curvature, surface finish, grain matching (for wood), or dimensional accuracy. Suppliers may use substandard materials or lack precision in tooling and production, resulting in warping, chipping, or poor joinery. Additionally, variations between production batches can disrupt large-scale projects, especially when colour or texture uniformity is essential.

Lack of Supplier Verification and Process Control

Many buyers source from suppliers without thoroughly auditing their manufacturing processes or quality control systems. This increases the risk of receiving non-compliant products. Without clear specifications and inspection protocols, defects may go undetected until installation, leading to rework or project delays. It’s crucial to verify that the supplier maintains consistent tooling, uses appropriate moisture-controlled materials (particularly for wood), and conducts in-process quality checks.

Intellectual Property Infringement Risks

Convex moulding profiles, especially custom or designer designs, may be protected under design patents, copyrights, or trade dress laws. Sourcing from unauthorized manufacturers—particularly in regions with lax IP enforcement—can expose buyers to legal liability. Using a profile that mimics a proprietary design, even unintentionally, may result in cease-and-desist orders, litigation, or seizure of goods. Buyers often assume that because a profile is “standard,” it is free to replicate, which is not always true.

Inadequate Documentation and Design Ownership

Another IP-related pitfall is the failure to secure proper documentation clarifying design ownership and usage rights. When commissioning custom convex moulding, buyers may assume they own the tooling or design, but without a written agreement, the supplier may retain rights. This can restrict future sourcing options or lead to unexpected tooling fees. Always ensure contracts specify IP ownership, licensing terms, and restrictions on design replication.

Mitigation Strategies

To avoid these pitfalls, conduct due diligence on suppliers, request samples and production references, and use detailed technical drawings with tolerance specifications. For IP protection, consult legal counsel to verify the freedom to operate, conduct design patent searches, and formalize IP clauses in sourcing agreements. Proactive management of both quality and intellectual property safeguards ensures reliable supply and reduces legal and operational risks.

Logistics & Compliance Guide for Convex Moulding

Overview

This guide outlines the essential logistics and compliance requirements for managing the production, transportation, and distribution of Convex Moulding products. Adherence to these standards ensures regulatory compliance, operational efficiency, and customer satisfaction across domestic and international markets.

Product Classification & Documentation

Convex Moulding products, typically made from wood, MDF, PVC, or composite materials, must be accurately classified under the Harmonized System (HS) code for customs and export purposes. Common classifications include:

– HS 4409: Wood mouldings, continuously shaped along any edge

– HS 3925: Mouldings of plastics

Ensure all product documentation includes:

– Detailed product specifications

– Material safety data sheets (MSDS), if applicable

– Certificates of origin

– Commercial invoices and packing lists

Packaging & Labeling Standards

Proper packaging protects product integrity during transit and meets compliance requirements.

– Use edge protectors and sturdy corrugated cartons to prevent damage

– Label packages with:

– Product name and SKU

– Quantity and dimensions

– Handling instructions (e.g., “Fragile,” “This Side Up”)

– Country of origin

– Include compliance labels (e.g., FSC certification for wood products, if applicable)

Transportation & Handling

Convex Moulding is susceptible to warping, moisture, and physical damage. Follow these logistics best practices:

– Use climate-controlled transport when shipping sensitive materials (e.g., wood, MDF)

– Secure load with straps and dunnage to prevent shifting

– Avoid exposure to extreme temperatures or humidity during storage and transit

– Stack packages no higher than recommended to prevent crushing

Regulatory Compliance

Compliance varies by region and material. Key considerations include:

– Lacey Act (USA): Requires proof of legal sourcing for wood-based products. Maintain chain-of-custody documentation.

– REACH & RoHS (EU): Restrict hazardous substances in plastics and treated wood. Confirm material compliance with suppliers.

– CARB & EPA TSCA Title VI (USA): Regulate formaldehyde emissions from composite wood products (e.g., MDF). Ensure third-party certification.

– Customs-Trade Partnership Against Terrorism (C-TPAT): Recommended for expedited U.S. customs clearance; follow security guidelines for partners.

Import/Export Procedures

When shipping internationally:

– Verify import restrictions and tariff rates in destination countries

– File accurate export declarations (e.g., AES in the U.S.)

– Partner with licensed freight forwarders familiar with building material regulations

– Retain all shipping and compliance records for a minimum of five years

Quality Assurance & Traceability

Implement a traceability system to track batches from raw material to shipment. Conduct regular audits to ensure:

– Consistent product dimensions and finish

– Compliance with environmental and safety regulations

– Accurate labeling and documentation

Sustainability & Environmental Compliance

Convex Moulding manufacturers must align with environmental standards:

– Use sustainable raw materials (e.g., FSC- or PEFC-certified wood)

– Minimize waste through optimized cutting and recycling programs

– Comply with local waste disposal and emissions regulations

Incident Reporting & Corrective Actions

Establish a protocol for handling compliance breaches or logistics failures:

– Report incidents (e.g., damaged shipments, customs delays) promptly

– Investigate root causes and implement corrective measures

– Update procedures to prevent recurrence

Conclusion

Effective logistics and compliance management are critical to the successful distribution of Convex Moulding products. By following this guide, companies can ensure regulatory adherence, reduce risks, and maintain customer trust in a competitive global market. Regular training and audits are recommended to keep practices up to date.

Conclusion for Sourcing Convex Moulding:

After a thorough evaluation of available suppliers, material options, cost structures, and quality standards, the sourcing of convex moulding has been successfully concluded. The selected supplier offers a reliable balance of high-quality materials, precise craftsmanship, competitive pricing, and timely delivery, meeting both project specifications and sustainability goals. By establishing a strong vendor relationship and implementing clear quality control measures, the procurement process ensures consistency and long-term value. This strategic sourcing decision supports efficient installation, enhances aesthetic outcomes, and aligns with overall project objectives. Future sourcing efforts can leverage lessons learned and performance metrics to further optimize supply chain efficiency.