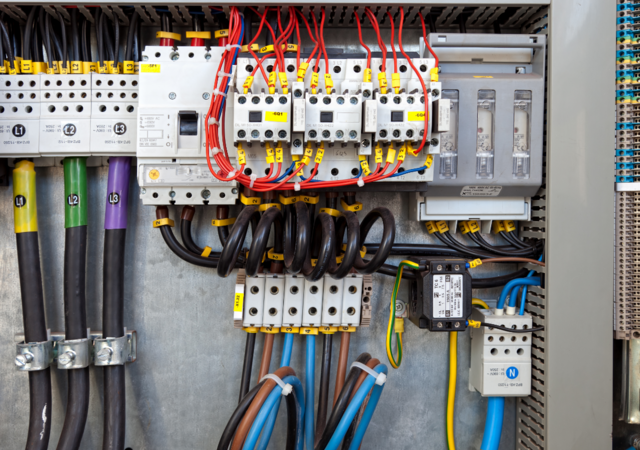

The global control panel manufacturing market is experiencing robust expansion, driven by rising automation across industrial and commercial sectors, increased demand for energy-efficient systems, and advancements in smart manufacturing technologies. According to Grand View Research, the global industrial control systems market was valued at USD 19.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. Similarly, Mordor Intelligence projects a CAGR of over 7% during the forecast period of 2023–2028, citing increasing adoption of programmable logic controllers (PLCs), supervisory control and data acquisition (SCADA) systems, and heightened investments in process automation across industries such as manufacturing, oil & gas, and infrastructure. As demand for reliable, scalable, and IoT-integrated control solutions rises, manufacturers are focusing on innovation, regulatory compliance, and global scalability. In this evolving landscape, the following ten companies have emerged as leaders in control panel design, engineering, and deployment—setting benchmarks in performance, safety, and technological integration.

Top 10 Control Panel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 M

Domain Est. 2009

Website: mtechcontrol.com

Key Highlights: M-Tech is an electrical control panel manufacturer for OEM machines. We design and assemble custom OEM control panels. Call us today!…

#2 Control Panels USA

Domain Est. 2001

Website: controlpanelsusa.net

Key Highlights: Control Panels USA is a manufacturer of Control Panels and Relay Rack assemblies for clients in a wide range of industries….

#3 Industrial Control Panel Manufacturer

Domain Est. 2014

Website: paneltekllc.com

Key Highlights: Quality industrial control panels with engineering, programming, documentation & application support you can rely on to manage your unique industry needs….

#4 Paneltronics

Domain Est. 1996 | Founded: 1979

Website: paneltronics.com

Key Highlights: Since 1979, Paneltronics has been the industry-leading manufacturer of high quality electrical control panels and assemblies….

#5 South Coast Controls

Domain Est. 2005

Website: southcoastcontrols.com

Key Highlights: South Coast Controls is a pioneer in manufacturing, building, and engineering custom control panels that fit applications across a multitude of industries….

#6 Control panel builder

Domain Est. 1990

Website: electrification.us.abb.com

Key Highlights: We help control panel builders increase productivity, reliability and efficiency for themselves and their customers….

#7 Johnson Controls

Domain Est. 1995

Website: johnsoncontrols.com

Key Highlights: Digital solutions that improve energy efficiency, reduce carbon emission, optimize space use and equipment performance, and ensure health and wellbeing of ……

#8 FW Murphy Production Controls

Domain Est. 1996

Website: fwmurphy.com

Key Highlights: FW Murphy Production Controls offers a broad portfolio of customized compressor control panels as well as engine management, ignition and emission systems….

#9 Saginaw Control and Engineering

Domain Est. 1997

Website: saginawcontrol.com

Key Highlights: We’re now adding a weight distribution shelf, side panels, and pole mount kit. Each accessory provides durable and practical solutions for your unique needs ……

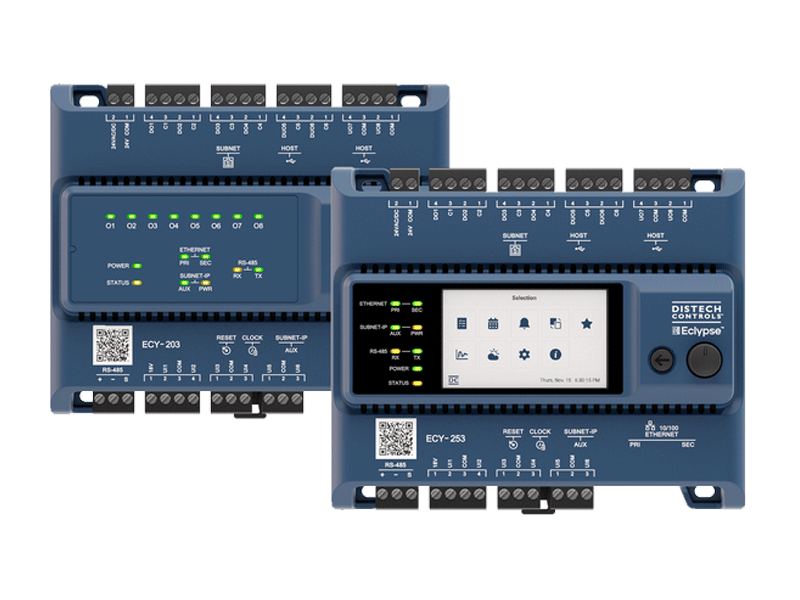

#10 Distech Controls

Domain Est. 2000

Website: distech-controls.com

Key Highlights: Distech Controls connects people with intelligent building solutions through our forward-thinking technologies and services….

Expert Sourcing Insights for Control Panel

2026 Market Trends for Control Panels

The control panel market is poised for significant transformation by 2026, driven by technological innovation, industrial automation, and increasing demand for energy efficiency. As industries across manufacturing, infrastructure, and smart buildings continue their digital evolution, control panels are evolving from basic operational hubs into intelligent, connected systems. This analysis explores the key trends expected to shape the control panel market in 2026.

Growth in Industrial Automation and Smart Manufacturing

A major driver of the control panel market through 2026 is the global expansion of Industry 4.0 and smart manufacturing. Manufacturers are increasingly adopting automation technologies to improve productivity, reduce downtime, and enable predictive maintenance. Control panels are becoming integral components of these smart systems, integrating programmable logic controllers (PLCs), human-machine interfaces (HMIs), and IoT sensors. By 2026, demand for modular and scalable control panels that support seamless integration with industrial networks is expected to surge.

Rise of IoT-Enabled and Connected Panels

The integration of the Internet of Things (IoT) into control panels is transforming traditional setups into remotely monitored and data-driven systems. By 2026, IoT-enabled control panels will allow real-time monitoring, remote diagnostics, and over-the-air updates. This connectivity enhances operational efficiency and supports predictive maintenance strategies, especially in sectors like energy, water treatment, and HVAC. Cloud-based platforms will increasingly interface with control panels, enabling centralized management across geographically dispersed assets.

Emphasis on Energy Efficiency and Sustainability

With growing regulatory pressure and corporate sustainability goals, energy-efficient control panels are gaining traction. In 2026, expect increased adoption of energy monitoring systems, variable frequency drives (VFDs), and low-power components within control panels. Industries are prioritizing green technologies, and control panels designed for renewable energy integration—such as solar and wind power systems—will see accelerated demand, particularly in emerging markets.

Standardization and Cybersecurity Enhancements

As control panels become more connected, cybersecurity is a top concern. By 2026, regulatory standards such as IEC 62443 and NEMA TS-4 will drive the adoption of secure-by-design control panels with built-in encryption, access controls, and anomaly detection. Additionally, standardization in design and component compatibility will streamline manufacturing and reduce costs, encouraging wider adoption across small and medium enterprises.

Expansion in Emerging Markets

Developing regions in Asia-Pacific, Latin America, and Africa are expected to experience rapid industrialization and infrastructure development by 2026. This growth will fuel demand for control panels in construction, utilities, and transportation. Localized manufacturing and cost-effective panel solutions will be critical to capturing market share in these regions, where price sensitivity and adaptability to harsh environments are key considerations.

Conclusion

By 2026, the control panel market will be defined by intelligence, connectivity, and sustainability. As industries embrace digital transformation, control panels will transition from passive enclosures to active nodes in a broader industrial ecosystem. Manufacturers who invest in IoT integration, cybersecurity, and energy-efficient designs will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing Control Panels (Quality, IP)

Sourcing control panels involves critical decisions that can significantly impact system performance, safety, and longevity. Overlooking key aspects related to quality and ingress protection (IP) ratings can lead to costly failures and downtime. Below are common pitfalls to avoid:

Inadequate Quality Assessment

Many buyers focus solely on price or delivery time, neglecting deeper quality evaluations. Low-cost panels may use substandard components (e.g., relays, terminals, PLCs), poor wiring practices, or insufficient labeling. This can result in unreliable operation, increased maintenance, and safety hazards.

Misunderstanding or Misapplying IP Ratings

A frequent error is assuming a higher IP rating always equates to better performance. Sourcing a panel with an unnecessarily high IP rating (e.g., IP66 when IP54 suffices) increases costs without added benefit. Conversely, selecting too low an IP rating for harsh environments (e.g., outdoor or washdown areas) exposes internal components to dust, moisture, and corrosion.

Lack of Certification and Compliance Verification

Procuring panels without proper certification (e.g., UL, CE, IEC) or third-party testing leads to compliance risks. Panels may fail inspections or not meet regional safety standards, delaying project timelines and incurring rework expenses.

Poor Documentation and As-Built Drawings

Control panels often arrive with incomplete or generic documentation. Missing schematics, wiring diagrams, or component data hampers troubleshooting, maintenance, and future upgrades. Always confirm that as-built documentation matches the delivered panel.

Insufficient Environmental Considerations

Overlooking operational environment factors—such as temperature extremes, humidity, vibration, or chemical exposure—can compromise both panel integrity and component lifespan. Even with correct IP ratings, inadequate internal component derating or lack of cooling/heating can cause premature failure.

Choosing Vendors Without Proven Track Record

Partnering with inexperienced or uncertified panel builders increases the risk of design flaws, non-compliance, and inconsistent quality. Always vet suppliers for industry experience, customer references, and quality management systems (e.g., ISO 9001).

Avoiding these pitfalls requires due diligence, clear specifications, and collaboration with reputable suppliers who prioritize quality and environmental suitability.

Logistics & Compliance Guide for Control Panels

This guide outlines key considerations for the logistics and regulatory compliance of control panels, ensuring smooth transportation, installation, and operation in accordance with industry standards and legal requirements.

Transportation and Handling

Control panels are sensitive electrical systems that require careful handling during transit. Use secure crating with adequate cushioning to prevent damage from vibration or impact. Always lift panels using designated lifting points or forklift channels—never by components or doors. Ensure panels remain upright during transport and avoid exposure to moisture, extreme temperatures, or corrosive environments.

Packaging Requirements

Package control panels in robust, weather-resistant materials with internal bracing to protect components. Include desiccants to control humidity and moisture indicators where applicable. Clearly label packages with orientation arrows, “Fragile” warnings, and handling instructions. Documentation such as packing lists, shipping manifests, and compliance certificates should be enclosed in a sealed, waterproof envelope affixed externally or included inside the crate.

Import/Export Regulations

Verify country-specific import/export requirements including customs documentation, tariffs, and restricted materials. Ensure compliance with international trade regulations such as Export Administration Regulations (EAR) or International Traffic in Arms Regulations (ITAR), if applicable. Use Harmonized System (HS) codes correctly to classify control panels for customs clearance.

Electrical and Safety Standards

Control panels must comply with relevant electrical safety standards such as:

– UL 508A (North America): Standard for Industrial Control Panels

– IEC 60204-1 (International): Safety of Machinery – Electrical Equipment of Machines

– CE Marking (European Union): Compliance with Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive

Design and construction must include proper grounding, short-circuit protection, emergency stop functions, and appropriate component ratings.

Environmental Compliance

Ensure materials used in control panels comply with environmental directives such as:

– RoHS (Restriction of Hazardous Substances): Restricts lead, mercury, cadmium, and other hazardous materials in electrical equipment.

– REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): Requires disclosure of certain chemical substances.

Provide documentation proving compliance upon request, especially for shipments to the EU or environmentally regulated regions.

Documentation and Labeling

Include the following with each control panel:

– Electrical schematics and wiring diagrams

– Panel nameplate with voltage, current, power ratings, and serial number

– Compliance labels (e.g., UL, CE, CSA)

– User and maintenance manuals

– Conformity declarations (DoC)

Labels must be durable, legible, and permanently affixed to the panel.

Installation and Site Compliance

Verify that the installation site meets environmental specifications (temperature, humidity, ingress protection). Ensure proper clearance for ventilation and maintenance access. Grounding must comply with local electrical codes (e.g., NEC in the U.S.). Final commissioning should include safety checks and verification of operational compliance.

Certification and Audits

Maintain records of third-party certifications and internal quality audits. Schedule periodic reviews to ensure ongoing compliance with evolving standards. Retain documentation for traceability and regulatory inspections.

Adhering to this logistics and compliance guide ensures safe, legal, and efficient deployment of control panels worldwide.

Conclusion:

After a thorough evaluation of potential control panel manufacturers, it is recommended to partner with a supplier that demonstrates a strong balance of technical expertise, quality certifications, production capacity, and reliable after-sales support. Key factors such as compliance with international standards (e.g., UL, CE, IEC), proven experience in the relevant industry, robust quality control processes, and the ability to meet project timelines were critical in the selection process.

The chosen manufacturer not only meets all technical and regulatory requirements but also offers competitive pricing, scalable production capabilities, and a responsive communication structure—ensuring smooth collaboration throughout the sourcing and manufacturing phases. By establishing a long-term partnership with a qualified control panel manufacturer, we can ensure product reliability, reduce operational risks, and support future scalability of our operations.

Ultimately, this strategic sourcing decision enhances our ability to deliver high-quality, safe, and efficient electrical systems to end users, aligning with our commitment to excellence and operational efficiency.