The global HVAC market is experiencing robust expansion, driven by rising urbanization, increasing energy efficiency demands, and growing residential and commercial infrastructure development. According to Grand View Research, the global air conditioning market was valued at USD 103.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. A key segment within this landscape is control panel air conditioners—systems that integrate advanced controls for precise temperature management, energy optimization, and remote monitoring. With industrial automation and smart building technologies accelerating adoption, demand for reliable, high-performance control panels has surged. As manufacturers increasingly focus on IoT-enabled solutions and energy-efficient designs, identifying the leading players in control panel air conditioner production becomes critical for stakeholders across construction, manufacturing, and facility management sectors. This analysis highlights the top 10 manufacturers shaping this evolving market.

Top 10 Control Panel Air Conditioner Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 First Co.

Domain Est. 1996

Website: firstco.com

Key Highlights: First Co., an HVAC manufacturer in Dallas, specializes in innovative heating and cooling systems for residential, multi-occupant, and commercial ……

#2 Thermoelectric Air Conditioners, cold plates, liquid chillers, Peltier …

Domain Est. 1996

Website: thermoelectric.com

Key Highlights: TECA Corp. leading manufacturer of thermoelectric air conditioners, cold plates, liquid chillers, panel coolers, enclosure coolers, kiosk coolers….

#3 Friedrich Air Conditioning: Room Air Conditioning Expert

Domain Est. 1998

Website: friedrich.com

Key Highlights: Founded in 1883, Friedrich Air Conditioning Co. is a leading US manufacturer of premium room A/C and other home environment products….

#4 HVAC Equipment

Domain Est. 1995

Website: johnsoncontrols.com

Key Highlights: Johnson Controls’ extensive portfolio of HVAC equipment and controls for efficient, reliable climate control in healthy buildings….

#5 YORK

Domain Est. 1995

Website: york.com

Key Highlights: From cooling systems and heating systems to HVAC components that control humidity, YORK provides indoor air quality solutions for the way you live today….

#6 Climate Control

Domain Est. 1996

#7 Saginaw Control and Engineering

Domain Est. 1997

Website: saginawcontrol.com

Key Highlights: Saginaw Control & Engineering now offers vortex cooling for your enclosure cooling needs! A vortex cooler uses compressed air to increase your cooling capacity ……

#8 Lennox

Domain Est. 1997

Website: lennox.com

Key Highlights: Explore Lennox comfort and energy-efficient solutions for heating and cooling your space. Upgrade your home’s HVAC system with industry-leading solutions….

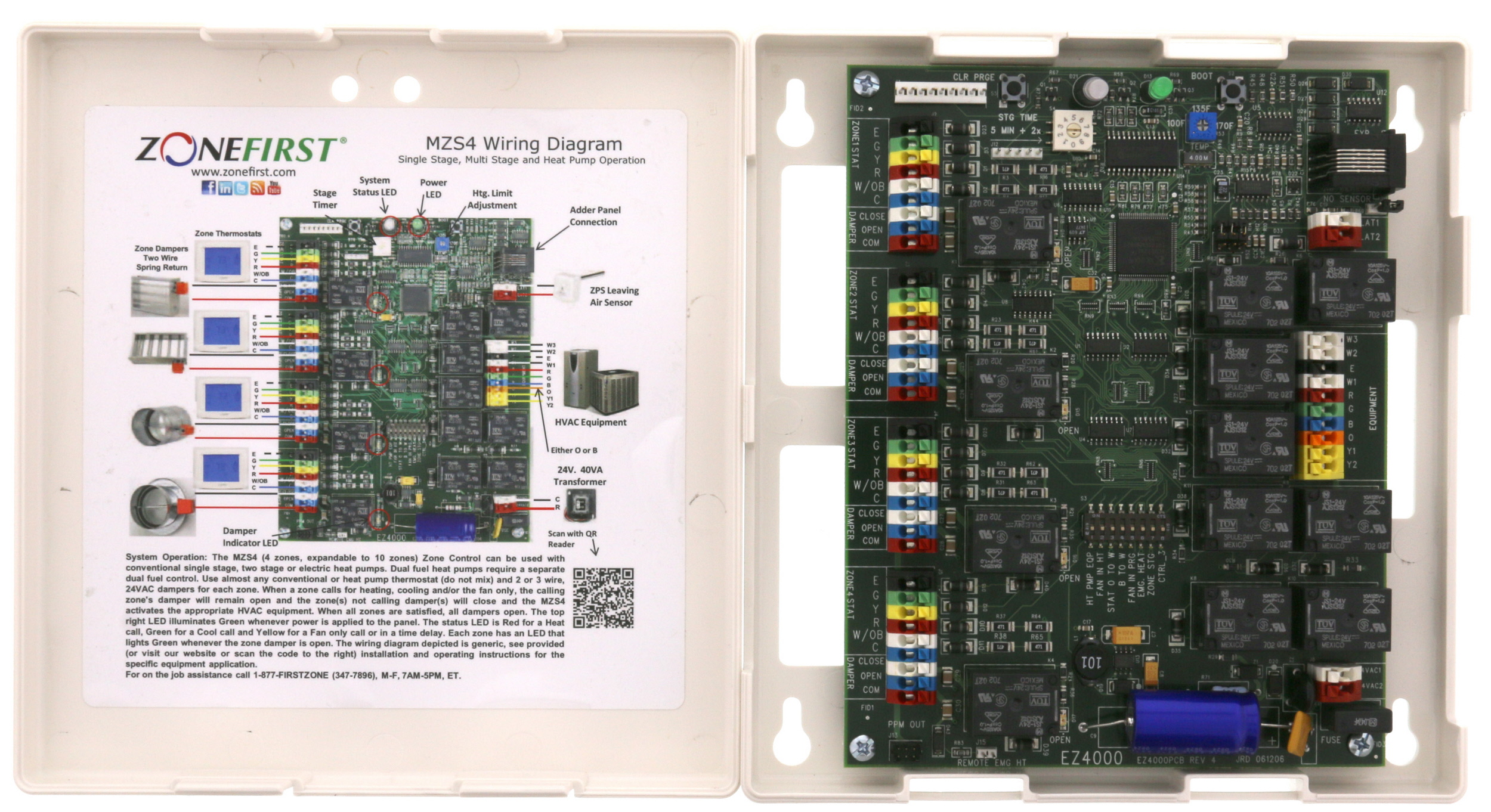

#9 HVAC Zone Control Panels

Domain Est. 2006

Website: zonefirst.com

Key Highlights: 6-day deliveryZone controllers from ZONEFIRST are HVAC control panels that regulate heating, cooling, and fan systems based on the demands of a zone’s thermostat….

#10 Control panel cooling unit (ENC)

Domain Est. 2011

Website: apiste-global.com

Key Highlights: Using control panel cooling units to reduce temperature increase by 20°C can extend the life of electronic devices by more than four times. Dust protection. The ……

Expert Sourcing Insights for Control Panel Air Conditioner

H2: 2026 Market Trends for Control Panel Air Conditioners

The Control Panel Air Conditioner (CPAC) market is poised for significant transformation by 2026, driven by industrial digitization, sustainability mandates, and evolving operational demands. Here are the key trends shaping this specialized segment:

1. Accelerated Integration of IIoT and Smart Controls:

By 2026, IIoT (Industrial Internet of Things) connectivity will be a baseline feature. CPACs will increasingly embed sensors and communication modules (e.g., Modbus, Ethernet/IP, MQTT) enabling real-time remote monitoring of temperature, humidity, power consumption, and filter status. Integration with PLCs and SCADA systems will allow predictive maintenance alerts and adaptive cooling based on environmental or operational loads, minimizing downtime.

2. Dominance of Energy Efficiency and Sustainability:

Stringent global regulations (e.g., EU F-Gas phase-down, U.S. EPA standards) will push demand toward ultra-low-GWP (Global Warming Potential) refrigerants like R-1234ze or R-290. High-efficiency components (EC fans, variable-speed compressors) and intelligent control algorithms will be standard. CPACs will contribute to ESG (Environmental, Social, Governance) goals, with manufacturers emphasizing lifecycle energy analysis and recyclability.

3. Rise of Compact and Modular Designs:

Space constraints in modern control panels (especially in renewable energy, EV charging, and data centers) will drive demand for smaller, higher-capacity units. Modular designs allowing easy expansion, service, or retrofitting of legacy panels will gain traction, reducing installation time and costs.

4. Enhanced Cybersecurity Features:

As CPACs become networked devices, cybersecurity will be critical. By 2026, CPACs with secure boot, encrypted communications, and compliance with standards like IEC 62443 will be preferred, especially in critical infrastructure (utilities, transportation).

5. Expansion in High-Growth Sectors:

Demand will surge in electric vehicle (EV) charging stations, battery energy storage systems (BESS), 5G infrastructure, and semiconductor manufacturing. These applications require precise, reliable thermal management in harsh or high-density environments, accelerating innovation in CPAC durability and performance.

6. Shift Toward Preventive and Predictive Maintenance Models:

CPACs will provide actionable data (e.g., compressor run hours, dew point trends) to enable shift from reactive to predictive maintenance. OEMs will offer subscription-based monitoring services, bundling hardware with cloud analytics platforms.

Conclusion:

By 2026, the Control Panel Air Conditioner market will evolve from a basic thermal solution to an intelligent, connected component of industrial ecosystems. Success will depend on manufacturers’ ability to deliver energy-efficient, secure, and data-enabled solutions tailored to high-growth, technologically advanced industries.

Common Pitfalls When Sourcing Control Panel Air Conditioners (Quality and IP Rating)

Sourcing the right control panel air conditioner is critical for ensuring the reliable operation of electrical enclosures. However, several common pitfalls related to quality and Ingress Protection (IP) ratings can compromise performance and lead to costly failures. Being aware of these issues helps in making informed procurement decisions.

Overlooking IP Rating Compatibility with the Environment

One of the most frequent mistakes is selecting an air conditioner with an IP rating that does not match the operating environment. For example, using an IP54-rated unit in a washdown or outdoor setting where IP65 or higher is required can result in moisture and dust ingress, leading to electrical faults or corrosion. Always verify that the air conditioner’s IP rating meets or exceeds the enclosure’s and site’s environmental demands.

Assuming Higher IP Ratings Guarantee Better Quality

While a high IP rating indicates good protection against solids and liquids, it does not equate to overall product quality. Some manufacturers may advertise high IP ratings but use substandard compressors, poor insulation, or inferior control electronics. This can result in premature failure, inefficient cooling, or unreliable temperature control despite adequate sealing.

Ignoring Build Quality and Component Standards

Low-cost units often cut corners on materials and components—such as using plastic housings instead of stainless steel, low-grade refrigerants, or non-industrial-grade fans. These compromises reduce durability, especially in demanding industrial environments. Always assess the construction materials, compressor type, and certifications (e.g., CE, UL) to ensure robust, long-term performance.

Failing to Verify Third-Party IP Certification

Some suppliers claim IP ratings without independent testing or certification. Relying on self-declared ratings can be risky. Always request test reports or certifications from recognized bodies to confirm the stated IP rating. Units tested under IEC 60529 standards provide reliable assurance of ingress protection.

Mismatched Cooling Capacity and Ambient Conditions

Selecting a unit based solely on size without considering ambient temperature, heat load, and enclosure size can lead to underperformance. Poor-quality units may also overstate their cooling capacity. Always cross-check technical specifications with real-world performance data and consider derating in high-temperature environments.

Neglecting Maintenance and Serviceability

Even high-IP-rated units require periodic maintenance. Some designs make cleaning filters or accessing internal components difficult, increasing downtime and long-term costs. Evaluate ease of service and availability of spare parts when assessing quality—especially for sealed units marketed as “maintenance-free,” which may hide accessibility issues.

Choosing Based on Price Alone

The cheapest option often leads to higher total cost of ownership due to failures, energy inefficiency, and downtime. Investing in a reputable brand with proven reliability and proper IP certification reduces risk and ensures the control panel remains protected under varying conditions.

By avoiding these common pitfalls, buyers can ensure they select a control panel air conditioner that delivers reliable performance, appropriate environmental protection, and long-term value.

Logistics & Compliance Guide for Control Panel Air Conditioners

This guide outlines key logistics considerations and compliance requirements for the safe, efficient, and legal handling, transportation, and installation of Control Panel Air Conditioners.

Product Classification and HS Code

Control Panel Air Conditioners are typically classified under international trade tariff systems as specialized air conditioning units for enclosures. The most common Harmonized System (HS) Code is 8414.59.00 (Air conditioning machines, combining a fan with a cooling unit, other than those of subheading 8414.51 or 8414.52). Confirm the specific code with your customs broker based on technical specifications, as variations may apply.

Packaging and Handling Requirements

Use robust, manufacturer-recommended packaging to protect units during transit. Palletize securely, ensuring units are firmly strapped and protected from moisture and physical damage. Always handle the air conditioner in an upright position to prevent oil leakage from the compressor. Avoid tilting beyond 45 degrees during loading, unloading, or transport.

Transportation Regulations

Ship via ground or air freight depending on urgency and destination. For air transport, ensure compliance with IATA Dangerous Goods Regulations if the unit contains refrigerant classified as hazardous (e.g., certain quantities of R134a or R407C may require special labeling and documentation). Ground shipments must comply with national regulations such as FMCSA rules in the U.S., including proper load securement.

Import and Export Compliance

Verify import/export eligibility based on destination country regulations. Obtain necessary documentation, including Commercial Invoice, Packing List, Bill of Lading/Air Waybill, and Certificate of Origin. Some countries may require product certification (e.g., CE, UKCA, CCC) or energy efficiency declarations prior to import. Screen end-users against denied party lists to comply with export control laws.

Environmental and Refrigerant Regulations

Comply with international environmental agreements such as the Montreal Protocol and Kigali Amendment, which regulate the use and handling of ozone-depleting substances and high-GWP refrigerants. Ensure proper refrigerant recovery and recycling during servicing or disposal, in accordance with local regulations (e.g., EPA Section 608 in the U.S., F-Gas Regulation in the EU).

Electrical and Safety Certifications

Verify that the Control Panel Air Conditioner meets applicable safety standards for the destination market. Required certifications may include:

– CE Marking (EU – EMC, LVD, RoHS directives)

– UKCA Marking (UK)

– UL/cUL Certification (U.S. and Canada)

– CCC Mark (China)

– RCM Mark (Australia and New Zealand)

Ensure nameplate data matches local voltage, frequency, and plug standards.

Installation and Usage Compliance

Installation must follow manufacturer guidelines and local electrical codes (e.g., NEC in the U.S., IEC standards internationally). Units must be properly grounded, and condensate drainage must be managed to prevent water damage. Periodic maintenance is required to ensure operational safety and efficiency, especially in industrial environments.

Documentation and Recordkeeping

Maintain comprehensive records including:

– Product compliance certificates

– Shipping and customs documentation

– Refrigerant handling logs (charge amount, recovery records)

– Installation and maintenance reports

Retention periods vary by jurisdiction but typically range from 5 to 10 years for environmental and safety compliance.

Disposal and End-of-Life Management

Dispose of units in accordance with WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions. Ensure refrigerants are recovered by certified technicians and components are recycled responsibly. Do not dispose of in regular landfill waste.

Conclusion for Sourcing Control Panel Air Conditioners

Sourcing control panel air conditioners is a critical aspect of ensuring the reliable and efficient operation of electrical and control systems. These specialized cooling units play a vital role in maintaining optimal temperature and humidity levels within enclosures, protecting sensitive electronic components from overheating, condensation, and premature failure.

After evaluating various suppliers, product specifications, cooling capacities, energy efficiency, and environmental compatibility, it is clear that selecting the right air conditioner requires a strategic approach. Key factors such as proper sizing, NEMA/IP ratings for environmental protection, ease of installation and maintenance, energy consumption, and long-term reliability must be prioritized.

Additionally, partnering with reputable manufacturers and suppliers who offer proven technical support, warranty coverage, and compliance with industry standards (such as UL, CE, or ISO) ensures quality and reduces lifecycle costs. Investing in high-performance control panel air conditioners not only enhances system uptime and safety but also contributes to overall operational efficiency.

In conclusion, a well-informed sourcing strategy—based on technical requirements, total cost of ownership, and supplier credibility—will lead to the successful integration of control panel cooling solutions, safeguarding critical infrastructure and supporting continuous, trouble-free operation.