The global precast concrete market is experiencing robust growth, driven by rising infrastructure development, urbanization, and demand for faster, more sustainable construction methods. According to Grand View Research, the global precast concrete market size was valued at USD 144.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This surge is further supported by increased investments in transportation, residential, and commercial infrastructure, particularly in emerging economies. As contractors seek reliable, high-performance concrete solutions, the role of leading manufacturers becomes increasingly pivotal. With supply chain resilience and product consistency top of mind, identifying the top contractor-focused concrete manufacturers offers critical insights for stakeholders navigating a competitive and rapidly evolving landscape. Mordor Intelligence also underscores this momentum, projecting the construction materials market—of which concrete is a cornerstone—to grow steadily, fueled by public and private sector capital expenditures. In this environment, the following ten manufacturers have distinguished themselves through scalability, innovation, and widespread contractor adoption.

Top 10 Contractor Concrete Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Serving the Precast Concrete Industry

Domain Est. 1996

Website: precast.org

Key Highlights: The National Precast Concrete Association serves precast concrete manufacturers and suppliers through education, opportunities and advocacy….

#2 Largo Concrete

Domain Est. 1998

Website: largoconcrete.com

Key Highlights: Largo Concrete, Inc. is a full service self-performing structural concrete and general contractor. We have been a family-owned business for over 30 years ……

#3 • Concrete Industries

Domain Est. 2000

Website: concreteindustries.com

Key Highlights: Concrete Industries, Inc. of Lincoln, Nebraska is one of the region’s premier suppliers of high-quality structural concrete building and bridge girder systems….

#4 Leading Supplier of Concrete & Building Materials

Domain Est. 1996

Website: cemexusa.com

Key Highlights: Trusted building materials supplier and concrete supplier, Cemex US delivers ready-mix concrete, aggregates, and sustainable solutions nationwide for ……

#5 Concrete Products Provider

Domain Est. 1996

Website: daytonsuperior.com

Key Highlights: As the leading single-source provider of concrete accessories, concrete chemicals, and concrete forming products for the non-residential construction industry….

#6 Thomas Concrete

Domain Est. 1997

Website: thomasconcrete.com

Key Highlights: After almost 40 years of serving customers, we are one of the leading suppliers of high quality ready-mixed concrete in the Southeast….

#7 GCC

Domain Est. 1997

Website: gcc.com

Key Highlights: GCC produces cement, concrete, aggregates and innovative products for the construction industries in Mexico, the United States, Latin America and Canada….

#8 Baker Construction:

Domain Est. 1998

Website: bakerconstruction.com

Key Highlights: Baker Concrete Construction is the nation’s leading commercial concrete construction contractor. Our drive is to perform safer, smarter, better, and faster….

#9 CTS Cement

Domain Est. 1999

Website: ctscement.com

Key Highlights: Your quarterly concrete guides include information and resources on new construction, repairs and restoration, and decorative concrete….

#10 Chaney Enterprises

Domain Est. 2003

Website: chaneyenterprises.com

Key Highlights: We provide ready-mix concrete, sand, stone, gravel, and hardscapes throughout the Mid-Atlantic and Southeastern regions….

Expert Sourcing Insights for Contractor Concrete

H2: 2026 Market Trends for Contractor Concrete

As the construction industry evolves, Contractor Concrete—a specialized segment focusing on concrete services delivered by independent contractors and small to mid-sized firms—is poised for significant transformation by 2026. Driven by technological advancements, sustainability mandates, labor dynamics, and economic shifts, the market is expected to undergo strategic realignment. Below is an analysis of key trends shaping the Contractor Concrete landscape through 2026.

Growing Demand for Sustainable Concrete Solutions

Environmental regulations and green building certifications (such as LEED and BREEAM) are pushing contractors toward low-carbon concrete alternatives. By 2026, demand for supplementary cementitious materials (SCMs) like fly ash and slag, as well as carbon-capture-enabled concrete, is projected to rise. Contractors who adopt eco-friendly practices and offer sustainable concrete solutions will gain a competitive edge, especially in public infrastructure and commercial developments.

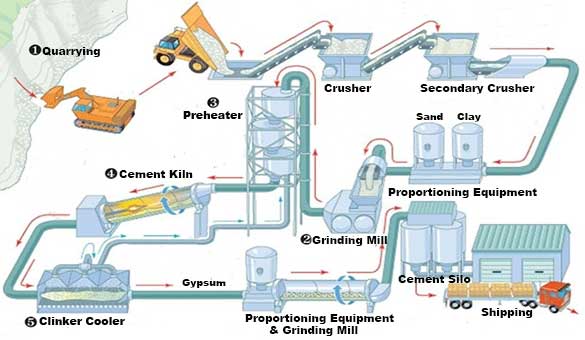

Increased Adoption of Prefabricated and Precast Concrete

Off-site fabrication is gaining momentum due to its efficiency, quality control, and reduced labor needs. By 2026, more Contractor Concrete firms are expected to partner with precast manufacturers or invest in modular systems. This trend supports faster project timelines—critical in urban environments where on-site construction disruptions are minimized.

Labor Shortages and Automation Integration

The skilled labor shortage in construction continues to pressure concrete contractors. In response, automation technologies—such as robotic concrete finishers, 3D concrete printing, and GPS-guided grading equipment—are becoming more accessible. By 2026, mid-sized contractors who integrate automation will improve productivity, reduce dependency on manual labor, and enhance project consistency.

Digital Project Management and BIM Adoption

Building Information Modeling (BIM) and cloud-based project management platforms are becoming standard in concrete contracting. By 2026, contractors who leverage digital tools for scheduling, estimating, and real-time collaboration will experience fewer delays, better cost control, and stronger client relationships. Integration with subcontractors and general contractors via shared digital environments will be a differentiator.

Infrastructure Investment as a Key Growth Driver

The U.S. Infrastructure Investment and Jobs Act (IIJA), along with similar initiatives globally, is funneling billions into roads, bridges, and water systems—all major markets for concrete contractors. By 2026, government-backed infrastructure projects will provide sustained workloads, especially for firms with bonding capacity and experience in public works bidding.

Regional Market Diversification and Urbanization

Urban redevelopment and population growth in Sun Belt regions (e.g., Texas, Florida, and the Southeast U.S.) are driving demand for residential and commercial concrete work. Contractor Concrete firms that expand geographically or specialize in high-density urban applications (e.g., tilt-up construction, polished slabs) will see greater growth opportunities.

Price Volatility and Supply Chain Resilience

Fluctuating cement prices and supply chain disruptions remain concerns. By 2026, successful contractors will prioritize supplier diversification, local sourcing, and long-term material contracts to mitigate risk. Those with strong supply chain partnerships will maintain margins amid volatility.

Conclusion

By 2026, the Contractor Concrete market will be defined by innovation, sustainability, and adaptability. Firms that embrace digital transformation, invest in workforce development, and align with green construction goals will thrive. While challenges like labor shortages and material costs persist, proactive strategies will position contractors for long-term success in an increasingly competitive and regulated environment.

Common Pitfalls When Sourcing Contractor Concrete (Quality, IP)

Inadequate Specification of Concrete Mix Design

Failing to clearly define the required mix proportions, strength (e.g., compressive strength at 28 days), slump, and durability characteristics can lead to inconsistent or substandard concrete. Contractors may use default mixes that don’t meet project-specific performance needs, especially in aggressive environments (e.g., freeze-thaw, sulfate exposure).

Poor Quality Control During Production and Placement

Lack of oversight during batching, transport, pouring, and curing increases the risk of segregation, improper consolidation, and inadequate curing. This results in reduced strength, cracking, and surface defects. Relying solely on contractor assurances without third-party testing or field inspections compounds this risk.

Inconsistency in Material Sourcing and Batch Variability

Using different aggregate sources or varying cement types between batches can cause color differences, variable strength development, and long-term durability issues. Without strict controls, even minor changes in raw materials can impact final concrete quality.

Inadequate Documentation and Lack of Traceability

Failure to maintain proper records—such as batch tickets, test results, and material certifications—compromises accountability and traceability. This becomes critical during quality disputes, warranty claims, or forensic investigations.

Intellectual Property (IP) Risks in Proprietary Mix Designs

When using specialized or high-performance concrete formulations (e.g., self-consolidating, ultra-high-performance), contractors may employ proprietary mixes. Without clear contractual agreements, there can be ambiguity over ownership, reuse rights, or disclosure of mix components, potentially leading to IP disputes or unintended reverse engineering.

Unverified Contractor Qualifications and Experience

Engaging contractors without verifying their track record, equipment capability, or technical expertise in handling specified concrete types increases the likelihood of poor workmanship. This is especially critical for complex pours or architectural concrete with strict finish requirements.

Insufficient Testing and Compliance Verification

Relying on infrequent or non-representative sampling (e.g., skipping slump tests, compressive strength cubes, or air content checks) undermines quality assurance. Without adherence to standards (e.g., ASTM, EN), compliance cannot be objectively demonstrated.

Ambiguous Contractual Terms Regarding Responsibility

Vague contracts may fail to assign clear responsibility for material quality, testing protocols, or remediation of defects. This can lead to blame-shifting between client, contractor, and supplier when quality issues arise, delaying resolution and increasing costs.

Logistics & Compliance Guide for Contractor Concrete

This guide outlines the essential logistics and compliance procedures for concrete contractors to ensure safe, efficient, and legally compliant operations on all construction projects.

Site Access and Scheduling

Coordinate delivery times with the project manager and site supervisor at least 24–48 hours in advance. Confirm gate access, laydown areas, and any site-specific traffic restrictions. Deliveries must align with the approved construction schedule to avoid delays and congestion. Use GPS tracking for real-time fleet monitoring and proactive delay communication.

Equipment and Fleet Requirements

All concrete mixer trucks and auxiliary equipment must be routinely inspected and maintained per manufacturer guidelines and OSHA standards. Vehicles must display valid registration, commercial insurance, and Department of Transportation (DOT) compliance signage where applicable. Drivers must hold a valid Commercial Driver’s License (CDL) with appropriate endorsements.

Material Handling and Placement

Ensure proper chute length and pumping equipment are available for accurate concrete placement. Avoid segregation by minimizing discharge height and preventing premature dumping. Follow project specifications for slump, temperature, and air content. Document batch tickets and test results (slump, temperature, air) for quality assurance and traceability.

Environmental Compliance

Comply with local, state, and federal environmental regulations, including EPA and NPDES stormwater rules. Prevent washout water from entering storm drains by using designated washout areas with containment berms or settling tanks. Dispose of concrete slurry and washout materials according to approved waste management plans. Minimize dust and noise during operations, especially in residential zones.

Safety Protocols

All personnel must wear appropriate PPE, including hard hats, high-visibility vests, steel-toed boots, and gloves. Implement a site-specific safety plan adhering to OSHA 29 CFR 1926 standards. Conduct pre-pour safety meetings and ensure spotters are used during reversing operations. Maintain clear communication between drivers, pump operators, and site crews.

Documentation and Recordkeeping

Maintain accurate records for each pour, including delivery tickets, inspection reports, and compliance certifications. Store batch records for a minimum of three years. Submit required compliance documentation to the general contractor or project owner upon request. Use digital logs for real-time updates and audit readiness.

Regulatory and Permitting Requirements

Verify all necessary permits are obtained prior to operations, including right-of-way permits for public road access and local concrete discharge permits. Ensure adherence to building codes (e.g., ACI 318), DOT specifications (if applicable), and project-specific quality control plans. Conduct regular compliance audits to identify and correct deficiencies promptly.

Conclusion for Sourcing Contractor for Concrete Work

In conclusion, sourcing the right contractor for concrete work is a critical step in ensuring the success, durability, and cost-effectiveness of any construction project. A thorough evaluation process—considering experience, qualifications, references, pricing, and adherence to safety and quality standards—helps identify a reliable and skilled contractor. By prioritizing licensed professionals with a proven track record and clear communication practices, project managers can minimize risks, avoid delays, and achieve high-quality results. Ultimately, investing time in selecting the right concrete contractor contributes significantly to the overall integrity and longevity of the structure, delivering value both in the short and long term.