The global continuous hinge market is experiencing steady growth, driven by rising demand across industrial, commercial, and residential applications. According to Mordor Intelligence, the global hinges market—encompassing continuous, butt, and specialty hinges—is projected to grow at a CAGR of over 5.2% from 2023 to 2028. Continuous hinges, known for their durability, consistent support, and seamless integration into doors, cabinets, and enclosures, are increasingly favored in sectors such as healthcare, automotive, and data centers where reliability is critical. As industrial automation and smart building technologies expand, the demand for precision-engineered continuous hinges is expected to rise in tandem. With North America and Asia Pacific leading in manufacturing activity and infrastructure development, sourcing from established and innovative suppliers has become a strategic priority for procurement teams. Below are the top 10 continuous hinge manufacturers shaping the market through quality, scalability, and technological advancement.

Top 10 Continous Hinge Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Continuous Hinge Manufacturer

Domain Est. 1995

Website: erwagner.com

Key Highlights: We manufacture stock and custom industrial continuous hinges for lift gates, electrical and industrial cabinets, toolboxes, pianos, furniture, blast doors, and ……

#2 Buy Continuous Piano Hinge direct from the Manufacturer!

Domain Est. 1996

Website: sandshinge.com

Key Highlights: S & S Hinge Company is a leading manufacturer of continuous hinges (also known as piano hinge) in steel, stainless, aluminum, pre-plate brass and pre-plate ……

#3 Larsen Shaw: Piano Hinges

Domain Est. 1997

Website: larsenhinge.com

Key Highlights: Larsen & Shaw has been a leading manufacturer of quality custom hinges, specialty hinges, metal brackets, braces and supports….

#4 Aluminum Continuous Hinges

Domain Est. 1997

Website: abhmfg.com

Key Highlights: A high quality manufacturer of Overhead Holders & Stops, Hospital Latches, Electromagnetic Holders, Pivots, Strikes and Rescue Stops, Aluminum Hinges….

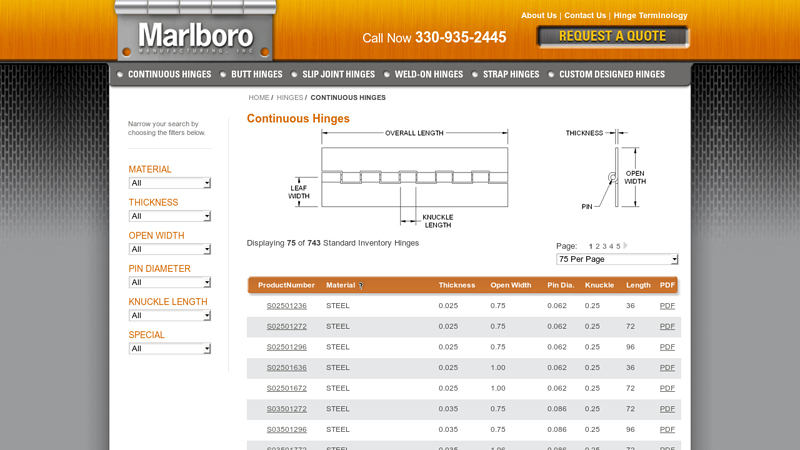

#5 Continuous Hinge Manufacturer

Domain Est. 2002

Website: marlborohinge.com

Key Highlights: Are you in need of continuous hinges? You have come to the right place! Marlboro Hinge is a continuous hinge manufacturer that offers a wide variety of products ……

#6 Continuous Hinges

Domain Est. 1995

#7 SELECT Hinges

Domain Est. 1999

Website: select-hinges.com

Key Highlights: There are a SELECT few who only make hinges. Nothing else. Explore our geared continuous door hinges that are built to last longer than any other brand….

#8 IVES

Domain Est. 1999

Website: us.allegion.com

Key Highlights: For more than 120 years IVES has produced a full line of premium-quality building hardware and accessories that delivers application flexibility and superior ……

#9 Commercial Door Hinges

Domain Est. 2006

Website: stanleyhinges.com

Key Highlights: Stanley Hinges provide high quality commercial door hinges including stainless steel, butt, spring, cabinet & continuous hinges. Buy online today….

#10 Ives Continuous Hinges

Domain Est. 2007

Website: iveshinges.com

Key Highlights: We offer the entire line of Ives Door Hardware including Hinges, Pivots, and architectural finish products, Glynn-Johnson Overhead Stops & Holders and Schlage ……

Expert Sourcing Insights for Continous Hinge

H2 2026 Market Trends for Continuous Hinges

As the global construction, industrial manufacturing, and architectural hardware sectors evolve, the continuous hinge market is poised for notable shifts in demand, innovation, and regional dynamics by the second half of 2026 (H2 2026). Continuous hinges—also known as piano hinges—span the entire length of doors, lids, and access panels, offering enhanced durability, weight distribution, and aesthetic continuity. This analysis examines key market trends expected to shape the continuous hinge industry during H2 2026.

1. Increased Demand from Commercial and Institutional Construction

The recovery and expansion of institutional and commercial building projects—including schools, hospitals, government facilities, and data centers—are driving strong demand for continuous hinges. These applications favor continuous hinges due to their superior structural support and longevity. In H2 2026, delayed infrastructure investments from earlier in the decade are expected to materialize, particularly in North America and Western Europe, further boosting procurement of heavy-duty and fire-rated continuous hinges.

2. Growth in Sustainable and Smart Building Integration

Sustainability and smart building technologies are influencing hinge design and material selection. In H2 2026, manufacturers are increasingly offering continuous hinges made from recycled stainless steel and aluminum, aligning with green building certifications like LEED and BREEAM. Additionally, integration with smart access systems (e.g., electromagnetic locks and access sensors) is pushing demand for hinges with embedded wiring channels or low-friction, maintenance-free bearings—particularly in automated doors and high-traffic facilities.

3. Shift Toward High-Performance and Specialty Materials

There is a growing preference for corrosion-resistant and high-strength materials in continuous hinges, especially in harsh environments (e.g., coastal, industrial, and healthcare settings). By H2 2026, hinges made from 316 stainless steel, duplex alloys, and polymer-composite blends are gaining market share. These materials offer extended service life and lower maintenance, appealing to facility managers focused on lifecycle cost reduction.

4. Regional Market Divergence and Supply Chain Resilience

Geopolitical stability and regional manufacturing reshoring efforts are impacting supply chains. North America and Europe are witnessing a rebound in domestic hinge production to reduce dependency on Asian imports, especially amid ongoing trade fluctuations. In contrast, Asia-Pacific—particularly India and Southeast Asia—continues to expand its construction output, becoming both a manufacturing hub and a growing consumer market for mid-range continuous hinges.

5. Customization and Digital Procurement Channels

Digitalization of procurement processes is accelerating. By H2 2026, B2B e-commerce platforms and configurator tools allow architects and contractors to customize hinge length, finish, hole patterns, and torque specifications online. This trend supports just-in-time manufacturing and reduces lead times. OEMs that offer digital integration with building information modeling (BIM) systems are gaining competitive advantage.

6. Regulatory and Safety Compliance Pressures

Regulatory standards for fire safety, accessibility (ADA compliance), and security are tightening globally. Continuous hinges with fire-rated certifications (e.g., UL 10C) and non-handed designs for universal access are seeing increased adoption. In H2 2026, compliance is becoming a key differentiator, especially in public and multi-family residential construction.

Conclusion

The continuous hinge market in H2 2026 reflects broader industrial and technological shifts—sustainability, digital integration, and resilience. While traditional applications remain strong, growth is increasingly driven by innovation in materials, smart infrastructure needs, and regional supply chain adaptations. Manufacturers that invest in R&D, sustainability, and digital customer engagement are best positioned to capture emerging opportunities in this specialized hardware segment.

Common Pitfalls Sourcing Continuous Hinge (Quality, IP)

Sourcing continuous hinges—also known as piano hinges—can present several challenges, particularly when balancing quality requirements with intellectual property (IP) considerations. Overlooking these pitfalls can lead to performance issues, compliance risks, and supply chain disruptions. Below are key areas of concern:

Quality Consistency and Material Integrity

One of the most frequent issues in sourcing continuous hinges is inconsistent quality across production batches. Low-cost suppliers may use substandard materials such as inferior-grade stainless steel or inadequate plating, leading to premature corrosion, warping, or pin failure. Additionally, poor welding or riveting techniques in long-length hinges can result in weak points along the barrel, compromising durability. Buyers must verify material certifications (e.g., ASTM, RoHS) and conduct periodic batch testing to ensure long-term reliability.

Tolerance and Dimensional Accuracy

Continuous hinges require precise alignment and uniform hole spacing to function correctly, especially in applications like access panels, enclosures, or doors with tight tolerances. Poor manufacturing control can lead to warping, misaligned knuckles, or inconsistent hole patterns, making installation difficult and affecting the final product’s performance. Sourcing from manufacturers with robust quality management systems (e.g., ISO 9001) helps mitigate these risks.

Intellectual Property (IP) Infringement Risks

Some continuous hinge designs—particularly those with proprietary features like tamper resistance, self-lubricating pins, or specialized mounting systems—may be protected by patents or design rights. Sourcing generic versions that closely mimic patented designs can expose buyers to IP litigation, especially in regulated markets like medical devices, aerospace, or security enclosures. Conducting due diligence on supplier design origins and ensuring freedom-to-operate (FTO) is essential to avoid legal and financial exposure.

Misrepresentation of Specifications

Suppliers may exaggerate performance claims, such as load capacity, corrosion resistance, or operating temperature range, without providing test data or third-party verification. This is particularly common with hinges marketed as “marine-grade” or “industrial-duty.” Requesting detailed technical documentation and independent lab reports can help validate these claims and prevent field failures.

Supply Chain and Long-Term Availability

Because continuous hinges are often custom-cut or ordered in specific lengths, reliance on a single supplier increases risk if that supplier discontinues a product line or experiences production delays. Lack of documentation or standardization can also hinder sourcing replacements. Ensuring design documentation is retained and sourcing from suppliers with stable production histories supports long-term maintainability.

Avoiding these pitfalls requires thorough vetting of suppliers, clear technical specifications, and proactive IP assessment—ensuring both performance and compliance in the final application.

Logistics & Compliance Guide for Continuous Hinge

This guide outlines the key logistics considerations and compliance requirements for the handling, transportation, and use of continuous (piano) hinges in commercial and industrial applications.

Product Overview and Specifications

Continuous hinges, also known as piano hinges, are elongated hinges that span the full length of the doors or panels they connect. They are commonly used in applications requiring high durability and even weight distribution, such as industrial enclosures, cabinets, fire doors, access panels, and medical equipment. Typical materials include stainless steel, steel with protective coatings (zinc, powder coat), and brass. Hinges may be perforated (for mounting) or non-perforated, with various pin styles (non-removable, lift-off, or swivel).

Packaging and Handling Requirements

To ensure product integrity during transit, continuous hinges must be protected from bending, corrosion, and surface damage. Hinges should be coiled or cut to specified lengths and packaged in corrugated cardboard tubes or rigid edge protectors. For longer lengths, wooden crates or palletized bundles with protective wrapping (VCI paper for corrosion resistance) are recommended. Handling should avoid dragging or dropping; use mechanical aids for bundles exceeding 25 lbs (11 kg). Workers should wear gloves to prevent oil transfer and surface contamination.

Storage Conditions

Store continuous hinges in a dry, climate-controlled environment with temperatures between 50°F and 80°F (10°C–27°C) and relative humidity below 60%. Keep materials off the floor using pallets or shelving to prevent moisture absorption and contamination. Protect from direct sunlight and corrosive chemicals. Stainless steel hinges should be stored separately from carbon steel to avoid cross-contamination and galvanic corrosion.

Transportation Guidelines

Ship continuous hinges via ground or air freight depending on urgency and destination. Secure packages on pallets using stretch wrap and banding to prevent shifting. For international shipments, ensure compliance with ISPM-15 for wood packaging materials. Declare accurate weights, dimensions, and material composition on shipping documents. Avoid extreme temperature exposure during transit—use climate-controlled containers when necessary, especially for coated or plated finishes.

Regulatory Compliance

Continuous hinges used in construction, transportation, or safety-critical applications must meet relevant regulatory standards. Fire-rated doors require hinges compliant with ASTM E152 or UL 10C for fire endurance. Marine and offshore applications may require compliance with ABS, DNV, or SOLAS standards. Hinges in food processing or medical equipment should meet FDA or NSF standards for material safety. Export shipments must comply with ITAR, EAR, or REACH (EU) as applicable, particularly for stainless steel alloys.

Labeling and Documentation

Each shipment must include clear labeling with product description, length, material type, finish, part number, batch/lot number, and manufacturer information. Safety Data Sheets (SDS) must be provided if required by jurisdiction. Certificates of Compliance (CoC) or Material Test Reports (MTRs) should accompany regulated or high-specification orders. Barcodes or QR codes are recommended for traceability in inventory systems.

Installation and End-Use Compliance

Installers must follow manufacturer guidelines for torque specifications, fastener types, and alignment. Hinges used in fire-rated assemblies must be installed per NFPA 80 and labeled accordingly. Improper installation may void compliance certifications. End users should conduct periodic inspections for wear, corrosion, or misalignment, especially in high-cycle or outdoor environments.

Environmental and Disposal Considerations

At end-of-life, continuous hinges—primarily metal—should be recycled through certified metal recyclers. Comply with local and federal regulations (e.g., EPA, WEEE) regarding disposal of coated or plated metals. Avoid landfill disposal when recycling is available. Manufacturers should support sustainability by using recyclable packaging and minimizing hazardous substances in production.

Contact and Support

For compliance verification, technical support, or logistics inquiries, contact the manufacturer’s customer service team with the product lot number and purchase documentation. Updates to standards or regulatory changes will be communicated through official channels and product documentation.

Conclusion on Sourcing Continuous Hinges

After evaluating various suppliers, materials, pricing, quality standards, and lead times, it is concluded that sourcing continuous hinges requires a strategic approach balancing cost, durability, and application-specific requirements. Continuous hinges offer superior strength, alignment, and longevity compared to traditional butt hinges, making them ideal for high-traffic or heavy-duty applications such as commercial doors, industrial enclosures, and cabinetry.

Based on the analysis, aluminum and stainless steel hinges from reputable manufacturers in North America and Asia offer the best combination of corrosion resistance, load capacity, and ease of installation. While domestic suppliers provide quicker turnaround and better quality control, overseas options can offer significant cost savings if minimum order quantities and quality assurance protocols are properly managed.

To ensure reliability and performance, it is recommended to:

- Prioritize hinges made from high-grade materials with appropriate finishes (e.g., anodized aluminum, powder-coated or stainless steel).

- Partner with suppliers that provide certifications (e.g., ISO, ASTM) and offer product testing data.

- Conduct pilot orders to assess fit, finish, and performance before large-scale procurement.

- Consider total cost of ownership, including installation, maintenance, and lifespan, rather than unit price alone.

In summary, a well-informed sourcing strategy for continuous hinges will enhance product durability, reduce long-term maintenance costs, and support consistent performance across applications. Establishing strong supplier relationships and maintaining clear technical specifications will be key to successful implementation.