The global air conditioner market continues to expand at a robust pace, driven by rising urbanization, increasing household incomes, and growing demand for climate control in both residential and commercial sectors. According to a 2023 report by Mordor Intelligence, the global air conditioning market was valued at USD 135.3 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2028. This upward trajectory is further fueled by technological advancements, energy efficiency regulations, and the proliferation of smart HVAC systems across emerging economies.

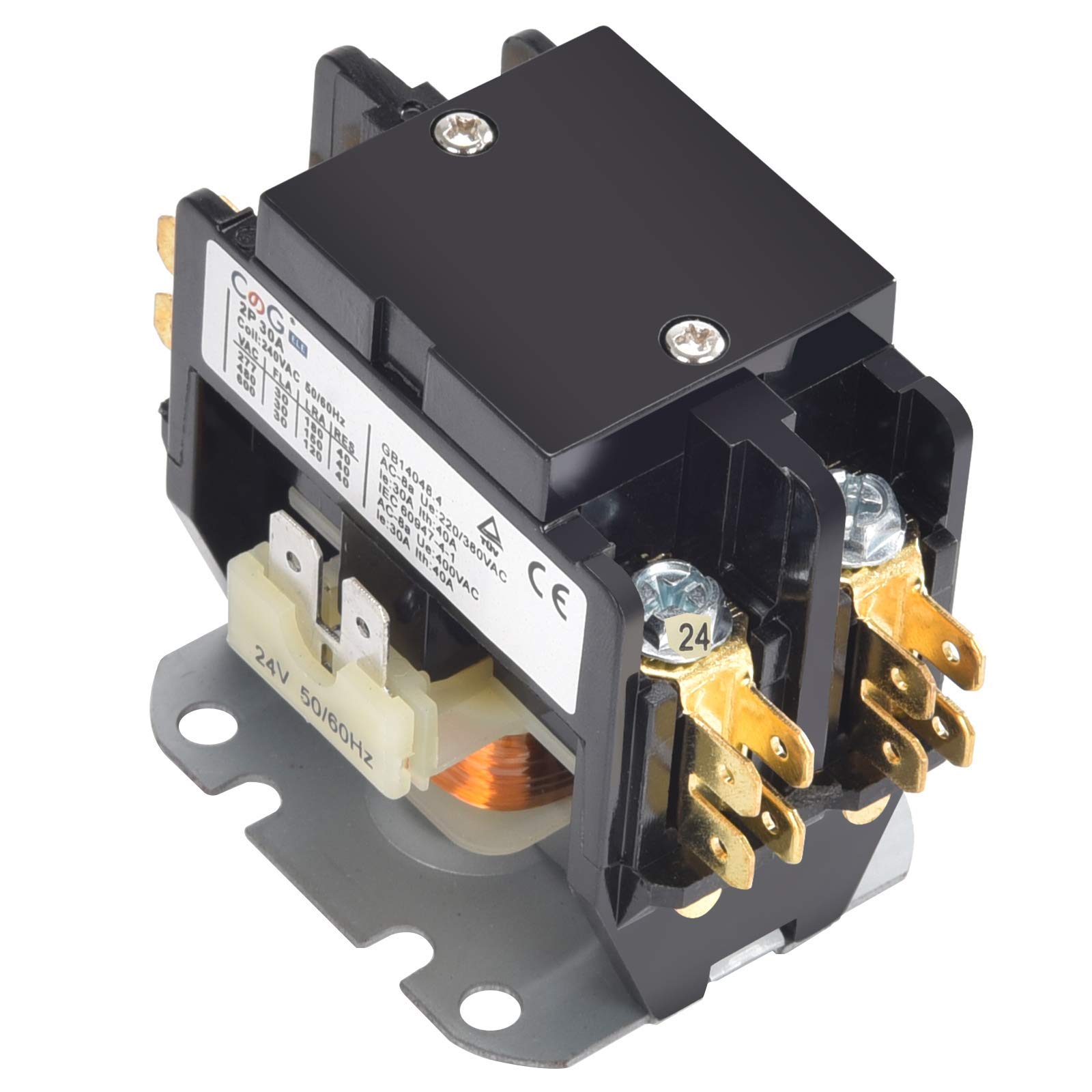

At the heart of every efficient air conditioning unit lies a critical yet often overlooked component—the contractor. As demand for reliable, energy-efficient AC systems rises, so does the need for high-performance contactors that ensure safe and consistent operation of compressors and fans. With manufacturers increasingly prioritizing durability, responsiveness, and integration with smart controls, selecting the right contactor supplier has become a strategic imperative.

Based on market presence, product innovation, reliability ratings, and customer feedback, the following seven contactor manufacturers have emerged as key enablers for leading air conditioner brands worldwide. These companies are not only keeping pace with industry demands but are also shaping the future of HVAC control systems through advanced electromagnetic design and smart switching technologies.

Top 7 Contactor For Air Conditioner Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 AC Contactor Manufacturers

Domain Est. 2005

Website: cncele.com

Key Highlights: Diverse product line: Their CJX2 series contactors cover voltages from 24V to 380V, making them suitable for everything from residential HVAC ……

#2 AC Contactor Manufacturer & Supplier

Domain Est. 2008

Website: geya.net

Key Highlights: GEYA AC power contactor is installed with 35mm, 75mm type DIN rail. It is also lightweight and has a very low power consumption which gives it a long life span, ……

#3 Contactors and contactor relays

Domain Est. 1990

Website: new.abb.com

Key Highlights: ABB offers a comprehensive selection of contactors for simple and extreme application as well as products with specific purposes….

#4 AC Contactor Relay Switch

Domain Est. 1992

Website: te.com

Key Highlights: TE offers small, light, and efficient AC contactors for harsh environments. They are available in multiple contact configurations and mounting styles….

#5 Contactors

Domain Est. 1995

Website: parts.rheem.com

Key Highlights: Free delivery over $25 30-day returnsUse the search bar above to find: Search by Part Number; Search by Description; Search by HVAC Model Number Search by HVAC Model or Serial Numb…

#6 AC Contactor

Domain Est. 2024

Website: weltrus.com

Key Highlights: Product Features · Wide range of models from FX-6 to FX-630 · Suitable for AC-1, AC-2, AC-3, and AC-4 applications · Multiple coil voltage options (24V to 380V) ……

#7 The Ultimate Guide to AC Contactor

Website: tosunlux.eu

Key Highlights: In this comprehensive guide, we will explore what AC contactors are, how they work, their applications, and essential maintenance practices….

Expert Sourcing Insights for Contactor For Air Conditioner

H2: Projected 2026 Market Trends for Contactors in Air Conditioning Systems

The global market for contactors used in air conditioning systems is poised for significant transformation by 2026, driven by technological innovation, regulatory shifts, and evolving consumer demands. As a critical electromechanical component responsible for controlling the flow of electrical power to compressors and fans in HVAC systems, the contactor plays a pivotal role in system efficiency, reliability, and safety. Here are the key projected trends shaping the contactor for air conditioner market in 2026:

-

Growth in Energy-Efficient HVAC Systems

With increasing global emphasis on energy conservation and carbon reduction, air conditioning systems are being redesigned for higher efficiency. Contactors are evolving to support variable frequency drives (VFDs) and smart HVAC controls, enabling precise motor control and reduced electrical losses. By 2026, demand is expected to rise for contactors compatible with inverter-based and smart air conditioning units, especially in residential and commercial applications across North America, Europe, and Asia-Pacific. -

Integration with Smart and IoT-Enabled HVAC Systems

The proliferation of smart buildings and connected appliances is pushing contactor manufacturers to develop intelligent switching solutions. In 2026, contactors with integrated sensors, remote monitoring capabilities, and communication protocols (e.g., Modbus, BACnet) are anticipated to gain traction. These smart contactors can provide real-time diagnostics, predictive maintenance alerts, and seamless integration with building management systems (BMS), enhancing operational efficiency and reducing downtime. -

Rise in Demand from Emerging Markets

Rapid urbanization, rising disposable incomes, and increasing adoption of air conditioning in countries such as India, Indonesia, and Brazil are expected to drive market expansion. By 2026, these regions will represent key growth areas for contactor manufacturers, particularly for cost-effective, durable, and climate-resilient models capable of operating under high-temperature and high-humidity conditions. -

Stringent Regulatory Standards and Safety Requirements

Governments and international bodies are tightening regulations around electrical safety and equipment performance. Contactors must comply with standards such as IEC 60947-4-1, UL 508, and regional energy efficiency benchmarks. By 2026, manufacturers will need to prioritize certifications, arc-fault protection, and longer electrical/mechanical life cycles to meet compliance and gain market access—especially in Europe and North America. -

Shift Toward Compact and Modular Designs

As air conditioning units become more compact and serviceability becomes a key concern, contactors are being designed for space efficiency and easier replacement. In 2026, modular contactors with plug-in terminals, tool-less mounting, and reduced footprint are expected to dominate, particularly in split and ductless AC systems. -

Increased Focus on Reliability and Durability

With climate change leading to more frequent heatwaves and extreme weather, air conditioners are operating under heavier loads and longer cycles. Contactors must withstand repeated switching, voltage fluctuations, and high ambient temperatures. By 2026, demand will grow for contactors made with advanced silver alloy contacts, reinforced insulation, and anti-corrosion materials to ensure longevity. -

Sustainability and Circular Economy Influences

Environmental concerns are prompting manufacturers to adopt greener production practices and recyclable materials. By 2026, contactor producers may face pressure to reduce hazardous substances (e.g., cadmium-free contacts) and offer take-back or recycling programs, aligning with broader circular economy goals in the HVAC industry. -

Competitive Landscape and Innovation

The market will see intensified competition among key players such as Schneider Electric, Siemens, ABB, Eaton, and TE Connectivity. Innovation in coil technology (e.g., low-power consumption coils), silent operation, and digital twin integration for design optimization will differentiate leading brands by 2026.

In conclusion, the 2026 market for contactors in air conditioning systems will be shaped by the convergence of energy efficiency, digitalization, regulatory pressures, and global demand growth. Manufacturers that embrace smart technologies, sustainability, and regional customization are likely to capture significant market share in this evolving landscape.

Common Pitfalls When Sourcing a Contactor for an Air Conditioner (Quality and IP Rating)

When sourcing a contactor for an air conditioner, especially in HVAC systems, overlooking critical quality and ingress protection (IP) factors can lead to system failure, safety hazards, and increased maintenance costs. Below are common pitfalls buyers and technicians should be aware of:

1. Prioritizing Cost Over Quality

One of the most frequent mistakes is selecting the cheapest contactor available. Low-cost contactors often use inferior materials such as substandard copper coils, weak spring mechanisms, or poor-grade contacts that degrade quickly under load. This can result in:

- Premature contact welding or pitting

- Inconsistent switching performance

- Shorter operational lifespan

Always verify the manufacturer’s reputation and ensure the contactor meets recognized standards (e.g., UL, IEC, or CE).

2. Ignoring Electrical Specifications

Using a contactor with incorrect voltage or current ratings can lead to overheating or failure to engage. Common mismatches include:

- Coil voltage incompatible with control circuit (e.g., 24V vs. 120V)

- Insufficient ampacity for compressor load

- Failure to account for inrush current during startup

Always match the contactor’s ratings to the air conditioner’s requirements as specified in the equipment datasheet.

3. Overlooking Ingress Protection (IP) Rating

The IP rating indicates the level of protection against dust and moisture. In outdoor or high-humidity environments, selecting a contactor without adequate IP protection is a critical error. For example:

- Indoor units may only need IP20

- Outdoor condensing units require at least IP54 or higher

Using a low-IP-rated contactor outdoors can result in:

- Corrosion of internal components

- Short circuits due to moisture ingress

- Reduced reliability and increased downtime

Always verify the environmental conditions and select a contactor with an appropriate IP rating.

4. Assuming Interchangeability Without Verification

Many assume that contactors with similar physical dimensions are interchangeable. However, differences in:

- Terminal placement

- Mounting style

- Arc suppression features

- Coil resistance and inductance

can affect performance and safety. Always consult the OEM specifications before substituting a contactor.

5. Neglecting Certification and Compliance

Using non-certified contactors—especially in commercial or industrial HVAC systems—can void equipment warranties and violate electrical codes. Ensure the contactor has:

- Proper safety certifications (e.g., UL 466, IEC 60947-4-1)

- Compliance with regional electrical standards

6. Failing to Consider Ambient Operating Conditions

Contactors are rated for specific temperature ranges. Installing a contactor in an environment exceeding its rated temperature (e.g., inside a poorly ventilated electrical panel in direct sunlight) reduces lifespan and efficiency. Always consider:

- Ambient temperature

- Altitude (affects cooling and dielectric strength)

- Presence of dust, oil, or corrosive gases

Conclusion

Avoiding these common pitfalls requires attention to detail, adherence to specifications, and sourcing from reputable suppliers. Investing in a high-quality, correctly rated contactor ensures reliable air conditioner operation, reduces maintenance costs, and enhances system safety.

Logistics & Compliance Guide for Contractor for Air Conditioner

This guide outlines the key logistics and compliance considerations when shipping or handling contractors (contactors) used in air conditioning systems. Proper planning ensures timely delivery and adherence to regulatory standards.

Product Classification and Identification

Contractors for air conditioners are electromechanical switching devices typically classified under HS Code 8536.50 (Relays and contactors, for a voltage ≤ 60V or > 60V). Accurate classification is essential for customs clearance and tariff determination. Include detailed product specifications such as voltage rating, current capacity, coil type, and intended application (e.g., HVAC systems) in shipping documentation.

Packaging and Handling Requirements

Contractors must be packaged to prevent damage during transit. Use anti-static packaging where applicable, especially for sensitive electronic components. Secure units in rigid outer containers with cushioning materials to avoid shock, vibration, and moisture exposure. Label packages with “Fragile,” “Electronics,” and “Do Not Stack” as needed. Handle with care to avoid mechanical stress on terminals or coil windings.

Transportation Modes and Considerations

Choose transportation modes based on volume, urgency, and destination. Air freight is suitable for urgent, low-volume shipments, while ocean freight is cost-effective for bulk orders. Ensure temperature and humidity controls are maintained, especially in extreme climates, to protect component integrity. Confirm compliance with IATA (air) or IMDG (sea) regulations if batteries or hazardous materials are included (rare for standard contactors).

Import/Export Compliance

Verify export controls based on the country of origin and destination. Most contactors are not subject to strict export controls (e.g., EAR99 under U.S. regulations), but dual-use assessments may apply. Ensure all export documentation—including commercial invoice, packing list, and bill of lading—is accurate and includes end-use statements when required. Importers must comply with local electrical safety and conformity standards.

Regulatory and Safety Standards

Contractors must meet electrical safety certifications in the target market. Common standards include:

– UL 508 (U.S. – Industrial Control Equipment)

– IEC 60947-4-1 (International – Electromechanical contactors)

– CE Marking (EU – Low Voltage and EMC Directives)

– CCC (China – Compulsory Certification for certain models)

Confirm that products are certified by accredited bodies and retain documentation for customs and audit purposes.

Environmental and RoHS Compliance

Ensure contactors comply with environmental regulations such as the EU’s RoHS (Restriction of Hazardous Substances) directive, which limits lead, mercury, cadmium, and other hazardous materials. Provide a Declaration of Conformity (DoC) and material disclosure data upon request. Properly label RoHS-compliant units.

Customs Clearance and Duties

Prepare complete customs documentation, including:

– Accurate Harmonized System (HS) code

– Country of origin

– Value declaration

– Certificates of conformity or test reports

Be aware of preferential trade agreements (e.g., USMCA, ASEAN) that may reduce or eliminate duties. Delays may occur if documentation is incomplete or inspections are required.

Storage and Inventory Management

Store contactors in a clean, dry, temperature-controlled environment (typically 5°C to 40°C). Avoid exposure to dust, corrosive gases, or condensation. Use first-in, first-out (FIFO) inventory practices to prevent obsolescence. Maintain traceability through batch/lot numbering.

End-of-Life and Disposal

Follow local e-waste regulations for the disposal of defective or obsolete contactors. Many components (e.g., copper, steel, plastics) are recyclable. Partner with certified e-waste recyclers to ensure environmentally sound disposal and compliance with WEEE (EU) or similar programs.

Documentation and Recordkeeping

Maintain records of:

– Certifications and test reports

– Shipping and customs documents

– Compliance declarations (RoHS, REACH, etc.)

– Supplier conformity statements

Retain records for a minimum of 5–10 years, depending on jurisdiction, to support audits or recalls.

Conclusion for Sourcing a Contactor for an Air Conditioner:

Sourcing the appropriate contactor for an air conditioner is a critical step in ensuring the system’s reliability, efficiency, and safety. After evaluating factors such as electrical specifications (voltage, current rating, pole configuration), compatibility with the HVAC unit, brand reputation, and certification standards (e.g., UL, CE), it is evident that selecting a high-quality, correctly rated contactor is essential. Opting for genuine OEM parts or reputable aftermarket equivalents helps prevent premature failure, reduces maintenance costs, and supports optimal performance. Additionally, considering availability, lead times, and supplier reliability ensures minimal downtime during repairs or installations. In conclusion, a well-informed sourcing decision—balancing technical requirements, quality, cost, and supplier dependability—contributes to the long-term functionality and durability of the air conditioning system.